Creating fuel tank fuel lines is a crucial step in any vehicle maintenance or repair project. This process involves carefully routing the fuel lines from the fuel tank to the engine, ensuring they are secure, flexible, and resistant to fuel leaks. The procedure typically includes selecting the appropriate fuel line material, measuring and cutting the lines to the required length, and then securely attaching them to the fuel tank and engine components. Proper installation is essential to maintain the vehicle's performance and safety, so it's important to follow detailed instructions and use the right tools for a successful outcome.

What You'll Learn

- Materials and Tools: Gather necessary supplies like fuel lines, fittings, and tools

- Tank Preparation: Clean and inspect the fuel tank, ensuring it's ready for assembly

- Line Routing: Plan the optimal path for fuel lines, considering vehicle structure

- Fittings and Connections: Securely attach fittings and connections to fuel lines and tank

- Testing and Inspection: Verify fuel flow, pressure, and leaks before final assembly

Materials and Tools: Gather necessary supplies like fuel lines, fittings, and tools

To begin the process of creating fuel lines for your fuel tank, it's crucial to gather the right materials and tools. Here's a comprehensive guide on what you'll need:

Materials:

- Fuel Lines: Select the appropriate fuel lines based on the specific requirements of your project. Consider the length, diameter, and material (such as rubber, vinyl, or braided steel) that suits your engine and vehicle. Ensure the fuel lines are compatible with the fuel type you'll be using.

- Fittings: You'll require various fittings to connect the fuel lines. Common types include quick-connect fittings, barbed fittings, and compression fittings. Obtain the fittings that match the fuel line sizes and ensure they are compatible with your engine's fuel system.

- Fuel Tank: If you're building a new fuel tank, source a suitable container that can hold the required fuel capacity. Ensure it meets the necessary specifications and regulations for your vehicle.

- Gaskets and Seals: These are essential to ensure a secure and leak-free connection. Get a variety of gaskets and seals that fit the fittings and fuel lines.

- Fuel Filter: Consider adding a fuel filter to improve the quality of the fuel entering your engine.

Tools:

- Pipe Cutter or Scissors: A sharp and precise tool is necessary for cutting the fuel lines to the desired length.

- Fitting Cutter or Pliers: These tools will help you cut and shape the fittings to create secure connections.

- Crimping Tool: If you're using compression fittings, a crimping tool is required to ensure a tight and reliable seal.

- Hose Clamps: Useful for holding the fuel lines in place and providing additional support.

- Wrenches and Sockets: Essential for tightening fittings and ensuring a secure connection.

- Sandpaper or Embelishing Compound: These can be used to smooth any rough edges and ensure a professional finish.

- Safety Gear: Don't forget to wear safety gloves and goggles to protect yourself during the process.

Having all these materials and tools ready will ensure a smooth and efficient fuel line installation process. It's important to double-check the compatibility of each component to guarantee a safe and effective fuel system.

Mastering the Art of Removing Saturn SC1 Fuel Line Connectors: A Step-by-Step Guide

You may want to see also

Tank Preparation: Clean and inspect the fuel tank, ensuring it's ready for assembly

Tank Preparation: Clean and Inspect for Assembly

Before you begin the assembly process, ensuring the fuel tank is clean and properly inspected is crucial. This step is often overlooked but plays a vital role in the overall performance and longevity of your fuel system. Start by removing any existing fuel or debris from the tank. This can be done by draining the tank if it's empty or using a fuel pump to extract any remaining liquid. It's important to wear protective gear, such as gloves and goggles, to avoid any potential hazards from fuel contact. Once the tank is empty, use a suitable cleaning agent to remove any dirt or contaminants. A mild detergent or a specialized fuel tank cleaner can be effective, ensuring a thorough clean.

