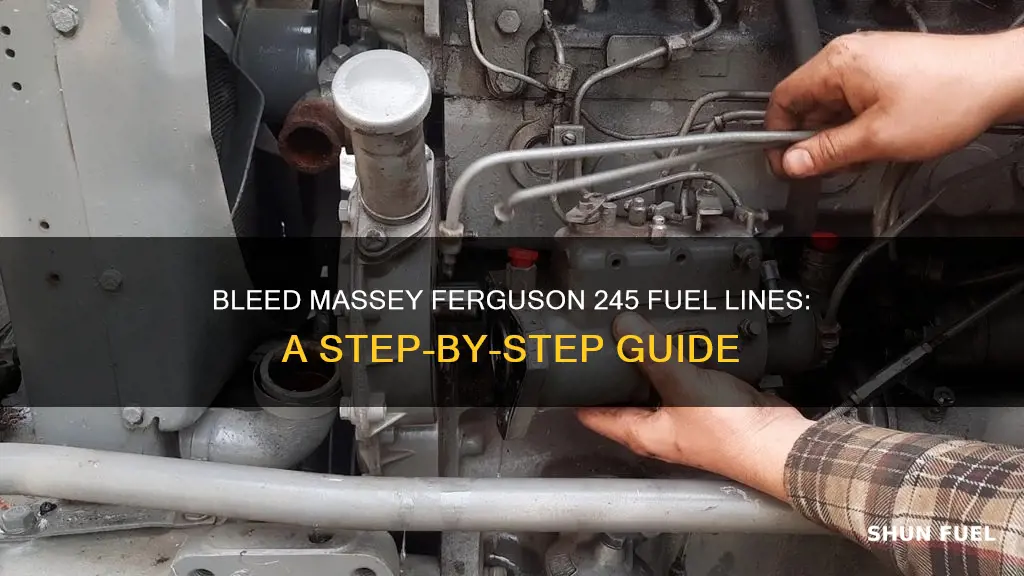

Bleed fuel lines on a Massey Ferguson 245 to ensure a consistent and reliable fuel supply to the engine. This process involves removing the fuel tank, disconnecting the fuel lines, and opening the lines to allow air to escape and fuel to flow freely. It's important to follow safety precautions, such as wearing protective gear and working in a well-ventilated area, to avoid fuel inhalation or spills. By carefully following the steps outlined in the owner's manual or a trusted repair guide, you can effectively bleed the fuel lines and maintain optimal performance of your Massey Ferguson 245.

| Characteristics | Values |

|---|---|

| Fuel System Type | In-line fuel pump |

| Fuel Tank Capacity | 12.5 gallons (47.3 liters) |

| Engine Displacement | 245 cubic inches (4.01 liters) |

| Bleed Procedure | 1. Turn the key to the "On" position. 2. Start the engine and let it run for a few minutes. 3. Locate the fuel line bleeder valve, typically near the fuel tank. 4. Open the bleeder valve to release any air or contaminants from the fuel lines. 5. Close the bleeder valve and restart the engine. 6. Repeat the process until the engine runs smoothly. |

| Tools Required | - Wrench or fuel line tool - Bleeder valve key - Rags or paper towels - Clean fuel |

| Safety Precautions | - Ensure the engine is cool before removing any fuel lines. - Use proper ventilation when working with fuel. - Avoid contact with hot engine components. - Dispose of used fuel properly. |

| Common Issues | - Clogged fuel lines - Air bubbles in the fuel system - Leaking fuel lines - Faulty fuel pump |

| Maintenance Tips | - Regularly check for fuel line damage. - Use fuel stabilizers to prevent sludging. - Keep the fuel tank full to maintain pressure. |

What You'll Learn

- Preparation: Ensure engine is off, and fuel tank is empty or drained

- Locate Lines: Identify fuel lines on the Massey Ferguson 245

- Bleeding Process: Open fuel line bleeder valves and release pressure

- Cleaning: Use fuel filter cleaner to remove contaminants

- Testing: Check for leaks and ensure proper fuel flow

Preparation: Ensure engine is off, and fuel tank is empty or drained

Before you begin the process of bleeding the fuel lines on your Massey Ferguson 245, it is crucial to ensure that the engine is turned off and the fuel system is properly prepared. This step is essential for your safety and the success of the procedure. Firstly, locate the fuel tank and drain any remaining fuel. This might require removing the fuel tank or using a drain valve, depending on your model. Make sure to drain the tank completely to avoid any fuel-related hazards during the bleeding process.

Once the fuel tank is empty, it's time to turn off the engine. Locate the engine's fuel shut-off valve, which is typically found near the fuel tank or the engine's fuel lines. Turn this valve to the 'off' position to prevent any fuel from flowing into the engine. It is important to allow the engine to cool down before proceeding, as working on a hot engine can be dangerous.

