Fixing a leaking fuel line can be a challenging task, especially when it comes to identifying the specific color of the line. Different colors often indicate different types of fuel lines, and the repair process varies accordingly. For instance, a black fuel line might be a high-pressure line, while a white line could be a return line. Understanding the color-coding system is crucial to ensure the right repair method is applied. This guide will provide a comprehensive overview of how to identify and fix leaks in fuel lines of various colors, offering practical tips and solutions for a successful repair.

What You'll Learn

- Identify the source: Locate the specific leaking fuel line and inspect for damage or disconnections

- Clean and prepare: Use a degreaser to clean the area and ensure a secure connection

- Repair or replace: Depending on the condition, either repair the line or replace it entirely

- Secure connections: Tighten any loose fittings and ensure all connections are secure

- Test and verify: After repairs, test the system to ensure the leak is fixed and no further issues arise

Identify the source: Locate the specific leaking fuel line and inspect for damage or disconnections

To effectively address a leaking fuel line, the first crucial step is to pinpoint the exact source of the leak. This involves a methodical inspection of the fuel system to identify the specific fuel line that is causing the issue. Here's a detailed guide on how to locate and inspect the leaking fuel line:

Step 1: Visual Inspection

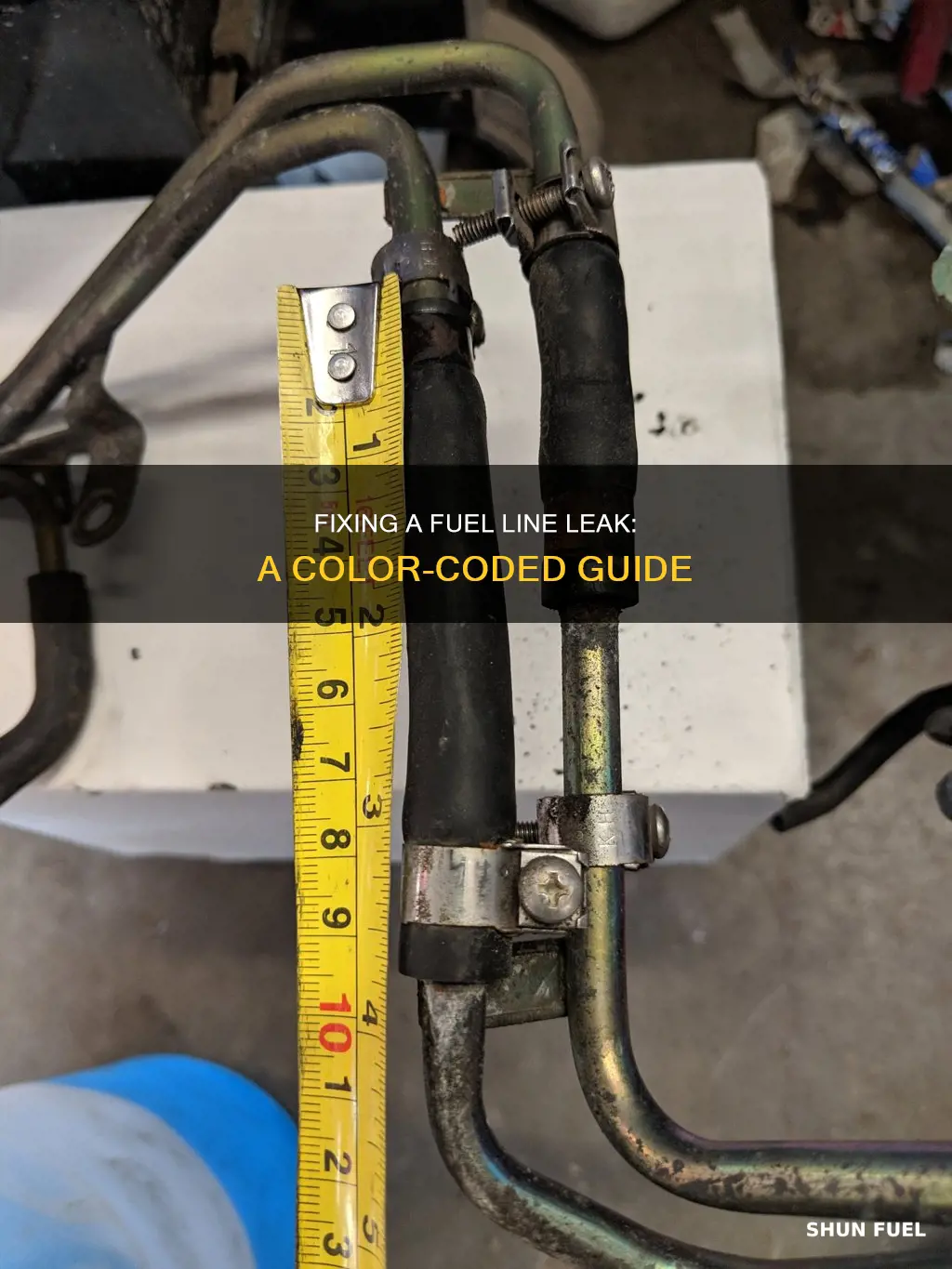

Start by visually examining the fuel lines in your vehicle. Leaks can occur at various points, including connections, fittings, or where the lines run along the engine bay. Look for any visible signs of damage, such as cracks, punctures, or corrosion. Pay close attention to areas where the fuel lines are connected to the fuel tank, fuel pump, or injectors. These connections are critical and often prone to developing leaks over time.

Step 2: Check for Disconnections

Fuel lines are typically secured in place with clamps or brackets. Inspect these fasteners to ensure they are tight and secure. If a fuel line has come loose, it will likely be the source of the leak. Check all connections, including those between the fuel pump and the lines, and between the lines and the injectors or carburetor (if applicable). A loose connection can cause fuel to spill, leading to contamination and potential engine issues.

