Removing water from a fuel line is a crucial step in maintaining the performance and longevity of a vehicle's engine. Over time, water can accumulate in the fuel system, leading to various issues such as engine misfires, reduced power, and potential damage to engine components. This guide will provide a step-by-step process to effectively eliminate water from the fuel line, ensuring optimal engine operation and preventing costly repairs.

What You'll Learn

- Identify the Source: Locate the fuel pump and disconnect the fuel line to access the source of the water

- Drain and Clean: Remove the water using a suction device and clean the fuel line with a solvent

- Replace Filters: Check and replace any filters that may have allowed water to enter the system

- Use Fuel Additives: Add a fuel additive to help prevent water accumulation and improve fuel quality

- Test and Reassemble: After cleaning, test the fuel system and reassemble, ensuring proper water-free operation

Identify the Source: Locate the fuel pump and disconnect the fuel line to access the source of the water

To effectively address the issue of water in your fuel line, it's crucial to first identify the source of the problem. This involves locating the fuel pump and disconnecting the fuel line to gain access to the source. Here's a step-by-step guide to help you through this process:

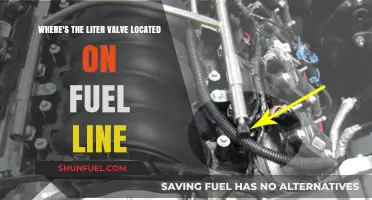

Locate the Fuel Pump: The fuel pump is a critical component in your vehicle's fuel system, responsible for pumping fuel from the tank to the engine. It is typically located beneath the vehicle, often near the front or rear of the engine compartment. You can usually find it by following the fuel lines, which will lead you to the pump's housing.

Access the Fuel Pump: Once you've located the fuel pump, you'll need to access it. This might involve removing some panels or covers in the engine compartment. Carefully remove any necessary components to expose the fuel pump and its associated lines.

Disconnect the Fuel Line: With the fuel pump accessible, locate the fuel line that connects it to the fuel tank. This line is usually a thick, rubber hose. Carefully disconnect this line by loosening the clips or fittings that hold it in place. Ensure you have a container or rag ready to catch any fuel that might spill during the process.

Inspect for Water: Now that you have access to the source, inspect the fuel line and the pump for any signs of water. Water can enter the system through various means, such as condensation, leaks, or improper fuel tank maintenance. Look for any discolored or cloudy fuel, as well as any signs of moisture or corrosion around the pump and lines.

Address the Source: If you find water in the fuel line or pump, it's essential to address the issue promptly. This might involve drying the fuel pump and lines, replacing any damaged components, or seeking professional advice to ensure the problem is resolved effectively. Properly drying and cleaning the system can prevent further issues and ensure your vehicle's optimal performance.

Fram G3727 Inline Fuel Filter: Compatibility and Benefits

You may want to see also

Drain and Clean: Remove the water using a suction device and clean the fuel line with a solvent

To effectively remove water from a fuel line, a systematic approach is necessary. One of the most reliable methods is to use a suction device specifically designed for this purpose. These devices are typically equipped with a long, flexible hose that can reach deep into the fuel line to extract any accumulated water. Begin by locating the fuel line, which is usually a thin, flexible tube running from the fuel tank to the engine. Identify any low points or areas where water might have pooled, as these are the most likely spots for water accumulation.

Once you've identified these areas, attach the suction device to the fuel line, ensuring a secure connection. Turn on the device and carefully guide the hose into the fuel line, starting from the lowest point. The suction will draw out any water present, and you may need to adjust the position of the hose to access all parts of the line. This process might take some time, especially if the water has been sitting in the line for a while. As you remove the water, you'll likely notice a slight improvement in the fuel flow, as the line is now free of the water that can impede it.

After the suction process, it's crucial to clean the fuel line to prevent any residue from the water or the suction process from causing further issues. This is where a solvent comes into play. Choose a solvent that is safe for your fuel system and can effectively dissolve any remaining water or contaminants. Common choices include fuel line cleaner or a mixture of vinegar and water. Apply the solvent to the fuel line, ensuring it reaches all areas where water was present. Allow the solvent to work for the recommended time, which is usually a few minutes, to ensure it penetrates and loosens any stubborn deposits.

During this cleaning process, you might need to remove certain components of the fuel system, such as the fuel filter or the fuel pump, to gain better access to the entire length of the fuel line. Once the solvent has done its job, rinse the fuel line with clean water to remove any remaining solvent and contaminants. This step is essential to ensure that the fuel line is now clean and ready to function optimally.

Finally, reassemble any removed components and refill the fuel tank to restore the fuel system to its normal operation. This method of draining and cleaning the fuel line is a practical and effective way to address the issue of water accumulation, ensuring your vehicle's engine runs smoothly and efficiently. It's a process that requires patience and attention to detail but is well worth the effort for the long-term health of your vehicle's fuel system.

Chevy Truck Return Fuel Line: 2003 Model Year Guide

You may want to see also

Replace Filters: Check and replace any filters that may have allowed water to enter the system

When dealing with water in fuel lines, one of the critical steps is to inspect and replace any filters that might have contributed to the issue. Filters play a vital role in preventing contaminants, including water, from entering the fuel system. Here's a detailed guide on how to approach this task:

Start by locating the fuel filters in your vehicle. These filters are typically found along the fuel line, often near the engine or in the fuel tank. Different vehicles may have varying filter locations, so consult your vehicle's manual for specific guidance. Once you've identified the filters, inspect them for any signs of damage or contamination. Look for visible water accumulation, corrosion, or any debris that might indicate water ingress. If you notice any issues, it's essential to replace the affected filters immediately.

