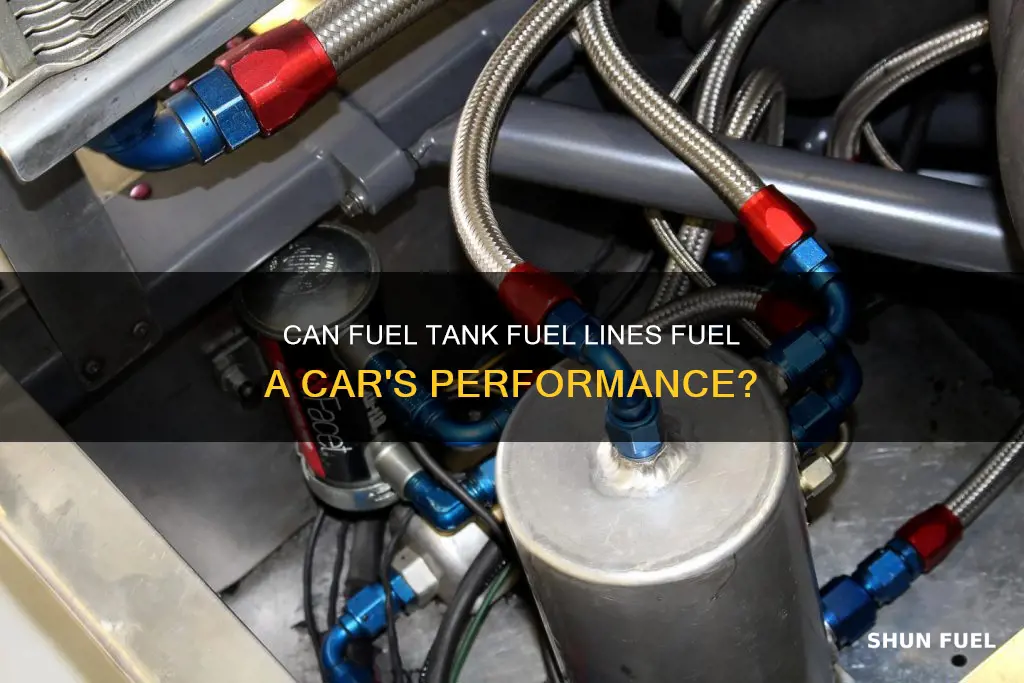

The fuel tank and fuel lines are critical components of a vehicle's fuel system, responsible for transporting gasoline from the tank to the engine. Over time, these lines can develop leaks, clogs, or damage, leading to reduced engine performance, increased emissions, and potential safety hazards. Regular maintenance and inspections are essential to ensure the fuel lines remain in good condition, preventing costly repairs and ensuring the vehicle operates efficiently and safely.

What You'll Learn

- Fuel Tank Capacity: Determine the size and volume of the fuel tank

- Fuel Line Material: Identify the type of material used for the fuel lines

- Fuel Pump Location: Locate the fuel pump and its functionality

- Fuel Filter Maintenance: Understand the maintenance requirements for the fuel filter

- Fuel System Diagnostics: Learn methods for diagnosing fuel system issues

Fuel Tank Capacity: Determine the size and volume of the fuel tank

When considering the fuel tank capacity of a vehicle, it's essential to understand the size and volume it can hold. This is a critical aspect of vehicle maintenance and performance, especially for those who frequently travel long distances or require a vehicle with a specific range. The fuel tank's capacity directly impacts the vehicle's range, and thus, its usability for various purposes.

To determine the fuel tank's size, you can start by checking the vehicle's manual or specifications. Most manufacturers provide detailed information about the vehicle's fuel system, including the tank's capacity. This information is typically found in the owner's manual, which is a valuable resource for any vehicle owner. The manual will specify the volume of the fuel tank in liters or gallons, giving you a clear understanding of its capacity.

For those who prefer a more hands-on approach, measuring the fuel tank's volume can be done using simple tools. A graduated cylinder or a measuring tape can be used to determine the tank's internal dimensions. By carefully measuring the length, width, and height of the tank, you can calculate its volume. This method provides an accurate assessment of the tank's capacity, ensuring that you have a clear understanding of how much fuel it can hold.

Additionally, it's worth noting that fuel tank capacity can vary depending on the vehicle's model and year. Different vehicles may have fuel tanks of varying sizes, and this information is crucial for proper fuel management. Understanding the specific capacity of your vehicle's fuel tank allows for better planning and ensures that you have sufficient fuel for your journeys.

