Connecting a fuel line under the rear left tire requires careful attention to detail and adherence to safety guidelines. This process involves several steps, including preparing the necessary tools and materials, ensuring the vehicle is properly supported, and following a systematic approach to connect the fuel line securely and safely. It is crucial to understand the specific requirements of your vehicle and consult the appropriate manual or seek professional guidance to ensure a successful and safe installation.

What You'll Learn

Locate the fuel line access point under the rear left tire

To locate the fuel line access point under the rear left tire, you'll need to inspect the vehicle's underbody. Here's a step-by-step guide to help you find the correct spot:

- Jack Up the Vehicle: Start by safely jacking up the vehicle to lift the rear left tire off the ground. Ensure the jack is positioned correctly to support the vehicle's weight. This step is crucial for accessing the underbody without causing damage.

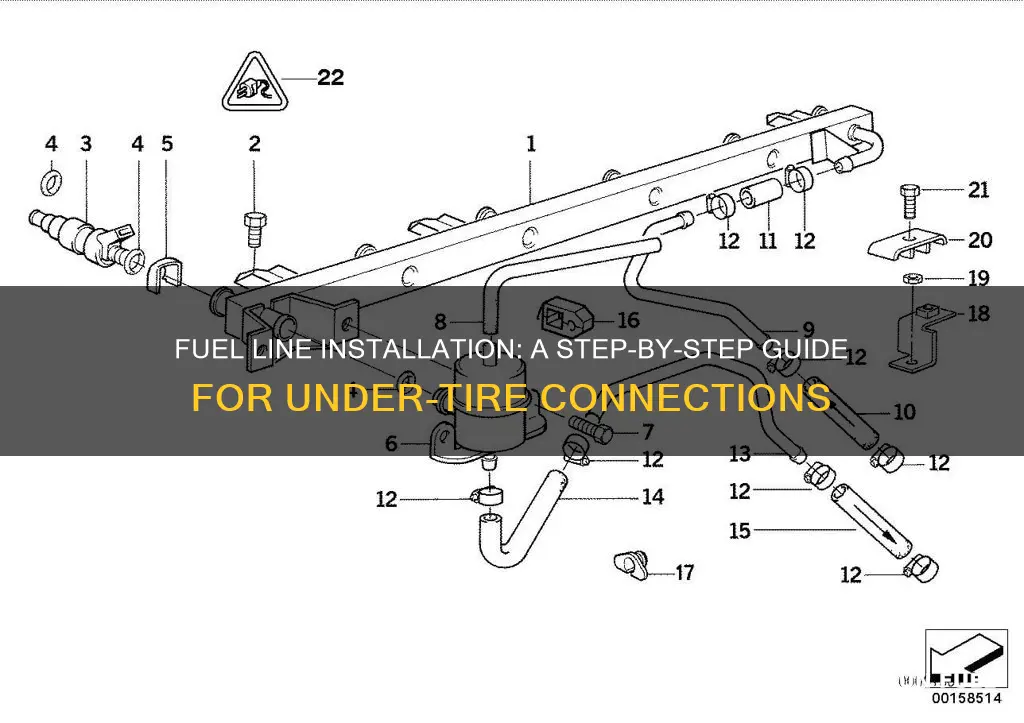

- Inspect the Underbody: With the tire raised, carefully inspect the area directly beneath it. The fuel line access point is typically located in this area, often protected by a rubber or plastic cover to shield it from road debris and potential damage. Look for a small opening or a dedicated access port.

- Locate the Fuel Line: The fuel line might be running along the frame rail or attached to the suspension components. It could be a flexible hose or a rigid tube. Carefully trace the path of the fuel line until you reach the access point. You may need to gently move aside any obstructions or components to get a clear view.

- Identify the Access Point: Once you've located the fuel line, identify the specific point where it can be accessed. This could be a small opening in the fuel tank, a dedicated port, or a connection point where the fuel line attaches to another component. Ensure you have a clear view of this access point for the next steps.

