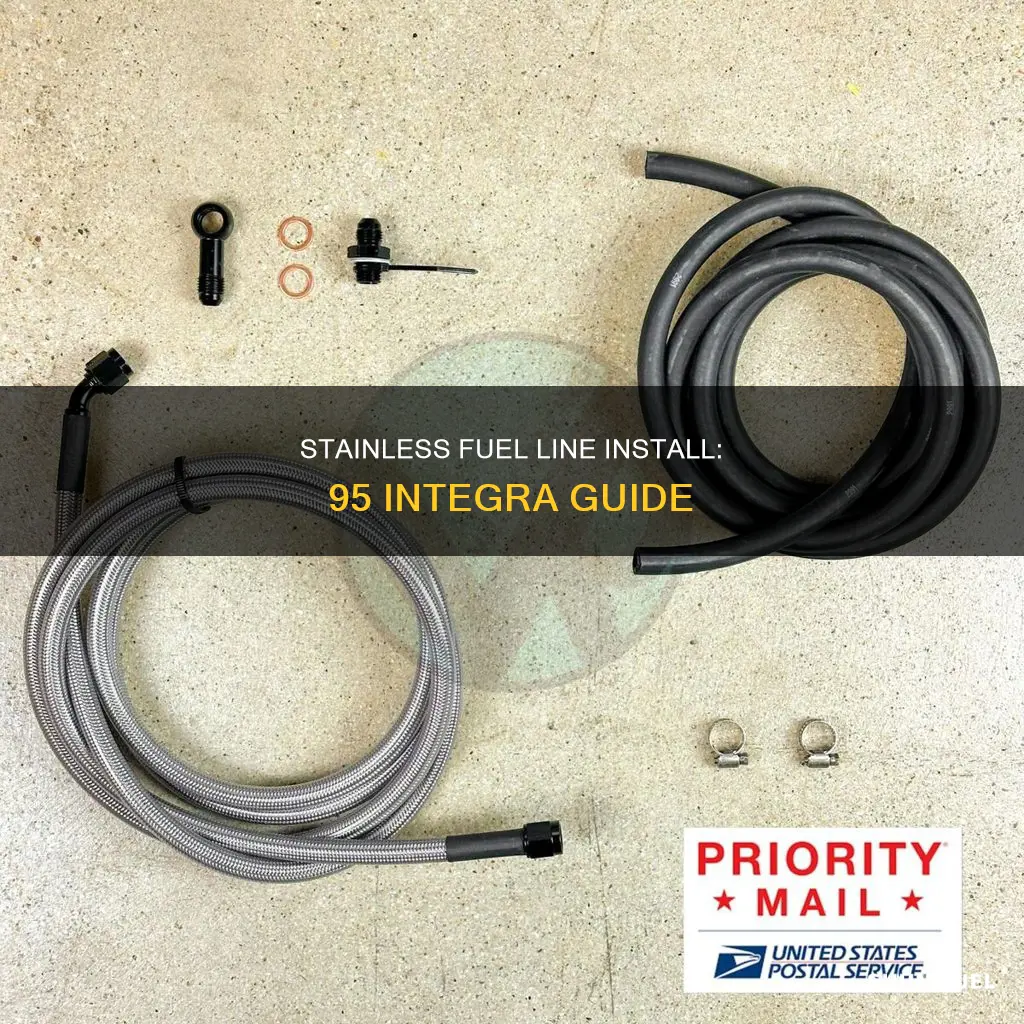

Installing a stainless steel fuel line on a 1995 Honda Integra is a great way to improve the reliability and performance of your vehicle. This process involves replacing the original fuel line with a high-quality, corrosion-resistant alternative. Here’s a step-by-step guide to help you through the installation process, ensuring a smooth and efficient upgrade.

