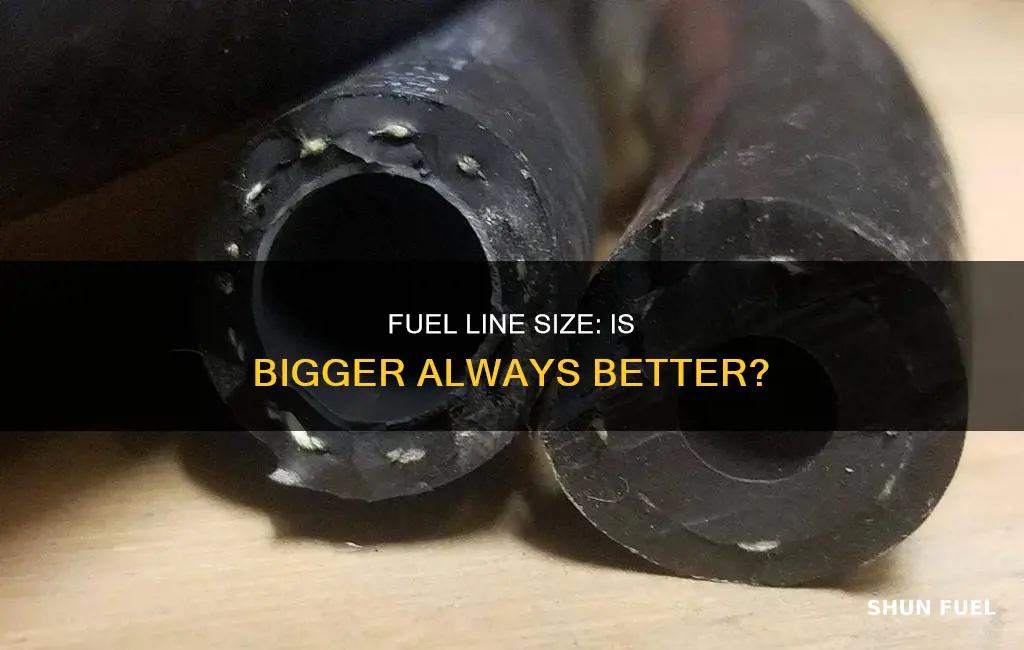

When it comes to fuel lines, an interesting question arises: can they be too big? While it might seem counterintuitive, the answer is yes. The size of a fuel line is crucial in determining the efficiency and performance of a vehicle's fuel system. A fuel line that is too large can lead to several issues, including reduced fuel pressure, increased fuel consumption, and even potential safety hazards. In this discussion, we will explore the factors that determine the appropriate size of a fuel line and the consequences of using a line that is either too small or too large.

| Characteristics | Values |

|---|---|

| Fuel Line Diameter | The size of the fuel line is typically measured in inches or millimeters. Common diameters range from 3/8" to 1/2" (9.5 to 12.7 mm) for automotive applications. |

| Flow Rate | The capacity of a fuel line to handle fuel flow is crucial. A larger diameter can accommodate higher flow rates, which is essential for high-performance engines or those with multiple fuel injectors. |

| Pressure Rating | Fuel lines need to withstand internal fuel pressure. The pressure rating should match or exceed the engine's requirements to prevent leaks and ensure safety. |

| Material | Common materials include rubber, plastic, and steel. The choice depends on factors like temperature resistance, flexibility, and cost. |

| Length | The length of the fuel line is determined by the vehicle's layout and engine position. Longer lines might be necessary for certain engine configurations. |

| Flexibility | Fuel lines should be flexible to accommodate engine movement during operation. Thicker walls or specialized materials can enhance flexibility. |

| Temperature Range | Fuel lines must withstand the temperature extremes of the engine environment. Some materials are more suitable for high or low-temperature conditions. |

| Compatibility | Compatibility with the fuel type (gasoline, diesel, etc.) and the engine's fuel system is essential. |

| Installation Ease | Larger fuel lines might be more challenging to install due to space constraints in the engine bay. |

| Cost | Larger fuel lines can be more expensive due to the increased material and manufacturing costs. |