After ensuring the engine is off and the fuel tank is empty, you should also consider the location of the fuel lines. Identify the main fuel lines that connect the fuel tank to the engine. These lines are usually made of rubber or plastic and can be quite long. Mark their positions or take reference photos to ensure you can reconnect them correctly after the bleeding process.

Additionally, it is recommended to wear protective gear, such as gloves and safety goggles, to protect yourself from any potential fuel spills or splashes. This simple precaution can prevent skin irritation and eye irritation, ensuring a safer working environment.

By following these preparation steps, you are creating a safe and controlled environment for the fuel line bleeding process, which will be the focus of the next steps in the guide.

Stainless Steel Fuel Lines: Sealant Necessity Unveiled

You may want to see also

Locate Lines: Identify fuel lines on the Massey Ferguson 245

To begin the process of bleeding the fuel lines on your Massey Ferguson 245, you must first locate the fuel lines themselves. These lines are typically made of rubber or plastic and carry fuel from the tank to the engine. On the Massey Ferguson 245, the fuel lines are usually located along the frame, running from the fuel tank to the engine compartment. They are often secured with clips or ties to keep them in place.

Start by inspecting the engine compartment and look for any visible fuel lines. They might be running along the top or sides of the engine, depending on the specific model and year of your tractor. The fuel lines will typically be connected to the fuel pump and the engine's fuel injection system. Locate the fuel pump, as it is often a good reference point for finding the lines. The pump is usually located near the engine, and it will have a small electric motor and a few connections.

In addition to the main fuel lines, there may be smaller lines or hoses connected to the fuel filter and the engine's fuel rails. These smaller lines are often less visible but are crucial for the proper functioning of the fuel system. The fuel filter is typically located near the fuel tank, and the fuel rails are where the fuel injectors are connected. Identifying these smaller components is essential for a thorough inspection.

If you're having trouble finding the lines, refer to your Massey Ferguson 245's service manual. It will provide detailed diagrams and illustrations specific to your tractor model. These diagrams can help you identify the exact locations of the fuel lines and ensure you don't miss any important components. The manual will also guide you through the process of removing any necessary parts to access the fuel lines.

Once you have located all the fuel lines, you can proceed with the bleeding process, ensuring that you have the necessary tools and safety equipment ready. Remember to be cautious when working with fuel lines, as they can be delicate, and any damage could lead to fuel leaks. Proper identification of the lines is the first step towards successfully bleeding the fuel system on your Massey Ferguson 245.

Mastering the Fuel Line: A Step-by-Step Guide to Removing It from Your Petcock

You may want to see also

Bleeding Process: Open fuel line bleeder valves and release pressure

The bleeding process for fuel lines on a Massey Ferguson 245 involves a series of steps to ensure the fuel system is properly pressurized and free of air bubbles. Here's a detailed guide on how to open the fuel line bleeder valves and release pressure:

Locate the Bleeder Valves: Begin by familiarizing yourself with the fuel system of your Massey Ferguson 245. The bleeder valves are typically located near the fuel tank and along the fuel lines. They are often small, screw-on caps or valves that can be easily identified. It's important to note the positions of these valves to avoid confusion during the bleeding process.

Prepare the Equipment: Gather the necessary tools, including a fuel pump primer bulb, a clean rag, and a container to catch any fuel that may drain from the system. Ensure you have a stable work area and take necessary safety precautions, such as wearing protective gear and ensuring proper ventilation.

Open the Bleeder Valves: Locate the bleeder valves along the fuel lines. Start with the valve closest to the fuel tank. Use a suitable tool, such as a small wrench or pliers, to carefully open the valve. You should hear a hissing sound as air is released from the system. Allow the air to escape until the sound subsides. Repeat this process for each bleeder valve, ensuring you open them one at a time.

Release Pressure: As you open each valve, you'll need to release the pressure to allow the fuel to flow. This step is crucial to ensure the fuel lines are properly bled. When you hear the hissing sound, gently press the primer bulb to create a vacuum, drawing fuel into the bulb. Then, quickly release the bulb to allow the fuel to flow back into the system. This process creates a temporary vacuum, which helps to remove air bubbles. Repeat this action for each valve, ensuring a steady flow of fuel.

Catch and Dispose of Fuel: As you open the valves, some fuel may drain from the system. Place the container under the bleeder valves to catch any fuel that flows out. This is important to prevent fuel wastage and ensure a clean work area. Dispose of the collected fuel according to local regulations and guidelines.

Close the Valves and Test: Once you've opened and bled all the fuel line bleeder valves, carefully close them using the appropriate tools. Start the engine and allow it to idle for a few minutes. Check for any unusual noises or vibrations, ensuring that the fuel system is now properly pressurized and free of air bubbles.

Gasket Sealer for Fuel Lines: A Quick Fix or a No-Go?

