Installing the fuel and return lines on a 1971 Le Mans car can seem daunting, but with the right tools and a methodical approach, it's a manageable task. This guide will walk you through the process step-by-step, ensuring you understand the importance of each component and how they work together to keep your engine running smoothly. From preparing the necessary tools and materials to connecting the lines properly, you'll learn the techniques to make your Le Mans car run like new again.

What You'll Learn

- Prepare Tools: Gather necessary tools like wrenches, pliers, and fuel filter

- Remove Old Fuel Line: Disconnect and carefully remove the old fuel line

- Install Fuel Filter: Securely attach the new fuel filter to the engine

- Connect Return Line: Route and connect the return line to the engine block

- Test and Adjust: Check for leaks and ensure proper fuel flow

Prepare Tools: Gather necessary tools like wrenches, pliers, and fuel filter

Before you begin the installation process, it's crucial to ensure you have the right tools and equipment to make the job efficient and effective. Here's a detailed guide on preparing the necessary tools for installing the fuel and return lines on a 71 Lehman:

Gather Wrenches and Pliers: Start by collecting a variety of wrenches and pliers, as these will be your primary tools for tightening connections and adjusting fittings. You'll need both standard and adjustable wrenches in different sizes to accommodate various bolt and nut sizes. For example, a 1/2-inch and 3/4-inch adjustable wrench will be versatile for different applications. Additionally, get a set of pliers, including slip-joint pliers and needle-nose pliers, which are essential for gripping small components and reaching tight spaces.

Fuel Filter Preparation: The fuel filter is a critical component of the fuel system, and you'll need to ensure it is in good condition before installation. Gather a new fuel filter that is compatible with your 71 Lehman model. Check the filter's specifications and ensure it matches the required size and flow rate. Having a clean workspace is also essential, so consider using a filter cleaning tool or a brush to remove any dirt or debris from the old filter, if you are replacing one.

Other Essential Tools: Besides the above, you might also require a few more items. A fuel line cutter or a sharp knife will help you trim the fuel lines to the appropriate length. Additionally, consider having a fuel line crimping tool or a pair of pliers with a crimping feature to secure the lines properly. Don't forget a funnel for filling the fuel tank and a container to catch any spills during the process.

By gathering these tools and ensuring you have everything readily available, you'll be well-prepared to tackle the fuel and return line installation on your 71 Lehman. This organized approach will make the task more manageable and efficient.

Perfect Fuel Line Fit for Your 1992 Polaris Trail Deluxe

You may want to see also

Remove Old Fuel Line: Disconnect and carefully remove the old fuel line

Before you begin the process of removing the old fuel line, it's crucial to ensure you have the necessary tools and safety precautions in place. Gather the appropriate tools, such as a fuel line disconnect tool or a pair of adjustable pliers, to safely and effectively disconnect the fuel line. Additionally, wear protective gear, including gloves and safety goggles, to shield yourself from any potential fuel spills or splashes.

Locate the fuel line that needs to be replaced. It is typically connected to the fuel tank and runs along the frame or under the vehicle. Identify the specific points where the fuel line is attached to the fuel tank, engine, and any other components. Carefully inspect the connections to ensure they are secure and intact.

Start by disconnecting the fuel line from the fuel tank. Locate the fuel line clamp or bracket that holds the line in place and use the appropriate tool to loosen and remove it. Be cautious not to damage the surrounding components during this process. Once the clamp is removed, gently pull the fuel line away from the fuel tank, ensuring you don't twist or kink the line.

Next, disconnect the fuel line from the engine or any other connected components. This may involve removing screws or clips that secure the line in place. Carefully follow the fuel line's path and identify the points where it connects to the engine or other parts. Use the appropriate tools to loosen and remove these connections, being mindful of any fuel lines that may be running alongside the engine.

As you remove the old fuel line, take note of its routing and any potential obstacles it may encounter. Carefully guide the line through any tight spaces or openings, ensuring it doesn't get caught or damaged. Once the fuel line is completely disconnected from the old system, you can proceed with the installation of the new fuel and return lines.

Understanding the Choke Fuel Line: A Car's Essential Component

You may want to see also

Install Fuel Filter: Securely attach the new fuel filter to the engine

To install the fuel filter on your 71 Lehman, you'll need to follow these steps carefully. Start by locating the existing fuel filter, which is typically found along the fuel line near the engine. Carefully inspect the old filter for any signs of damage or contamination. If it's in poor condition, replace it with a new one.

