The NHRA (National Hot Rod Association) has specific requirements for fuel line routing in the engine compartment to ensure safety and performance. Understanding the fuel line route is crucial for any drag racing enthusiast or mechanic, as it directly impacts the efficiency and reliability of the fuel system. This paragraph will delve into the details of the fuel line route that NHRA mandates, providing an overview of the critical components and considerations involved in meeting these standards.

| Characteristics | Values |

|---|---|

| Fuel Line Material | High-pressure fuel lines made of steel or aluminum with a minimum wall thickness of 0.030 inches |

| Fuel Line Diameter | Typically 3/8" or 1/2" ID (inside diameter) |

| Routing | Fuel lines should be routed in a straight line as much as possible, avoiding sharp bends and kinks. They should be secured with ties or clips to prevent movement and potential damage. |

| Connections | All fuel line connections must be tight and secure, using appropriate fittings and clamps. No leaks are allowed. |

| Length | Fuel lines should be long enough to reach the fuel pump and the injectors without excessive tension or stress. |

| Compatibility | Ensure the fuel lines are compatible with the fuel type (e.g., ethanol, methanol) and the engine's fuel system. |

| NHRA Regulations | Adhere to NHRA rules and guidelines for fuel system components, including fuel lines, to ensure safety and performance. |

What You'll Learn

- Fuel Line Routing: Specific path for fuel lines from tank to engine, following NHRA rules

- Engine Compartment: Fuel lines must be routed within the engine compartment, adhering to NHRA regulations

- NHRA Rules: Fuel line placement and routing must comply with NHRA competition guidelines

- Safety Considerations: Fuel lines should be secure and away from heat sources to prevent hazards

- Performance Impact: Proper fuel line routing can enhance engine performance and efficiency

Fuel Line Routing: Specific path for fuel lines from tank to engine, following NHRA rules

The NHRA (National Hot Rod Association) has specific rules and regulations regarding the routing of fuel lines in engine compartments to ensure safety and performance. Proper fuel line routing is crucial to prevent fuel leaks, maintain optimal fuel pressure, and adhere to the association's standards. Here's an overview of the recommended fuel line route:

The fuel line should typically start from the fuel tank, which is usually located at the rear of the vehicle. From the tank, the fuel line should run forward, following a specific path to reach the engine compartment. The primary goal is to keep the fuel line as short and direct as possible to minimize the risk of damage and ensure efficient fuel delivery. One common approach is to route the line along the driver's side of the vehicle, running parallel to the firewall. This path provides easy access and visibility, allowing for quick inspections and potential adjustments.

As the fuel line enters the engine compartment, it should be secured using appropriate clamps or ties to maintain a neat and organized appearance. The line should avoid any sharp bends or kinks, as these can lead to fuel restriction and potential performance issues. NHRA rules emphasize the importance of a smooth and continuous path for the fuel line. It is recommended to use flexible fuel lines with a suitable diameter to accommodate the fuel flow rate and prevent excessive pressure drops.

In the engine compartment, the fuel line should be positioned away from hot surfaces, exhaust components, and moving parts to avoid damage or potential hazards. It is essential to maintain a safe distance from the engine's intake manifold and any other critical components. The line should also be routed away from the driver's side to prevent interference with the driver's movement.

Additionally, NHRA guidelines suggest using a fuel line filter to ensure clean fuel delivery and protect the engine from potential contaminants. This filter should be positioned near the engine and securely attached to the fuel line. Regular inspection and maintenance of the fuel line and filter are vital to guarantee optimal performance and safety.

By following these specific routing guidelines, racers and enthusiasts can ensure their fuel lines comply with NHRA regulations, promoting a safer and more efficient racing environment. Proper fuel line management is a critical aspect of vehicle preparation, contributing to overall performance and driver safety.

Pipe Thread Sealant: Essential for Fuel Line Maintenance?

You may want to see also

Engine Compartment: Fuel lines must be routed within the engine compartment, adhering to NHRA regulations

