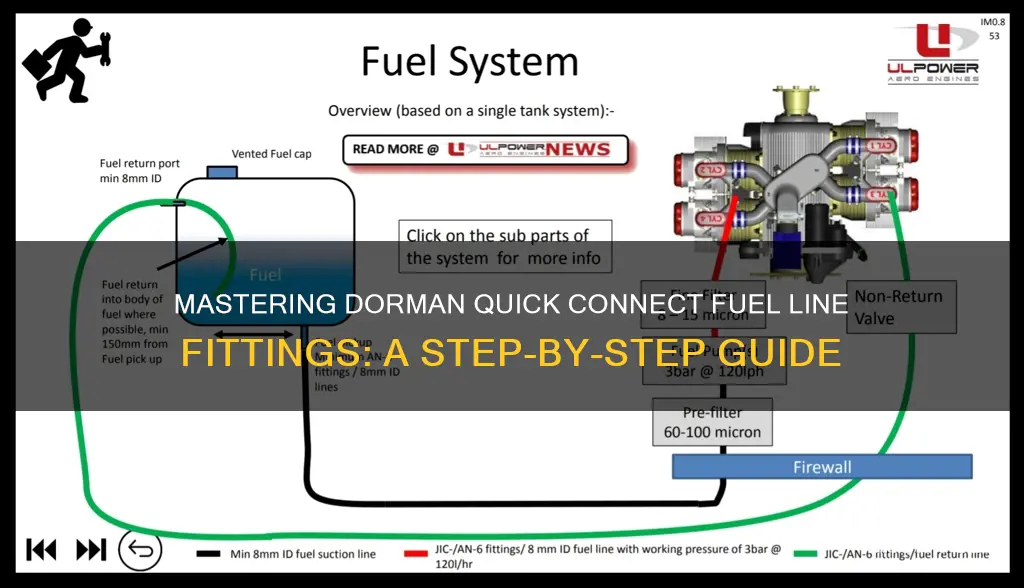

Installing Dorman Quick Connect fuel line fittings is a straightforward process that can save time and ensure a secure connection for your vehicle's fuel system. These fittings are designed for easy installation and offer a reliable way to connect fuel lines without the need for welding or extensive plumbing skills. This guide will provide a step-by-step approach to help you understand the process, ensuring a successful and safe installation.

What You'll Learn

- Preparation: Gather tools and materials, ensuring a clean workspace

- Fuel Line Inspection: Check for damage, ensuring compatibility with fittings

- Fitting Selection: Choose the right size and type for your fuel line

- Assembly Steps: Follow a step-by-step guide for secure installation

- Testing: Ensure a tight seal and no leaks after installation

Preparation: Gather tools and materials, ensuring a clean workspace

Before you begin the installation process, it's crucial to prepare your workspace and gather the necessary tools and materials. This step ensures a smooth and efficient project, minimizing potential issues and saving you time. Here's a detailed guide on how to get ready:

Gather the Tools and Materials:

- Dorman Quick Connect Fuel Line Fittings: Ensure you have the specific fittings required for your application. Check the vehicle's manual or online resources to identify the correct part numbers.

- Fuel Line: Obtain a suitable fuel line that matches the diameter and material of your existing lines. Common materials include rubber, vinyl, or braided steel.

- Hose Clamps: Get a few hose clamps to secure the connections. Choose the appropriate size and material (e.g., metal or plastic) based on the fuel line's specifications.

- Cleaning Supplies: You'll need a mild detergent, clean rags, and a brush to ensure a thorough cleaning of the fuel lines and fittings.

- Lubricant: A light machine oil or fuel line lubricant will be helpful for a smooth installation.

- Safety Gear: Safety goggles and gloves are essential to protect your eyes and hands during the process.

Prepare Your Workspace:

- Cleanliness is key. Clear a spacious area where you can work comfortably. Ensure the surface is free from debris and potential hazards.

- Lay down a drop cloth or old newspapers to catch any spills or debris. This protects your work area and surrounding surfaces.

- Gather all the tools and materials in one place. Organize them according to the steps of the installation process to avoid any confusion.

- If you have a workbench or table, ensure it is sturdy and provides enough space for the fittings and fuel lines.

Clean and Inspect:

- Start by cleaning the existing fuel lines and fittings. Remove any dirt, rust, or debris using the cleaning supplies. Pay attention to the threads and connections.

- Inspect the fittings for any signs of damage or wear. Replace any faulty parts before proceeding.

- Ensure that the fuel lines are in good condition and free from any leaks or cracks.

Organize and Plan:

- Lay out the new fuel lines and fittings in the order you intend to install them. This visual planning will help you stay organized.

- If you're working on a complex system, consider sketching out the layout to ensure proper placement.

- Have a supply of hose clamps and lubricant nearby to facilitate quick adjustments and tightenings.

