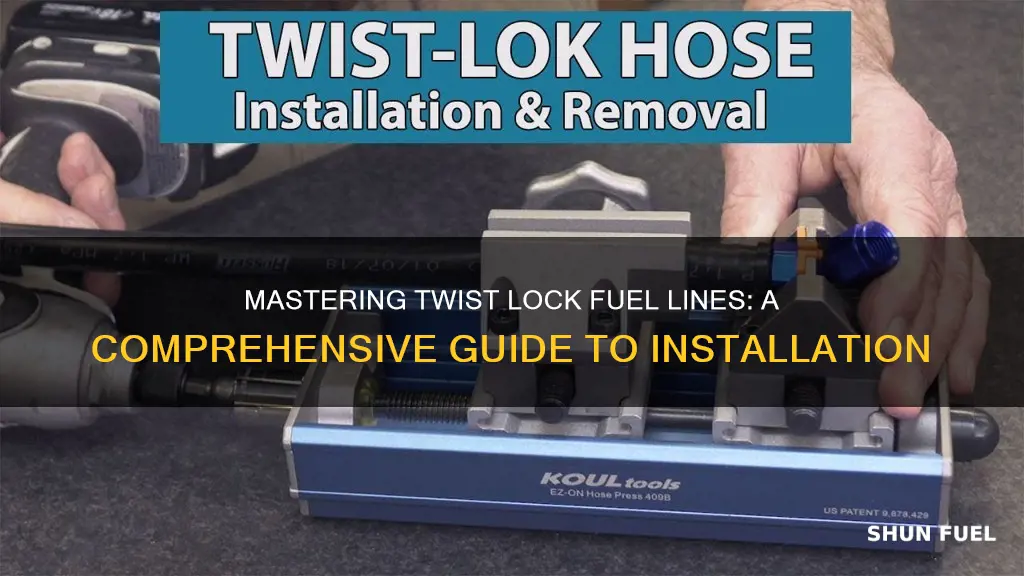

Installing twist lock fuel line fittings is a straightforward process that ensures a secure and leak-free connection for your vehicle's fuel system. This method of fitting installation is popular due to its ease of use and the ability to quickly and easily connect fuel lines without the need for tools like clamps or adhesives. The twist lock mechanism provides a tight seal by twisting the fitting onto the fuel line, creating a reliable and durable connection. This guide will provide a step-by-step overview of the installation process, ensuring you can confidently and efficiently secure your fuel lines.

| Characteristics | Values |

|---|---|

| Compatibility | Universal fit for most fuel lines |

| Material | Aluminum alloy or brass |

| Design | Twist-lock mechanism for secure connection |

| Installation | Easy and quick installation process |

| Durability | Weather-resistant and durable |

| Flexibility | Allows for some movement and flexibility |

| Leak-proof | Ensures no fuel leaks |

| Cost-effective | Affordable compared to other fuel line systems |

| Maintenance | Low maintenance required |

What You'll Learn

- Preparation: Gather tools and materials, ensure fuel line is clean and dry

- Fitting Selection: Choose the right size and type of fitting for your fuel line

- Assembly: Follow manufacturer's instructions to assemble the fitting and fuel line

- Testing: Check for leaks and ensure a secure connection using a twist lock

- Maintenance: Regularly inspect and maintain the twist lock fuel line fittings

Preparation: Gather tools and materials, ensure fuel line is clean and dry

Before you begin the installation process of twist lock fuel line fittings, it's crucial to prepare the necessary tools and materials to ensure a smooth and successful job. Start by gathering all the required components, including the twist lock fittings, fuel line, and any additional hardware such as clamps or brackets that might be needed for a secure connection. Having everything ready will save you time and prevent any unnecessary trips to the hardware store during the installation.

Next, inspect the fuel line to ensure it is in good condition. Check for any signs of damage, cracks, or leaks. If you notice any issues, it's best to replace the fuel line before proceeding. A damaged fuel line can lead to fuel leaks, which are not only dangerous but also costly to repair. Once you've confirmed the fuel line is intact, ensure it is clean and dry. Any moisture or dirt on the fuel line can interfere with the installation process and compromise the system's integrity.

To prepare the fuel line for installation, you may need to cut it to the desired length. Measure carefully and mark the line accordingly. Use a sharp, clean blade to make precise cuts, ensuring you don't damage the surrounding area. After cutting, inspect the ends of the fuel line to check for any damage. If there are any nicks or scratches, smooth them out with a file or sandpaper to create a clean surface for the fittings.

While you're preparing the fuel line, it's also a good idea to have a work area that is clean and organized. Lay out all the components and tools you'll be using to have everything within reach. This will make the installation process more efficient and less time-consuming. Additionally, ensure that the work area is well-ventilated, especially if you're working in a confined space, to avoid inhaling any fumes that might be present.