Step 3: Inspect for External Damage

Examine the fuel lines for any external damage that might have occurred due to road debris, impacts, or vibrations. Look for signs of wear and tear, especially in areas where the lines cross or run alongside other components. Over time, fuel lines can develop small holes or tears, especially if they are old or have been subjected to harsh conditions. These small damages can lead to significant leaks if left unattended.

Step 4: Use a Fuel Line Inspection Tool (Optional)

For a more thorough inspection, consider using a fuel line inspection tool, which is a flexible tube with a camera attached. This tool can help you visualize the interior of the fuel line, allowing you to identify any internal damage or blockages. However, this step is often unnecessary for minor leaks and can be reserved for more complex or hard-to-reach areas.

By following these steps, you can accurately identify the source of the leaking fuel line, which is essential before proceeding with any repairs or replacements. Once the source is confirmed, you can then decide on the appropriate course of action to fix the issue and ensure your vehicle's fuel system operates safely and efficiently.

Optimizing Performance: Choosing the Right Fuel Line for Your Mahle 145 Engine

You may want to see also

Clean and prepare: Use a degreaser to clean the area and ensure a secure connection

When dealing with a leaking fuel line, it's crucial to start by cleaning and preparing the area to ensure a secure and effective repair. Begin by gathering the necessary tools and materials, including a degreaser, a clean cloth, and a fuel line repair kit (if needed). Degreasers are essential as they help remove any built-up grease, dirt, or debris that could interfere with the repair process.

Locate the leaking fuel line and assess the damage. It's important to identify the exact point of the leak to determine the appropriate repair method. Once identified, use a degreaser to thoroughly clean the area around the leak. Apply the degreaser generously and allow it to sit for a few minutes to loosen and dissolve any contaminants. This step ensures that the repair material will have a clean surface to adhere to, preventing future leaks.