By following these preparation steps, you'll create a structured and safe environment for the installation of Dorman Quick Connect Fuel Line Fittings. This organized approach will make the entire process more efficient and less prone to errors.

Fixing a Broken Fuel Line: Can You Trick a Truck?

You may want to see also

Fuel Line Inspection: Check for damage, ensuring compatibility with fittings

Fuel lines are a critical component of any vehicle's fuel system, and regular inspection is essential to ensure optimal performance and safety. When it comes to inspecting fuel lines, a thorough check for damage is paramount. This process involves a visual examination and a series of tests to identify any potential issues. Here's a step-by-step guide to help you inspect your fuel lines effectively:

Start by visually inspecting the fuel lines for any visible signs of damage. Look for cracks, cuts, punctures, or any other abnormalities along the length of the line. Pay close attention to areas where the line connects to fittings, pumps, or the fuel tank. Even small tears or frays can lead to fuel leaks, which can be dangerous and cause engine misfires. Check for any signs of corrosion or rust, especially if the fuel lines are exposed to the elements. Corrosion can weaken the line over time, making it more susceptible to damage.

Next, ensure that the fuel lines are compatible with the quick-connect fittings. Quick-connect fittings are commonly used for their ease of installation and removal, but they require specific fuel line types to function properly. Check the manufacturer's specifications for your vehicle's fuel lines and compare them with the fittings you intend to use. Using the wrong type of fitting can result in an improper seal, leading to fuel leaks and potential engine damage. Ensure that the fittings have a secure and tight connection to the fuel lines to prevent any fuel from escaping.

To further inspect the fuel lines, you can use a fuel line inspection kit, which typically includes a flexible probe and a light source. Insert the probe into the fuel line to check for blockages or debris. This is especially important if you suspect a previous fuel leak or contamination. The kit can help you identify any internal damage or obstructions that may not be visible to the naked eye. Additionally, listen for any unusual noises, such as hissing or roaring, which could indicate a damaged or leaking fuel line.

During the inspection, it's crucial to identify any potential sources of fuel contamination. Check for any signs of water or moisture in the fuel lines, as this can lead to corrosion and engine damage. If you notice any water accumulation, it may indicate a problem with the fuel tank or fuel pump. Addressing these issues promptly is essential to prevent further complications.

Remember, regular maintenance and inspection of fuel lines can help prevent costly repairs and ensure your vehicle's engine runs smoothly. By following these steps, you can effectively check for damage and ensure compatibility with quick-connect fittings, ultimately contributing to the overall reliability of your vehicle's fuel system.

Mastering Fuel Line Union Insertion: A Comprehensive Guide

You may want to see also

Fitting Selection: Choose the right size and type for your fuel line

When it comes to installing Dorman Quick Connect fuel line fittings, selecting the appropriate size and type is crucial for a successful and safe fuel system. Here's a guide to help you choose the right fittings:

Understanding Fuel Line Sizes: Fuel lines come in various diameters, typically measured in inches or millimeters. It's essential to know the diameter of your existing fuel line to ensure compatibility. Measure the inside diameter of the fuel line where the fitting will be connected. Common diameters for fuel lines range from 3/8" to 1/2" (9.5mm to 12.7mm). Always refer to the vehicle's manual or the manufacturer's specifications to determine the correct size for your application.

Fitting Types: Dorman offers a range of Quick Connect fittings, including compression, barbed, and sleeve-style connections. Compression fittings are ideal for rigid fuel lines and provide a secure seal using a compression nut and ferrule. Barbed fittings are commonly used for flexible fuel lines and feature a barbed end with an O-ring for a quick and easy connection. Sleeve fittings, also known as compressionless fittings, are designed for flexible lines and use a sleeve and ferrule for a tight seal. Choose the fitting type that matches the material of your fuel line.

Considering Flow Rate and Pressure: The flow rate and pressure of your fuel system should also influence your fitting selection. If your fuel line handles high-pressure fuel, consider fittings with a higher pressure rating to ensure reliability. Additionally, ensure that the flow rate of the fittings can accommodate the volume of fuel your engine requires. Higher flow rates might be necessary for performance applications or engines with larger displacement.

Material Compatibility: Dorman fittings are typically made from durable materials like brass, steel, or stainless steel. Ensure that the material of the fitting is compatible with the fuel type and system. For example, if you're working with ethanol-blended fuel, consider stainless steel fittings to prevent corrosion. Always check the manufacturer's recommendations for compatibility.

By carefully considering the size, type, flow rate, and material compatibility of the fittings, you can ensure a proper fit and reliable fuel delivery to your engine. Remember, using the correct fittings is essential for maintaining the integrity of your fuel system and preventing potential issues.

