Volvo Trucks, renowned for their reliability and innovation, have been a leading player in the heavy-duty trucking industry. One of the key features that sets Volvo apart is its attention to detail, especially when it comes to fuel efficiency and performance. A critical component in achieving optimal fuel efficiency is the fuel system, and one specific aspect that has garnered interest is the equalizing fuel line. This feature is designed to ensure that fuel is distributed evenly to all cylinders, optimizing engine performance and reducing fuel consumption. In this paragraph, we will delve into the specifics of the equalizing fuel line in Volvo Trucks, exploring its design, benefits, and how it contributes to the overall efficiency and reliability of these vehicles.

| Characteristics | Values |

|---|---|

| Equalizing Fuel Line | Volvo trucks do not typically have equalizing fuel lines. |

| Fuel System Design | Volvo employs a conventional fuel system with a single main line and individual lines to each cylinder head. |

| Fuel Delivery | The fuel is delivered to the engine via a high-pressure common-rail system, ensuring precise injection. |

| Engine Type | Volvo offers both diesel and gasoline engines, with different fuel system configurations depending on the model. |

| Fuel Line Material | The fuel lines used in Volvo trucks are often made of high-quality materials like steel or rubber, designed to withstand high pressure and temperature. |

| Fuel Line Routing | Fuel lines are strategically routed to minimize vibration and potential damage, ensuring optimal performance and longevity. |

| Equalization Mechanism | There is no specific equalizing mechanism for fuel lines in Volvo trucks, as the design focuses on efficient fuel delivery and engine performance. |

What You'll Learn

- Fuel Line Design: Volvo trucks use a balanced fuel distribution system to ensure even power

- Performance Optimization: Equalizing fuel lines enhance engine performance and fuel efficiency

- Safety Features: These lines prevent fuel starvation and maintain stable engine operation

- Maintenance Tips: Regular checks ensure the lines remain unblocked and functional

- Environmental Impact: Efficient fuel usage reduces emissions and promotes sustainability

Fuel Line Design: Volvo trucks use a balanced fuel distribution system to ensure even power

Volvo Trucks, a renowned manufacturer of heavy-duty vehicles, has designed its fuel systems with a focus on efficiency and performance, particularly in the context of fuel distribution. One of the key innovations in their fuel line design is the implementation of a balanced or equalizing fuel distribution system. This system is crucial for ensuring that the fuel is delivered evenly to all cylinders, which is essential for optimal engine performance and fuel efficiency.

The balanced fuel distribution system in Volvo trucks is designed to counteract the effects of gravity and ensure that fuel is supplied to the engine cylinders at the same rate. This is particularly important in vehicles that operate at various angles, such as on uneven terrain or during maneuvers. By using this system, Volvo aims to maintain consistent engine power output, regardless of the vehicle's orientation. This design feature is a significant advantage, especially in heavy-duty applications where engine performance and reliability are critical.

In traditional fuel systems, fuel lines are often designed without considering the vehicle's operating angles, leading to uneven fuel distribution. This can result in reduced engine performance, increased fuel consumption, and even potential engine damage over time. Volvo's approach addresses these issues by ensuring that the fuel lines are positioned and routed in a way that promotes equalization, thus providing a steady and consistent fuel supply to all cylinders.

The design of this fuel distribution system involves careful placement of fuel pumps and lines to maintain a consistent pressure and flow rate. By doing so, Volvo trucks can deliver the required amount of fuel to each cylinder, ensuring that the engine operates at its peak efficiency. This level of precision in fuel delivery is a testament to Volvo's commitment to engineering excellence and its understanding of the critical role that fuel distribution plays in vehicle performance.

In summary, Volvo trucks' use of a balanced fuel distribution system is a sophisticated design feature that ensures even power delivery to the engine cylinders. This approach not only enhances the vehicle's performance but also contributes to improved fuel efficiency and overall reliability, making Volvo trucks a preferred choice for heavy-duty transportation needs. Understanding this design aspect can provide valuable insights into the engineering principles behind modern vehicle systems.

The Ultimate Guide to Choosing the Best 1-2 Fuel Line

You may want to see also

Performance Optimization: Equalizing fuel lines enhance engine performance and fuel efficiency

The concept of equalizing fuel lines is an essential aspect of optimizing engine performance and fuel efficiency, especially in heavy-duty vehicles like Volvo trucks. These lines play a crucial role in ensuring that fuel is distributed evenly to all cylinders, which directly impacts the engine's power output and overall efficiency. When fuel is not evenly distributed, it can lead to a phenomenon known as "fuel starvation" in certain cylinders, causing uneven combustion and reduced performance.