After the degreaser has done its work, rinse the area with clean water to remove any residue. Ensure that the water is gentle and directed away from the repair area to avoid further damage. Use a clean cloth to wipe the surface dry, removing any remaining moisture. This preparation process is vital to creating a solid foundation for the repair, ensuring the new material bonds effectively.

Take the time to inspect the fuel line and the surrounding components for any additional damage or wear. Look for frayed or damaged sections that may require further attention or replacement. By thoroughly cleaning and preparing the area, you can ensure a secure connection and minimize the chances of the leak recurring. This step is often overlooked but is essential for a successful and long-lasting repair.

Remember, proper preparation is key to a successful fuel line repair. By using a degreaser and following these steps, you can create a clean and secure environment for the repair, ensuring the fuel line's integrity and preventing further leaks. Always exercise caution when working with fuel lines and consider seeking professional assistance if you're unsure about any step.

Motorcycle Fuel Line: Top Stores for Quality Parts

You may want to see also

Repair or replace: Depending on the condition, either repair the line or replace it entirely

When dealing with a leaking fuel line, it's crucial to assess the situation carefully before deciding on the appropriate course of action. The condition of the line will dictate whether a repair or a replacement is necessary. Here's a step-by-step guide to help you make an informed decision:

Assess the Damage: Start by inspecting the fuel line thoroughly. Look for any visible signs of damage, such as cracks, punctures, or corrosion. Check for any signs of deterioration, especially if the line is old or has been exposed to harsh conditions. Also, identify the source of the leak; is it a small pinhole or a more extensive tear? Understanding the nature and extent of the damage is essential for determining the next steps.

Consider the Material: Fuel lines are typically made from rubber, vinyl, or metal. If the line is made of rubber or vinyl, it may be more susceptible to cracking or puncturing over time. In such cases, repairing the line might be feasible if the damage is minor. However, if the line is made of metal, the repair process could be more complex, and replacement might be more practical.

Repair or Replace:

- Repair: For minor leaks or small holes, you can attempt to repair the fuel line. Start by cleaning the area around the damage to ensure a secure bond. Use a suitable adhesive or sealant designed for fuel lines to patch the hole. Ensure you follow the manufacturer's instructions for application and drying time. After the repair, test the line for leaks to ensure the issue is resolved.

- Replacement: If the damage is extensive, the line is old and beyond repair, or if you're dealing with a critical component like the main fuel line, replacement is often the best option. Start by disconnecting the fuel line from the fuel tank and the engine. Carefully remove the old line, ensuring you don't damage any surrounding components. Measure and cut the new fuel line to the appropriate length, then securely install it, following the manufacturer's guidelines.

Remember, the key is to evaluate the condition of the fuel line objectively. Sometimes, a repair might be temporary, especially if the damage is minor, but it's essential to ensure the line is secure and sealed properly. In other cases, a replacement could be more cost-effective and reliable in the long run. Always prioritize safety and consult a professional if you're unsure about any step during the repair or replacement process.

Overfilling: A Common Mistake with Fuel Lines

You may want to see also

Secure connections: Tighten any loose fittings and ensure all connections are secure

When dealing with a leaking fuel line, ensuring secure connections is crucial to prevent further issues and potential hazards. Start by identifying any loose fittings or connections along the fuel line. These can often be found at the ends of the line, where it connects to the fuel tank, pump, or engine. Use a wrench or appropriate tool to tighten these fittings securely. It's important to apply the right amount of force to avoid over-tightening, which can damage the fittings or fuel line itself. A good rule of thumb is to tighten the fittings until they are snug, but not so tight that they become difficult to loosen again if needed.

After tightening the fittings, inspect all connections to ensure they are secure. Look for any signs of damage, corrosion, or wear. Over time, connections can become compromised due to fuel exposure, temperature changes, or vibration. If you notice any corrosion or damage, replace the affected fittings and connections. It's also a good practice to use fuel-resistant tape or sealant on threads and connections to provide an extra layer of protection against leaks.

