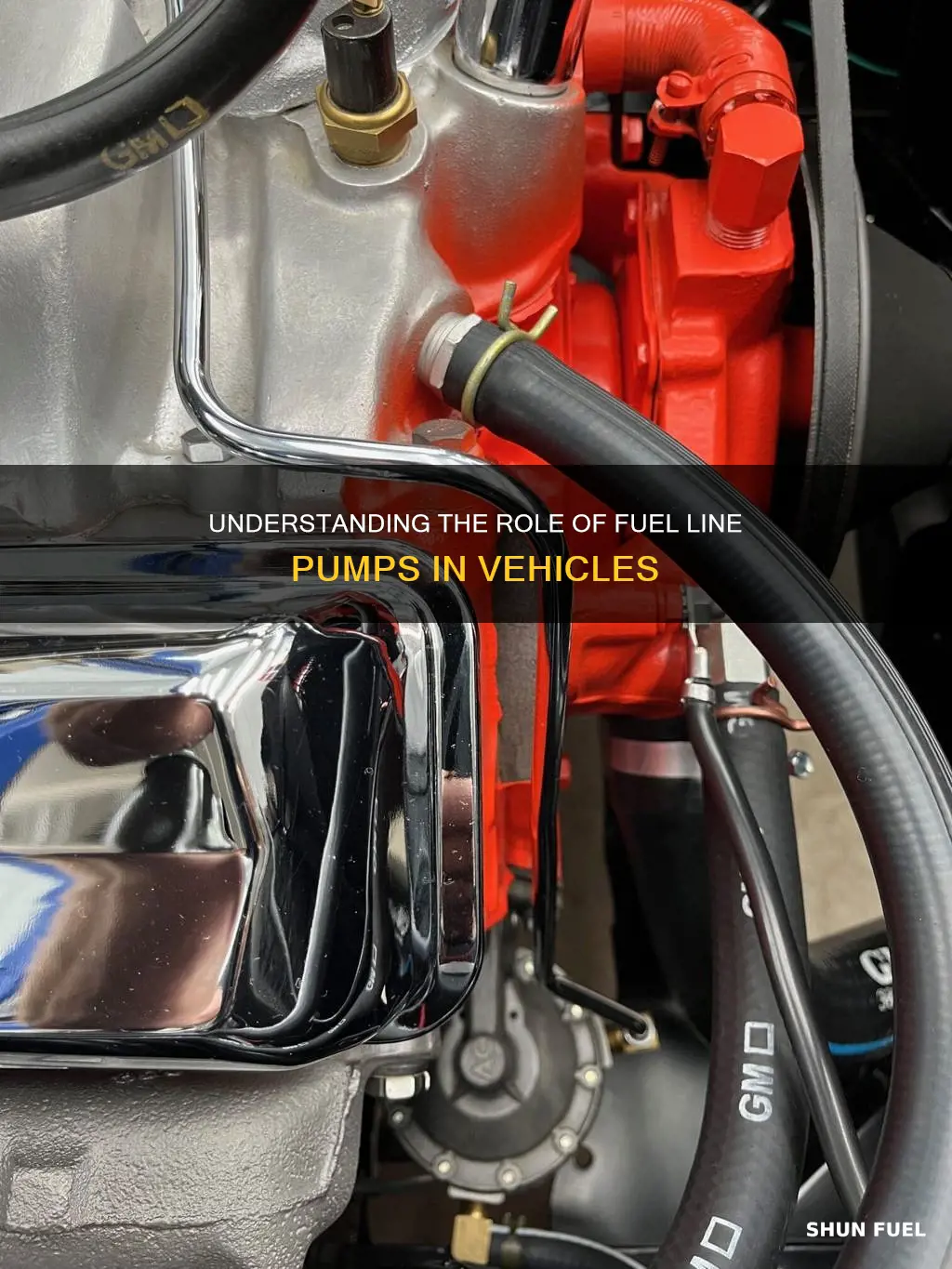

A fuel line pump is a crucial component in the fuel delivery system of an engine, responsible for ensuring a steady and controlled flow of fuel from the fuel tank to the engine's combustion chamber. It is designed to maintain optimal fuel pressure, which is essential for efficient engine operation and performance. This pump is typically driven by the engine's timing belt or chain and operates in conjunction with the fuel pump module or unit to deliver the required amount of fuel at the right pressure to the engine's injectors or carburetor. Understanding the function and importance of the fuel line pump is key to maintaining a vehicle's performance and reliability.