By taking the time to gather the right tools and materials, inspect and prepare the fuel line, and organize your work area, you'll set yourself up for a successful installation of the twist lock fuel line fittings. This preparation phase is essential to ensure a safe and effective repair or modification to your fuel system.

Fuel Line Fabrication: Expert Services for Your Vehicle

You may want to see also

Fitting Selection: Choose the right size and type of fitting for your fuel line

When it comes to installing twist-lock fuel line fittings, selecting the right size and type of fitting is crucial for a secure and reliable connection. Here's a detailed guide to help you choose the appropriate fittings:

Understanding Fuel Line Requirements: Begin by assessing the specific needs of your fuel line setup. Consider the diameter of the fuel line, as this will determine the size of the fitting. Twist-lock fittings typically come in various sizes, such as 3/8", 1/2", or 3/4" diameters. Measure the fuel line to ensure you select a fitting that matches its dimensions. Additionally, consider the length of the fuel line and the number of fittings required to connect the system.

Fitting Types: Twist-lock fittings offer different types, each serving a unique purpose. The most common types include the straight fitting, elbow, and tee. Straight fittings are used to join two fuel lines of the same diameter, creating a straight connection. Elbows, as the name suggests, provide a 90-degree turn and are useful for changing the direction of the fuel line. Tees allow for a branch connection, enabling you to split the fuel flow into two separate lines. Choose the fitting type based on the layout and requirements of your fuel system.

Size Considerations: Selecting the correct size is critical to ensure a proper fit. Measure the fuel line's inside diameter accurately. Twist-lock fittings usually have a specific size range, such as 3/8" or 1/2" fittings. Ensure that the fitting's bore diameter matches the fuel line's diameter for a tight seal. Using a fitting that is too small may result in restricted fuel flow, while a larger fitting might not provide a secure connection.

Material and Compatibility: Twist-lock fittings are available in various materials, including steel, aluminum, and plastic. Consider the compatibility of the fitting material with the fuel line and the overall system. For example, if your fuel line is made of aluminum, choose fittings with a compatible material to ensure a secure bond. Additionally, check if the fittings are compatible with the type of fuel being used, as some materials may require specific fittings to prevent contamination.

Quality and Brand: Opt for high-quality fittings from reputable brands to ensure durability and reliability. Well-known manufacturers often provide fittings that meet industry standards and offer better resistance to fuel line pressures and temperatures. Check for any certifications or ratings that indicate the fitting's performance and suitability for your application.

By carefully considering the size, type, material, and compatibility of the twist-lock fittings, you can ensure a professional and secure installation, maximizing the efficiency and longevity of your fuel line system.

Fuel Line to Catalyst: Unraveling the Connection

You may want to see also

Assembly: Follow manufacturer's instructions to assemble the fitting and fuel line

When it comes to installing twist-lock fuel line fittings, it's crucial to follow the manufacturer's instructions meticulously. These fittings are designed to provide a secure and leak-free connection between fuel lines, ensuring the safe operation of your vehicle. Here's a step-by-step guide on how to assemble the fitting and fuel line:

Preparation: Before you begin, ensure you have all the necessary tools and components. This includes the twist-lock fitting, the appropriate fuel line, and any additional hardware provided by the manufacturer. Check the fitting for any visible damage or defects. If any issues are found, contact the manufacturer for a replacement.

Assembly: Locate the fuel line and align it with the twist-lock fitting. The manufacturer's instructions will provide specific details on the correct orientation. Insert the fuel line into the fitting, ensuring it is fully seated. Twist the fitting onto the fuel line, following the recommended torque specifications. Tighten the fitting securely, but be careful not to over-tighten, as this can damage the fuel line.

Securement: Once the fitting is in place, secure it using the provided locking mechanism. This twist-lock feature ensures a tight and reliable connection. Follow the instructions to engage the lock, which may involve twisting or clicking it into position. Make sure the lock is fully engaged to prevent any accidental disconnection.

Testing: After assembly, it's essential to test the installation. Start the vehicle's engine and check for any leaks around the fitting. Inspect the connection for any signs of damage or movement. If everything appears secure, you can proceed with the vehicle's operation.

Remember, each manufacturer may have slightly different procedures, so always refer to their specific instructions. Following these steps will help ensure a proper and safe installation of the twist-lock fuel line fittings.

Choosing the Right Fuel Line for Your Homelite Trimmer: A Guide

You may want to see also

Testing: Check for leaks and ensure a secure connection using a twist lock

When working with twist lock fuel line fittings, ensuring a secure and leak-free connection is crucial to prevent fuel leaks and potential engine damage. Here's a step-by-step guide on how to test and verify the installation:

Step 1: Visual Inspection

Start by visually inspecting the twist lock fuel line fitting. Check for any visible signs of damage, such as cracks or bends in the fitting itself or the fuel line. Ensure that all components are clean and free from debris or contaminants. Look for any signs of corrosion or oxidation, especially around the threads and the twist lock mechanism.

