Finding an air leak in an outboard fuel line is a crucial step in maintaining the performance and longevity of your boat's engine. This guide will provide a step-by-step process to help you identify and fix the issue. By following these instructions, you can ensure that your fuel system is operating efficiently and prevent potential engine problems caused by air leaks.

What You'll Learn

Inspect visually for bubbles or condensation

When inspecting your outboard fuel line for air leaks, a visual examination is a crucial step. Start by ensuring the engine is cool and the boat is in a stable position. This initial check is essential for safety and to avoid any potential fuel spillage. Begin by removing the fuel line from the engine and examining it closely. Look for any signs of damage, such as cracks, tears, or kinks, as these could be potential sources of air leaks. Pay close attention to the connections and fittings, as these areas are often prone to developing leaks over time.

Now, the key to this inspection is to look for bubbles or condensation. If you notice any bubbles forming in the fuel line, it's a clear indication of an air leak. Air bubbles in the fuel line can cause engine misfires, reduced performance, and even stall. Condensation, on the other hand, might not be as immediately visible but can be detected by feeling the fuel line for moisture. If you suspect condensation, it's important to address the issue promptly, as it can lead to corrosion and further damage.

To make this inspection more effective, you can use a bright light or a flashlight to shine into the fuel line. This will help you see any small bubbles or moisture that might not be visible to the naked eye. Start at the fuel tank and work your way along the line, checking for any anomalies. If you find a section with bubbles or condensation, mark its location for further investigation or repair.

In addition to looking for bubbles and condensation, keep an eye out for any fuel spillage around the engine and the boat's hull. Even a small leak can indicate a larger issue, so it's important to be thorough. If you notice any fuel residue or a sweet odor, it could be a sign of a more significant air leak or fuel system problem.

Remember, regular maintenance and inspections are vital to keeping your outboard engine in top condition. By visually inspecting the fuel line for air leaks, you can identify and fix potential issues before they cause major problems, ensuring a smooth and efficient boating experience.

Ford Fuel Line: Understanding the Connection to the Fuel Rail

You may want to see also

Use a fuel pressure gauge to measure pressure

When dealing with an outboard fuel line that might have an air leak, using a fuel pressure gauge is a crucial step in the diagnostic process. This tool allows you to measure the pressure of the fuel system, helping you pinpoint the exact location of the leak. Here's a step-by-step guide on how to use a fuel pressure gauge effectively:

Step 1: Prepare the Equipment

Before you begin, ensure you have the necessary tools and equipment. You'll need a fuel pressure gauge, which can be either mechanical or digital. These gauges are designed to measure the pressure in the fuel system, typically in pounds per square inch (PSI). Additionally, have a fuel pump primer or a small hand pump to create a temporary vacuum in the system if needed.

Step 2: Locate the Fuel Pressure Sensor

Identify the fuel pressure sensor on your outboard engine. This sensor is usually located near the fuel tank or the fuel lines leading to the engine. It is often a small, cylindrical component with electrical connections. Understanding the location of this sensor will be essential for accurate measurements.

Step 3: Disconnect the Fuel Line

Carefully disconnect the fuel line from the fuel pressure sensor or the fuel tank. Ensure you have a clear understanding of the fuel flow direction to reconnect the line correctly later. When disconnected, cover the ends of the fuel line with your hand or a cloth to prevent fuel from spilling or evaporating.

Step 4: Prime the Fuel System (Optional)

If your outboard engine has a manual fuel pump, you might need to prime the system to create a vacuum. This step is crucial if you suspect a leak in the fuel line or the pump. Use the primer or hand pump to create a temporary vacuum, then quickly release it to draw fuel into the system. This process helps in identifying any leaks or issues with the fuel pump.

Step 5: Connect the Fuel Pressure Gauge

Reattach the fuel line to the fuel pressure sensor, ensuring a secure connection. Now, connect the other end of the fuel line to the fuel pressure gauge. Make sure the gauge is positioned where you can read the pressure easily.