After cleaning, thoroughly rinse the tank to eliminate any chemical residue. This step is essential to prevent any unwanted reactions between the cleaning agents and the tank material. Rinsing can be done by running water through the tank or using a high-pressure sprayer to ensure no residue remains. Once the tank is clean and dry, it's time for inspection. Check for any signs of corrosion, cracks, or damage to the tank walls. Look for any leaks or potential weak spots that could compromise the tank's integrity. Pay attention to the fuel lines' connections and ensure they are intact and securely attached.

If any issues are found during the inspection, address them promptly. Repair or replace damaged parts to ensure a safe and functional fuel system. This might involve seeking professional help for complex repairs. Proper preparation and inspection will not only ensure a successful assembly but also contribute to the overall safety and efficiency of your fuel tank and lines. It's a critical step that should not be rushed or overlooked.

Fuel Line Cleaning: Essential Tune-Up Component?

You may want to see also

Line Routing: Plan the optimal path for fuel lines, considering vehicle structure

When planning the route for fuel lines in a vehicle, it is crucial to consider the structural layout and potential obstacles within the engine compartment. The primary goal is to ensure that the fuel lines are secure, flexible, and resistant to potential impacts or vibrations during the vehicle's operation. Here's a step-by-step guide to achieving this:

- Understand the Vehicle's Anatomy: Begin by thoroughly examining the vehicle's engine bay and fuel system layout. Identify the location of the fuel tank, which is typically positioned at the rear or front of the vehicle, and the points where fuel needs to be distributed to various engine components. Understanding the vehicle's architecture will help you anticipate potential challenges and plan the line routing accordingly.

- Route Planning: Decide on the optimal path for the fuel lines, ensuring they are as short and direct as possible. This minimizes the risk of fuel line damage and reduces the chances of leaks. Aim to route the lines away from high-stress areas, such as the engine's moving parts, exhaust systems, and underbody components. Consider the vehicle's suspension and potential movement during operation to ensure the lines remain taut and secure.

- Flexibility and Protection: Fuel lines should be flexible to accommodate the vehicle's movement but also need to be protected from sharp edges and potential impacts. Use flexible hoses and consider the placement of protective sleeves or shields along the line's path. This is especially important near the fuel tank, where the lines might be more susceptible to damage.

- Secure Mounting: Properly secure the fuel lines to prevent them from moving or becoming entangled. Use appropriate clamps or brackets that can withstand the forces exerted by the vehicle's operation. Ensure that the mounting points are easily accessible for maintenance and inspection.

- Consideration of Engine Components: Take into account the proximity of the fuel lines to various engine components, such as the air intake system, exhaust manifold, and engine block. Avoid routing lines too close to hot surfaces or areas with high heat dissipation to prevent potential damage or fuel contamination.

By carefully planning the route and considering the vehicle's structure, you can ensure that the fuel lines are efficiently installed, well-protected, and less prone to issues during the vehicle's lifetime. This approach contributes to a reliable and safe fuel system, which is essential for optimal engine performance.

