Replacing a fuel line can seem daunting, but with the right tools and a bit of know-how, it's a manageable DIY project. This guide will walk you through the process step-by-step, ensuring you have the necessary information to complete the job safely and effectively. Whether you're dealing with a worn-out line or a leak, replacing it can save you money and keep your vehicle running smoothly. Let's get started!

What You'll Learn

Materials Needed: Gather tools and replacement fuel lines

Before you begin the process of replacing your fuel line, it's essential to gather all the necessary materials and tools to ensure a successful and efficient repair. Here's a detailed breakdown of what you'll need:

Tools:

- Fuel Line Cutter: This tool is specifically designed to cut through fuel lines without damaging the surrounding components. It's crucial to have a sharp and precise cutter to ensure a clean and accurate cut.

- Hacksaw or Pipe Cutter: In some cases, you might need a hacksaw or a pipe cutter to make cuts on the fuel line, especially if it's thicker or more robust. Ensure you have a variety of blade sizes to accommodate different fuel line diameters.

- Sandpaper or Embellisher: These tools are used for smoothing and preparing the cut ends of the fuel lines. Sanding ensures a clean and smooth surface for a proper connection.

- Fuel Line Crimping Tool: If your replacement fuel lines require crimping fittings, you'll need a specialized tool to create secure and leak-proof connections.

- Pliers: Standard pliers are essential for gripping and holding various components during the installation process.

- Wrenches: Different sizes of wrenches will be useful for tightening and securing fuel line fittings and connections.

- Safety Gear: Don't forget to wear safety goggles and gloves to protect your eyes and hands from any potential fuel line debris or splashes.

Replacement Fuel Lines:

- Obtain the correct replacement fuel lines that are compatible with your vehicle's make and model. Ensure you get the right size and length to match the existing fuel line. You can find these at auto parts stores or online retailers.

- Consider purchasing fuel line kits that include all the necessary fittings and connectors for a complete replacement. These kits often provide everything you need in one package, making the installation process more straightforward.

Additional Materials:

- Fuel Line Adhesive or Sealant: Some fuel lines may require an adhesive or sealant to ensure a secure and leak-free connection. Choose a product specifically designed for fuel line repairs.

- Rags or Cloths: Keep some rags or clean cloths handy for wiping away any fuel or debris during the installation.

- New Gaskets or Seals: If your fuel line fittings have gaskets or seals, consider replacing them to ensure a tight and leak-free connection.

By gathering these materials and tools, you'll be well-prepared to tackle the DIY fuel line replacement project. Having everything readily available will make the process smoother and more efficient, allowing you to get your vehicle back on the road with confidence.

Diagnosing Fuel Line Leaks: A Step-by-Step Guide

You may want to see also

Preparation: Clean and inspect the old line

Before you begin the replacement process, it's crucial to ensure that the old fuel line is thoroughly cleaned and inspected to identify any potential issues. This step is essential to guarantee a successful and safe installation of the new fuel line. Here's a detailed guide on how to prepare and clean the old fuel line:

