Taking off Ford fuel lines requires careful preparation and attention to detail to ensure a safe and efficient process. This guide will provide a step-by-step approach to removing fuel lines from a Ford vehicle, covering essential safety measures, identifying the correct tools, and understanding the specific procedures for different Ford models. By following these instructions, you can effectively disconnect the fuel lines, whether for maintenance, repairs, or modifications, while minimizing the risk of spills or damage.

What You'll Learn

- Location Identification: Locate fuel lines under hood, near tank, or in trunk

- Preparation: Turn off engine, release parking brake, and wear safety gear

- Fuel System Check: Ensure no fuel pressure, and drain any residual fuel

- Line Removal: Disconnect lines at fittings, using appropriate tools for each

- Reinstallation: Follow reverse process, securing lines and testing for leaks

Location Identification: Locate fuel lines under hood, near tank, or in trunk

When it comes to identifying the location of fuel lines on a Ford vehicle, it's important to understand that the placement can vary depending on the specific model and year. However, there are some general guidelines that can help you locate these important components.

Under the hood: The fuel lines are often located in the engine compartment, running from the fuel tank to the engine. These lines are typically positioned near the front of the engine bay, close to the firewall. You might find the fuel pump and lines connected to the engine's fuel injectors or carburetor. It's crucial to be cautious when working under the hood, as it can be a tight and dangerous space.

Near the fuel tank: Another common location for fuel lines is in the vicinity of the fuel tank, which is usually found in the front or rear of the vehicle's trunk or behind the rear seat. The fuel lines from the tank will lead to the engine, and you might also find the fuel pump and filter in this area. Accessing the fuel tank and its associated components requires removing the trunk or rear seat, depending on the vehicle's design.

In the trunk or rear compartment: In some Ford models, the fuel tank and associated lines might be positioned in the trunk or rear compartment. This is especially true for vehicles with a separate fuel tank and fuel lines that run to the engine in the front of the car. To access these components, you may need to remove the trunk lining or lift the floor panel, depending on the vehicle's design.

Remember, it's essential to consult the vehicle's manual or seek professional guidance if you're unsure about any specific steps or locations. Safety should always be a top priority when working with fuel lines.

Best Sources for High-Quality Steel Fuel Lines

You may want to see also

Preparation: Turn off engine, release parking brake, and wear safety gear

Before you begin the process of removing the fuel lines from your Ford vehicle, it is crucial to prioritize safety and ensure you have everything in order. Here's a detailed breakdown of the preparation steps:

Step 1: Turn Off the Engine

The first and most important safety measure is to switch off the engine. This is essential to prevent any accidental fuel release or engine operation during the removal process. Make sure the vehicle is in a secure and stable position, and then turn the ignition key to the 'Off' position. Allow a few moments for the engine to come to a complete stop. This simple step can significantly reduce the risk of accidents and potential hazards.

Step 2: Release the Parking Brake

Engaging the parking brake (also known as the emergency brake) can restrict movement and make it challenging to work on the fuel lines. To ensure a smooth and safe process, release the parking brake. This action will provide you with more accessibility and maneuverability, making it easier to handle the fuel lines and associated components.

Step 3: Wear Appropriate Safety Gear

Safety should always be a top priority when working on any vehicle. Put on your safety gear, including gloves and eye protection. Gloves will provide a better grip and protect your hands from potential sharp edges or hot surfaces. Eye protection is essential to shield your eyes from any debris, fuel spills, or potential splashes that might occur during the removal process. Taking these precautions ensures that you are well-protected and can focus on the task at hand without unnecessary risks.

By following these preparation steps, you are setting the foundation for a safe and efficient fuel line removal process. It is always advisable to take the necessary precautions to ensure your well-being and the success of the task. Remember, a little preparation goes a long way in preventing accidents and making your work more manageable.

Fixing a Fuel Line Leak: A Step-by-Step Guide for Push Mowers

You may want to see also

Fuel System Check: Ensure no fuel pressure, and drain any residual fuel

When performing a fuel system check on a Ford vehicle, it's crucial to ensure that there is no fuel pressure present and to drain any residual fuel to prevent potential hazards and ensure a thorough inspection. Here's a step-by-step guide to help you through this process:

Locate the Fuel Tank and Lines: Start by identifying the fuel tank and the fuel lines connected to it. Ford vehicles typically have a fuel tank located in the rear of the vehicle, and the fuel lines will run to the engine compartment. Carefully inspect the lines for any signs of damage, corrosion, or leaks.

Release the Fuel Pressure: To ensure safety, it is essential to release any fuel pressure in the system. Locate the fuel pressure relief valve, which is usually found near the fuel tank. This valve is often a small, screw-capped opening. Use a flathead screwdriver or a specialized tool to carefully pry the cap off, allowing the fuel pressure to be released. Be cautious as fuel can be hazardous, and it may spray out under pressure.