In summary, determining the fuel tank capacity is a straightforward process that involves consulting the vehicle's manual or measuring the tank's dimensions. This knowledge is essential for optimizing vehicle performance, ensuring sufficient fuel supply, and making informed decisions regarding fuel consumption and vehicle maintenance. By taking the time to understand your vehicle's fuel tank capacity, you can enhance your overall driving experience and maintain your vehicle effectively.

Unraveling the Mystery: Why Animals Chew Fuel Lines

You may want to see also

Fuel Line Material: Identify the type of material used for the fuel lines

When it comes to the fuel lines in a vehicle, the material used is crucial for the overall performance and safety of the system. These lines are responsible for transporting fuel from the tank to the engine, and the choice of material directly impacts their durability and resistance to various factors.

The most common material used for fuel lines is rubber, specifically synthetic rubber compounds. Rubber is a popular choice due to its flexibility, which allows the lines to bend and move with the vehicle's components without restricting fuel flow. It also has good resistance to fuel-related chemicals, ensuring that the material doesn't degrade or become brittle over time. Additionally, rubber fuel lines are generally easy to install and can be connected to various fuel system components using standard fittings.

Another material used in some fuel lines is steel. Steel lines are known for their strength and durability, making them suitable for high-pressure applications. They are often used in older vehicles or in situations where the fuel lines need to withstand extreme temperatures. However, steel lines can be less flexible and more rigid, which might require careful routing to avoid damage.

In recent years, some manufacturers have started using synthetic rubber compounds reinforced with fibers, such as nylon or polyester. These composite materials offer enhanced flexibility and strength, making them ideal for modern fuel systems. The reinforced structure provides better resistance to fuel-related chemicals and can handle higher pressure, ensuring a reliable fuel supply.

Identifying the material of your fuel lines is essential for maintenance and replacement purposes. Rubber lines are typically black or dark-colored, while steel lines might appear silver or have a distinct coating. Composite materials can vary in color but often have a more uniform appearance. Understanding the material will help you choose the right replacement parts and ensure the longevity of your vehicle's fuel system.

Mastering the Art: Removing Fuel Line Fittings on Your 2008 RMZ450

You may want to see also

Fuel Pump Location: Locate the fuel pump and its functionality

The fuel pump is a critical component in any vehicle's fuel system, responsible for delivering fuel from the tank to the engine. Its location and functionality are essential to understand for vehicle maintenance and troubleshooting. Here's a detailed guide on locating and understanding the fuel pump:

Locate the Fuel Pump: The fuel pump is typically located inside the fuel tank or in close proximity to it. Its exact position can vary depending on the vehicle make and model. In many cars, the fuel pump is positioned at the rear or bottom of the fuel tank, often secured with brackets or mounting hardware. It is usually accessible by removing the rear or bottom panel of the tank. For some vehicles, especially older models, the fuel pump might be found outside the tank, connected to the fuel lines. In such cases, it is often located near the engine compartment, allowing for easier access during maintenance.

Fuel Pump Functionality: The primary function of the fuel pump is to pressurize and deliver fuel to the engine's carburetor or fuel injection system. When the ignition is turned on, the fuel pump activates and starts pumping fuel from the tank. This process ensures a steady supply of fuel to the engine, allowing it to start and run efficiently. The pump's operation is controlled by the engine control unit (ECU), which sends electrical signals to activate the pump when needed. This system ensures that the engine receives the correct amount of fuel for optimal performance and fuel efficiency.

In some modern vehicles, the fuel pump may be electric, powered by the battery. This design allows for more precise fuel delivery and can improve engine performance. Electric fuel pumps are often quieter and more reliable compared to their mechanical counterparts. Understanding the fuel pump's location and function is crucial for diagnosing issues related to fuel delivery, such as engine misfires or difficulty starting. Regular maintenance, including checking the pump's condition and ensuring proper fuel line connections, is essential to keep the vehicle's fuel system in good working order.

Fuel Line Fixes: A Guide to Common Issues and Solutions

You may want to see also

Fuel Filter Maintenance: Understand the maintenance requirements for the fuel filter

The fuel filter is a critical component in your vehicle's fuel system, responsible for removing contaminants and ensuring clean fuel delivery to the engine. Over time, this filter can become clogged or contaminated, leading to reduced engine performance and potential damage. Understanding the maintenance requirements for the fuel filter is essential to keep your vehicle running smoothly and avoid costly repairs.

Fuel filters typically require replacement at regular intervals, which can vary depending on the vehicle make and model, as well as driving conditions. As a general rule, it is recommended to replace the fuel filter every 30,000 to 50,000 miles. However, this can be influenced by factors such as the presence of contaminants in the fuel, the age of the vehicle, and the overall health of the fuel system. Regular maintenance and monitoring of the fuel filter's condition can help ensure optimal engine performance and longevity.