Step 2: Tighten the Fitting

Securely tighten the twist lock fitting by hand. You should feel a distinct 'click' or 'snap' when the fitting is fully engaged. This click indicates that the internal locking mechanism has been activated, ensuring a secure connection. If you don't hear the click, it might suggest that the fitting is not fully tightened or that there's an issue with the mechanism.

Step 3: Apply Pressure

To check for leaks, apply pressure to the fuel line fitting. Squeeze the fuel line gently with your hand and observe for any signs of fuel escaping. You can also use a small, clean rag to wipe the area and check for any fuel residue. If you notice any leaks, it's essential to identify the source and address it immediately.

Step 4: Use a Bubble Test

For a more comprehensive leak test, use a simple bubble test. Fill a clear container with a small amount of water and carefully place the fuel line fitting into the water, ensuring it is fully submerged. If there are no leaks, you should not see any bubbles escaping from the fitting. If bubbles appear, it indicates a potential leak, and you should investigate further.

Step 5: Final Check

After ensuring the fitting is tight and leak-free, give the fuel line a gentle shake to simulate various driving conditions. This additional step helps identify any potential issues that might arise during actual use. If the fitting remains secure and there are no leaks, you can be confident in your installation.

Remember, proper installation and testing are critical to maintaining a safe and efficient fuel system. Always follow manufacturer guidelines and best practices to ensure optimal performance and longevity.

The Hidden Heroes: Who Crafts Your Car's Fuel Lines?

You may want to see also

Maintenance: Regularly inspect and maintain the twist lock fuel line fittings

Regular maintenance of twist lock fuel line fittings is essential to ensure the efficient and safe operation of your vehicle's fuel system. These fittings are designed to securely connect fuel lines, preventing leaks and potential engine damage. Over time, however, they can wear out or become compromised due to various factors like temperature changes, fuel contamination, or physical damage. Therefore, it's crucial to inspect and maintain them regularly.

Start by familiarizing yourself with the location of the twist lock fittings on your vehicle. These are typically found along the fuel lines, often near the fuel tank and the engine. Inspect each fitting for any signs of damage, corrosion, or wear. Look for cracks, brittleness, or any visible deterioration that could indicate a compromised seal. Also, check for any signs of fuel leakage around the fittings, as even a small leak can lead to serious issues over time.

A simple yet effective maintenance routine involves using a twist lock fuel line fitting cleaner. This specialized cleaner is designed to remove any built-up debris, corrosion, or fuel residue that may have accumulated inside the fittings. Apply the cleaner according to the manufacturer's instructions, ensuring you cover all parts of the fittings. This process helps to restore the integrity of the seals and ensures a tight connection. After cleaning, thoroughly rinse the fittings to remove any remaining cleaner and allow them to dry completely before reinstalling.

In addition to cleaning, it's important to periodically replace worn-out or damaged twist lock fittings. Over time, the seals can degrade, leading to fuel leaks. If you notice any signs of wear or damage, it's best to replace the fittings immediately. When replacing, ensure you use high-quality, compatible fittings that meet the manufacturer's specifications. Properly secure the new fittings according to the installation guidelines to maintain the integrity of the fuel system.

Regularly scheduled inspections and maintenance can help prevent unexpected fuel system failures and costly repairs. By taking the time to inspect and maintain your twist lock fuel line fittings, you contribute to the overall reliability and longevity of your vehicle's fuel system. Remember, proper maintenance is a proactive approach that can save you from potential headaches and expenses associated with fuel system malfunctions.

Mastering Aluminum Fuel Line Installation: A Comprehensive Guide

You may want to see also

Frequently asked questions

Twist lock fittings are designed to securely connect fuel lines to fuel tanks, pumps, or other components in a vehicle's fuel system. They provide a reliable and leak-free connection, ensuring that fuel is delivered efficiently and safely.

Before installation, ensure you have the necessary tools such as fuel line cutters, crimping tools, and a fuel line cleaner. Prepare the fuel lines by cutting them to the appropriate length and cleaning any debris or contaminants. It's also crucial to inspect the fittings for any damage or defects.

Start by inserting the male end of the fuel line into the female fitting, ensuring it is aligned correctly. Then, twist the fitting onto the fuel line until it is securely locked in place. Use a crimping tool to apply pressure and create a tight seal. Repeat this process for all connections, ensuring each fitting is tightened to the manufacturer's recommended torque specifications.

One common issue is an improper fit, which can lead to leaks. Ensure the fuel line is the correct size and shape for the fitting. Another problem is over-tightening, which may damage the fuel line or fitting. Always follow the torque specifications to avoid this. Additionally, check for any obstructions or interference that might affect the installation process.

Regularly inspect the fittings for any signs of wear, corrosion, or damage. Clean the fittings periodically to remove any built-up fuel residue or contaminants. It's also a good practice to check the connections for tightness periodically, especially after any fuel system modifications or repairs.