| Characteristics | Values |

|---|---|

| Definition | A fuel line pump is a component in a vehicle's fuel system that delivers fuel from the fuel tank to the engine. It ensures a consistent and controlled flow of fuel, which is crucial for optimal engine performance. |

| Function | The primary function is to maintain a steady pressure in the fuel line, providing the engine with the required amount of fuel for efficient combustion. |

| Types | There are two main types: mechanical and electric. Mechanical pumps are typically found in older vehicles and use a diaphragm or a diaphragm and piston combination to pump fuel. Electric pumps are more common in modern cars and are powered by the vehicle's electrical system. |

| Location | Usually located near the engine, often integrated into the fuel rail or mounted on the engine block. |

| Pressure Regulation | Fuel line pumps regulate pressure to ensure the fuel reaches the engine at the correct pressure, typically around 4-6 psi (pounds per square inch). |

| Material | Often made of durable materials like aluminum or plastic to withstand fuel's corrosive nature. |

| Maintenance | Regular maintenance is essential to ensure longevity. This includes checking for leaks, replacing worn-out parts, and ensuring proper fuel filter maintenance. |

| Common Issues | Can develop leaks, become clogged, or fail due to wear and tear, leading to engine misfires, reduced power, or complete fuel cutoff. |

| Compatibility | Compatibility varies by vehicle make and model, so it's important to choose the correct pump for a specific car. |

What You'll Learn

- Fuel Line Pump Function: Delivers fuel from the tank to the engine via a precise, high-pressure system

- Fuel Pressure Regulation: Maintains optimal fuel pressure for efficient combustion and engine performance

- Fuel Delivery System: A crucial component in fuel injection systems, ensuring accurate fuel metering

- Engine Performance Impact: Improves engine power, fuel efficiency, and reduces emissions

- Common Issues: Clogging, leaks, and pressure drops can lead to engine misfires and reduced performance

Fuel Line Pump Function: Delivers fuel from the tank to the engine via a precise, high-pressure system

A fuel line pump is a crucial component in a vehicle's fuel system, responsible for ensuring a steady and precise supply of fuel from the tank to the engine. Its primary function is to deliver fuel at high pressure, which is essential for efficient engine operation. This pump is typically located near the engine and is often part of the fuel injection system, which is common in modern vehicles.

The process begins with the pump receiving fuel from the vehicle's fuel tank. It then pressurizes the fuel, raising its pressure to a level that is optimal for the engine's requirements. This high-pressure fuel is then directed through a network of fuel lines, which are designed to withstand the increased pressure. The fuel lines carry the pressurized fuel to the engine, where it is injected into the combustion chambers at the precise moment required for optimal performance.

The precision of the fuel line pump is critical to the vehicle's performance and efficiency. It ensures that the correct amount of fuel is delivered to the engine at the right pressure, allowing for accurate fuel-air mixture control. This results in improved engine power, better fuel economy, and reduced emissions. The pump's ability to maintain a consistent pressure throughout the fuel delivery process is vital, as it prevents fuel starvation and ensures the engine receives the necessary fuel for efficient operation.

In addition to delivering fuel, the fuel line pump also plays a role in preventing air from entering the fuel system. It creates a vacuum that helps to draw fuel from the tank and into the pump, ensuring a continuous flow. This process is known as 'vacuum-assisted fuel delivery' and is designed to optimize fuel transfer and maintain the required pressure.

Modern fuel line pumps are often electronic, with built-in sensors and controls that allow for precise management of fuel pressure. These sensors monitor the pressure and can adjust the pump's performance accordingly, ensuring that the engine always receives the correct amount of fuel. This level of control contributes to the overall reliability and efficiency of the vehicle's fuel system.

Fads' Fuel Line: Unveiling the Secret to Their Success

You may want to see also

Fuel Pressure Regulation: Maintains optimal fuel pressure for efficient combustion and engine performance

The fuel line pump is a crucial component in modern vehicle engines, responsible for ensuring optimal fuel pressure to facilitate efficient combustion and overall engine performance. This pump is designed to maintain a consistent and precise fuel pressure, which is essential for the engine's operation. When the engine is running, the fuel line pump delivers the required amount of fuel at the right pressure to the injectors or carburetor, ensuring a balanced and controlled fuel-air mixture. This process is vital for achieving optimal power output, fuel efficiency, and engine longevity.

In the context of fuel pressure regulation, the pump plays a pivotal role in managing the flow of fuel. It operates by creating a vacuum or pressure differential, which draws fuel from the fuel tank and pushes it through the fuel lines to the engine. The pump's efficiency is critical as it needs to provide the necessary pressure to overcome the resistance in the fuel system, ensuring a steady supply of fuel to the engine's combustion chambers. This regulation is particularly important in high-performance engines or those with increased power demands, where precise fuel pressure control is essential to prevent engine knock and maintain optimal performance.