What You'll Learn

- Fuel Flow and Efficiency: Larger fuel lines may not necessarily increase efficiency, as other factors like engine design play a role

- Pressure Drop: Excessively large fuel lines can lead to pressure drops, affecting engine performance and fuel delivery

- Cost and Maintenance: Oversized fuel lines may be more expensive and require more frequent maintenance, potentially increasing overall costs

- Engine Compatibility: Some engines may not be designed to handle larger fuel lines, leading to performance issues or damage

- Safety and Reliability: Larger fuel lines can pose safety risks, such as increased fire hazard or fuel spillage, if not properly installed and maintained

Fuel Flow and Efficiency: Larger fuel lines may not necessarily increase efficiency, as other factors like engine design play a role

The idea that bigger is better when it comes to fuel lines is a common misconception. While it's true that larger fuel lines can provide some benefits in terms of flow capacity, it's important to understand that this alone does not guarantee increased efficiency or performance. The relationship between fuel line size and engine efficiency is a complex one, influenced by various factors.

One key aspect to consider is the engine's design and its specific requirements. Different engines have unique characteristics and performance needs. For instance, a high-performance racing engine might benefit from larger fuel lines to accommodate its increased power output and fuel demands. However, for everyday vehicles or those with smaller engines, larger fuel lines may not be necessary and could even lead to inefficiencies. The engine's ability to utilize the fuel efficiently depends on its design, including the fuel injection system, combustion chamber, and overall engine management.

Engineers and designers must carefully consider the engine's power output, fuel consumption rates, and the desired performance when determining fuel line size. Simply increasing the diameter of the fuel line without considering these factors may result in unnecessary complexity and potential drawbacks. For example, larger fuel lines could lead to increased pressure drop, especially in engines with high compression ratios or those operating at high RPMs. This pressure drop can reduce the overall fuel-air mixture quality, impacting combustion efficiency.

Additionally, the length of the fuel line is a critical factor. Longer fuel lines may introduce additional resistance, which can restrict fuel flow, especially at high engine speeds. This restriction can lead to a phenomenon known as 'fuel starvation,' where the engine receives an inadequate fuel supply, resulting in reduced power and performance. Therefore, while larger fuel lines can be beneficial in specific scenarios, they should be carefully integrated into the overall engine design to optimize efficiency.

In summary, when considering fuel line size, it is essential to take into account the engine's unique characteristics and performance requirements. Larger fuel lines might not always be the solution, as other factors, such as engine design, play a crucial role in determining efficiency. Finding the right balance between fuel line size and engine specifications is key to ensuring optimal performance and fuel efficiency.

Optimizing Performance: Choosing the Right Fuel Line for Your HMSK80

You may want to see also

Pressure Drop: Excessively large fuel lines can lead to pressure drops, affecting engine performance and fuel delivery

Excessively large fuel lines can indeed cause more than just aesthetic issues; they can significantly impact engine performance and fuel delivery. The primary concern here is the pressure drop that occurs when fuel is forced through a line that is larger than necessary. This pressure drop can lead to a variety of problems, all of which can negatively affect your vehicle's performance.

When a fuel line is too large, it creates an unnecessary increase in the internal diameter of the line. This larger diameter results in a reduced cross-sectional area, which in turn affects the flow rate of the fuel. According to the principles of fluid dynamics, the flow rate (Q) of a fluid is inversely proportional to the square of the diameter (D) of the pipe. Mathematically, this can be expressed as Q ∝ 1/D^2. Therefore, a larger fuel line will have a lower flow rate, which means less fuel can be delivered to the engine per unit of time.