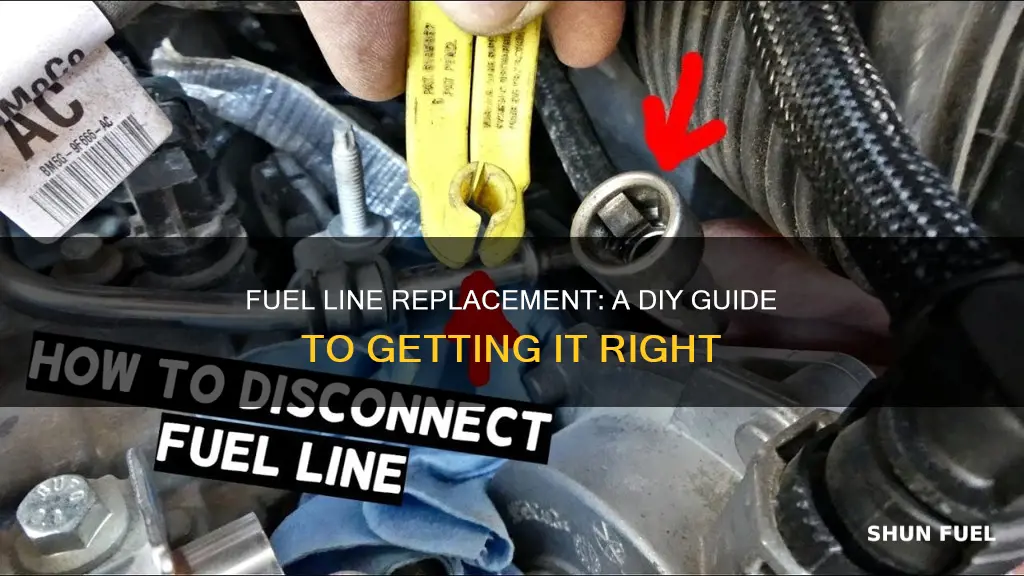

Step 1: Remove the Old Fuel Line: Start by disconnecting the fuel line from the existing fuel source and the vehicle's engine. Carefully detach any clamps or fittings that secure the line to the fuel tank and the engine. Take note of the positioning of the fuel line to ensure you can reconnect the new line correctly. Once removed, you'll have access to the old fuel line, which is now ready for inspection and cleaning.

Step 2: Inspect for Damage: Carefully examine the old fuel line for any signs of wear, corrosion, cracks, or leaks. Look for areas where the line may have been damaged by sharp edges, road debris, or previous repairs. Inspect both the inner and outer surfaces of the line. If you notice any significant damage, such as large holes or deep cracks, it's best to replace the entire line to prevent potential fuel leaks and ensure safety.

Step 3: Clean the Fuel Line: Cleaning the fuel line is an important step to ensure it is free from contaminants and ready for the new installation. You can use a fuel line cleaner or a mixture of vinegar and water to flush out any debris or residue. Start at the fuel tank and work your way towards the engine, using a pressure washer or a garden hose with a spray nozzle to flush the line. Ensure that you remove any built-up fuel, dirt, or old fuel line cleaner. This process helps to prevent any contamination that could affect the performance of the new fuel line.

Step 4: Check for Clogged Areas: While cleaning, pay attention to any areas where the fuel line might be narrowed or clogged. These areas can restrict fuel flow and may indicate potential issues with the old line. Use a small brush or a fuel line cleaning tool to gently clear any blockages. Ensure that the line is clear and free-flowing throughout its entire length.

Step 5: Document and Measure: As you inspect and clean the fuel line, take notes on any specific issues or measurements. This documentation will be useful when selecting the appropriate replacement line and ensuring a proper fit. Measure the length of the old fuel line to determine the required length for the new replacement. Accurate measurements will help you choose the correct size and ensure a seamless installation.

By following these preparation steps, you'll be well-prepared to replace the fuel line, ensuring a clean and safe installation. It's important to take the time to thoroughly inspect and clean the old line to avoid any potential complications during the replacement process.

Vacuum Line Fuel Spill: Causes and Solutions

You may want to see also

Cutting: Measure and cut the new line to length

When replacing a fuel line, accurate measurements are crucial to ensure a proper fit. Start by carefully inspecting the old fuel line to determine its length. Measure the distance from the fuel tank to the engine, noting any bends or twists in the line's path. This will give you an idea of the total length required for the new line. It's important to measure twice to avoid any mistakes, as cutting the line to an incorrect length can lead to issues during installation.

Using a tape measure or a flexible measuring tool, mark the desired length on the new fuel line. Ensure that the measurement aligns with the bends and twists of the original line to maintain the correct positioning. For a seamless installation, consider adding a small allowance for any potential adjustments or fittings. This extra length will provide flexibility during the installation process.

Once you have the measurement, use a sharp utility knife or a fuel line cutter to make a clean cut. Hold the cutter steady and guide it along the marked line to ensure a precise cut. Take your time with this step, as a clean cut will make the installation process smoother. If you're using a fuel line cutter, follow the manufacturer's instructions to ensure you're using the tool correctly and safely.

After cutting the new fuel line, inspect the ends for any damage or burrs. Smooth any rough edges with a file or sandpaper to prevent damage to the fuel tank or engine during installation. This attention to detail will contribute to a successful and long-lasting repair.