In Volvo trucks, the equalizing fuel line is a strategic design feature that addresses this issue. It is a dedicated fuel line that connects the main fuel supply to the engine's fuel injectors. This line is designed to maintain a consistent fuel pressure across all cylinders, ensuring that each cylinder receives the required amount of fuel for optimal combustion. By doing so, the equalizing fuel line helps to prevent the occurrence of "hot spots" or areas of uneven fuel distribution, which can lead to reduced power and efficiency.

The benefits of this design are twofold. Firstly, it ensures that the engine operates at its peak performance. With equal fuel distribution, all cylinders work in harmony, resulting in a more powerful and responsive engine. This is particularly important for heavy-duty trucks, where maintaining high performance is essential for efficient transportation and hauling. Secondly, equalizing fuel lines contribute to improved fuel efficiency. When fuel is used more efficiently, it reduces fuel consumption, leading to cost savings for fleet operators and a more environmentally friendly operation.

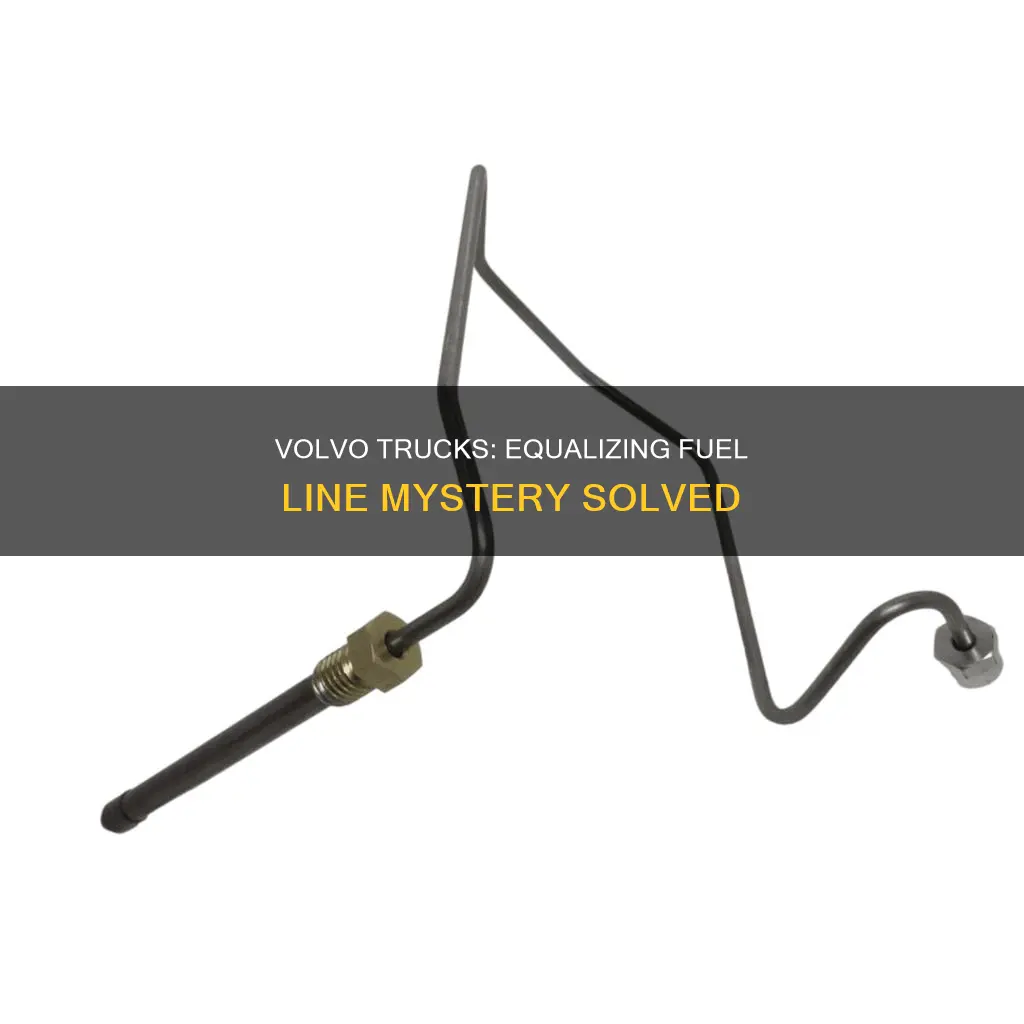

In terms of implementation, Volvo engineers have carefully designed the equalizing fuel line system to be robust and reliable. It is typically made from high-quality materials that can withstand the demanding conditions of heavy-duty trucking. The line is often equipped with precision-engineered connectors and valves to ensure a seamless and consistent fuel flow. Additionally, regular maintenance and inspection of this fuel line are recommended to ensure its longevity and optimal performance.

