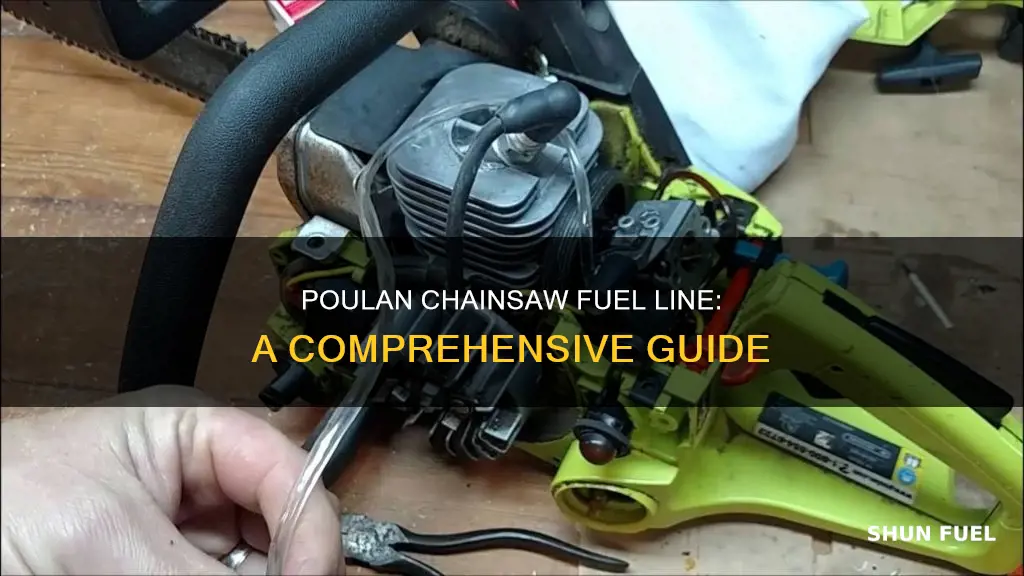

Poulan chainsaws are a popular choice for homeowners and professionals alike, known for their durability and performance. One of the key components that contribute to their efficiency is the fuel line, which is responsible for delivering gasoline to the engine. However, a common question that arises among users is whether all Poulan chainsaws use the same fuel line. This paragraph aims to explore this query, providing insights into the variations in fuel line designs and compatibility across different Poulan chainsaw models. Understanding these differences is crucial for ensuring proper maintenance and optimal performance of these powerful tools.

What You'll Learn

- Fuel Line Material: Poulan chainsaws use rubber or plastic fuel lines, which may differ in durability and flexibility

- Fuel Line Length: Different models have varying fuel line lengths, affecting ease of access and maintenance

- Fuel Line Routing: Proper routing is crucial to prevent damage and ensure efficient fuel flow

- Fuel Line Compatibility: Ensure the fuel line is compatible with the engine type and fuel type used

- Fuel Line Maintenance: Regular cleaning and inspection can extend the life of the fuel line

Fuel Line Material: Poulan chainsaws use rubber or plastic fuel lines, which may differ in durability and flexibility

Poulan chainsaws, like many other chainsaw models, utilize fuel lines to deliver gasoline from the tank to the carburetor. The material of these fuel lines is an important consideration for performance and longevity. Typically, Poulan chainsaws employ either rubber or plastic fuel lines, each offering distinct advantages and disadvantages.

Rubber fuel lines are known for their durability and resistance to heat and chemicals. They are less prone to cracking or leaking compared to plastic lines, making them a reliable choice for chainsaws that operate in demanding conditions. The flexibility of rubber allows for easier routing and installation, accommodating the various angles and bends within a chainsaw's engine compartment. However, rubber fuel lines may be more susceptible to damage from sharp edges or vibrations over time, requiring careful installation and maintenance.

On the other hand, plastic fuel lines are lightweight and flexible, making them easier to work with during installation. They are often more cost-effective than rubber lines, which can be a significant advantage for those seeking a budget-friendly option. Plastic lines are also less likely to absorb gasoline, reducing the risk of evaporation and potential carburetor issues. Nevertheless, plastic fuel lines may not withstand extreme temperatures as well as rubber lines and can be more prone to cracking or becoming brittle over time, especially in harsh environments.

The choice between rubber and plastic fuel lines often depends on the specific model and intended use of the Poulan chainsaw. Some models may come equipped with rubber lines as standard, while others might offer plastic lines as an option. It is essential to consider the operating conditions, such as outdoor exposure, frequent use, and environmental factors, to determine the most suitable fuel line material for optimal performance and longevity.

In summary, Poulan chainsaws utilize rubber or plastic fuel lines, each with its own set of advantages and considerations. Rubber lines offer superior durability and heat resistance, while plastic lines provide flexibility and cost-effectiveness. Understanding the characteristics of these materials can help users make informed decisions when maintaining or upgrading their chainsaw's fuel system.