When performing fuel filter maintenance, it is crucial to use the correct type of filter recommended by the vehicle manufacturer. Using an incorrect filter can lead to improper fit, reduced filtration efficiency, and potential engine issues. Consult your vehicle's manual or seek professional advice to determine the appropriate filter size and specifications for your specific make and model.

During the replacement process, it is essential to follow a step-by-step approach. Start by locating the fuel filter, which is usually positioned near the fuel tank or along the fuel lines. Carefully remove the old filter, being mindful of any fuel that may spill. Clean the mounting surface and ensure a proper seal when installing the new filter. Tighten the filter securely, but avoid over-tightening, as this can damage the filter or fuel lines.

After replacing the fuel filter, it is advisable to perform a visual inspection of the fuel lines and connections. Check for any signs of damage, leaks, or corrosion. Ensure that all connections are tight and secure. If any issues are identified, address them promptly to prevent further complications. Regularly checking and maintaining the fuel system, including the fuel filter, will contribute to the overall reliability and performance of your vehicle.

Choosing the Right Hose for Your 1.4-Inch Fuel Line

You may want to see also

Fuel System Diagnostics: Learn methods for diagnosing fuel system issues

When it comes to diagnosing fuel system issues, understanding the fuel tank and its components is crucial. The fuel tank is a critical part of the fuel system, and any issues with it can lead to a variety of problems. Here's a guide on how to approach fuel system diagnostics:

Visual Inspection: Start by visually inspecting the fuel tank and its connections. Look for any signs of damage, corrosion, or leaks. Check the fuel tank for any visible cracks, rust, or contamination. Inspect the fuel lines for any bends, kinks, or signs of deterioration. Even minor damage can lead to fuel leaks, which can be dangerous and cause engine performance issues.

Fuel Pressure Testing: Fuel pressure is essential for proper engine operation. Use a fuel pressure gauge to measure the pressure at the fuel rail or injectors. Low fuel pressure can indicate issues with the fuel pump, fuel filter, or even the fuel tank itself. If the pressure is below the recommended range, it may be due to a clogged filter, a faulty pump, or a problem with the fuel tank's ability to hold pressure.

Fuel Pump Operation: The fuel pump is responsible for delivering fuel from the tank to the engine. To test it, listen for the pump's operation when the engine is running. A weak or non-functional pump will result in insufficient fuel flow. You can also use a fuel pressure tester to check the pump's performance by temporarily bypassing it and measuring the pressure rise.

Fuel Filter Inspection: Clogged or dirty fuel filters can restrict fuel flow and cause engine problems. Remove the fuel filter and inspect it for any signs of contamination or blockage. Cleaning or replacing the filter may be necessary to restore proper fuel delivery.

Engine Diagnostics: Engine-specific diagnostics can provide valuable insights. Check for error codes using an OBD-II scanner, which can indicate fuel-related issues. Monitor the engine's performance, such as idle quality, acceleration, and power output. Irregularities in these areas may suggest fuel system problems.

Remember, when dealing with fuel system diagnostics, safety should be a top priority. Always ensure the engine is cool before performing any inspections, and use appropriate personal protective equipment. If you're unsure about any aspect of the diagnostic process, consult a professional mechanic to ensure accurate and safe troubleshooting.

Fuel Line Repair: A Simple Fix or a Tricky Task?

You may want to see also

Frequently asked questions

Yes, absolutely! While it may require some specialized knowledge and tools, replacing the fuel tank and lines is a common restoration task for classic car enthusiasts. It's important to source genuine or compatible parts to ensure the vehicle's performance and safety.

Regular maintenance is key. It's recommended to inspect the fuel lines at least once a year or every 10,000 miles. Look for any cracks, leaks, or signs of deterioration, especially if your vehicle is older or has been in harsh conditions.

Fuel lines can be susceptible to damage from age, heat, cold temperatures, and chemical degradation. Over time, fuel can also cause corrosion, leading to leaks or blockages. Additionally, physical damage from accidents or rough terrain can result in punctures or cracks.

No, it is not advisable. Driving with a damaged fuel line can lead to fuel leaks, which pose serious fire hazards. It's crucial to address the issue promptly to ensure your safety and the proper functioning of your vehicle.

Regular maintenance and inspections are the best preventive measures. Keep your fuel tank and lines clean, use the recommended fuel type, and avoid driving over rough terrain that could damage the lines. Regularly checking for any signs of wear or damage will also help catch issues early on.