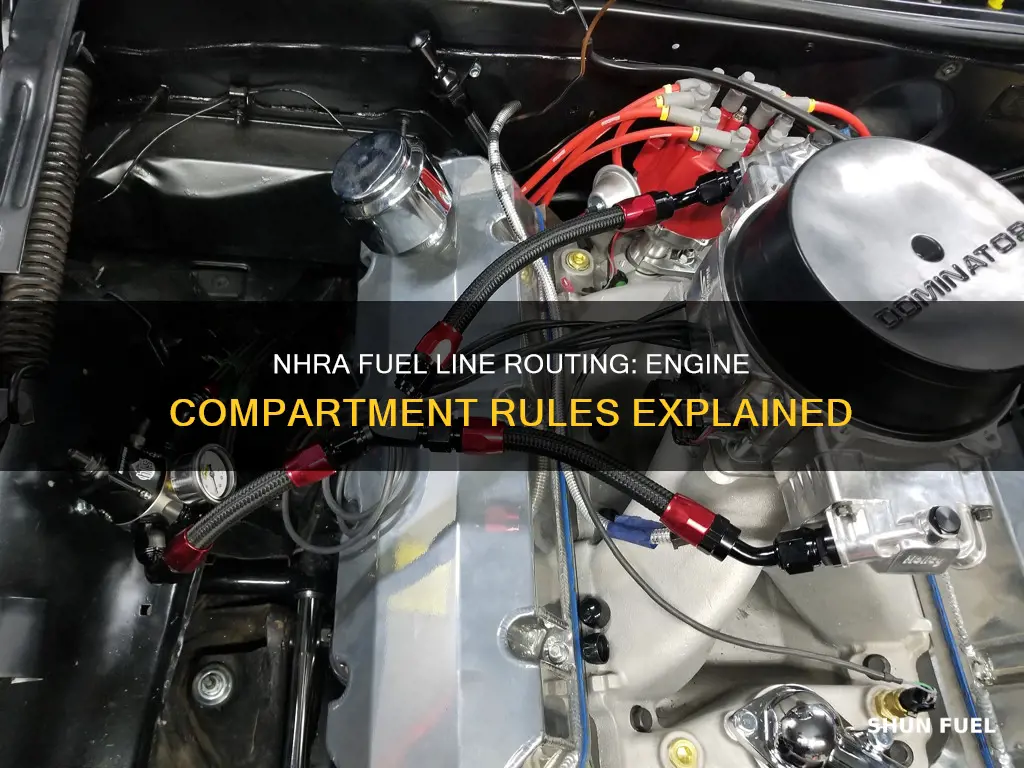

When it comes to NHRA (National Hot Rod Association) regulations, the routing of fuel lines within the engine compartment is a critical aspect of vehicle preparation. These rules are in place to ensure the safety and performance of the vehicle during racing events. Here's a detailed guide on how fuel lines should be routed within the engine compartment:

The primary goal is to maintain a secure and organized layout for the fuel lines, minimizing the risk of damage or disconnection during high-performance driving. NHRA regulations specify that fuel lines must be carefully positioned to avoid interference with moving parts and potential hazards. The lines should be routed in a way that allows for easy access and inspection, ensuring that any issues can be quickly identified and resolved.

Within the engine compartment, fuel lines should be secured using appropriate clamps or ties to prevent movement and potential damage. It is essential to keep the lines away from hot surfaces, such as exhaust manifolds or engine blocks, to avoid the risk of fire or fuel contamination. A common practice is to route the fuel lines along the top of the engine compartment, ensuring they are clear of any moving components. This positioning also provides better visibility and accessibility for maintenance and inspections.

Additionally, NHRA rules may require specific markings or color-coding for fuel lines to differentiate them from other hoses and cables. This practice aids in quick identification and troubleshooting. It is crucial to ensure that all connections are secure and that there are no kinks or bends in the lines that could restrict fuel flow or cause damage over time.

In summary, adhering to NHRA regulations for fuel line routing within the engine compartment is essential for both safety and performance. By following these guidelines, racers can ensure their vehicles are prepared to the highest standards, providing a competitive edge while maintaining a secure and organized engine bay. Proper routing and securing of fuel lines contribute to the overall reliability and success of the vehicle during NHRA events.

Mastering Snowmobile Fuel Direction: A Guide to Smooth Riding

You may want to see also

NHRA Rules: Fuel line placement and routing must comply with NHRA competition guidelines

The National Hot Rod Association (NHRA) has strict rules and regulations to ensure the safety and performance of vehicles in drag racing. One critical aspect of these rules is the proper placement and routing of fuel lines within the engine compartment. This is a crucial safety measure to prevent fuel leaks and potential fires, which could have devastating consequences during high-speed racing.

According to NHRA competition guidelines, fuel lines must be carefully routed to avoid any potential hazards. The fuel lines should be positioned in a way that minimizes the risk of damage during the race, especially when considering the high-speed acceleration and deceleration of the vehicle. The rules mandate that fuel lines should be protected and secured to prevent any movement or damage that could lead to a fuel leak.

In the engine compartment, fuel lines must be placed in a specific route, often referred to as the 'fuel line route'. This route is designed to ensure that the fuel lines are not in close proximity to hot engine components, high-pressure areas, or any potential impact zones during the race. The NHRA guidelines provide detailed instructions on the optimal path for fuel lines, often requiring them to be routed away from certain critical areas.

For instance, fuel lines should be kept away from the engine's intake manifold, exhaust system, and any moving parts like the camshaft or valves. They must also be secured to prevent tangling or interference with other components. The rules may specify the use of specific tie-downs, clips, or brackets to ensure the fuel lines remain in place and are not susceptible to damage.

NHRA inspectors are responsible for verifying that the fuel line placement and routing comply with these guidelines during pre-race inspections. Non-compliance with these rules can result in penalties or disqualification, emphasizing the importance of adhering to the specified fuel line route to ensure a safe and fair racing environment.

