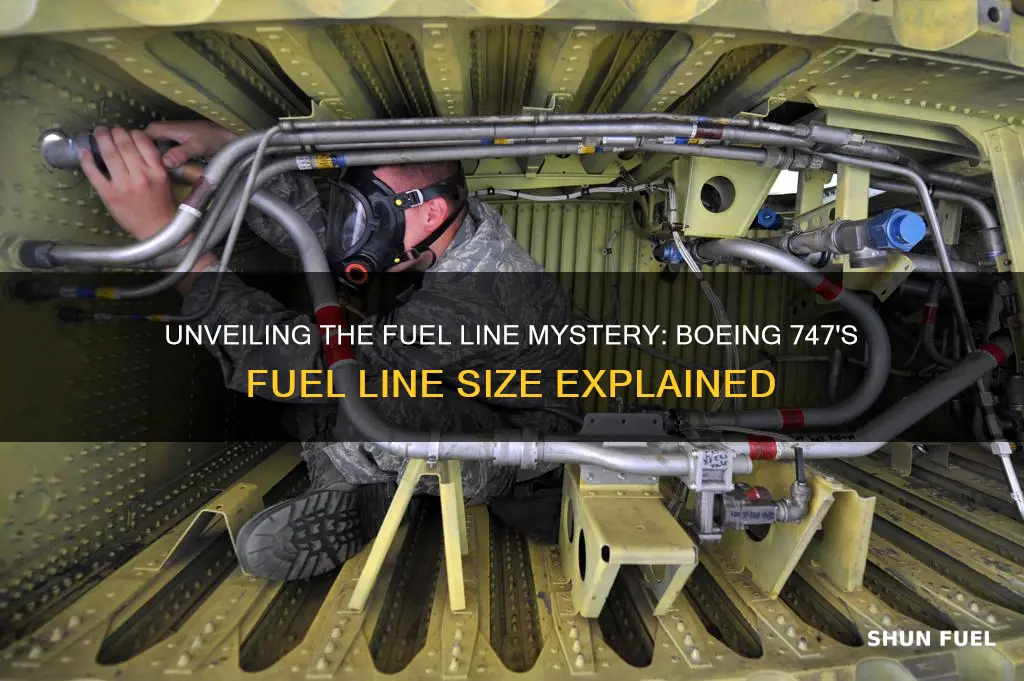

The Boeing 747, a legendary wide-body aircraft, relies on a complex network of fuel lines to transport jet fuel from the tanks to the engines. Understanding the fuel line size is crucial for maintenance and ensuring the aircraft's safe operation. This paragraph will delve into the specific dimensions and specifications of the fuel lines used in the 747, providing insights into their design and functionality.

What You'll Learn

- Fuel System Design: The fuel line size of a Boeing 747 is a critical component of its fuel system design

- Fuel Tank Capacity: The fuel line size is determined by the fuel tank capacity of the Boeing 747

- Fuel Flow Rate: The fuel line size affects the fuel flow rate of the Boeing 747

- Fuel Pressure Regulation: The fuel line size impacts fuel pressure regulation in the Boeing 747's fuel system

- Fuel Line Material: The material of the fuel line is chosen based on the size of the fuel line

Fuel System Design: The fuel line size of a Boeing 747 is a critical component of its fuel system design

The fuel line size of a Boeing 747 is a crucial aspect of its fuel system design, ensuring efficient and safe operation during long-haul flights. This aircraft, known for its massive cargo capacity and range, requires a robust fuel system to meet the demands of such extensive journeys. The fuel lines are responsible for transporting fuel from the tanks to the engines, and their size directly impacts the aircraft's performance and reliability.

Designing the fuel lines involves careful consideration of various factors. Engineers must account for the aircraft's weight, speed, and altitude capabilities, as these factors influence the fuel flow rate and pressure requirements. The fuel line size must accommodate the high-pressure fuel environment while ensuring minimal fuel loss and efficient delivery to the engines. A well-designed fuel system with appropriate line sizes prevents fuel starvation during critical phases of flight, such as takeoff and landing, where engine performance is vital.

In the case of the Boeing 747, the fuel line size is likely to be substantial to handle the large fuel capacity required for extended operations. The aircraft's fuel tanks are designed to hold a significant amount of fuel, and the lines must be able to manage the flow efficiently. Typically, larger aircraft like the 747 use fuel lines with diameters ranging from 2 to 4 inches, depending on the specific model and engine configuration. These lines are often made of high-strength materials to withstand the corrosive effects of fuel and the stresses of flight.

The design process involves creating a network of fuel lines that connect the main fuel tanks to the engines, ensuring a continuous supply of fuel. This network must be carefully planned to minimize pressure drops and potential bottlenecks, which could lead to performance issues. Engineers use computational fluid dynamics (CFD) simulations to optimize the fuel line layout, ensuring that the flow rates meet the engine's requirements at different altitudes and speeds.