Remember, taking accurate measurements and cutting the fuel line carefully are essential steps in the DIY fuel line replacement process. These steps will help ensure a proper fit and a successful installation.

Frozen Fuel Lines: The Silent Culprit Behind Your Car's Failure to Start

You may want to see also

Fitting: Attach the new line securely with clamps

Once you've successfully installed the new fuel line, the next crucial step is to ensure it's securely attached and won't come loose under pressure or vibration. This involves using the appropriate clamps and following a systematic approach. Here's a detailed guide on how to attach the new line with clamps:

Choose the Right Clamps: Select clamps that are specifically designed for fuel lines. These clamps are typically made of durable materials like stainless steel or rubber compounds that can withstand the corrosive nature of fuel. Ensure the clamps have a suitable size to fit around the fuel line without being too tight or loose.

Prepare the Clamps: Before attaching the clamps, make sure they are clean and free of any debris. You can use a wire brush or a small brush to remove any dirt or old clamp material. This ensures a clean and secure attachment.

Position the Clamps: Locate the points where the fuel line connects to various components, such as the fuel tank, engine, or fuel pump. Carefully position the clamps over the fuel line at these connection points. Ensure the clamps are positioned in a way that they can evenly distribute the pressure around the fuel line.

Secure the Clamps: Tighten the clamps firmly but carefully. You want to ensure a secure hold without causing any damage to the fuel line. Use a wrench or a spanner to tighten the clamps, but be cautious not to overtighten, as this can lead to damage. The goal is to achieve a snug fit that prevents any movement or leakage.

Test for Leaks: After securing the clamps, it's essential to test for any potential leaks. Turn on the fuel system and check for any signs of fuel escaping around the clamp areas. If you notice any leaks, carefully inspect the clamps and the fuel line for any damage or misalignment. Tighten the clamps further or adjust their position if necessary.

Remember, the key to a successful fuel line replacement is attention to detail. Take your time with each step, ensuring a secure and leak-free installation. Regularly checking the clamps and fuel line connections over time will also help maintain the integrity of your fuel system.

Troy Bilt Mower Fuel Line Cleaning: A Step-by-Step Guide

You may want to see also

Testing: Check for leaks and ensure proper flow

When replacing a fuel line, it's crucial to test for leaks and ensure proper flow to guarantee the system's safety and efficiency. Here's a step-by-step guide to help you through this process:

Step 1: Visual Inspection

Start by visually inspecting the fuel line and its connections. Look for any visible signs of damage, such as cracks, punctures, or corrosion. Check for any loose fittings or connections that might have been caused by the removal process. Ensure that all components are clean and free from debris.

Step 2: Pressure Test

A pressure test is essential to identify potential leaks. You can use a simple setup with a pump and a gauge to apply pressure to the fuel line. Start with a low pressure and gradually increase it while monitoring for any drops or fluctuations. Leaks will be indicated by a sudden drop in pressure. Make sure to test all connections and bends in the line.

Step 3: Bubble Test

For a more comprehensive leak detection, perform a bubble test. Soak the fuel line in a container of water and use a small amount of dish soap as a detergent. If there are any leaks, air bubbles will form and rise to the surface. This method is particularly useful for identifying small pinhole leaks that might not be visible during a pressure test.

Step 4: Flow Rate Check

Ensure that the fuel line is functioning correctly by checking the flow rate. You can use a calibrated flow meter to measure the volume of fuel passing through the line per unit of time. Compare the results with the manufacturer's specifications to verify that the flow is within the acceptable range. This step is crucial to ensure that the fuel is delivered efficiently to the engine.

Step 5: Final Inspection

After the tests, inspect the fuel line once more to identify any areas that require further attention. If any leaks or issues are found, address them before proceeding with the installation. Properly secure all connections and ensure that the line is routed correctly to prevent future problems.

Remember, thorough testing is essential to ensure a successful DIY fuel line replacement. It helps prevent potential hazards and ensures that your vehicle's fuel system operates optimally.

Craftsman Chainsaw Fuel Line Insert: A Step-by-Step Guide

You may want to see also