| Characteristics | Values |

|---|---|

| Vehicle Model | Honda Integra (1995) |

| Fuel Line Material | Stainless Steel |

| Installation Process | 1. Remove the old fuel line and associated components. 2. Cut the stainless steel fuel line to the desired length, ensuring a precise fit. 3. Use fuel line connectors or clamps to secure the new line. 4. Route the line through the engine bay, considering the available space and any obstructions. 5. Reinstall the fuel pump and related parts. |

| Benefits | - Improved corrosion resistance compared to standard fuel lines. - Enhanced durability, reducing the risk of leaks. - Aesthetic upgrade to the engine bay. |

| Considerations | - Ensure the stainless steel fuel line is compatible with the vehicle's fuel system. - Properly secure the line to prevent movement and potential damage. - Regularly inspect the fuel line for any signs of wear or damage. |

| Tools Required | - Fuel line cutters or shears - Fuel line connectors or clamps - Wrenches or screwdrivers - Cleaning supplies (for removing old fuel line residue) |

| Safety Precautions | - Wear protective gear, including gloves and eye protection. - Ensure the vehicle is parked on a level surface and the engine is cool before starting the installation. - Avoid contact with fuel during the installation process. |

What You'll Learn

- Preparation: Gather tools, prepare workspace, and inspect fuel line for damage

- Clamping: Choose appropriate clamps, ensure proper fit, and secure fuel line

- Routing: Route fuel line neatly, avoiding sharp bends and tight spaces

- Connection: Attach fuel line to engine, ensure tight connections, and test for leaks

- Finishing: Clean up, verify functionality, and enjoy your modified Integra

Preparation: Gather tools, prepare workspace, and inspect fuel line for damage

Before you begin the installation process, it's crucial to prepare your workspace and gather the necessary tools to ensure a smooth and efficient project. Start by setting up your work area in a well-ventilated and clean space, preferably a garage or workshop. Ensure you have ample room to work on the car and lay out all the required materials.

The first step in preparation is to gather the essential tools and equipment. You will need a set of wrenches and pliers in various sizes, a fuel line cutter, a file, and a sandpaper block. Additionally, have some rags or paper towels ready for cleaning and wiping down the fuel line and the surrounding areas. It is also advisable to wear protective gear, such as gloves and safety goggles, to safeguard your hands and eyes from any potential hazards.

Next, carefully inspect the fuel line that will be replaced. Check for any signs of damage, such as cracks, leaks, or corrosion. Look for any bends or kinks in the line, as these can affect the flow of fuel and potentially cause issues during the installation. If you notice any damage, it is best to replace the entire fuel line to ensure optimal performance and safety.

Prepare the new stainless steel fuel line by cleaning it thoroughly. Use the sandpaper block to remove any excess coating or protective layer from the fuel line's interior. This step ensures a proper connection and allows for a tight seal. Additionally, wipe down the fuel line with the rags to remove any dust or debris that may have accumulated during the preparation process.

By taking the time to properly prepare your workspace, gather the necessary tools, and inspect the fuel line, you are setting yourself up for a successful installation. This detailed approach ensures that you have everything you need and that the fuel line is in optimal condition, reducing the risk of any issues during the installation process.

Power Limits: Unlocking the Potential of Your Engine's Horsepower

You may want to see also

Clamping: Choose appropriate clamps, ensure proper fit, and secure fuel line

When installing a stainless steel fuel line on your 95 Integra, clamping is a crucial step to ensure a secure and reliable connection. The right clamps will provide the necessary tension to hold the fuel line in place without causing any damage or restricting flow. Here's a detailed guide on how to choose and install the appropriate clamps:

Choosing the Right Clamps:

- Consider the diameter of your fuel line. Stainless steel fuel lines typically come in various diameters, and you need to select clamps that match this size. Common diameters for fuel lines include 3/8" and 1/2".

- Look for clamps specifically designed for fuel lines. These clamps are often made from durable materials like stainless steel or aluminum to withstand the corrosive nature of fuel. They usually feature a smooth interior surface to prevent any damage to the fuel line.

- Ensure the clamps have a secure grip. The clamps should provide enough tension to hold the fuel line firmly in place but should not be so tight that they cause any distortion or damage to the line.

Clamping Process:

- Start by identifying the points where you need to secure the fuel line. These are usually the areas where the fuel line connects to the fuel tank, fuel pump, and various fuel injectors or carburetors.

- Cut the clamps to the appropriate length, ensuring they are long enough to wrap around the fuel line and provide a secure grip. You can use a pair of sharp scissors or a clamp cutting tool for this.