Step 6: Measure the Fuel Pressure

Start the outboard engine and allow it to idle. With the engine running, observe the fuel pressure gauge. The reading should stabilize at a specific value, typically between 40 and 60 PSI, depending on the engine's specifications. If the pressure is significantly lower than expected, it could indicate an air leak in the fuel line or a problem with the fuel pump.

Step 7: Interpret the Results

Compare the measured fuel pressure with the engine's recommended specifications. A significant drop in pressure during idling suggests an air leak in the fuel line. If the pressure is consistently low, further investigation is required to identify the exact location of the leak.

By following these steps and using a fuel pressure gauge, you can effectively diagnose and locate air leaks in the outboard fuel line, ensuring your engine operates efficiently and reliably.

Understanding Ski-Doo Fuel Line: On or Off?

You may want to see also

Apply a soapy water solution to the line

To locate and fix an air leak in an outboard fuel line, a simple yet effective method is to use a soapy water solution. This technique helps to visualize any potential issues along the fuel line, making it easier to pinpoint the source of the leak. Here's a step-by-step guide on how to apply this method:

Start by preparing the soapy water solution. Mix a few drops of dish soap or a similar non-detergent soap with water. The soap acts as a foaming agent, creating bubbles that will help identify any small cracks or holes in the fuel line. Ensure the solution is well-mixed to create a consistent lather.

Next, locate the fuel line that you suspect might have an air leak. It is typically a rubber or plastic hose that connects the fuel tank to the engine. Carefully remove any protective covers or insulation around the fuel line to expose the entire length. This step is crucial to ensure you can access the entire line for testing.

Now, slowly run the soapy water solution along the length of the fuel line, ensuring an even coverage. Pay close attention to the areas where the line connects to the fuel tank, engine, and any other components. The soap will create bubbles wherever there is a breach or a gap in the line, allowing you to easily identify the leak.

As you move the soapy water, observe the bubbles carefully. If you notice a steady stream of bubbles forming and escaping, you've likely found the location of the air leak. The bubbles will provide a clear indication of the problem area, making it easier to repair or replace the damaged section of the fuel line.

Remember, this method is a visual inspection technique, and it requires patience and a keen eye for detail. Take your time to thoroughly examine the fuel line, and if you're unsure about any step, consult a professional mechanic for guidance. By following these steps, you can effectively locate and address air leaks in your outboard fuel line.

Cost to Flush Fuel Lines: A Breakdown of Expenses

You may want to see also

Check for hissing sounds near the engine

When you suspect an air leak in the outboard fuel line, one of the most effective ways to locate it is by listening for hissing sounds near the engine. This method is based on the principle that air escaping from a damaged or compromised fuel line will create a distinct noise. Here's a step-by-step guide on how to check for these hissing sounds:

Step 1: Engine Operation and Observation: Start your outboard engine and let it run for a few minutes. During this time, pay close attention to the engine's behavior and any unusual sounds it produces. Hissing or whistling noises are often the first indicators of an air leak. These sounds are typically high-pitched and may vary in intensity depending on the severity of the leak.

