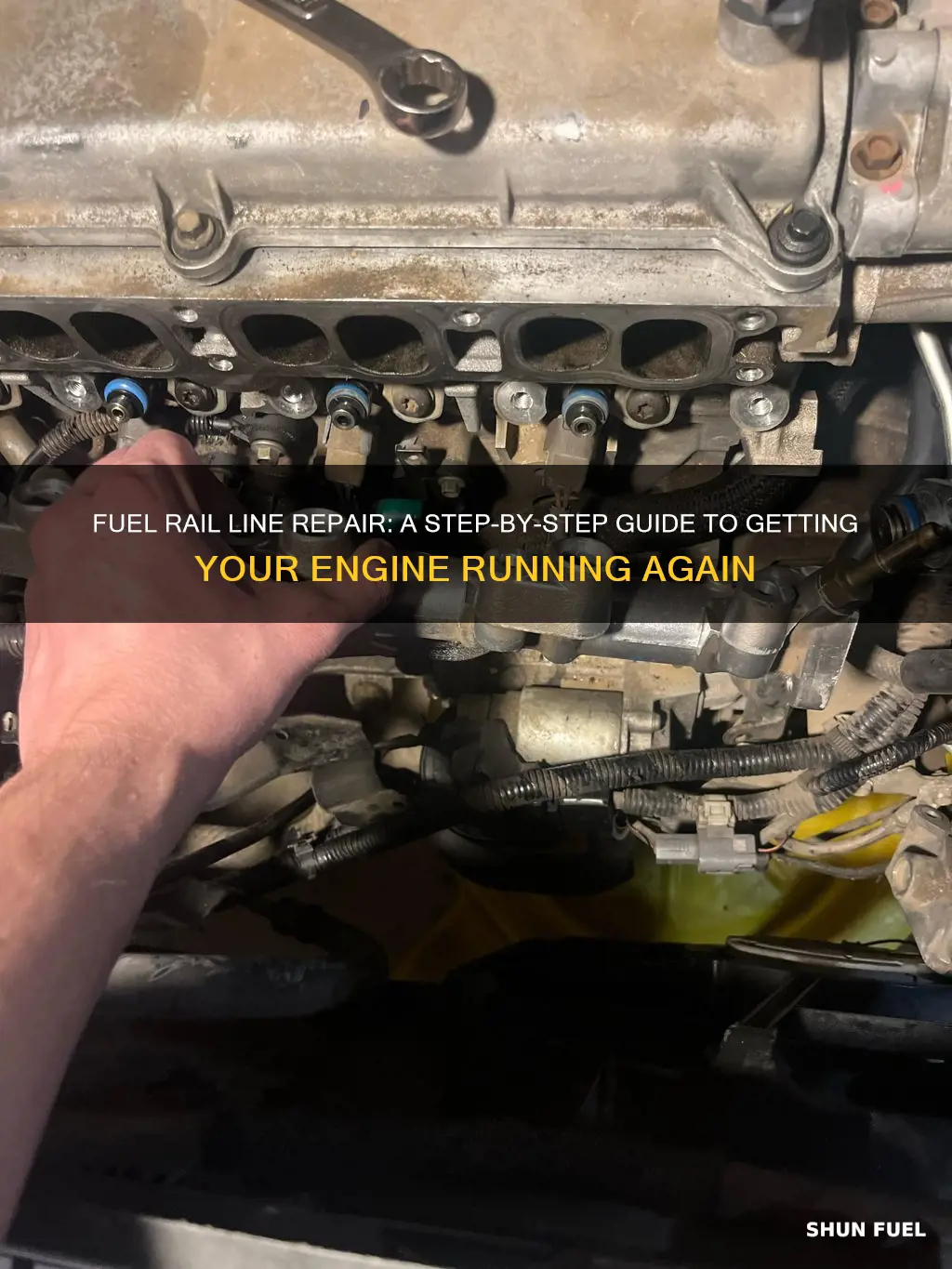

Fixing a fuel rail line is a crucial task for vehicle owners and mechanics alike, as it ensures optimal engine performance and fuel efficiency. The fuel rail line, a critical component in the fuel injection system, delivers fuel to the engine's cylinders under high pressure. When this line becomes damaged or leaks, it can lead to poor engine performance, reduced fuel efficiency, and even engine failure. This guide will provide a step-by-step approach to repairing or replacing the fuel rail line, covering everything from identifying the issue to the necessary tools and techniques for a successful fix.