This reduction in flow rate can lead to a noticeable decrease in engine performance. You might experience a loss of power, a reduction in acceleration, and even a decrease in fuel efficiency. In extreme cases, the engine may even stall due to a lack of fuel supply. This is particularly problematic during high-demand situations, such as when you need to accelerate quickly or when the engine is under heavy load.

The pressure drop in the fuel line is also a critical factor. As the fuel flows through the larger line, it experiences a lower pressure, which can lead to a situation where the fuel pressure at the engine's fuel injectors or carburetor is insufficient to ensure proper atomization and combustion. This can result in poor engine performance, increased emissions, and even engine misfires.

To mitigate these issues, it's essential to ensure that the fuel lines are appropriately sized for the engine's requirements. Consulting the vehicle's manual or seeking advice from a professional mechanic can help determine the correct diameter for the fuel lines. Properly sizing the fuel lines will help maintain optimal engine performance and ensure a reliable fuel supply, ultimately contributing to a smoother and more efficient driving experience.

Mastering LS Swap Fuel Line Routing: A Comprehensive Guide

You may want to see also

Cost and Maintenance: Oversized fuel lines may be more expensive and require more frequent maintenance, potentially increasing overall costs

When considering the size of fuel lines, it's important to understand that there can indeed be such a thing as "too big." While it might seem counterintuitive, oversized fuel lines can present several challenges and potential drawbacks, particularly in terms of cost and maintenance.

One of the primary concerns with oversized fuel lines is the increased material and manufacturing costs. Fuel lines are designed to fit specific vehicles and engine requirements, and larger diameters often mean more expensive materials and a more complex manufacturing process. The use of larger-than-necessary fuel lines can lead to unnecessary expenses, especially when considering the overall cost of the vehicle or equipment.

Additionally, oversized fuel lines may require more frequent maintenance and repairs. Larger lines can be more susceptible to issues such as leaks, blockages, and damage from external factors like road debris or temperature fluctuations. Regular maintenance, including inspections and potential replacements, can become more frequent and costly over time. This is particularly relevant for vehicles or equipment that are used in demanding environments or for extended periods.

The increased maintenance requirements can also impact the overall reliability and performance of the vehicle or system. Regular checks and replacements of fuel lines can disrupt the normal operation and may require specialized tools and expertise, further adding to the maintenance costs. In some cases, oversized fuel lines might even lead to reduced engine performance or efficiency, as the larger diameter can affect the flow rate and pressure of the fuel, ultimately impacting the engine's ability to function optimally.

In summary, while it might be tempting to assume that larger fuel lines are always better, the reality is that oversized fuel lines can lead to increased costs and maintenance challenges. It is essential to carefully consider the specific requirements of the vehicle or equipment and choose fuel lines that are appropriately sized to ensure optimal performance, reliability, and cost-effectiveness.

Unleash the Power: Milwaukee's Fuel Line Revolution

You may want to see also

Engine Compatibility: Some engines may not be designed to handle larger fuel lines, leading to performance issues or damage

When considering the size of a fuel line, it's important to understand that not all engines are created equal, and their compatibility with fuel lines of varying diameters is a critical factor. Some engines may have specific requirements and limitations when it comes to fuel line dimensions, and using a fuel line that is too large can lead to a range of performance issues and potential damage.

Engine manufacturers design fuel systems with precise specifications, including the diameter of the fuel lines. These specifications are carefully chosen to ensure optimal fuel flow, pressure, and atomization for efficient combustion. If a larger fuel line is installed, it can disrupt the carefully calibrated fuel delivery system. The increased diameter may cause fuel to flow too quickly, leading to excessive pressure and potential damage to the engine's fuel injectors or pump. This can result in reduced power output, poor fuel efficiency, and even engine misfires.

In some cases, a larger fuel line might not physically fit within the engine's confines. Engines have limited space for fuel lines, and an oversized line could interfere with other components, causing mechanical issues. Additionally, the increased size of the fuel line might lead to higher fuel temperatures due to reduced surface area, which can negatively impact fuel quality and engine performance.