Polaris Ranger 570 Fuel Line Fittings: A Comprehensive Guide

You may want to see also

Safety Considerations: Fuel lines should be secure and away from heat sources to prevent hazards

In the high-octane world of NHRA drag racing, ensuring the safety of fuel lines is paramount. These lines are critical components of the fuel system, responsible for delivering the high-octane fuel required to achieve those mind-blowing speeds. However, they also present unique challenges and potential hazards that need to be carefully managed.

One of the primary safety considerations is securing the fuel lines. NHRA regulations mandate that fuel lines must be firmly attached to the vehicle's frame and engine compartment to prevent movement during the intense acceleration and deceleration of the race. Any loose connections can lead to fuel leaks, which pose a significant fire hazard. The fuel lines should be clamped securely and supported at regular intervals to maintain tension and prevent sagging, ensuring they remain in place even under extreme conditions.

Additionally, fuel lines must be positioned away from heat sources within the engine compartment. High temperatures can cause fuel to vaporize, increasing the risk of fuel line damage and potential leaks. The proximity of fuel lines to exhaust manifolds, engine blocks, or other hot components can lead to fuel line degradation over time. To mitigate this, NHRA teams often use heat shields or protective sleeves to insulate the fuel lines, ensuring they remain intact and functional during the race.

Another critical aspect is the routing of fuel lines. The path taken by the fuel lines should be as direct and efficient as possible to minimize the risk of damage. Twists, turns, and sharp bends can create stress points, potentially leading to cracks or punctures. It is essential to plan the fuel line route carefully, avoiding any unnecessary bends and ensuring a smooth path that doesn't compromise the structural integrity of the lines.

Furthermore, regular inspections and maintenance are vital to identifying and addressing potential issues. NHRA teams should conduct thorough inspections before each race to check for any signs of damage, corrosion, or wear. This includes examining the fuel lines for cracks, leaks, or signs of heat distortion. By staying proactive and addressing any problems promptly, teams can ensure the fuel system remains reliable and safe.

Winterizing Outboard: Fuel Line Disconnect: A Wise Move?

You may want to see also

Performance Impact: Proper fuel line routing can enhance engine performance and efficiency

The routing of fuel lines within an engine compartment is a critical aspect of NHRA (National Hot Rod Association) racing, as it directly impacts engine performance and efficiency. Proper fuel line management is essential to ensure that the engine receives the correct amount of fuel at the right pressure, which is crucial for optimal power output and overall performance.

In high-performance racing environments, such as NHRA, every fraction of a second matters. The fuel system, including the lines, must be designed and routed to minimize any potential delays or restrictions in the fuel flow. When fuel lines are poorly routed, it can lead to a decrease in power and efficiency. For instance, if the lines are too close to hot engine components, they may overheat, causing fuel to vaporize and reducing its effectiveness. This can result in a loss of power and potential engine damage.

The ideal fuel line route should be carefully planned to avoid any unnecessary bends or twists, as these can create pressure drops and restrict fuel flow. A straight and smooth path is ideal, ensuring that the fuel travels efficiently from the fuel pump to the engine. Additionally, the lines should be positioned to maintain a consistent temperature, preventing fuel degradation and ensuring the engine receives clean, high-octane fuel.

Furthermore, the routing should consider the placement of other components. For example, the fuel lines should be positioned away from moving parts like the camshaft and valves to avoid potential damage or interference. Proper insulation and protection are also essential to shield the lines from heat and mechanical stress, ensuring their longevity and reliability.

By optimizing the fuel line route, NHRA teams can significantly impact engine performance. Efficient fuel delivery allows for better combustion, resulting in increased power, improved throttle response, and enhanced overall efficiency. This attention to detail in fuel line management is a testament to the precision and engineering required in high-performance racing.

Quick Fix: Temporary Solutions for Leaky Fuel Lines

You may want to see also

Frequently asked questions

NHRA has specific rules to ensure the safety and performance of fuel lines in the engine compartment. The fuel lines must be routed in a way that prevents any potential hazards or interference with other components. The general requirement is to have the fuel lines run along the top of the engine compartment, parallel to the firewall, and away from any moving parts or heat sources.

Yes, NHRA specifies that the fuel lines should have a minimum clearance of 1 inch (2.54 cm) from the firewall and other critical components. This ensures that the fuel lines do not come into contact with hot surfaces, moving parts, or electrical wiring, reducing the risk of fire or damage.

No, the routing can vary depending on the vehicle's design and the specific requirements of the class or division in NHRA. However, the primary goal is to maintain a safe and consistent route that meets the organization's standards.

Yes, some engine configurations, such as V-8 or V-6 layouts, may require additional considerations. For example, in a V-8 engine, the fuel lines might need to be routed in a way that accounts for the angle of the cylinders. NHRA provides guidelines for these specific cases to ensure compliance.

Fuel line routes are typically inspected during the technical inspection process before each race. This inspection ensures that the fuel lines are correctly routed, secure, and meet the safety standards. Any deviations or non-compliance may result in penalties or disqualification.