What You'll Learn

- Identify the Issue: Check for leaks, blockages, or damage to the fuel rail line

- Prepare the Tools: Gather necessary tools like wrenches, sockets, and a fuel pump tester

- Locate the Rail: Access the fuel rail line, often found under the hood

- Remove the Line: Disconnect the fuel rail line from the engine and fuel pump

- Inspect and Repair: Examine the line for damage, clean or replace as needed

Identify the Issue: Check for leaks, blockages, or damage to the fuel rail line

When dealing with a fuel rail line issue, the first step is to identify the problem. This involves a thorough inspection to ensure you can address the issue effectively. Start by checking for any visible signs of damage or leaks along the fuel rail line. Look for cracks, corrosion, or any other physical damage that might indicate a potential issue. Inspect the connections and fittings for any signs of leakage. If you notice any fluid or fuel seeping from these areas, it could be a sign of a damaged seal or a loose connection.

Next, check for blockages. Over time, debris, dirt, or even fuel residue can accumulate in the fuel rail line, leading to restricted flow. Use a fuel filter to inspect the line for any blockages. If you find any debris or clogs, you may need to clean or replace the filter to restore proper fuel flow. It's also important to check for any signs of contamination in the fuel itself. Contaminated fuel can cause blockages and other issues, so ensure the fuel is clean and free from any debris.

The fuel rail line is a critical component of the fuel injection system, and its integrity is essential for optimal engine performance. Inspect the fuel rail for any visible damage, such as bends or kinks, which could affect the fuel's flow rate and pressure. Additionally, check for any signs of corrosion or deterioration, especially in areas where the fuel rail connects to the engine block. These connections are crucial for maintaining the structural integrity of the fuel system.

If you suspect any issues, further investigation is necessary. Use a fuel pressure gauge to measure the pressure at the fuel rail. Low pressure might indicate a blockage or a faulty pump. On the other hand, high pressure could suggest a leak or a malfunctioning pressure regulator. These diagnostic tools will help pinpoint the exact nature of the problem. Remember, early detection is key to preventing further complications and ensuring your engine runs efficiently.

Stratos Fuel Line Removal: A Step-by-Step Guide for Boat Owners

You may want to see also

Prepare the Tools: Gather necessary tools like wrenches, sockets, and a fuel pump tester

Before you begin any fuel rail repair, it's crucial to have the right tools on hand to ensure a smooth and efficient process. Here's a breakdown of the essential tools you'll need:

Wrenches and Sockets:

- Various Sizes: Gather a set of wrenches and sockets in different sizes, covering a range of common fuel rail bolt and nut sizes. This ensures you can access and tighten connections effectively.

- Adjustable Wrench: An adjustable wrench is versatile and allows you to work with different bolt sizes.

Fuel Pump Tester:

- Essential for Diagnosis: A fuel pump tester is indispensable for diagnosing fuel rail issues. It helps you confirm if the fuel pump is functioning correctly, which is crucial for identifying problems related to fuel delivery.

- Features to Look For:

- Voltage Measurement: Look for a tester that can measure voltage to accurately assess pump operation.

- Flow Rate Testing: Some advanced testers can measure fuel flow rate, providing valuable insights into potential blockages or restrictions.

Other Useful Tools:

- Fuel Filter: If you're replacing a fuel filter as part of the repair, have a new one readily available.

- Cleanliness Supplies: Keep your workspace clean with rags, cleaning solutions, and a vacuum to prevent contamination.