- Prepare for Connection: If you're connecting a new fuel line, you'll need to prepare the ends of the new line. This might involve cutting the existing fuel line to the correct length and ensuring the ends are clean and smooth. Have the replacement fuel line ready, ensuring it matches the original specifications.

Remember, working with fuel lines requires caution. Always ensure the vehicle is properly supported, and never modify fuel lines unless you are a qualified professional. If you're unsure, consult a mechanic or refer to the vehicle's manual for specific instructions tailored to your car model.

Unraveling the Mystery: Why Outboard Motors Have Two Fuel Lines

You may want to see also

Disconnect the old fuel line, ensuring no spills

Before you begin, it's crucial to understand the importance of handling fuel lines with care. Fuel lines carry gasoline or diesel from the tank to the engine, and any mistake during disconnection can lead to fuel leaks, which pose serious safety risks. Always wear protective gear, such as gloves and safety goggles, to minimize the risk of injury.

Locate the fuel line under the rear left tire. It is typically a thin, flexible tube running along the frame rail. Identify the specific fuel line you need to disconnect. There might be multiple lines, so double-check the diagram or consult your vehicle's manual to ensure you're disconnecting the correct one.

Using the appropriate tools, carefully disconnect the fuel line from the fuel tank or the engine. This process may involve unscrewing fittings or using a fuel line cutter. Take your time and be gentle to avoid damaging the surrounding components. Once disconnected, place a suitable container under the line to catch any residual fuel that may remain.

As you work, be mindful of any potential spills. Fuel is highly flammable, so any leaks should be addressed immediately. If you notice any fuel dripping, stop the process, and contact a professional mechanic or a qualified individual for assistance. Always prioritize safety when working with fuel.

After disconnecting the line, inspect it for any signs of damage or wear. If the line is cracked or damaged, it should be replaced to ensure safe operation. Properly dispose of any used fuel lines and ensure that all connections are tight and secure before reassembling the system.

Mastering the Art: Removing Fuel Lines on Your 88 Ford Ranger

You may want to see also

Route the new fuel line through the designated path

When replacing or relocating a fuel line under the rear left tire, it's crucial to follow a precise path to ensure a safe and functional setup. Here's a step-by-step guide on how to route the new fuel line through the designated path:

- Access the Underbody: Begin by lifting the vehicle to access the underbody. Locate the existing fuel line that needs to be replaced or relocated. Identify the path it takes and take note of any obstacles or areas where the new line will need to pass.

- Mark the Route: Carefully plan the route the new fuel line will take. Consider the vehicle's structure, including the frame, suspension components, and any other parts that might interfere with the line's placement. Mark the path on the vehicle's body or use temporary markers to ensure accurate routing.

- Prepare the New Line: Obtain a new fuel line that is compatible with your vehicle's specifications. Ensure it has the correct length and diameter to fit the designated route. If necessary, use fuel line connectors or fittings to join the new line to the existing system or the fuel tank.

- Route the Line: Start at the fuel source (usually the fuel tank) and carefully guide the new fuel line through the marked path. Route it along the designated path, ensuring it avoids any sharp bends or kinks that could lead to damage or restriction. Secure the line temporarily with ties or clips to keep it in place as you work.

- Secure and Protect: As you progress along the route, secure the fuel line using appropriate ties or clips to prevent movement and potential damage. Consider using protective sleeves or insulation to shield the line from sharp edges, vibrations, or heat sources. Ensure the line is routed away from moving parts and potential impact zones.

- Finalize Connections: Once the new fuel line is in place, make the necessary connections to the fuel system. Ensure all fittings and connectors are tightened securely and checked for leaks. Verify that the line is properly supported and protected throughout its length.

Remember, working with fuel lines requires caution and attention to detail. Always refer to your vehicle's manual for specific instructions and safety guidelines. Proper routing and secure installation will contribute to a reliable fuel system and overall vehicle performance.

Powerful Engine Demands: Choosing the Right Fuel Line for 700 HP

You may want to see also

Secure the fuel line with clips or ties

When working with fuel lines, it's crucial to ensure they are properly secured to prevent any potential leaks or damage. In the case of connecting a fuel line under the rear left tire, you'll need to follow a few steps to ensure a secure and safe installation.