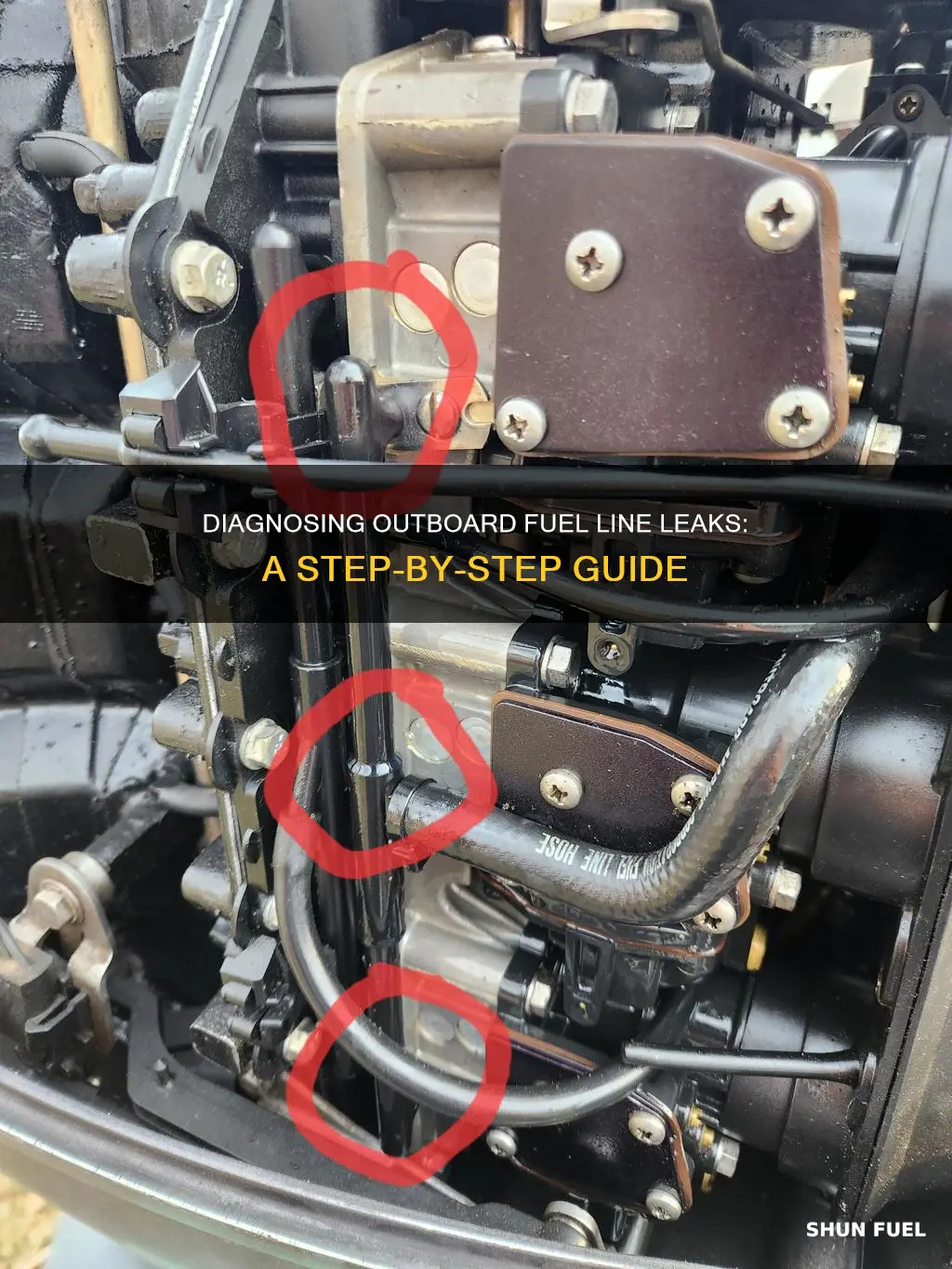

Step 2: Engine Compartment Inspection: After the engine has been running, carefully inspect the engine compartment. Look for any visible signs of fuel leakage, such as wet spots or stains on the engine block or nearby components. If you notice any fuel-related issues, it's crucial to address them promptly, as they could be related to the air leak.

Step 3: Fuel Line Examination: Locate the fuel lines connected to the engine. These lines are typically made of rubber or plastic and run from the fuel tank to the engine. Carefully inspect each fuel line for any visible damage, cracks, or signs of deterioration. Pay attention to areas where the lines connect to the engine or other components, as these points are more susceptible to leaks.

Step 4: Listening for Hisses: Now, the critical part of the process. Turn off the engine and listen carefully to the engine compartment. Use your ears to pinpoint any hissing or whistling sounds. These noises often indicate that air is escaping from the fuel line. The sound may be more noticeable when the engine is idling or just after it has been turned off, as the air pressure inside the line changes.