In summary, the equalizing fuel line in Volvo trucks is a critical component for performance optimization. It ensures even fuel distribution, leading to improved engine power and efficiency. This design feature showcases Volvo's commitment to delivering reliable and high-performing heavy-duty vehicles, making it a trusted choice for transportation and logistics companies worldwide. Understanding and maintaining this system can significantly contribute to the overall efficiency and longevity of Volvo trucks.

Best Sources for High-Quality Steel Fuel Lines

You may want to see also

Safety Features: These lines prevent fuel starvation and maintain stable engine operation

Volvo Trucks, renowned for their reliability and robust engineering, incorporate a crucial safety feature in their fuel system: equalizing fuel lines. These lines are designed to prevent fuel starvation and ensure stable engine operation, which is vital for the overall performance and safety of the vehicle. The primary function of equalizing fuel lines is to maintain a consistent fuel supply to the engine, especially during high-speed maneuvers or when the truck is in motion.

In the event of a sudden change in the truck's attitude, such as when it takes a sharp turn or experiences a rapid acceleration, the fuel lines equalize the pressure to ensure that the engine receives the required amount of fuel. This is achieved through a network of lines that connect the fuel tank to the engine, allowing for a balanced distribution of fuel. By preventing fuel starvation, these lines ensure that the engine operates optimally, maintaining power and performance even under challenging conditions.

The design of equalizing fuel lines is a critical aspect of Volvo Trucks' safety features. These lines are strategically placed to optimize fuel flow and minimize the risk of fuel accumulation in specific areas. The equalizing process is automatic and instantaneous, responding to the dynamic nature of the truck's operation. This real-time adjustment ensures that the engine receives the necessary fuel, even when the truck is navigating through varying terrains or experiencing changes in speed.

Furthermore, the equalizing fuel lines contribute to the overall stability of the vehicle. By maintaining a consistent fuel supply, they help prevent engine surges or stalls, which could lead to hazardous situations on the road. This feature is particularly important for long-haul trucking, where the truck may be driven over extended periods, and the driver's ability to control the vehicle is crucial.

In summary, the equalizing fuel lines in Volvo Trucks are a vital safety feature that ensures the engine receives a consistent fuel supply, preventing fuel starvation and maintaining stable engine operation. This design element showcases Volvo's commitment to engineering vehicles that are not only powerful but also prioritize the safety and performance of their drivers and the vehicle itself. Understanding and appreciating these safety features contribute to the overall reliability and trustworthiness of Volvo Trucks in the transportation industry.

Hydraulic Hose for Diesel Fuel: A Practical Guide

You may want to see also

Maintenance Tips: Regular checks ensure the lines remain unblocked and functional

Volvo trucks, renowned for their reliability and durability, are equipped with sophisticated fuel systems, including equalizing fuel lines, which play a crucial role in maintaining optimal fuel distribution to the engine. These lines are designed to ensure that fuel is delivered evenly to all cylinders, promoting efficient combustion and overall engine performance. However, like any component in a vehicle, equalizing fuel lines require regular maintenance to function effectively. Here are some essential maintenance tips to keep in mind:

Regular inspections are the cornerstone of maintaining the health of your Volvo truck's fuel system. It is recommended to inspect the fuel lines at least once a year or during routine service intervals. During these inspections, look for any signs of damage, such as cracks, leaks, or corrosion. Pay close attention to the connections and fittings, as these areas are prone to deterioration over time. Even a small puncture or leak can lead to fuel contamination and reduced engine performance. If you notice any issues, it's crucial to address them promptly to prevent further complications.

Keeping the fuel lines clear of debris and blockages is vital. Over time, dirt, rust, and other contaminants can accumulate in the lines, leading to restricted fuel flow. Regularly check for any blockages and ensure that the lines are clean. You can use a fuel filter to trap contaminants, and it's advisable to replace the filter according to the manufacturer's schedule. Additionally, maintaining a clean fuel tank is essential, as it helps prevent the buildup of sludge and ensures that the fuel lines remain unobstructed.

The condition of the fuel lines themselves is another critical aspect of maintenance. Volvo trucks often use high-quality materials for these lines, but they can still degrade over time due to factors like temperature fluctuations and fuel quality. Inspect the lines for any signs of wear, such as brittleness or softening. If you notice any deterioration, it may be necessary to replace the fuel lines to maintain optimal performance. Regularly checking the lines' flexibility and ensuring they are not kinked or damaged during routine maintenance tasks is essential.

