When preparing your boat for winter storage, one crucial step is ensuring that your outboard engine is properly winterized to prevent damage. A common question that arises is whether disconnecting the fuel lines is necessary for this process. This paragraph will explore the benefits and considerations of disconnecting fuel lines for winterizing an outboard engine, providing valuable insights to help you make an informed decision.

| Characteristics | Values |

|---|---|

| Fuel Line Disconnection | Yes, disconnecting fuel lines is a common practice for winterizing outboard motors. |

| Reason | Prevents fuel from sitting in the lines and engine, reducing the risk of engine damage from ethanol-induced corrosion or fuel degradation. |

| Benefits | Protects the engine from potential issues like fuel system corrosion, engine misfires, and reduced performance during storage. |

| Precautions | Ensure the engine is properly cooled down before disconnecting the fuel lines to avoid fuel splashing and potential hazards. |

| Reattachment | Reattach the fuel lines before starting the engine in the spring to ensure proper fuel supply. |

| Alternative Methods | Some engines may have fuel shut-off valves or fuel tanks with winterizing features, reducing the need for complete fuel line disconnection. |

| Consultation | Always refer to the manufacturer's guidelines for specific winterization instructions for your outboard motor. |

What You'll Learn

- Fuel Line Material: Consider fuel line material compatibility with antifreeze solutions

- Fuel Tank Protection: Protect fuel tank from corrosion and freezing

- Engine Maintenance: Disconnecting fuel lines aids in engine maintenance and cleaning

- Winter Storage: Disconnecting fuel lines prevents fuel degradation and engine issues during winter

- Safety Precautions: Follow safety guidelines to avoid fuel spills and engine damage

Fuel Line Material: Consider fuel line material compatibility with antifreeze solutions

When preparing your outboard engine for winter storage, one crucial aspect is understanding the compatibility of fuel line materials with antifreeze solutions. Antifreeze, also known as engine coolant, is essential to prevent engine damage during cold temperatures. However, not all fuel lines are created equal, and their materials can vary significantly.

The primary concern is to ensure that the fuel lines used in your engine can withstand the corrosive effects of antifreeze. Antifreeze contains additives designed to lower the freezing point of water, making it effective at preventing engine damage in cold climates. However, these additives can be harmful to certain materials, leading to degradation, cracking, or even leaking.

Common fuel line materials include rubber, vinyl, and various types of plastic. Rubber fuel lines are known for their flexibility and durability, making them a popular choice for many engines. However, some rubber compounds may not be compatible with antifreeze, especially those containing ethylene glycol, a common antifreeze additive. Over time, the rubber can deteriorate, leading to fuel leaks and potential engine damage.

Vinyl fuel lines are another option, offering similar flexibility to rubber but with different chemical compositions. Some vinyl types are more resistant to antifreeze, making them a better choice for winter storage. However, it's essential to check the specific type of vinyl used in your fuel lines, as not all vinyls are created equal.

For optimal winterization, it is recommended to use fuel lines made from materials specifically designed to withstand antifreeze. These materials are often more expensive but ensure the longevity of your fuel lines and the overall health of your engine. Additionally, consider using fuel line protectors or sleeves to provide an extra layer of defense against potential corrosion.

In summary, when winterizing your outboard engine, pay close attention to the material of your fuel lines. Choose materials that are known to be compatible with antifreeze solutions to ensure the engine's longevity and reliability during storage. Always refer to the manufacturer's guidelines and recommendations for the best results.

Fuel Line Flaring: A Double-Edged Decision

You may want to see also

Fuel Tank Protection: Protect fuel tank from corrosion and freezing

When preparing your outboard engine for winter storage, one crucial aspect often overlooked is the protection of the fuel tank. Proper fuel tank maintenance is essential to prevent corrosion and ensure the engine's longevity. Here's a comprehensive guide to safeguarding your fuel tank during the colder months:

Fuel Tank Corrosion Prevention:

Corrosion in the fuel tank can lead to contamination and reduced engine performance. To combat this, start by draining the tank if possible. This process involves removing the fuel lines and allowing the tank to empty, which helps eliminate any moisture and old fuel that may have accumulated. After draining, clean the tank interior using a suitable fuel tank cleaner or a mixture of fuel and vinegar. This step ensures that any corrosion-causing agents are neutralized. Rinse the tank thoroughly to remove any residue and allow it to dry completely. Consider using a fuel tank sealant to create a protective barrier, especially if your tank is made of older materials that are more susceptible to corrosion.