- Position the clamp around the fuel line, ensuring it is centered and aligned with the fuel line's diameter.

- Tighten the clamp securely by hand, ensuring it is snug. You can use a wrench or a pair of pliers to apply firm pressure, but be careful not to overtighten, as this can damage the fuel line.

- Repeat this process for each section of the fuel line that requires clamping. Typically, you will have two clamps per section, one on either side of the fuel line's bend or connection point.

Proper Fit and Security:

- Ensure that the clamps are positioned in a way that allows the fuel line to move freely without any restrictions. The clamps should hold the line in place without causing any kinks or bends that could affect performance.

- Check the fit regularly, especially during the initial installation, to ensure the clamps remain secure. Over time, vibration and movement can cause clamps to loosen, so periodic inspections are essential.

- Consider using lockwashers or threadlock compounds on the clamp bolts to prevent them from loosening due to fuel vibrations.

By carefully selecting the right clamps and following a precise clamping technique, you can ensure a professional-looking and functional fuel line installation on your 95 Integra. This process is vital to maintaining the integrity of your fuel system and ensuring optimal engine performance.

Fixing a Fuel Line Leak: A Color-Coded Guide

You may want to see also

Routing: Route fuel line neatly, avoiding sharp bends and tight spaces

When installing a stainless steel fuel line on your 95 Integra, proper routing is crucial for both aesthetics and performance. Here's a detailed guide on how to route the fuel line neatly, ensuring it avoids sharp bends and tight spaces:

Plan Your Route:

- Visualize the Installation: Before you begin, carefully examine the engine bay of your Integra. Identify the existing fuel lines and their routes. This will help you plan a path for the new stainless steel line that complements the existing layout.

- Consider Engine Components: Be mindful of engine components like the air filter, intake manifold, and other hoses. Avoid routing the fuel line directly over or under these parts to prevent damage or interference.

Start at the Fuel Tank:

Secure Connections: Begin routing the fuel line from the fuel tank, ensuring it connects securely to the existing fuel pump and filter. Use appropriate fittings and clamps to guarantee a tight and leak-free connection.

Neat and Straight:

- Avoid Sharp Bends: The key to a professional installation is to minimize sharp bends in the fuel line. Aim for smooth, gradual curves. Sharp bends can restrict fuel flow and potentially damage the line over time.

- Use Support: Consider using fuel line supports or brackets to keep the line in place and prevent sagging or kinking. These supports are available in various materials and can be easily installed along the route.

Manage Space:

- Tight Spaces: When routing through tight spaces, be extra careful. Use the smallest possible radius for bends to avoid putting unnecessary stress on the fuel line. Consider using a fuel line cutter and deburer to ensure clean, precise cuts.

- Clearance: Ensure the fuel line has adequate clearance from moving parts and heat sources. This will prevent damage and ensure optimal performance.

Finish with Care:

- Securely Fastened: Once you've reached the destination (usually the engine block or fuel injection system), securely fasten the fuel line using appropriate clamps or brackets.

- Test for Leaks: After completing the installation, thoroughly inspect all connections and the entire fuel line for any signs of leaks.

Remember, taking the time to route the fuel line neatly will pay off in terms of aesthetics, performance, and longevity.

John Deere 4020 Fuel Line Filling: A Step-by-Step Guide

You may want to see also

Connection: Attach fuel line to engine, ensure tight connections, and test for leaks

When attaching the stainless fuel line to the engine, it's crucial to ensure a secure and leak-free connection. Start by locating the fuel injectors and the fuel pump, as these are the key components you'll be connecting to. Carefully align the fuel line with the appropriate ports, ensuring it is positioned correctly. Use the appropriate fuel line connectors, typically available in various sizes and types, to secure the line. These connectors often have a locking mechanism to ensure a tight seal. Tighten the connectors by hand first, then use a wrench to ensure a firm grip, being careful not to overtighten.

After connecting the fuel line, it's essential to double-check the connections for tightness and security. Use a torque wrench to apply the recommended amount of force to each connection point. This ensures that the fuel line is securely fastened and less likely to come loose during operation. Inspect the connections for any signs of damage or wear, especially if the previous fuel line was damaged.