To replace the filters, you'll need to follow a step-by-step process. First, ensure the engine is cool to avoid any burns during the replacement process. Locate the filter housing, which is usually a small container or cylinder. Carefully remove the old filter by unscrewing or unclipping it from the housing. Be cautious not to spill any fuel or contaminants. Rinse the housing and the old filter with clean fuel or a suitable solvent to remove any residual debris.

Now, prepare the new filters by ensuring they are the correct size and type for your vehicle. You can purchase replacement filters from automotive stores or online retailers. When installing the new filters, follow the manufacturer's instructions. Tighten the filters securely but avoid over-tightening, as this can damage the housing. Once all filters are replaced, carefully reconnect the fuel lines and ensure they are properly secured.

Remember, regular maintenance and filter replacement are crucial to preventing water-related issues in your fuel system. By taking the time to inspect and replace filters, you can ensure that your vehicle's fuel lines remain free from water and other contaminants, thus maintaining optimal engine performance.

Quick Fix: Temporary Solutions for Leaky Fuel Lines

You may want to see also

Use Fuel Additives: Add a fuel additive to help prevent water accumulation and improve fuel quality

Water in fuel lines can be a common issue, especially in older vehicles or those exposed to harsh weather conditions. One effective method to address this problem is by using fuel additives, which can help prevent water accumulation and improve overall fuel quality. These additives are designed to work in harmony with your vehicle's fuel system, offering a proactive approach to maintaining optimal performance.

When considering fuel additives, look for products specifically formulated to inhibit water accumulation. These additives typically contain ingredients that attract and bind with water molecules, preventing them from separating from the fuel and settling in the fuel lines. By doing so, they ensure that the fuel remains clean and free-flowing, reducing the risk of engine issues caused by water contamination.

Adding a fuel additive is a relatively simple process. Start by purchasing a high-quality additive suitable for your vehicle's fuel type. Most additives come in concentrated forms, so you'll need to mix them with fuel according to the manufacturer's instructions. Typically, you'll add the additive directly to your fuel tank, ensuring it mixes thoroughly with the existing fuel. Some additives might also require an initial dose to activate their water-repelling properties.

Regular use of fuel additives can provide long-term benefits. Over time, these additives help maintain the cleanliness of your fuel system, reducing the likelihood of water-related issues. They can also improve engine performance by ensuring a consistent and clean fuel supply. Additionally, fuel additives can enhance fuel economy, as a clean fuel system allows for more efficient combustion.

It's important to note that while fuel additives are a useful tool, they should be used in conjunction with regular maintenance practices. Keeping your vehicle well-maintained, including routine engine inspections and fuel system cleanings, will further ensure optimal performance and longevity. By combining these methods, you can effectively manage water accumulation in fuel lines and keep your vehicle running smoothly.

Understanding Rag Fuel Lines: A Comprehensive Guide

You may want to see also

Test and Reassemble: After cleaning, test the fuel system and reassemble, ensuring proper water-free operation

After you've thoroughly cleaned the fuel line and removed any visible water, it's crucial to test the system to ensure the issue is resolved. Start by checking the fuel pressure; low pressure can indicate a problem with the fuel pump or a clogged filter. You can use a fuel pressure gauge to measure the pressure at the fuel rail or injectors. If the pressure is below the recommended range, it may suggest a faulty pump or a restricted flow path.

Next, inspect the fuel injectors for any signs of water contamination. Over time, water can accumulate in the injectors, leading to improper atomization and potential engine misfires. Remove the injectors and visually inspect them for any water residue or corrosion. If you notice any issues, consider replacing the injectors to ensure optimal performance.

To further test the system, start the engine and monitor for any unusual noises or behavior. A properly functioning fuel system should operate smoothly without any sputtering or hesitation. Listen for any gurgling or hissing sounds, which could indicate the presence of air bubbles or water in the system. If you hear such noises, it's essential to address the issue promptly to prevent potential engine damage.

Once you've confirmed that the fuel line is dry and the system is functioning correctly, it's time to reassemble the components. Ensure that all fuel lines are securely connected and free from any kinks or bends that could restrict flow. Double-check the fuel filter and replace it if it shows signs of wear or contamination. Proper reassembly is critical to maintaining a water-free fuel system.

Finally, before starting the vehicle, verify that all fuel-related sensors and components are operational. This includes the fuel level sensor, pressure sensor, and any other sensors that monitor the fuel system's health. By thoroughly testing and reassembling the fuel system, you can ensure that the water issue has been effectively resolved, providing a reliable and efficient engine performance.

Optimizing Fuel Flow: Choosing the Right Fuel Line Diameter for Horsepower

You may want to see also

Frequently asked questions

To remove water from the fuel line, you can start by locating the fuel tank and the fuel lines connected to it. Use a fuel line bleeder valve or a small pump to draw the water out of the system. This process may require draining some fuel to ensure the water is completely removed.

Driving with water in the fuel line can cause significant issues. Water can damage the fuel pump, block fuel injectors, and even lead to engine misfires or stalling. It's best to address the water issue promptly to prevent further complications.

Yes, a fuel water separator is a useful device to install in your fuel system. It captures water droplets and sediment, preventing them from entering the engine. Regularly draining and replacing the separator's contents will help maintain a dry fuel supply.

Water can enter the fuel line due to condensation, especially in older vehicles or during colder weather. It can also be a result of a damaged fuel tank or fuel line, allowing moisture to seep in. Regular maintenance and inspections can help identify and prevent such issues.

In emergency situations, you can temporarily use a fuel line drying agent or a small amount of engine oil to absorb moisture. However, this is a temporary fix and it's crucial to address the root cause to ensure long-term prevention of water-related problems.