Barb Connectors: A Guide to Fuel Line Compatibility

You may want to see also

Fuel Line Length: Different models have varying fuel line lengths, affecting ease of access and maintenance

The fuel line length on Poulan chainsaws can vary significantly between different models, and this variation has practical implications for both accessibility and maintenance. Longer fuel lines are often associated with larger, more powerful chainsaws, which are typically used in professional settings or for heavy-duty tasks. These extended lines provide more flexibility, allowing users to move around and maneuver the chainsaw with greater ease, especially in tight or confined spaces. For instance, the Poulan Pro 500 series features a longer fuel line, enabling operators to reach and work in areas that might be otherwise inaccessible with a shorter line. This is particularly beneficial for tree care professionals who need to navigate around obstacles while cutting.

On the other hand, shorter fuel lines are more common in smaller, lighter chainsaws designed for residential use or hobbyists. These models often prioritize compactness and ease of use, making them more manageable and less cumbersome to operate. For example, the Poulan 300 series is equipped with a shorter fuel line, ensuring that the chainsaw remains balanced and easy to control, even when working in narrow or elevated positions. This design consideration is crucial for user comfort and safety, especially during extended periods of use.

The length of the fuel line also influences the frequency of maintenance tasks. Longer lines may require more frequent checks and adjustments to ensure optimal performance and prevent issues like fuel starvation or air intake restrictions. Regular maintenance is essential to keep the chainsaw running smoothly and efficiently, especially in demanding conditions. Users of longer-line models should be prepared to spend more time on maintenance, ensuring that the fuel line remains free of clogs and debris.

In contrast, shorter fuel lines often simplify maintenance routines. With less line to manage, users can quickly identify and address issues, such as fuel leaks or blockages, without extensive troubleshooting. This is particularly advantageous for those who prefer a more straightforward and less time-consuming maintenance process.

Ultimately, the fuel line length on a Poulan chainsaw is a critical design feature that impacts the overall user experience. It influences the chainsaw's versatility, ease of use, and maintenance requirements, catering to the specific needs of different users and applications. Whether it's the flexibility of a longer line for professional use or the convenience of a shorter line for residential tasks, understanding and considering fuel line length is essential for choosing the right Poulan chainsaw for any given situation.

Subaru Impreza 2010: Canister Fuel Line Location Guide

You may want to see also

Fuel Line Routing: Proper routing is crucial to prevent damage and ensure efficient fuel flow

Fuel line routing is a critical aspect of maintaining a Poulan chainsaw, as it directly impacts the performance and longevity of the machine. Proper routing ensures that the fuel flows efficiently to the engine, preventing any blockages or restrictions that could lead to performance issues. When the fuel line is not routed correctly, it can cause a variety of problems, including poor engine performance, stalling, and even damage to the fuel system.

The fuel line should be routed in a way that avoids any sharp bends or kinks, as these can restrict the flow of fuel and cause pressure drops. It is recommended to use flexible fuel lines that can be easily bent and routed around obstacles without causing any damage. The line should be secured with ties or clips to prevent it from coming loose or being caught on moving parts. A good practice is to route the fuel line as close to the ground as possible, as this helps to prevent damage from debris and provides better protection against accidental impacts.

In addition to avoiding sharp bends, it is essential to keep the fuel line away from hot surfaces and high-speed moving parts. Proximity to heat sources can cause the fuel to vaporize, leading to potential performance issues. Similarly, routing the fuel line too close to the chain bar and guide can increase the risk of damage during operation. It is advisable to use protective sleeves or shields to safeguard the fuel line from potential hazards.

For Poulan chainsaws, the fuel line routing may vary slightly depending on the model and its specific design. However, the general principles remain the same. It is always recommended to refer to the manufacturer's manual for detailed instructions on the correct routing method for your particular model. Proper routing will not only ensure the efficient operation of your chainsaw but also contribute to its overall reliability and longevity.

In summary, fuel line routing is a vital task for any chainsaw owner, including those with Poulan models. By following the guidelines mentioned above and taking into account the specific design of your chainsaw, you can ensure that the fuel line is properly routed, preventing damage and optimizing engine performance. Regular maintenance and inspection of the fuel line can also help identify any potential issues early on, ensuring your chainsaw operates at its best.

Mastering the Art of Fuel Line Removal: A Step-by-Step Guide

You may want to see also

Fuel Line Compatibility: Ensure the fuel line is compatible with the engine type and fuel type used

When it comes to maintaining your Poulan chainsaw, one crucial aspect often overlooked is the fuel line compatibility. This component is essential for ensuring your chainsaw runs efficiently and reliably. The fuel line connects the fuel tank to the engine, delivering the necessary gasoline or oil mixture for combustion. Therefore, using the correct fuel line is vital to avoid performance issues and potential damage to your chainsaw.