The fuel line pump's operation is often integrated with the engine's electronic control unit (ECU). The ECU monitors various engine parameters, including speed, load, and temperature, to determine the required fuel pressure. It then sends signals to the pump to adjust its output accordingly. This electronic control ensures that the fuel pressure is automatically regulated, providing the engine with the precise amount of fuel needed for efficient combustion at all operating conditions.

Maintaining optimal fuel pressure is critical for several reasons. Firstly, it ensures complete combustion, where fuel and air mix thoroughly, resulting in a more efficient power output. Secondly, it helps prevent engine knock, a condition where the air-fuel mixture ignites too early, leading to reduced performance and potential engine damage. By regulating fuel pressure, the pump also contributes to better fuel economy, as a balanced fuel-air mixture allows for more efficient burning of fuel.

In summary, the fuel line pump is a vital component that regulates fuel pressure, ensuring efficient combustion and optimal engine performance. Its role in maintaining the correct fuel-air mixture and pressure is essential for engine longevity, power output, and fuel efficiency. Modern vehicles rely on this pump's precision and integration with electronic controls to provide a seamless and powerful driving experience. Understanding the function of the fuel line pump highlights its significance in the overall engine system.

Flare for Aluminum Fuel Lines: Unlocking the Secrets of a Perfect Fit

You may want to see also

Fuel Delivery System: A crucial component in fuel injection systems, ensuring accurate fuel metering

The fuel delivery system is an essential component of modern fuel injection systems, playing a critical role in ensuring optimal engine performance and efficiency. This system is responsible for accurately metering and delivering the precise amount of fuel required by the engine, which is a complex task that requires careful design and precision. At the heart of this system is the fuel delivery pump, a vital component that regulates the fuel flow and pressure to meet the engine's demands.

In the context of fuel injection, the fuel delivery pump is designed to provide a controlled and consistent fuel supply to the engine. It operates by drawing fuel from the fuel tank and pressurizing it to a specific level, ensuring that the fuel is delivered at the right pressure and volume to the injectors. This process is crucial as it directly impacts the engine's performance, fuel economy, and overall emissions. The pump's efficiency and accuracy are key factors in maintaining the engine's optimal operation.

The design of the fuel delivery pump involves several critical considerations. Firstly, it must be capable of handling the required fuel flow rate, which varies depending on the engine's specifications and operating conditions. Modern engines often demand high-pressure fuel systems, requiring pumps with robust construction and precise control mechanisms. Secondly, the pump's durability is essential, as it operates in a harsh environment with varying temperatures and pressures. It should be able to withstand these conditions while maintaining its performance over extended periods.

Accurate fuel metering is a primary function of the fuel delivery system. The pump must precisely control the fuel-air mixture, ensuring that the engine receives the correct ratio of fuel and air for efficient combustion. This is achieved through sophisticated control mechanisms, such as pressure regulators and flow meters, which monitor and adjust the fuel pressure and volume accordingly. By maintaining this accuracy, the fuel delivery system contributes to improved engine performance, reduced emissions, and enhanced fuel efficiency.

In summary, the fuel delivery system, particularly the fuel delivery pump, is a critical component in fuel injection systems. Its role in accurate fuel metering and pressure regulation ensures that the engine receives the optimal fuel supply, leading to improved performance and efficiency. With its precise control and robust design, the fuel delivery pump plays a vital part in modern vehicle engineering, contributing to the overall reliability and environmental performance of the engine. Understanding its function and specifications is essential for maintaining and optimizing the engine's operation.

Fuel Line Break: Engine Chaos Unveiled

You may want to see also

Engine Performance Impact: Improves engine power, fuel efficiency, and reduces emissions

A fuel line pump, also known as a fuel pump, is a critical component in an engine's fuel system. Its primary function is to deliver fuel from the fuel tank to the engine at the precise moment it is needed for combustion. This process is essential for optimal engine performance and efficiency. When the engine is running, the fuel line pump operates continuously to ensure a steady supply of fuel, which is crucial for maintaining power and preventing engine stalls.

The impact of a fuel line pump on engine performance is significant. Firstly, it directly influences engine power output. By delivering fuel at the right pressure and volume, the pump ensures that the engine receives the necessary amount of fuel-air mixture for efficient combustion. This results in improved power delivery, allowing the engine to perform at its peak. With a well-functioning fuel pump, you can expect a noticeable increase in acceleration and overall engine response.

In addition to power, the fuel line pump plays a vital role in enhancing fuel efficiency. When the pump operates efficiently, it ensures that the fuel is delivered precisely when required, minimizing wastage. This precision in fuel delivery leads to a more complete combustion process, where the fuel is burned more effectively, resulting in better fuel economy. Over time, this can translate to significant savings on fuel costs, making it an essential component for those seeking to optimize their vehicle's fuel efficiency.