- Safety Gear: Safety goggles and gloves are essential for protecting your eyes and hands during the repair process.

Organize Your Workspace:

- Work Area: Set up your workspace in a well-ventilated area, preferably outdoors or with good ventilation. Fuel vapor is flammable, so proper ventilation is crucial.

- Organize Tools: Arrange your tools and parts in a logical order to save time and effort during the repair.

By gathering these tools and preparing your workspace, you'll be well-equipped to tackle fuel rail repairs with confidence. Remember to always prioritize safety and consult the vehicle's manual for specific instructions related to your make and model.

Fuel Line Installation: A Step-by-Step Guide for Under-Tire Connections

You may want to see also

Locate the Rail: Access the fuel rail line, often found under the hood

To begin the process of fixing a fuel rail line, you must first locate it. The fuel rail is a crucial component in a vehicle's fuel injection system, responsible for delivering fuel to the engine's injectors. It is typically positioned under the hood, often in close proximity to the engine. Here's a step-by-step guide to accessing the fuel rail:

- Prepare Your Vehicle: Park the car on a level surface and engage the parking brake. Ensure the engine is cool to avoid any burns or injuries. It is recommended to wear safety gear, including gloves and eye protection, when working on the engine.

- Locate the Hood Release: Open the hood by first locating the hood release mechanism, usually a small lever or button. This release allows you to lift the hood with ease. Once found, press or pull the release to unlock the hood and lift it gently.

- Access the Engine Compartment: With the hood open, you'll see the engine compartment. Locate the fuel rail, which is often a metal tube or pipe with fuel injectors attached. It is usually positioned near the front of the engine, running parallel to the engine block. You might need to remove some engine components or move aside other parts to gain better access.

- Identify the Fuel Rail Connections: Before attempting any repairs, identify the connections and components associated with the fuel rail. This includes fuel injectors, fuel pressure regulators, and any hoses or lines connected to the rail. Make a mental note of these connections to ensure you can reconnect them properly after any necessary repairs.

- Inspect for Damage: Carefully inspect the fuel rail for any signs of damage, corrosion, or leaks. Look for cracks, bends, or any visible issues. If you notice any problems, you may need to replace the fuel rail or address the specific issue.

Remember, working on a vehicle's fuel system requires caution and precision. If you are unsure about any step, it is best to consult a professional mechanic or refer to a detailed repair manual specific to your vehicle's make and model.

Optimizing Performance: Choosing the Right Fuel Line for Your 87 Ford F250

You may want to see also

Remove the Line: Disconnect the fuel rail line from the engine and fuel pump

To begin the process of removing the fuel rail line, you must first locate the fuel rail, which is typically positioned near the engine's front. It is a metal or plastic component that houses the fuel injectors. Once identified, carefully inspect the fuel rail line, which connects the fuel rail to the engine and the fuel pump. This line is usually a flexible hose or a rigid tube.

The next step is to disconnect the fuel rail line from the engine. Start by locating the appropriate connectors or fittings that secure the line to the engine block. These connections can vary depending on the vehicle's make and model. Often, you will find screws or bolts holding the fuel rail in place, which need to be removed to access the line. Carefully loosen and remove these fasteners, ensuring you keep track of their positions and orientations for reassembly.

After securing the fuel rail, you can now disconnect the fuel rail line from the engine. This may involve unscrewing or unclipping a fitting or connector. Be cautious as some fuel lines might have retaining clips or O-rings that need to be carefully removed or replaced to avoid damage. Take note of the orientation of the line and any specific connections to ensure an accurate reattachment later.

Once the fuel rail line is disconnected from the engine, you can proceed to remove it entirely. Carefully pull the line away from the engine and fuel pump, ensuring you don't damage any surrounding components. It might be necessary to gently rock the line side to side to break any stubborn connections. Keep the line organized and tangle-free to make the replacement process smoother.