Step 5: Isolate the Source: If you hear a hissing sound, try to isolate the source of the leak. This might involve temporarily disconnecting certain fuel lines and re-starting the engine to see if the noise persists. This step can help you narrow down the location of the air leak, making it easier to repair.

Remember, this method relies on your ability to hear and identify specific sounds, so a quiet environment is ideal. If you're unsure about any part of this process, consulting a professional mechanic is always a good idea to ensure a proper diagnosis and repair.

GMC Sierra Fuel Line: Size Matters for 2002 Model

You may want to see also

Use a fuel leak detector to identify leaks

To effectively locate and repair an air leak in an outboard fuel line, utilizing a fuel leak detector is a highly recommended method. This tool is specifically designed to identify fuel-related issues, including leaks, and can be a valuable asset for any boat owner or mechanic. Here's a step-by-step guide on how to use a fuel leak detector for this purpose:

Start by ensuring that the boat's fuel system is properly isolated and secured. Turn off the fuel supply and disconnect the fuel lines to prevent any accidental fuel release during the inspection. This step is crucial for safety and to avoid any potential hazards. Once the fuel supply is cut off, use the fuel leak detector to scan the fuel lines and connections. These devices typically use a sensitive sensor to detect the presence of fuel vapor or leaks. Hold the detector near the fuel lines and listen for any beeps or indicators that signal a leak. The detector might also provide visual cues, such as a glowing light, to indicate the location of the leak.

When you detect a potential leak, mark its location carefully. This could be a small drip, a hissing sound, or a visible fuel stain. It's important to note the exact spot to ensure you don't miss any crucial details during the repair process. After identifying the leak, you can use the detector to trace the fuel line and pinpoint the exact source of the issue. This might involve following the fuel line to its connections and fittings, checking for any damage or corrosion that could be causing the leak.

In some cases, the fuel leak detector might also help in identifying other related issues, such as a cracked fuel tank or a faulty fuel pump, which could be contributing to the air leak. By using this tool, you can systematically narrow down the potential causes and ensure a thorough inspection. Once you've identified the leak and its source, you can proceed with the necessary repairs, ensuring a safe and efficient fuel system for your outboard engine.

Remember, using a fuel leak detector is a non-invasive and efficient way to diagnose fuel-related problems, including air leaks, without causing further damage or risking fuel spills. It is a valuable tool for any boat owner or mechanic, ensuring a quick and accurate resolution to fuel system issues.

Dirt Bike Fuel Line: Location and Installation Guide

You may want to see also

Frequently asked questions

Air leaks in fuel lines can be tricky to detect, but there are a few methods you can try. First, start the engine and let it run for a few minutes. Then, shut it off and disconnect the fuel line at the engine's fuel inlet. Hold the line over a container and observe if any fuel drips. If it does, there's likely an air leak. Another way is to use a fuel pressure gauge to check for any drops in pressure, which could indicate an air leak.

Air leaks can occur due to several reasons. Over time, fuel lines can develop small cracks or holes due to wear and tear, especially if they're made of rubber. Corrosion or damage from sharp objects in the water can also lead to leaks. Additionally, improper fuel line installation or connections that are too tight can cause internal damage and air leaks.

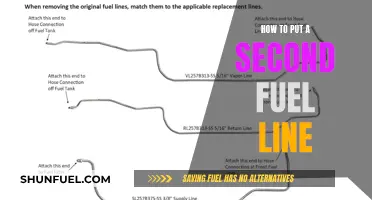

Fixing an air leak requires replacing the affected fuel line section. Start by disconnecting the fuel line from the engine and the fuel tank. Inspect the line for any visible damage or cracks. If you find a small hole, you might be able to temporarily patch it with a fuel line repair kit. However, for a permanent fix, it's best to replace the entire section of the fuel line that is leaking. Ensure you use the correct size and type of fuel line for your engine model.