Mastering the Connection: A Guide to Fuel Line PZ-19

You may want to see also

Assembly Steps: Follow a step-by-step guide for secure installation

Before you begin the installation process, ensure you have the necessary tools and materials, including the Dorman quick-connect fuel line fittings, fuel line, and any required adapters or connectors. It is crucial to work in a well-ventilated area and wear appropriate personal protective equipment, such as gloves and safety goggles, to avoid any potential hazards.

Start by identifying the fuel line that needs to be connected. Locate the existing fuel line and mark its position to ensure you can reconnect it later. Carefully cut the fuel line to the desired length, ensuring it is slightly longer than the distance you plan to connect the new fittings. Use a fuel line cutter or a sharp, clean blade to make a precise cut.

Now, it's time to assemble the Dorman quick-connect fittings. Locate the male and female fittings and align them according to the manufacturer's instructions. Typically, the male fitting will have a protruding collar or ring, while the female fitting has a corresponding groove or socket. Slide the male fitting into the female fitting until it is fully engaged and secure. Ensure that the fittings are properly aligned and locked in place to prevent any fuel leaks.

Next, connect the fuel line to the male fitting. Insert the fuel line into the male fitting, ensuring it is aligned with the groove or socket. Apply a small amount of fuel line sealant or tape around the connection to provide an additional layer of protection against leaks. Tighten the fitting securely by hand, and then use a fuel line tool or a wrench to ensure a firm and leak-tight connection.

Finally, repeat the process for each additional fitting and connection required. Make sure to double-check all connections for tightness and security. Once all the fittings are installed, test the fuel system to ensure there are no leaks. Use a fuel pressure gauge or a simple test to verify the integrity of the connections. If everything is secure, you can now reconnect the fuel line to its original position and complete the installation.

Mastering Crimping: Quick Disconnect Fuel Line Connectors for Napa

You may want to see also

Testing: Ensure a tight seal and no leaks after installation

After installing the Dorman Quick Connect fuel line fittings, it's crucial to perform a thorough test to ensure a secure and leak-free connection. This step is often overlooked, but it's essential to guarantee the safety and efficiency of your fuel system. Here's a detailed guide on how to test for a tight seal and prevent any leaks:

Step 1: Prepare the System

Before testing, ensure the fuel line is properly connected to both the source and the destination. Check that all fittings are tightened according to the manufacturer's specifications. Use a torque wrench if available to ensure the correct amount of force is applied. This initial check will provide a baseline for your test.

Step 2: Apply a Leak Detection Method

There are several ways to detect leaks, and you can choose the one that suits your preferences. One common method is to use a soapy water solution. Fill a spray bottle with a mixture of dish soap and water. Spray this solution onto all connections, including the fittings, the fuel line, and any potential leak points. Pay close attention to the areas where the fittings are attached to the fuel line.

Step 3: Observe for Leaks

After applying the soapy water, observe the system carefully. Leaks will create bubbles where the liquid escapes. Check for any signs of bubbles or wet spots around the connections. If you notice any, it indicates a potential leak. Ensure you inspect all surfaces, as leaks can occur even if they are not immediately visible.

Step 4: Tighten Further if Necessary

If you identify any leaks, do not panic. Tighten the fittings slightly more, being careful not to over-tighten. Retest the system with the soapy water to ensure the leaks have been sealed. This process may require a few attempts to get the perfect fit, but it's essential for a reliable fuel line connection.

Step 5: Final Check

Once you're satisfied that there are no leaks, perform a final visual inspection. Check for any signs of damage, corrosion, or improper installation. Ensure that all components are in good condition and securely attached. This comprehensive testing process will give you confidence in the integrity of your fuel line fittings.

Remember, taking the time to test and ensure a tight seal is crucial for the overall performance and safety of your vehicle's fuel system. It's a simple yet effective way to prevent potential issues and maintain a reliable fuel supply.

1975 Eldorado Fuel Line: Size Guide for Rubber Lines

You may want to see also

Frequently asked questions

These fittings are designed to provide a secure and efficient connection for fuel lines in vehicles. They offer a quick and easy installation process, ensuring a tight seal to prevent fuel leaks and improve overall system performance.

Dorman Quick Connect Fuel Line Fittings are typically made of durable materials like brass or stainless steel, ensuring compatibility with various fuel line types. However, it's always recommended to check the specific dimensions and thread sizes to ensure a proper fit with your existing fuel line setup.

Installation is straightforward. Start by cleaning the fuel line ends and inserting them into the fittings. Ensure a tight connection by using the appropriate tools, such as a fuel line crimping tool. Tighten the fittings securely, but be careful not to overtighten, as it may damage the fuel line.

Yes, these fittings are designed for multiple installations. As long as the fittings and fuel lines are in good condition, you can reuse them. However, inspect the fittings for any signs of wear or damage before reinstalling to ensure optimal performance and safety.