Furthermore, the fuel line size also considers the material properties and manufacturing processes. High-quality materials with excellent corrosion resistance and flexibility are chosen to ensure the lines' durability and longevity. The manufacturing process involves precise welding or joining techniques to create a seamless and leak-proof fuel system. This attention to detail is essential in aviation, where safety and reliability are paramount.

Understanding the Car's Fuel Line: A Comprehensive Guide

You may want to see also

Fuel Tank Capacity: The fuel line size is determined by the fuel tank capacity of the Boeing 747

The fuel line size for a Boeing 747 is a critical component of the aircraft's fuel system, and it is directly influenced by the fuel tank capacity of the aircraft. The Boeing 747, a wide-body commercial jet, has a substantial fuel requirement to support its long-range capabilities and heavy payload. The fuel tank capacity of this aircraft is designed to accommodate a significant amount of fuel, ensuring it can cover extensive distances without the need for frequent refueling.

The fuel tank capacity of a Boeing 747 typically ranges from 200,000 to 300,000 pounds (90,718 to 136,077 kilograms) of fuel, depending on the variant and configuration. This substantial capacity requires a fuel line system that can efficiently transport and manage such a large volume of fuel. The fuel line size is a crucial factor in ensuring the aircraft's performance and safety, as it determines the rate at which fuel can be supplied to the engines during flight.

Larger fuel tank capacities necessitate fuel lines with appropriate diameters to handle the increased flow rates. The fuel line size is often measured in inches or millimeters and is designed to minimize pressure drop while maximizing flow efficiency. Engineers and designers must carefully select the fuel line size based on the specific fuel tank capacity to ensure optimal performance and safety.

In the case of the Boeing 747, the fuel line size is a result of meticulous calculations and simulations to match the aircraft's fuel requirements. This process involves considering various factors, including the fuel flow rates, pressure requirements, and the overall design of the fuel system. By carefully determining the fuel line size, engineers can ensure that the fuel is efficiently delivered to the engines, enabling the aircraft to operate at its maximum potential.

Understanding the relationship between fuel tank capacity and fuel line size is essential for maintaining the Boeing 747's performance and safety. Properly sized fuel lines ensure that the aircraft can carry sufficient fuel for its missions while also optimizing fuel efficiency and reducing the risk of fuel-related issues during flight. This knowledge is particularly valuable for aviation professionals and engineers working on aircraft maintenance and design.

Exploring the Consequences: What Happens When You Cut the Fuel Line

You may want to see also

Fuel Flow Rate: The fuel line size affects the fuel flow rate of the Boeing 747

The fuel line size is a critical component in ensuring the efficient and safe operation of the Boeing 747 aircraft. When it comes to fuel flow rate, the size of the fuel line plays a significant role in determining how much fuel can be supplied to the engines during various phases of flight.

In the context of the Boeing 747, the fuel line is responsible for transporting fuel from the aircraft's fuel tanks to the engines. The flow rate, which is the volume of fuel passing through the line per unit of time, is directly influenced by the diameter and length of the fuel line. A larger fuel line diameter allows for a higher flow rate, enabling the aircraft to receive the required amount of fuel during takeoff, cruising, and other critical phases. This is especially important for the 747, as it is a large aircraft with substantial fuel requirements to sustain its massive wingspan and payload.

The fuel flow rate is a critical parameter in aviation, as it ensures that the engines receive the necessary fuel to maintain optimal performance. During takeoff, for instance, a higher fuel flow rate is required to accelerate the aircraft quickly and efficiently. Similarly, during cruising, a steady and controlled fuel flow rate is essential to maintain the desired altitude and speed. The fuel line size, therefore, becomes a crucial design consideration to meet these varying demands.

Engineers and designers must carefully calculate and select the appropriate fuel line size based on the specific requirements of the Boeing 747. This involves considering factors such as the aircraft's range, payload capacity, and expected fuel consumption rates. By optimizing the fuel line size, engineers can ensure that the fuel flow rate meets the needs of the engines, allowing for efficient and reliable operation throughout the aircraft's journey.

In summary, the fuel line size of a Boeing 747 directly impacts its fuel flow rate, which is vital for the aircraft's performance and safety. A well-designed fuel line system, tailored to the specific needs of the 747, ensures that the engines receive the required fuel at the right rate, enabling smooth operations and contributing to the overall efficiency of the aircraft.

Choosing the Right Diameter Fuel Line for Your Yamaha Outboard

You may want to see also

Fuel Pressure Regulation: The fuel line size impacts fuel pressure regulation in the Boeing 747's fuel system

The fuel line size is a critical aspect of the fuel system in Boeing 747 aircraft, and it directly influences fuel pressure regulation, which is essential for safe and efficient operation. The Boeing 747, being a large commercial airliner, requires a robust fuel system to ensure it can carry enough fuel for extended flights and to maintain optimal performance during various flight phases.