For fuel lines that run through the engine compartment, it's essential to check the connections inside the engine bay as well. These connections can be more challenging to access, but they are equally important to secure. Use a flashlight to inspect the connections and ensure they are tight and free from any signs of damage. If you find any loose connections inside the engine bay, carefully tighten them, being mindful of any sensitive components that might be nearby.

In some cases, you might need to adjust the position of the fuel line to ensure all connections are easily accessible and secure. This could involve slightly rerouting the line to provide better access to the fittings. Once all connections are tightened and inspected, start the engine and check for any leaks. If the issue persists, further investigation may be required, but securing the connections is a critical first step in resolving the leaking fuel line problem.

Fuel Line for Power Steering: A Viable Option?

You may want to see also

Test and verify: After repairs, test the system to ensure the leak is fixed and no further issues arise

After completing the necessary repairs to address a leaking fuel line, it is crucial to thoroughly test and verify the system to ensure the issue has been resolved and to prevent any potential future problems. Here's a step-by-step guide on how to conduct this testing process:

Step 1: Prepare the Environment

Before initiating the test, ensure that the vehicle is in a controlled and safe environment. Park it on a level surface, preferably in a well-ventilated area, to avoid any potential hazards from fuel vapor. Turn off the engine and allow it to cool down if it has been running.

Step 2: Inspect the Repaired Area

Carefully examine the section of the fuel line that was repaired. Check for any signs of damage, cracks, or loose connections. Ensure that all components are properly aligned and secured. This visual inspection will help identify if the repair was executed correctly.

Step 3: Perform a Visual Leak Test

Start the engine and allow it to idle. Visual inspection is a critical part of the testing process. Look for any signs of fuel leakage around the repaired area. Check for wet spots on the ground, especially under the vehicle, which could indicate a hidden leak. Pay close attention to the connections and joints, as these are common areas for leaks. If you notice any fuel accumulation or wet spots, it's a strong indication that the leak persists and further investigation is required.

Step 4: Use a Fuel Leak Detector

For a more comprehensive test, consider using a fuel leak detector or a soapy water solution. Apply a small amount of the detector or soapy water to the repaired fuel line and observe if any bubbles form or if the solution bubbles where the leak previously occurred. This method can help identify even the smallest leaks that might not be visible to the naked eye.

Step 5: Drive the Vehicle

If the visual and detector tests yield no signs of leaks, it's time to take the vehicle for a test drive. Start the engine and drive it at various speeds and in different conditions. Pay attention to the engine's performance, fuel consumption, and any unusual noises. Ensure that the vehicle operates smoothly and efficiently without any fuel-related issues.

Step 6: Monitor for Long-Term Performance

After the initial test drive, continue to monitor the vehicle's performance over the next few days or weeks. Keep an eye on the fuel gauge and overall engine behavior. If the fuel line was repaired correctly, you should not experience any further leaks or engine-related problems.

By following these testing procedures, you can confidently verify that the leaking fuel line issue has been successfully resolved, ensuring the vehicle's safe and efficient operation.

Duramax Fuel Line Bleed: A Step-by-Step Guide

You may want to see also

Frequently asked questions

A leaking fuel line is often due to damage, corrosion, or a faulty connection. Over time, fuel lines can deteriorate due to exposure to fuel, heat, and vibration, leading to cracks or punctures.

For a temporary fix, you can use a fuel line clamp or a temporary patch. Clamps provide a quick and effective solution to stop the leak, but it's essential to replace the damaged line as soon as possible to avoid further issues.

Replacing a fuel line requires basic automotive tools such as a fuel line cutter, a fuel line crimper, and a wrench set. It's crucial to have the correct tools to ensure a proper and secure connection.

Yes, some DIY enthusiasts can repair a fuel line with the right knowledge and tools. It involves cutting the damaged section, cleaning the ends, and using fuel line repair tape or a clamp. However, for complex or major leaks, it's recommended to seek professional assistance.