Remember, when working with fuel lines, it is crucial to exercise caution to avoid fuel spills and potential hazards. If you encounter any difficulties or are unsure about any step, consult the vehicle's repair manual or seek assistance from a professional mechanic to ensure the job is done safely and correctly.

Poulan Chainsaw Fuel Line: A Comprehensive Guide

You may want to see also

Inspect and Repair: Examine the line for damage, clean or replace as needed

When it comes to inspecting and repairing a fuel rail line, a thorough examination is crucial to ensure optimal engine performance and safety. Here's a step-by-step guide to help you through the process:

Step 1: Visual Inspection

Start by visually inspecting the fuel rail line for any visible signs of damage or deterioration. Look for cracks, punctures, leaks, or any discolored areas along the line. Pay close attention to the connections and fittings, as these are common points of failure. Check for any signs of corrosion or rust, especially if the line is exposed to harsh environmental conditions.

Step 2: Check for Leaks

A critical aspect of the inspection is to identify any leaks. Turn on the engine and listen for any unusual sounds, such as hissing or roaring. Feel the fuel rail line and surrounding areas for warmth, as this could indicate a leak. If you suspect a leak, shut off the engine immediately and locate the source. Use a soapy water solution to test for fuel leaks, as this will help you identify any potential issues.

Step 3: Examine Connections

Fuel rail lines often have various connections and fittings. Carefully inspect these connections for tightness and integrity. Ensure that all bolts and clamps are secure and in place. Over time, these connections can loosen or become damaged, leading to fuel leaks or reduced performance. Tighten any loose connections and consider replacing any damaged or corroded fittings.

Step 4: Clean and Maintain

Regular cleaning and maintenance can prevent many issues. If you find any dirt, debris, or contaminants in the fuel rail line, use a suitable fuel line cleaner to remove them. This ensures that the line remains clear and allows for optimal fuel flow. Additionally, consider using a fuel system cleaner to maintain the overall health of the engine.

Step 5: Replace if Necessary

In some cases, the fuel rail line may require replacement. If you've identified significant damage, multiple leaks, or extensive corrosion, it's best to replace the entire line. This is especially important if the damage is near the engine or fuel pump, as it could lead to dangerous situations. When replacing, ensure you use high-quality fuel rail line material and follow manufacturer guidelines for proper installation.

Remember, regular maintenance and inspections can help prevent costly repairs and ensure your engine operates efficiently. If you're unsure about any step, consult a professional mechanic who can provide expert guidance tailored to your vehicle's needs.

Unraveling the Mystery: Why Motorcycles Pop Pinholes in Fuel Lines

You may want to see also

Frequently asked questions

There are several signs that may indicate a damaged or leaking fuel rail line. These include a noticeable decrease in engine performance, increased fuel consumption, engine misfires or rough idling, and a strong odor of gasoline or fuel vapor around the engine bay. If you experience any of these symptoms, it's best to have your vehicle inspected by a professional mechanic to diagnose the issue.

While some minor fuel rail line issues can be temporary and may require simple fixes like tightening connections or replacing gaskets, major damage or leaks usually necessitate professional assistance. Fuel rail lines are often located under the hood and require specialized tools and knowledge to access and repair safely. It's recommended to consult a qualified mechanic to ensure proper diagnosis and repair.

Fuel rail lines can fail or develop leaks due to several factors. Over time, rubber components can degrade, leading to cracks or punctures. This can be caused by age, exposure to extreme temperatures, or chemical corrosion from fuel contaminants. Additionally, physical damage from accidents, improper installation, or regular wear and tear can also contribute to fuel rail line issues.

Driving with a damaged fuel rail line can lead to serious engine problems. Leaks in the line can cause fuel to spill onto hot engine components, potentially resulting in fires or explosions. Engine performance will deteriorate, leading to reduced power, increased emissions, and potential engine damage over time. It is crucial to address fuel rail line issues promptly to ensure safe and efficient vehicle operation.