Fuel pressure regulation is a complex process that involves managing the pressure of the fuel as it flows through the system. The size of the fuel lines plays a pivotal role in this regulation. Larger fuel lines can accommodate more fuel, which is crucial for long-haul flights and high-altitude operations. However, the size of the fuel lines also affects the pressure within the system. Thicker fuel lines can provide better pressure stability, ensuring a consistent fuel supply to the engines. This is particularly important during takeoff and climb, where the aircraft's engines demand a steady and high-pressure fuel supply.

In the context of the Boeing 747, the fuel lines are designed to handle the specific requirements of this aircraft. The fuel lines are typically made of high-strength materials to withstand the pressures and stresses encountered during flight. The size of these lines is carefully calculated to optimize fuel flow and pressure regulation. Engineers consider factors such as the aircraft's range, fuel capacity, and the performance requirements of the engines when determining the appropriate fuel line dimensions.

The impact of fuel line size on pressure regulation becomes evident during different flight phases. During takeoff, when the engines require a high-pressure fuel supply, the larger fuel lines ensure a consistent and adequate pressure level. This is crucial for achieving the necessary thrust and smooth engine operation. As the aircraft climbs to cruising altitude, the fuel line size continues to play a role in maintaining the required pressure, ensuring the engines receive the necessary fuel for efficient operation.

Additionally, the fuel line size influences the overall fuel system design, including the use of fuel pumps, filters, and pressure regulators. These components work in conjunction with the fuel lines to ensure the fuel is delivered at the correct pressure and quality to the engines. Proper fuel line sizing helps in managing the flow rate and pressure drop, ensuring the fuel system operates optimally across various flight conditions.

In summary, the fuel line size is a critical design consideration for the Boeing 747's fuel system, impacting fuel pressure regulation and overall aircraft performance. Engineers must carefully select the appropriate line sizes to meet the specific requirements of this large airliner, ensuring safe and efficient operations during different flight phases.

Understanding Impulse Fuel Lines: Powering Chainsaws Efficiently

You may want to see also

Fuel Line Material: The material of the fuel line is chosen based on the size of the fuel line

The fuel lines in an aircraft, such as the Boeing 747, are critical components that ensure the efficient and safe delivery of fuel to the engines. The size of the fuel line is a crucial factor in determining the appropriate material to use, as it directly impacts the performance and reliability of the system.

When considering the fuel line material, engineers and designers must take into account the size of the line, which is typically measured in terms of diameter and length. Smaller fuel lines, often used in smaller aircraft or for specific engine components, may require materials with higher flexibility and lower pressure resistance. These lines are usually made from materials like rubber or flexible plastics, ensuring ease of installation and the ability to navigate through tight spaces.

For larger aircraft like the Boeing 747, the fuel lines need to handle higher pressure and larger volumes of fuel. In these cases, the fuel line material must be chosen to withstand the demanding conditions. Common materials for larger fuel lines include high-density polyethylene (HDPE) or specialized rubber compounds. These materials offer excellent pressure resistance, ensuring the fuel lines can handle the force required to move large amounts of fuel efficiently.

The size of the fuel line also influences the wall thickness. Thicker walls are often necessary for larger lines to provide structural integrity and protect against potential damage from fuel contaminants or external factors. Thicker walls may also be required for lines that need to withstand higher pressure differentials.

Additionally, the material selection should consider factors such as temperature resistance, chemical compatibility with aviation fuels, and overall durability. For instance, some aircraft may require fuel lines that can operate in extreme temperatures, so materials like nylon or specialized polymers might be chosen. The choice of material ensures that the fuel lines remain functional and reliable throughout various operating conditions.

Understanding Fuel Line Connector Numbers: A Comprehensive Guide

You may want to see also

Frequently asked questions

The fuel line size for a Boeing 747 is typically 2.5 inches in diameter, but this can vary depending on the specific model and configuration.

The fuel line size is an important factor in the aircraft's fuel system design, ensuring efficient and safe fuel transfer. It is calculated based on the aircraft's fuel capacity, engine requirements, and overall system performance.

Yes, the fuel line sizes can vary across different sections of the aircraft. For instance, the main fuel lines connecting the wing tanks to the engines may have a different diameter compared to the smaller lines used for auxiliary power units or other systems.

In some cases, the fuel line size can be modified during maintenance or modifications, but it is a precise process and often requires specialized equipment and expertise. Upgrading the fuel lines may be necessary for performance enhancements or to accommodate changes in fuel types.

Using an incorrect fuel line size can lead to various issues, including reduced fuel efficiency, engine performance problems, and potential safety hazards. It is crucial to adhere to the manufacturer's specifications to ensure the aircraft's optimal performance and safety.