Once you've identified the correct position for the new filter, use the appropriate tools to remove the old one. This might involve loosening clamps or bolts that secure the filter in place. Take note of the orientation of the old filter, as you'll need to ensure the new one is installed in the same direction.

Now, take the new fuel filter and align it with the fuel line. Securely attach it using the provided clamps or bolts. Make sure the filter is tightly in place to prevent any potential leaks. Check for any signs of leakage around the filter and the connection points to ensure a proper seal.

After installing the fuel filter, it's crucial to test the system for any issues. Start the engine and listen for any unusual noises. Check for any leaks around the filter and the fuel lines. If everything is secure and there are no leaks, you can proceed to the next step of your project.

Remember, when working with fuel systems, it's essential to exercise caution and follow manufacturer guidelines. If you're unsure about any step, consult a professional mechanic to ensure a safe and successful installation.

Mastering Fuel Line Connections: A Guide to Two-Stroke Engines

You may want to see also

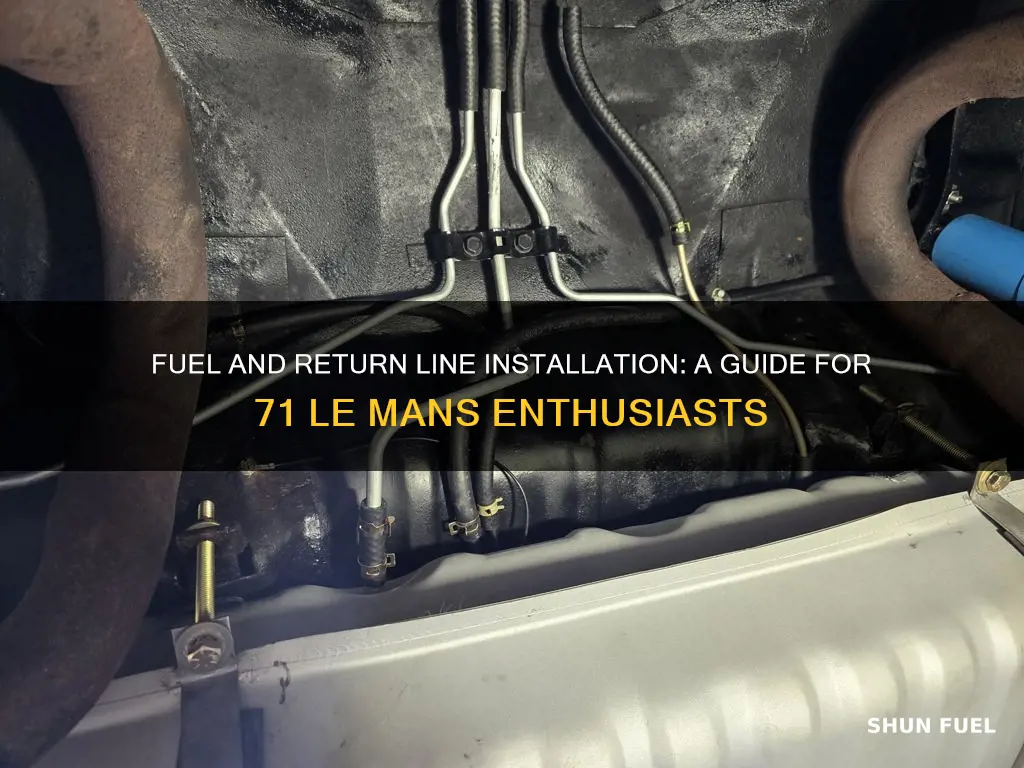

Connect Return Line: Route and connect the return line to the engine block

To connect the return line to the engine block, you'll need to carefully route the line and ensure a secure and leak-free installation. Here's a step-by-step guide:

- Locate the Engine Block: Start by identifying the engine block of your 71 Lehman. The return line will typically connect to the engine's internal passages, so locate the appropriate ports or openings on the block. These ports are usually marked or labeled for easy identification.