Maximizing Engine Performance: The Role of Fuel Coolers in Return Lines

You may want to see also

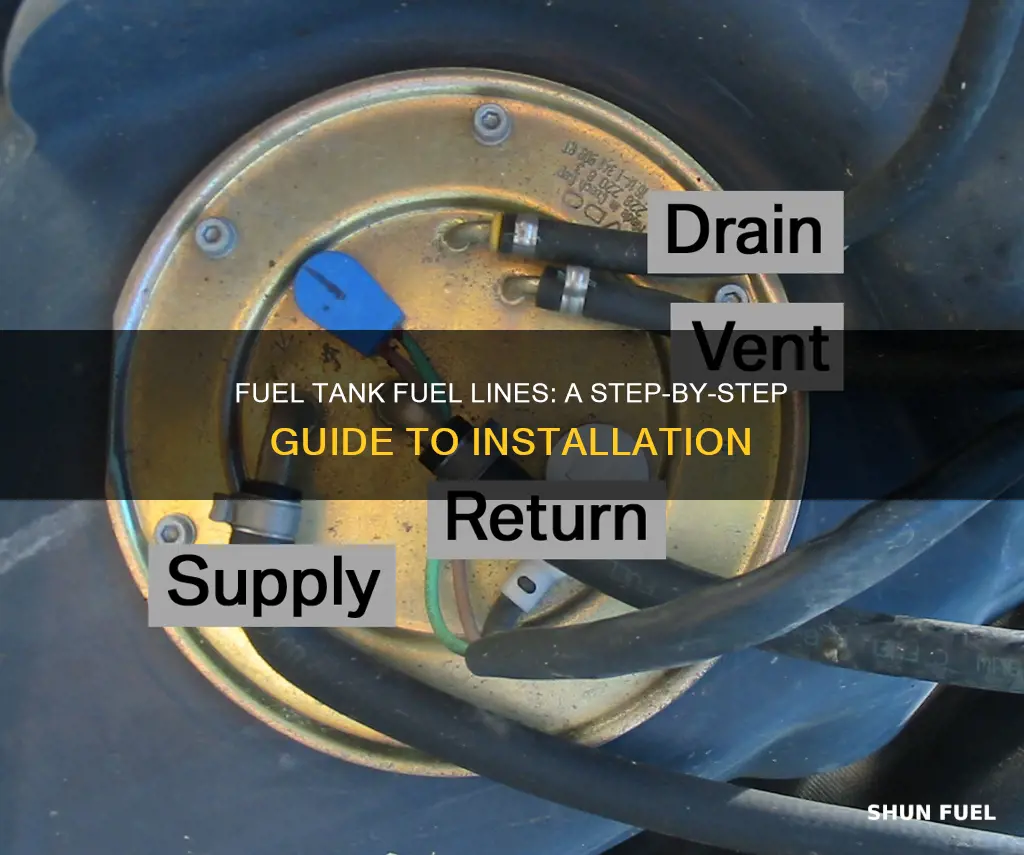

Fittings and Connections: Securely attach fittings and connections to fuel lines and tank

When it comes to connecting fuel lines to your fuel tank, proper fittings and secure connections are crucial to ensure a safe and efficient fuel system. Here's a step-by-step guide to help you achieve this:

Prepare the Materials: Before you begin, ensure you have the right fittings and connections. Common types include fuel line connectors, such as quick-connect couplings or compression fittings, and various types of fuel line adapters. Obtain these from a reputable source to guarantee compatibility with your fuel system. Additionally, gather the necessary tools, including fuel line cutters, sandpaper or a deburring tool, and a fuel line inspection kit to verify the quality of your connections.

Clean and Prepare the Fuel Lines: Start by cleaning the fuel lines to remove any dirt, debris, or old fuel residue. Use a fuel line cleaner and a soft cloth or brush to ensure a smooth and clean surface for the fittings. This step is essential to prevent contamination and ensure a tight seal.

Cut and Prepare the Fuel Lines: Measure and mark the fuel lines according to the manufacturer's instructions or your specific requirements. Use the fuel line cutters to make precise cuts. Ensure the ends of the fuel lines are smooth and free of any sharp edges. If necessary, use sandpaper or a deburring tool to create a rounded edge for a better connection.

Attach Fittings and Connections: Now, it's time to secure the fittings. Start by inserting the fuel line into the fitting, ensuring it is aligned correctly. For quick-connect couplings, simply snap the fitting onto the fuel line. For compression fittings, thread the fitting onto the fuel line and tighten it securely using a wrench. Double-check the tightness to avoid leaks. Always refer to the manufacturer's guidelines for the correct torque specifications.

Test for Leaks: After attaching the fittings, it's crucial to test for any leaks. Use the fuel line inspection kit to check for any signs of fuel escaping. If you detect a leak, tighten the fitting further or re-evaluate the connection. Ensure all connections are secure and tight to prevent fuel loss and potential safety hazards.