Once all connections are made and tightened, it's time to test for any potential leaks. Start the engine and allow it to idle, paying close attention to any unusual sounds or smells. Check for any signs of fuel escaping around the connections or at the fuel injectors. If you notice any leaks, carefully inspect the connections and tighten them further if necessary. You can also use a fuel line inspection mirror to get a better view of hard-to-reach areas.

If no leaks are found, it's a good idea to run the engine for an extended period to ensure the system is functioning correctly. Monitor the engine's performance and listen for any abnormal noises. If everything seems normal, you've successfully installed the stainless fuel line and can now enjoy the improved fuel delivery system in your 95 Integra. Remember, regular maintenance and inspections will help keep your fuel system reliable and efficient.

Boat Fuel Line Lifespan: How Long Will It Last?

You may want to see also

Finishing: Clean up, verify functionality, and enjoy your modified Integra

After completing the installation of the stainless steel fuel line on your 95 Integra, it's time to finish the job and ensure everything is in top shape. Here's a step-by-step guide to help you with the final touches:

Clean Up: Begin by giving your Integra a thorough cleaning. Remove any dirt, debris, or fingerprints that may have accumulated during the installation process. Pay close attention to the areas around the fuel line, as these spots might have been temporarily inaccessible during the installation. Use a mild detergent and a soft cloth to wipe down the exterior of the car, ensuring that no residue remains. This step is crucial to maintaining the sleek appearance of your Integra and ensuring that the new fuel line stands out without any unwanted grime.

Verify Functionality: Now, it's time to test the system. Start the engine and listen for any unusual noises. Check for any leaks around the connections and ensure that the fuel pump is functioning correctly. You can also use a fuel pressure gauge to measure the pressure and ensure it meets the recommended specifications. This verification process is essential to guarantee that the fuel line is securely installed and that the fuel system is operating optimally.

Final Adjustments: If any issues arise during the verification process, address them promptly. Tighten any loose connections, adjust the fuel pump settings, or replace any damaged components. This might require some technical knowledge, so feel free to consult online forums or seek professional assistance if needed. The goal is to ensure that your Integra's fuel system is reliable and efficient.

Enjoy Your Modified Integra: Once you've completed the cleaning and verified the functionality, it's time to hit the road. Take your Integra for a spin and experience the benefits of the new fuel line. You should notice improved performance, better fuel efficiency, and a smoother driving experience. Enjoy the satisfaction of seeing your modified car in action and appreciate the effort you put into enhancing its performance.

Remember, proper maintenance and regular checks will ensure that your Integra remains in excellent condition. Keep an eye on the fuel line and the overall fuel system, and you'll have a reliable and powerful vehicle for years to come.

Fuel Line Design: One Piece for Optimal Fuel Injection

You may want to see also

Frequently asked questions

Installing a stainless steel fuel line on your 1995 Integra involves several steps. First, ensure you have the necessary tools and materials, including the new fuel line, fittings, and a fuel line cutter. Then, locate the existing fuel line and carefully remove it, making sure to note the routing and any attachments. Cut the new fuel line to the appropriate length, ensuring it's slightly longer than the original to allow for adjustments. Slide the new line through the fittings and secure them using the appropriate tools. Tighten the fittings securely but avoid over-tightening. Finally, route the new fuel line along the original path, ensuring it's neatly organized and protected from any potential damage.

Yes, you'll need a few essential tools to ensure a successful installation. These include a fuel line cutter or a sharp knife to cut the line accurately, various sizes of fittings and adapters to match your fuel line and vehicle's requirements, a fuel line crimper or vice to secure the fittings, and a wrench or socket set for tightening the connections. Additionally, have a fuel pump primer or a similar tool to prime the fuel system after the installation.

Achieving a secure and leak-free connection is crucial. Start by cleaning the surfaces of the fittings and fuel line to ensure a proper bond. Use a suitable solvent or cleaner to remove any dirt or contaminants. Then, when attaching the fittings, ensure they are aligned correctly and tightened securely. Over-tightening can damage the fuel line, so use the appropriate tools and apply firm pressure. After installation, test the system by starting the engine and checking for any leaks. If any issues arise, double-check the connections and tighten them further if necessary.