In addition to visual inspections, it's beneficial to monitor the engine's performance regularly. Keep an ear out for any unusual noises, such as hissing or roaring sounds, which could indicate a problem with the fuel lines or other fuel system components. Also, pay attention to changes in engine behavior, such as reduced power, rough idling, or poor acceleration, as these could be early warning signs of fuel system issues. Addressing these symptoms promptly can save you from more extensive and costly repairs.

Lastly, always refer to the Volvo truck's owner's manual for specific maintenance guidelines and recommendations. The manual will provide detailed instructions on how to inspect and care for the fuel system, including the equalizing fuel lines. Following the manufacturer's guidelines ensures that your truck receives the proper care it needs to maintain its performance and longevity. Regular maintenance will help you avoid unexpected breakdowns and keep your Volvo truck running smoothly for years to come.

Understanding CPE Fuel Line: A Comprehensive Guide

You may want to see also

Environmental Impact: Efficient fuel usage reduces emissions and promotes sustainability

The concept of equalizing fuel lines in vehicles, particularly in heavy-duty trucks like Volvo, is an innovative feature designed to optimize fuel efficiency and reduce environmental impact. This system ensures that fuel is distributed evenly across the engine, maximizing power output while minimizing fuel consumption. By maintaining a consistent fuel pressure throughout the engine, the equalizing fuel line helps to prevent fuel wastage and promotes a more efficient combustion process. This efficiency directly translates to reduced emissions, as less fuel means fewer pollutants released into the atmosphere.

In the context of Volvo trucks, the implementation of equalizing fuel lines is a strategic move towards sustainability. These vehicles are renowned for their robust engineering and focus on environmental responsibility. By incorporating this technology, Volvo aims to enhance the overall performance and environmental credentials of its truck lineup. The equalizing fuel line system contributes to a more precise and controlled fuel injection process, ensuring that each cylinder receives the optimal amount of fuel required for efficient combustion.

The environmental benefits of this design are twofold. Firstly, it reduces the amount of fuel burned, which directly correlates to lower carbon dioxide (CO2) emissions. This is a significant advantage for the transportation industry, as heavy-duty trucks are known to produce substantial amounts of CO2, a major contributor to climate change. Secondly, the efficient fuel usage leads to reduced particulate matter and other harmful emissions, improving air quality and public health.

Moreover, the equalizing fuel line system can contribute to long-term cost savings for both the manufacturer and the end-user. By optimizing fuel efficiency, Volvo trucks can achieve better fuel economy, resulting in reduced fuel costs for businesses and individuals. This not only benefits the economy but also encourages a more sustainable approach to transportation, where environmental considerations are aligned with financial incentives.

In summary, the implementation of equalizing fuel lines in Volvo trucks is a practical step towards reducing the environmental footprint of the transportation sector. This technology promotes efficient fuel usage, leading to lower emissions and a more sustainable approach to heavy-duty trucking. As the industry continues to prioritize environmental responsibility, innovations like these will play a crucial role in shaping a greener future for transportation.

Wire-Lined Fuel Lines: Essential or Overkill?

You may want to see also

Frequently asked questions

An equalizing fuel line is a system designed to ensure that fuel is distributed evenly to all cylinders in an engine. For Volvo trucks, this is crucial as it helps maintain optimal engine performance, fuel efficiency, and power output. By balancing the fuel supply, the system prevents any cylinder from receiving too much or too little fuel, thus avoiding potential engine misfires and ensuring a smooth and reliable driving experience.

The equalizing fuel line system in Volvo trucks typically consists of a series of fuel lines, valves, and sensors. When the engine is running, the system continuously monitors the fuel pressure and flow rate. If a discrepancy is detected, the system adjusts the fuel supply to the affected cylinders, ensuring an even distribution. This real-time adjustment is vital for maintaining engine performance, especially during acceleration or when carrying heavy loads.

Yes, you can inspect your Volvo truck's fuel system to identify the equalizing fuel line. Look for fuel lines with specific markings or colors indicating their function. Additionally, check for any fuel pressure regulators, valves, or sensors located near the engine. These components are essential for the equalizing fuel line system's functionality. If you're unsure, consulting the vehicle's service manual or seeking professional advice is recommended.

The equalizing fuel line system offers several advantages. Firstly, it enhances engine performance by ensuring all cylinders receive the correct fuel-air mixture, resulting in improved power and torque. Secondly, it contributes to better fuel efficiency by optimizing the combustion process. This system also helps extend the engine's lifespan by reducing the risk of engine damage caused by improper fuel distribution. Overall, it provides a more reliable and efficient driving experience for Volvo truck owners.