Drain Residual Fuel: With the fuel pressure released, it's time to drain any residual fuel from the system. Locate the fuel drain valve, which is typically a small opening near the fuel tank. Insert a suitable drain pan or container beneath the valve to catch any fuel that drains out. Open the valve and allow the fuel to drain completely. This step ensures that you are not introducing any contaminated fuel into the system during the check.

Check for Fuel Pressure with a Gauge: If you have access to a fuel pressure gauge, you can now check for fuel pressure. Connect the gauge to the fuel line, ensuring a secure connection. Turn the ignition to the 'on' position but do not start the engine. Read the gauge to verify that there is no fuel pressure present. This step helps identify any potential issues with the fuel pump or pressure regulator.

Safety Precautions: Throughout this process, always exercise caution. Wear protective gear, such as gloves and safety goggles, to protect yourself from any potential fuel spills. Ensure the vehicle is parked on a level surface and engage the parking brake to prevent accidental movement.

By following these steps, you can effectively ensure that the fuel system is free from pressure and any residual fuel, providing a safe and controlled environment for further inspection and repairs.

Mastering Snowmobile Fuel Direction: A Guide to Smooth Riding

You may want to see also

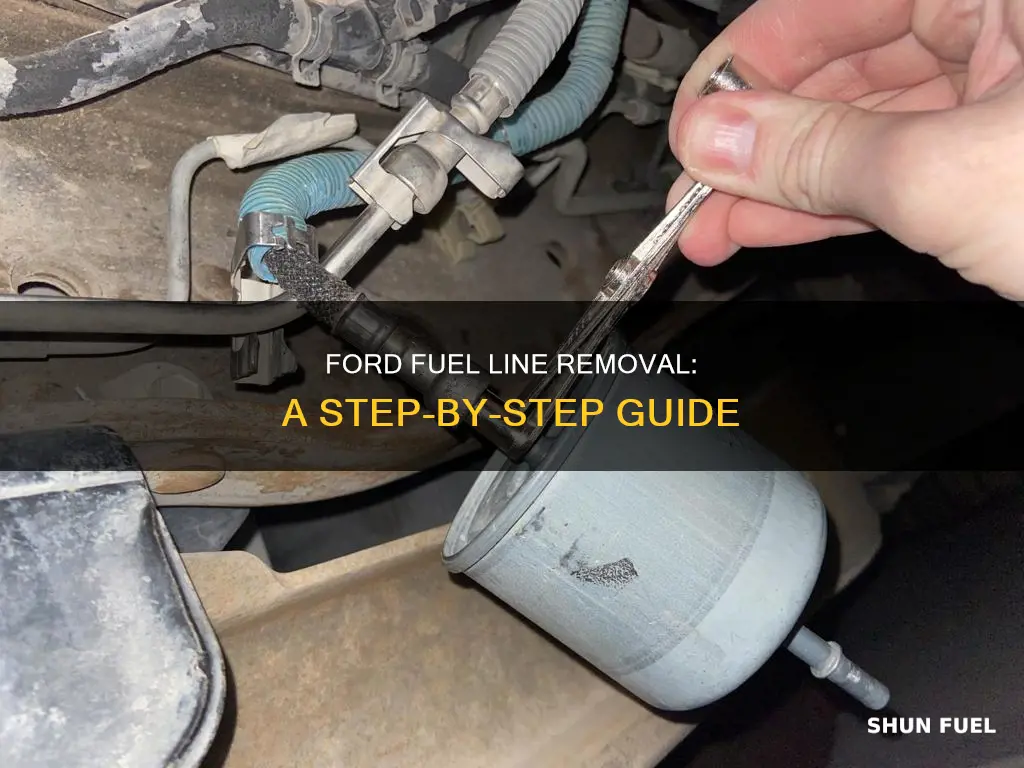

Line Removal: Disconnect lines at fittings, using appropriate tools for each

When it comes to removing fuel lines from a Ford vehicle, it's important to approach the task with care and precision. The process involves disconnecting the lines at their fittings, ensuring you use the right tools for each connection type. Here's a step-by-step guide to help you through this process:

Identify the Fittings: Before you begin, locate the fittings where the fuel lines connect to the engine, fuel tank, or other components. Ford vehicles typically use various types of fittings, including quick-connect fittings, clips, and bolts. Understanding the specific fittings on your vehicle is crucial for successful removal.

Gather the Right Tools: Different fittings require specific tools for disconnection. For quick-connect fittings, you'll need a fuel line disconnect tool or a similar specialized tool. These tools often have a V-shaped or U-shaped jaw that fits over the fitting, allowing you to release the connection. For fittings secured with clips or bolts, you'll need appropriate pliers, screwdrivers, or wrenches. Having the right tools will make the process much smoother.