Start by laying out the fuel line and ensuring it is routed correctly. The line should be positioned to avoid any sharp bends or kinks, as these can lead to potential issues. You'll want to allow some slack in the line to accommodate any movement of the vehicle. Once the line is in place, it's time to secure it.

One effective method is to use fuel line clips or ties. These small, specialized clips are designed to securely hold fuel lines in place without causing any damage. You can find these clips at most auto parts stores. Take a clip and slide it over the fuel line, ensuring it is positioned where the line enters the tire area. Repeat this process at regular intervals along the length of the line to create multiple anchor points. This will help distribute the tension and prevent the line from moving or sagging.

Alternatively, you can use rubber ties or straps to secure the fuel line. These ties are typically made of durable rubber and can be easily adjusted to hold the line in place. Wrap the tie around the fuel line, creating a secure loop. Make sure the tie is tight enough to prevent any movement but not so tight that it causes the line to kink. You can also use multiple ties at different points along the line for added security.

Remember, when securing the fuel line, it's important to avoid placing it under excessive tension, as this can lead to damage over time. By using clips or ties, you can ensure that the line remains in the desired position and is protected from any potential hazards. Regularly check the line's condition and adjust the ties or clips as needed to maintain a secure and safe fuel system.

Fuel Line Calculation: Optimizing Race Car Performance

You may want to see also

Test the connection for leaks and reattach the tire

Once you've connected the fuel line, it's crucial to ensure there are no leaks that could potentially cause issues down the line. Here's a step-by-step guide to testing for leaks and reattaching the tire:

- Visual Inspection: Start by visually inspecting the connection points. Look for any signs of damage, such as cracks or punctures, on the fuel line and the tire. Also, check for any visible signs of leakage around the connections. If you notice any damage or potential leak points, address them immediately before proceeding.

- Pressure Test: Apply pressure to the fuel line connection to simulate the conditions of a running engine. You can use a small hand pump or a compressed air source for this purpose. Gradually increase the pressure and observe for any leaks. Pay close attention to the areas where the fuel line connects to the tire and the engine. If you detect any leaks, you'll need to tighten the connections or replace the damaged parts.

- Bubble Test (For Plastic Lines): If the fuel line is made of plastic, you can perform a bubble test to identify leaks. Soak the connection area in a mixture of water and dish soap. If there are any leaks, air bubbles will form around the damaged area. This method is particularly useful for identifying small leaks that might not be visible to the naked eye.

- Reattachment: After ensuring there are no leaks, securely reattach the tire. Make sure all connections are tight and aligned correctly. Use the appropriate tools to tighten any fasteners or clamps. Double-check that the tire is firmly in place and cannot be easily moved.

- Final Check: Before driving the vehicle, perform a final inspection. Check for any signs of leakage around the tire and fuel line connections. Ensure that all components are secure and that there is no excessive movement or vibration that could cause damage over time.

Remember, proper connection and leak testing are essential to prevent fuel leaks, which can be dangerous and cause engine performance issues. Always follow safety guidelines and consult a professional if you're unsure about any step during the process.

Diagnosing Fuel Issues: A Guide to Checking the Return Line on Your Kubota Diesel Engine

You may want to see also

Frequently asked questions

The fuel line is typically located on the driver's side of the vehicle, running along the frame rail towards the rear. It is often protected by a rubber or plastic shield to prevent damage from the tire. You can access it by removing the wheel and any trim pieces that might be in the way.

You will need a set of wrenches or pliers to tighten the connections, a fuel line connector kit (if required for your vehicle), and possibly a fuel line cutter and crimper for any necessary adjustments. It is recommended to have a basic understanding of automotive mechanics and to work on a level surface for better control.

Absolutely! Before working on any fuel-related components, ensure the engine is turned off and the vehicle is in a secure position. Release the parking brake and engage the parking brake mechanism. Allow sufficient time for the fuel to dissipate from the system. Always wear safety gear, including gloves and eye protection, to avoid any potential hazards.