Preventing Freezing:

Freezing temperatures can cause fuel to thicken and potentially damage the engine. To prevent this, add a fuel stabilizer to the tank. These stabilizers are designed to maintain fuel quality and prevent gelling. They work by inhibiting the formation of ice crystals in the fuel, ensuring it remains in a usable state. Alternatively, you can use a fuel heater, which is a small device that circulates warm air or liquid through the fuel lines, keeping the fuel warm and preventing freezing. This method is particularly useful for long-term storage.

Fuel Line Management:

As mentioned in your initial search, disconnecting the fuel lines is a common practice during winterization. This step is crucial for several reasons. Firstly, it prevents fuel from spilling or leaking when the tank is drained. Secondly, it allows for easier access to the tank for cleaning and maintenance. However, ensure that you securely cap or plug the fuel lines to prevent dirt and moisture from entering the system. If you choose not to disconnect the lines, consider using a fuel line insulator to protect them from freezing temperatures.

Regular Maintenance:

Winter is an ideal time to perform comprehensive engine maintenance, including fuel tank care. Inspect the tank for any signs of damage, leaks, or corrosion. Address any issues promptly to avoid further complications. Additionally, consider using a fuel-specific rust inhibitor spray on the fuel tank's interior to provide an extra layer of protection.

By following these steps, you can effectively protect your fuel tank from corrosion and freezing, ensuring that your outboard engine is ready for the next boating season. Proper winterization practices contribute to the overall reliability and performance of your marine equipment.

Fuel Injector Linearity: A Matter of Efficiency and Precision

You may want to see also

Engine Maintenance: Disconnecting fuel lines aids in engine maintenance and cleaning

Disconnecting the fuel lines during winterization is a crucial step in maintaining an outboard engine, especially if you live in regions with harsh winters. This process ensures that the engine remains in optimal condition throughout the off-season, preventing potential issues that can arise from fuel degradation and accumulation of contaminants. Here's a detailed guide on why and how to disconnect fuel lines for winterizing your outboard engine.

Preventing Fuel-Related Issues: Over time, fuel can break down, especially in the presence of air, moisture, and heat. This degradation process can lead to the formation of varnish and other deposits, which can clog fuel passages and injectors, resulting in poor engine performance or even failure. By disconnecting the fuel lines, you essentially starve the engine of fuel, allowing you to clean and maintain the fuel system more effectively. This process helps to remove any old, contaminated fuel and ensures that the engine only receives fresh, clean fuel when you start it again in the spring.

Simplifying Maintenance: Winterizing the engine is an excellent opportunity to perform routine maintenance tasks. When the fuel lines are disconnected, you gain access to the entire fuel system, making it easier to inspect and clean. This includes checking for any signs of corrosion, replacing old fuel filters, and ensuring that the fuel pump is functioning correctly. By taking this proactive approach, you can identify and address potential issues before they become major problems, saving you time and money in the long run.