Disconnect the Lines: Start by identifying the fitting you want to remove. If it's a quick-connect fitting, position the disconnect tool over the fitting and apply gentle pressure to release the connection. Be careful not to force it, as this can damage the fitting or fuel line. For fittings with clips or bolts, use the appropriate tool to carefully remove the clip or loosen the bolt, then pull the fitting away from the connection. Take your time to avoid stripping threads or damaging the fittings.

Follow the Order: When removing multiple fuel lines, it's essential to follow a logical order. Start with the lines that are easiest to access and work your way to more challenging connections. This approach helps prevent confusion and ensures you don't accidentally disconnect a critical line. Always refer to your vehicle's manual or a trusted repair guide to determine the correct sequence for your specific Ford model.

Inspect and Test: As you remove each fitting, inspect the fuel line for any signs of damage, cracks, or leaks. If you notice any issues, address them promptly. After removing all the lines, test the system to ensure there are no leaks. This step is crucial to identify any potential problems before reassembling the vehicle.

Remember, working with fuel lines requires patience and attention to detail. Take your time, use the appropriate tools, and always prioritize safety when performing any maintenance or repair tasks on your Ford vehicle.

Yamaha 250 TX-RS Outboard Fuel Line Dimensions

You may want to see also

Reinstallation: Follow reverse process, securing lines and testing for leaks

Reinstallation: A Step-by-Step Guide

Once you've removed the old fuel lines, it's time to get them back in place. Reinstalling the fuel lines is a straightforward process, but it requires careful attention to detail to ensure a secure and leak-free system. Here's a step-by-step guide to help you through the reinstallation process:

- Prepare the Components: Before you begin, ensure you have all the necessary components ready. This includes the new fuel lines, fittings, and any necessary tools. Check the lines for any signs of damage or wear, especially if they were previously replaced. Clean any debris or old fuel residue from the lines and fittings to ensure a proper connection.

- Reverse the Removal Process: Reinstalling the fuel lines is essentially the reverse of the removal process. Start by locating the fuel tank and identifying the existing fuel lines. Carefully slide the new lines into the designated ports, ensuring they are aligned correctly. Use the appropriate tools to secure the lines in place. This might involve tightening clamps or fittings with a wrench, being careful not to overtighten and risk damage.

- Secure the Lines: Properly securing the fuel lines is crucial to prevent leaks and ensure the system's integrity. Tighten the clamps or fittings securely, but be mindful of the torque specifications provided by the manufacturer. Over-tightening can damage the lines or fittings. Use a torque wrench if available to ensure you're applying the correct amount of force. Make sure the lines are taut and there is no excessive play or movement.

- Test for Leaks: After securing the fuel lines, it's essential to test for any potential leaks. Start the engine and allow it to idle. Inspect the lines and fittings for any signs of fuel escaping. Check for wet spots or stains around the connections, as these could indicate a leak. If you notice any leaks, carefully tighten the connections further or re-evaluate the installation process to identify and rectify the issue.

- Final Inspection: Once you've ensured there are no leaks, perform a final inspection of the fuel line installation. Check for any signs of damage, such as cracks or kinks in the lines. Verify that all fittings are tight and secure. It's a good practice to start the engine again and let it run for a few minutes to ensure the fuel system operates correctly under load.

Remember, taking the time to properly secure and test the fuel lines during reinstallation is vital for the safety and performance of your vehicle. Always refer to your vehicle's manual for specific instructions and torque specifications to ensure a successful and safe fuel system repair.

Optimizing Fuel Line Routing for Maximum Performance in Race Cars

You may want to see also

Frequently asked questions

When working with fuel lines, it's crucial to prioritize safety. Always ensure the engine is off and the vehicle is in a secure position to prevent any accidental movement. Locate the fuel lines, typically found under the hood, and identify the specific lines you need to disconnect. Use a fuel line disconnect tool or a pair of adjustable pliers to carefully release the clips or fittings, being mindful of any fuel that may spill.

The tools needed may vary slightly depending on the Ford model, but generally, you'll require a fuel line disconnect tool, which is a specialized tool designed to release the fittings securely. A set of adjustable pliers can also be useful for gripping and turning the fittings. Additionally, have a container ready to catch any spilled fuel, and ensure you have gloves and safety goggles for protection.

Yes, it's essential to follow a systematic approach when reconnecting fuel lines. Start by ensuring all fuel has been drained or the lines are dry to prevent contamination. Reattach the fuel lines to the corresponding fittings, making sure they are properly aligned and secured. Use fuel line connectors or tape to ensure a tight seal. After reconnecting, start the engine and check for any leaks. If no leaks are found, your fuel lines are now safely reconnected.