To ensure optimal engine performance and longevity, it is crucial to adhere to the manufacturer's guidelines regarding fuel line dimensions. Using a fuel line that is too big can lead to performance problems, such as reduced power, poor fuel economy, and potential long-term damage to the engine's fuel system. It is always recommended to consult the engine's manual or seek professional advice to determine the appropriate fuel line size for a specific engine model.

Air in Fuel Lines: Will Your Pump Fail?

You may want to see also

Safety and Reliability: Larger fuel lines can pose safety risks, such as increased fire hazard or fuel spillage, if not properly installed and maintained

The size of a fuel line is an important consideration when it comes to vehicle performance and safety. While it might seem counterintuitive, having a fuel line that is too large can actually present several safety and reliability concerns. One of the primary issues is the potential for increased fire hazard. Larger fuel lines can carry more fuel at any given time, which means that in the event of a leak or damage, there is a higher risk of a more significant fuel spill. This can lead to dangerous situations, especially in high-temperature environments or when the vehicle is in close proximity to ignition sources. For instance, a small crack or puncture in a larger fuel line could result in a substantial amount of fuel leaking onto hot engine components, creating a highly flammable environment.

Proper installation and maintenance are crucial to mitigating these risks. Fuel lines should be carefully routed to avoid sharp bends or kinks, as these can cause stress points that may lead to leaks over time. It is also essential to ensure that all connections are secure and free from corrosion, as loose fittings can lead to fuel leakage and potential fire hazards. Regular inspections and maintenance checks should be conducted to identify any signs of wear and tear, corrosion, or damage to the fuel lines. This includes checking for any signs of fuel leakage, such as stains or odors, and addressing any issues promptly.

In addition to fire hazards, larger fuel lines can also contribute to fuel spillage, especially during vehicle operation. The increased volume of fuel in the line can lead to higher pressure, which may cause the fuel to spray out if there are any issues with the fuel pump or injectors. This can result in fuel being directed towards unintended areas, such as the engine compartment or even the surroundings, posing a risk of environmental contamination and potential health hazards. Properly managing fuel flow and ensuring the fuel system is functioning optimally can help prevent such spillage.

To ensure safety and reliability, it is recommended to use fuel lines that are appropriately sized for the vehicle's fuel requirements. Over-sizing the fuel line should be avoided, as it can lead to unnecessary complexity and potential safety issues. Regular maintenance, including fuel system checks and timely repairs, is essential to keeping the vehicle safe and efficient. By addressing these considerations, vehicle owners can minimize the risks associated with fuel lines and ensure a more secure and reliable driving experience.

Winterizing Outboard: Fuel Line Disconnect: A Wise Move?

You may want to see also

Frequently asked questions

While a larger fuel line might allow for a smoother flow of fuel, it is not necessarily the solution to improving engine performance. The size of the fuel line should be appropriate for the engine's requirements and the fuel pressure. An oversized fuel line can lead to unnecessary fuel wastage and potential performance issues.

If a fuel line is oversized, it can result in a few problems. Firstly, it may lead to fuel spillage or wastage, as the excess fuel might not be efficiently utilized. Secondly, it can cause fuel pressure issues, as the larger line might not provide the required pressure for optimal engine operation. This could potentially lead to poor engine performance and even starting difficulties.

Upgrading the fuel line is not always necessary when modifying an engine. It depends on the specific modifications and the engine's requirements. If the modifications involve a significant increase in power or a change in fuel type, then an upgrade might be beneficial to ensure efficient fuel delivery. However, for minor modifications, the stock fuel line may be sufficient.

Absolutely! A fuel line that is too small can restrict fuel flow, leading to engine performance problems. This restriction can cause a decrease in power, poor fuel efficiency, and even engine misfires. It is crucial to choose the correct fuel line size to match the engine's needs and ensure a smooth and efficient fuel supply.