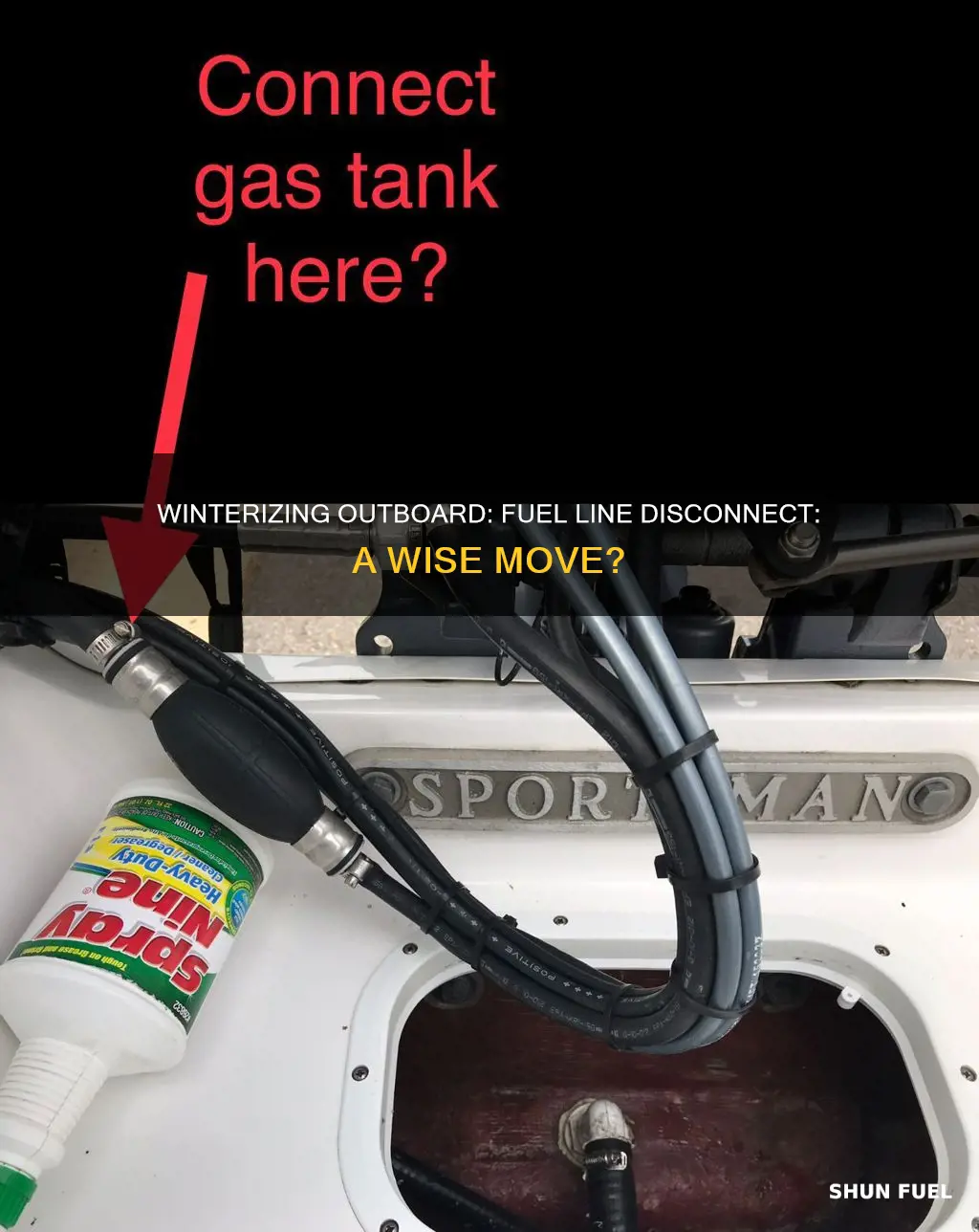

Step-by-Step Process: Disconnecting the fuel lines is a straightforward process that can be accomplished with a few simple tools. First, locate the fuel lines, which are typically rubber hoses connected to the fuel tank and the engine. Use a fuel line disconnect tool or a pair of adjustable pliers to carefully release the fuel lines from their connections. Once disconnected, you can drain the fuel tank by opening the drain valve, ensuring that any remaining fuel is safely disposed of or used in a compatible application. After draining, wipe down the fuel lines and connections to remove any dirt or debris.

Reassembly and Testing: Before reassembling the fuel lines, ensure that all connections are clean and dry. Reattach the fuel lines securely, making sure they are properly aligned and tightened. Then, fill the fuel tank with fresh fuel and start the engine to ensure that the fuel lines are functioning correctly. Let the engine run for a few minutes to allow the fuel to circulate, and check for any leaks or unusual noises. This final step is crucial to ensure that your engine is ready for the next boating season.

By following these steps, you can effectively winterize your outboard engine, ensuring its longevity and reliable performance. Remember, proper maintenance and care during the off-season will contribute to a smoother and more enjoyable boating experience when the warm weather returns.

Unleash the Power: Breaking Fuel Lines: A Quarry Decision

You may want to see also

Winter Storage: Disconnecting fuel lines prevents fuel degradation and engine issues during winter

Winterizing your outboard engine is an essential step to ensure its longevity and optimal performance when the warmer months return. One crucial aspect of this process is disconnecting the fuel lines. This simple yet effective measure can prevent a multitude of issues that may arise during the colder months.

When you disconnect the fuel lines, you essentially starve the engine of its primary energy source, preventing the fuel from degrading and causing potential problems. Fuel, especially in colder climates, can become thick and sticky, leading to a host of complications. Over time, fuel can absorb moisture, which can lead to corrosion and the formation of varnish and sludge. These substances can clog fuel filters, injectors, and even the engine's cylinders, resulting in reduced performance or even engine failure. By disconnecting the fuel lines, you eliminate the risk of these issues, ensuring that your engine remains in top condition.