- Prepare the Return Line: Ensure that the return line is clean and free of any debris or contaminants. If necessary, use a brush or a cleaning tool to remove any dirt or old fuel residue. This step is crucial to prevent any blockages or contamination of the fuel system.

- Route the Line: Carefully plan the path of the return line. It should be routed in a way that avoids sharp bends or kinks, as these can cause restrictions or damage over time. Consider the engine's layout and any existing hoses or cables to determine the optimal route. Secure the line with appropriate ties or clips to keep it in place without causing any interference.

- Connect to the Engine Block: Now, it's time to attach the return line to the engine block. Use the appropriate fittings or adapters to ensure a tight and secure connection. Tighten the connections securely, but be careful not to overtighten, as this can damage the engine block or the line itself. Double-check that the connection is leak-free by applying a small amount of fuel to the connection and ensuring there are no drips or spills.

- Final Adjustments: Once the return line is connected, make any necessary adjustments to ensure it is properly aligned and secure. Check for any tight spots or areas where the line might rub against other components. Adjust the routing as needed to ensure a smooth and unobstructed flow of fuel.

Feet of Fuel Line: F-Body Engine Requirements

You may want to see also

Test and Adjust: Check for leaks and ensure proper fuel flow

After installing the fuel and return lines on your 71 Lehman, it's crucial to thoroughly test and adjust the system to ensure optimal performance and prevent any potential issues. Here's a detailed guide on how to check for leaks and ensure proper fuel flow:

Leak Detection:

Start by inspecting all connections and fittings for any signs of leaks. Use a soapy water solution as a simple and effective leak detection method. Apply the soapy water to each connection and observe for bubbles. Even the tiniest bubble indicates a potential leak. Pay close attention to areas where the fuel lines connect to the fuel tank, the engine, and the return line. If you notice any leaks, carefully tighten the fittings or consider replacing damaged components to ensure a secure and leak-free system.

Fuel Flow Assessment:

With the engine running, monitor the fuel flow to ensure it's functioning correctly. Check for any unusual noises, such as hissing or roaring, which could indicate a restriction or leak in the system. Listen for any changes in the engine's performance, such as stalling or hesitation, which might be caused by improper fuel delivery. If you notice any discrepancies, carefully inspect the fuel lines for blockages or kinks. Ensure that the fuel pump is functioning adequately by checking the pressure. You can use a fuel pressure gauge to measure the pressure at the fuel rail or injectors. Ideal pressure varies depending on the engine specifications, so consult the manufacturer's guidelines.

Adjustments and Fine-Tuning:

If you identify any issues during the testing phase, make the necessary adjustments. Tighten loose connections, replace worn-out gaskets, or consider using fuel line seals to prevent leaks. Ensure that the fuel lines are routed correctly, allowing for adequate clearance and avoiding any potential damage. Fine-tune the fuel system by adjusting the fuel pump settings or the carburetor (if applicable) to achieve the desired performance. This may involve altering the fuel-air mixture or the fuel pump speed to optimize power and efficiency.

Remember, thorough testing and adjustment are essential to guarantee the longevity and reliability of your 71 Lehman's fuel system. By carefully checking for leaks and ensuring proper fuel flow, you can identify and rectify any potential problems before they cause significant issues.

2010 Multistrada Fuel Line Location: Left or Right?

You may want to see also

Frequently asked questions

You will need a set of fuel and return line installation tools, including a fuel filter adapter, a fuel line cutter, and a fuel pump adapter. Ensure you have the necessary wrenches, pliers, and a fuel pressure gauge for a successful installation.

The fuel and return lines on a 71 Lehman are typically located under the engine, running along the frame rails. You may need to remove some engine components and access panels to get a clear view and access to the lines. Refer to the vehicle's manual for specific instructions on identifying the correct locations.

Yes, it is crucial to follow a step-by-step procedure. Start by disconnecting the old fuel and return lines, then clean the fittings and ensure they are free of debris. Install the new fuel filter adapter and secure it in place. Connect the fuel line to the adapter and route it to the fuel pump. Repeat the process for the return line, ensuring proper alignment and secure connections.

After completing the installation, start the engine and check for any leaks. Verify that the fuel pressure is within the recommended range using the gauge. Test-drive the vehicle to ensure smooth fuel delivery and proper operation of the fuel system. Monitor the engine's performance and address any issues promptly.