The compatibility of the fuel line is closely tied to the engine type and the fuel type used. Different engine designs may require specific fuel line materials and configurations to function optimally. For instance, some Poulan chainsaws use two-stroke engines, which typically require a fuel mixture of gasoline and oil. In contrast, four-stroke engines might need pure gasoline without any oil addition. Using the wrong fuel line can lead to fuel leaks, poor engine performance, or even engine damage.

For two-stroke engine chainsaws, the fuel line is usually made of flexible plastic or rubber. These materials are designed to withstand the fuel's corrosive properties and the engine's operating temperatures. It's essential to choose a fuel line with the appropriate inner diameter to ensure proper fuel flow and pressure. Additionally, the fuel line should be long enough to reach from the tank to the engine without excessive bending, which could restrict fuel flow.

On the other hand, four-stroke engine chainsaws often use a different type of fuel line, typically made of a more rigid material like metal or reinforced plastic. This is because four-stroke engines do not require a fuel mixture and can operate with pure gasoline. The fuel line for these engines is usually shorter and more direct, as the fuel is delivered directly to the carburetor or fuel injection system.

In summary, when working on your Poulan chainsaw, always consider the fuel line compatibility with the engine type and fuel type. Using the correct fuel line ensures optimal performance, prevents engine damage, and provides peace of mind. Always refer to the manufacturer's guidelines or consult a professional if you're unsure about the specific requirements for your chainsaw model.

Fuel Return Line: Essential or Overrated?

You may want to see also

Fuel Line Maintenance: Regular cleaning and inspection can extend the life of the fuel line

Fuel line maintenance is a crucial aspect of ensuring the longevity and optimal performance of your Poulan chainsaw. The fuel line, a small but vital component, connects the fuel tank to the engine, delivering the necessary fuel for operation. Over time, this line can become susceptible to various issues, including clogs, contamination, and damage, which can lead to engine problems and reduced performance. Therefore, regular maintenance is essential to keep your chainsaw in top condition.

One of the primary methods to maintain the fuel line is through regular cleaning. Over time, the fuel line can accumulate deposits, such as varnish, which is formed by the evaporation of gasoline. These deposits can restrict fuel flow, leading to engine misfires, reduced power, and potential starting difficulties. To clean the fuel line, start by draining the fuel tank and removing the line. Use a fuel line cleaner or a mixture of gasoline and cleaner to flush out any deposits. Run the chainsaw for a few minutes to ensure the cleaner is distributed throughout the system. This process helps to remove any built-up contaminants and ensures a smooth, unobstructed fuel flow.

In addition to cleaning, regular inspection of the fuel line is essential. Visual inspections can help identify potential issues before they become major problems. Check for any signs of damage, such as cracks, kinks, or leaks, along the length of the fuel line. Inspect the connections between the line and the tank and the engine to ensure they are secure and free from corrosion. If you notice any damage, it's crucial to replace the fuel line promptly to prevent further issues.

Furthermore, it is recommended to use a fuel stabilizer in the gasoline, especially if the chainsaw is stored for extended periods. Fuel stabilizers help prevent the formation of varnish and other deposits, reducing the need for frequent cleaning. By incorporating these maintenance practices, you can ensure that your Poulan chainsaw's fuel system remains in excellent condition, providing reliable performance and extending the life of the fuel line.

In summary, regular fuel line maintenance is a simple yet effective way to keep your Poulan chainsaw in optimal condition. Cleaning and inspecting the fuel line periodically can prevent clogs, contamination, and damage, ensuring a reliable and efficient power source for your chainsaw's engine. By following these maintenance steps, you can enjoy the benefits of a well-maintained chainsaw with improved performance and longevity.

Is Fuel Line Safe for Coolant? Uncover the Truth

You may want to see also

Frequently asked questions

No, Poulan chainsaws typically use a unique fuel line design specific to their models. It's important to consult the owner's manual or contact the manufacturer to ensure you have the correct fuel line for your Poulan chainsaw.

It is not recommended to use generic or non-original fuel lines as they may not meet the required specifications and could potentially cause issues with performance or safety. Always refer to the manufacturer's guidelines for the best results.

The frequency of fuel line replacement depends on usage and maintenance. As a general rule, it is advised to replace the fuel line every 1-2 years or whenever you notice signs of wear, such as cracks, leaks, or reduced performance.

Poulan chainsaws often utilize fuel lines made of high-quality materials like rubber or plastic compounds. These materials are designed to withstand fuel exposure and provide durability. It's best to use the recommended fuel line material provided by the manufacturer to ensure compatibility and optimal performance.