The process of disconnecting the fuel lines is straightforward and can be done in a few simple steps. Start by locating the fuel lines, which are typically attached to the engine's fuel tank and injectors. Carefully detach these lines, making sure to label or mark their positions for easy reattachment in the spring. It is crucial to ensure a tight seal when disconnecting to prevent any fuel leakage. Once disconnected, you can further protect the fuel by adding a fuel stabilizer to the remaining fuel in the tank, especially if the engine will be stored for an extended period.

In addition to preventing fuel degradation, disconnecting the fuel lines also safeguards your engine from potential starting issues during winter. Cold temperatures can make fuel harder to ignite, and a clogged fuel system may result in difficulty starting the engine. By removing the fuel lines, you reduce the chances of starting problems and the potential for engine damage that may occur during the first few starts in the spring.

In summary, disconnecting the fuel lines is a vital step in winterizing your outboard engine. It prevents fuel degradation, corrosion, and engine issues, ensuring that your boat is ready for the water when spring arrives. This simple maintenance task can save you from potential headaches and costly repairs, making it an essential practice for any boat owner.

GSXR 750 Fuel Line Leaks: Normal or Cause for Concern?

You may want to see also

Safety Precautions: Follow safety guidelines to avoid fuel spills and engine damage

When preparing your outboard engine for winter storage, it's crucial to prioritize safety to prevent fuel spills and potential engine damage. Here are some essential safety precautions to follow:

Fuel Line Disconnection: One of the most common practices for winterizing is disconnecting the fuel lines. Before you proceed, ensure you have the necessary tools and a clear understanding of the process. Start by locating the fuel lines, which are typically attached to the engine and the fuel tank. Use the appropriate wrenches or pliers to carefully disconnect the lines, making sure to label or mark them for easy reattachment in the spring. This step is vital to prevent fuel from spilling or leaking, especially if the engine has been running and the fuel lines are hot.

Fuel Tank Emptying: It is generally recommended to empty the fuel tank to a certain level before winterizing. This practice helps reduce the risk of fuel expansion and potential leaks. Start by running the engine until it stops, ensuring it's completely empty. Alternatively, you can use a fuel pump primer bulb to draw out the remaining fuel. Always dispose of the fuel responsibly and in compliance with local regulations.

Engine Maintenance: Proper engine maintenance is key to avoiding damage during the winter months. Change the engine oil and filter to ensure optimal performance and protection against corrosion. Clean the engine and remove any debris or dirt that may have accumulated. Consider using a corrosion inhibitor to protect metal surfaces. Additionally, inspect the engine for any signs of wear or damage, and address any issues promptly.

Storage Environment: The storage area for your outboard engine should be dry and well-ventilated to prevent fuel evaporation and potential hazards. Avoid storing it in damp or enclosed spaces where fuel-related gases can accumulate. Keep the engine covered to protect it from dirt and debris. Regularly check on the stored engine to ensure it remains in good condition.

Safety First: Always exercise caution when working with fuel and engines. Wear appropriate personal protective equipment, such as gloves and safety goggles, to minimize the risk of injury. Keep a fire extinguisher nearby, especially when dealing with hot engine components. Be mindful of your surroundings and ensure there are no flammable materials nearby. By following these safety guidelines, you can effectively winterize your outboard engine while minimizing the chances of fuel spills and engine damage.

Camaro Fuel Line Placement: Above or Below Battery Cables?

You may want to see also

Frequently asked questions

Yes, disconnecting the fuel lines is a common practice when winterizing an outboard motor. This step helps prevent fuel from sitting in the lines and engine, which can cause corrosion, fuel degradation, and potential starting issues in the spring. It's a good maintenance practice to ensure your motor remains in good condition during the off-season.

When disconnecting the fuel lines, it's important to do so carefully to avoid spills and potential hazards. Locate the fuel lines, typically found near the engine's fuel tank or the fuel pump. Use the appropriate tools, such as fuel line connectors or clips, to release the lines from the engine and tank. Ensure you have a container or rag ready to catch any remaining fuel to prevent it from dripping onto hot engine parts.

It is not always necessary to completely drain the fuel tank. However, if you are in an area with cold temperatures and want to be extra cautious, partial draining can help reduce the risk of fuel expansion and potential leaks. You can use a fuel pump primer bulb or a small pump to remove some fuel, leaving enough to lubricate the engine components. Always refer to your boat's manual for specific recommendations.

Before reconnecting the fuel lines, ensure your outboard motor is properly cleaned and lubricated after winter storage. Check for any signs of corrosion or damage to the lines and fuel system. Reconnect the fuel lines securely, ensuring all connections are tight and free from leaks. Start the engine and let it run for a few minutes to ensure the fuel system is functioning correctly before taking your boat out for a test drive.