Final Inspection: Once all fittings are attached and tested, perform a final inspection. Check for any signs of damage, kinks, or bends in the fuel lines. Verify that all connections are tight and secure. This thorough inspection ensures the integrity of your fuel system and helps prevent potential issues down the line.

Powerful Engine Demands: Choosing the Right Fuel Line for 800 HP

You may want to see also

Testing and Inspection: Verify fuel flow, pressure, and leaks before final assembly

Before finalizing the assembly of the fuel tank and fuel lines, it is crucial to conduct a series of tests and inspections to ensure the system's functionality and safety. These checks are essential to verify that the fuel flow, pressure, and integrity of the fuel lines are all up to par. Here's a step-by-step guide on how to approach these tests:

Fuel Flow Verification: Start by checking the fuel flow rate through the lines. Use a flow meter or a calibrated orifice to measure the volume of fuel passing through the system over a specific time interval. Compare the measured flow rate with the expected value based on the engine's requirements. Ensure that the flow is consistent and meets the specifications. If the flow rate is inconsistent, it may indicate a blockage or restriction in the fuel lines, requiring further investigation and adjustment.

Pressure Testing: Measuring and monitoring fuel pressure is vital to ensure optimal engine performance. Connect a pressure gauge to the fuel line and measure the pressure at different points along the line. The pressure should match the engine's requirements, typically specified in the vehicle's manual. If the pressure is too low, it could lead to poor engine performance, while excessive pressure might cause damage to the fuel system. Adjust the fuel pump or restrictors if necessary to achieve the desired pressure.

Leak Detection: Inspect the fuel tank and fuel lines for any signs of leaks. Visually examine the connections, fittings, and joints for any visible damage or corrosion. Apply a small amount of diesel fuel or a suitable leak detection fluid along the fuel lines and observe if any seepage occurs. Leaks can lead to fuel loss, contamination, and potential safety hazards. Repair or replace any damaged components to ensure a tight and secure connection.

During these inspections, it is essential to document the results and any adjustments made. Record the measured values, pressure readings, and any issues encountered. This documentation will be valuable for future reference, troubleshooting, and ensuring compliance with the vehicle's fuel system specifications.

Additionally, consider using specialized tools and equipment to assist with these tests. For instance, a fuel pressure tester can provide accurate readings, and a fuel flow meter can measure flow rates precisely. These tools will help in identifying any anomalies or deviations from the expected performance.

By thoroughly testing and inspecting the fuel flow, pressure, and leaks, you can ensure that the fuel tank and fuel lines are ready for final assembly, meeting the required standards and contributing to the overall reliability of the vehicle's fuel system.

Mastering the Art of Bleeding Branson Fuel Lines: A Comprehensive Guide

You may want to see also

Frequently asked questions

Fuel lines are typically made from materials like rubber, vinyl, or synthetic compounds like ETFE (Ethylene Tetrafluoroethylene). The choice of material depends on factors such as temperature resistance, flexibility, and compatibility with the fuel type.

To achieve a secure fit, it's crucial to measure and cut the fuel lines to the correct length. Use a good quality fuel line connector or clamp to join the lines to the tank and other components. Ensure a tight seal to prevent fuel leaks.

Yes, you'll need a fuel line cutter or a sharp knife to cut the lines to size. A fuel line crimper or a pair of pliers can be used to secure the connections. It's also beneficial to have a fuel line cleaner to remove any contaminants before assembly.

Regularly inspect the fuel lines for any signs of damage, cracks, or brittleness. Ensure all connections are tight and secure. Use fuel line sealant or tape to reinforce vulnerable areas, especially where the lines bend or flex.

Keep the fuel lines free from debris and contaminants by using a fuel line cleaner periodically. Avoid storing fuel lines in areas exposed to extreme temperatures or direct sunlight for extended periods. Regularly check for any signs of deterioration and replace them if necessary.