You may want to see also

Cleaning: Use fuel filter cleaner to remove contaminants

To ensure optimal performance and longevity of your Massey Ferguson 245, it's crucial to maintain a clean fuel system, especially when dealing with fuel lines. One effective method to achieve this is by using fuel filter cleaner. This process involves the strategic application of fuel filter cleaner to eliminate contaminants and ensure the fuel system's health.

Fuel filter cleaner is a specialized product designed to dissolve and remove contaminants such as dirt, rust, and varnish from the fuel system. These contaminants can accumulate over time, leading to reduced engine performance, increased fuel consumption, and potential engine damage. By employing fuel filter cleaner, you can effectively clean the fuel lines and restore the engine's efficiency.

Here's a step-by-step guide on how to use fuel filter cleaner for cleaning fuel lines:

- Preparation: Begin by ensuring the engine is cool to the touch. This is essential to prevent any potential burns during the cleaning process. Additionally, park the tractor on a level surface and engage the parking brake for stability.

- Fuel Removal: Locate the fuel tank and carefully drain the fuel into a suitable container. This step is crucial to avoid any spills or contamination of the cleaner. Make sure to label the container to avoid confusion.

- Fuel Filter Access: Identify the fuel filter, which is typically located near the engine's fuel inlet. Carefully remove the fuel filter housing to gain access to the filter element. Take note of the filter's orientation to ensure proper reinstallation.

- Application of Cleaner: Pour the recommended amount of fuel filter cleaner into the fuel filter housing. Ensure that the cleaner comes into contact with all surfaces of the filter element. Allow the cleaner to sit for the specified time, usually a few minutes, to allow it to penetrate and dissolve contaminants.

- Rinsing: After the specified time has passed, rinse the fuel filter with a clean, degassed fuel to remove any loosened contaminants. Ensure that the fuel is properly degassed to prevent air bubbles from entering the system.

- Reinstallation: Reinstall the fuel filter, ensuring it is securely in place. Reattach the fuel filter housing and replace the fuel tank. This completes the cleaning process for the fuel lines.

By following these steps and using fuel filter cleaner, you can effectively remove contaminants from the fuel lines of your Massey Ferguson 245, ensuring optimal engine performance and longevity. Regular maintenance and cleaning of the fuel system are essential to keep your tractor running smoothly and efficiently.

Marine Fuel Line: Choosing the Right Option for Your Boat

You may want to see also

Testing: Check for leaks and ensure proper fuel flow

Before you begin the process of bleeding the fuel lines on your Massey Ferguson 245, it's crucial to understand the importance of testing for leaks and ensuring proper fuel flow. This step is essential to guarantee that your machine operates efficiently and safely. Here's a detailed guide on how to approach this testing process:

Leak Detection: Start by inspecting the fuel system for any signs of leaks. Locate the fuel lines, which are typically black in color, and examine them for any cracks, bulges, or damage. Pay close attention to connections, as these areas are prone to developing leaks over time. You can use a soapy water solution to test for leaks. Apply the solution to the fuel lines and connections, and if any bubbles appear, it indicates a potential leak. If you find any leaks, address them by replacing the damaged parts or tightening connections as necessary.

Fuel Flow Assessment: Proper fuel flow is critical for the engine's performance. Begin by ensuring that the fuel pump is operational and delivering fuel to the engine. You can check this by monitoring the fuel gauge or using a fuel pressure gauge if available. If the fuel flow is insufficient, it may indicate a clogged fuel filter or a problem with the fuel pump. Replace the fuel filter if it appears dirty or clogged. If the issue persists, consider consulting a mechanic to inspect the fuel pump and ensure it is functioning correctly.

Bleed Procedure: Once you've confirmed that the fuel system is leak-free and the fuel flow is adequate, you can proceed with bleeding the fuel lines. This process involves removing air bubbles from the system. Start by turning the key to the 'on' position and allowing the engine to idle. Then, locate the fuel bleed valves, typically found near the fuel tank. Open these valves and allow the engine to run for a few minutes. This action will help expel any remaining air bubbles. After a few minutes, close the bleed valves and check for any residual hissing sounds, which could indicate trapped air. If you hear any hissing, repeat the bleeding process until the sound disappears.

Post-Bleed Testing: After completing the bleeding process, it's essential to test the engine under various conditions. Start the engine and let it run for a while, ensuring it reaches its operating temperature. Check for any unusual noises or vibrations, as these could indicate issues with the fuel system. Additionally, monitor the engine's performance, including its response to throttle inputs and overall smoothness. Proper fuel flow and a well-bled system should result in a responsive and efficient engine.

Remember, regular maintenance and testing of the fuel system are vital to keeping your Massey Ferguson 245 in optimal condition. By following these steps, you can ensure that your machine operates safely and efficiently, providing reliable performance for your agricultural or construction needs.

Mastering the Art of Fuel Line Bending: A Comprehensive Guide

You may want to see also