Furthermore, the pump's impact extends to emissions reduction. A well-functioning fuel line pump contributes to cleaner combustion, which directly results in lower emissions. By delivering the correct amount of fuel, it helps prevent excessive fuel from being introduced into the engine, reducing the formation of harmful pollutants. This is particularly important for vehicles that are subject to strict emission regulations, as it can help drivers maintain compliance and avoid potential fines or penalties.

In summary, a fuel line pump is a key component that significantly influences engine performance. Its role in delivering fuel at the right time and pressure improves engine power, boosts fuel efficiency, and contributes to reduced emissions. Understanding the importance of this small but vital component can help vehicle owners make informed decisions about their engine's maintenance and performance optimization. Regular checks and timely replacements of the fuel line pump can ensure that the engine operates at its best, providing a smooth and efficient driving experience.

Unraveling the Mystery: Why Air Bubbles Form in Furnace Fuel Lines

You may want to see also

Common Issues: Clogging, leaks, and pressure drops can lead to engine misfires and reduced performance

The fuel line pump is a crucial component in an engine's fuel system, responsible for delivering fuel from the tank to the engine at the required pressure and volume. It ensures that the engine receives the necessary amount of fuel for optimal performance and combustion. However, like any other part, it is susceptible to various issues that can impact its functionality and, consequently, the engine's performance.

One common problem associated with fuel line pumps is clogging. Over time, the pump's internal passages can become blocked by contaminants such as dirt, rust, or debris. This clogging can occur due to several reasons, including the use of low-quality fuel, improper fuel storage, or the presence of water in the fuel. When the pump's passages are blocked, the fuel flow is restricted, leading to a decrease in fuel pressure and, ultimately, engine misfires. Engine misfires happen when the engine fails to ignite the air-fuel mixture in one or more cylinders, resulting in a rough idle, reduced power, and potential performance loss.

Leakage is another critical issue that can arise from faulty fuel line pumps. If the pump's seals or gaskets are damaged or worn out, fuel can leak from the pump's housing or connections. This leakage not only results in a waste of fuel but also poses a safety hazard as it can lead to fuel accumulation in the engine compartment, increasing the risk of fire or explosion. Moreover, fuel leaks can cause a loss of pressure in the system, further exacerbating the engine's performance problems.

Pressure drops within the fuel line can also contribute to engine misfires and reduced performance. The fuel line pump is designed to maintain a specific pressure to ensure efficient fuel delivery. However, if the pump fails to generate the required pressure, the fuel may not atomize properly, leading to incomplete combustion. This can result in misfires, where the engine struggles to ignite the fuel-air mixture, causing a loss of power and potential damage to the engine over time.

In summary, the fuel line pump plays a vital role in maintaining engine performance by delivering the correct amount of fuel at the right pressure. Common issues such as clogging, leaks, and pressure drops can significantly impact its functionality. Clogging restricts fuel flow, leading to engine misfires, while leaks result in fuel wastage and potential safety hazards. Pressure drops can cause improper fuel atomization, further exacerbating performance issues. Regular maintenance and the use of high-quality fuel can help prevent these problems and ensure the fuel line pump operates optimally, keeping the engine in top condition.

Honda CR-V '98 Fuel Line Cut-Off: Causes and Fixes

You may want to see also

Frequently asked questions

A fuel line pump is a component in a vehicle's fuel system that is responsible for delivering fuel from the fuel tank to the engine. It ensures a consistent and controlled flow of fuel, which is essential for optimal engine performance and fuel efficiency.

The fuel line pump is typically driven by the engine's camshaft or a dedicated electric motor. It creates a vacuum or pressure to move fuel through the fuel lines, ensuring a steady supply to the injectors or carburetor. This process maintains the correct fuel-air mixture for combustion.

Over time, fuel line pumps can experience wear and tear, leading to various problems. These include fuel leaks, reduced fuel pressure, and poor engine performance. Clogged or damaged fuel lines can also cause issues. Regular maintenance and inspections are crucial to prevent these issues.

In some cases, a fuel line pump can be repaired if the damage is minor. However, due to the high pressure and potential for fuel leaks, it is often recommended to replace the pump if it fails. Replacing the pump with a new one from the manufacturer or a reputable supplier is generally the best course of action.

The frequency of maintenance depends on various factors, including the vehicle's age, usage, and maintenance history. It is advisable to have the fuel system, including the pump, inspected during regular service intervals. If any issues are detected, prompt action should be taken to ensure the vehicle's performance and longevity.