If you're dealing with a fuel line leak on your push mower, it's important to address the issue promptly to prevent further damage and ensure safe operation. Here's a quick guide on how to stop a fuel line leak and get your mower back in working order.

| Characteristics | Values |

|---|---|

| Problem Identification | Inspect the fuel line for any visible damage, cracks, or signs of deterioration. Look for areas where the line connects to the fuel tank, carburetor, or engine. |

| Fuel Line Replacement | If the fuel line is damaged or worn, replace it with a new one of the same diameter and material. Ensure a proper fit and secure connections. |

| Fuel Line Routing | Route the fuel line away from sharp edges, vibrations, and potential impact areas. Use protective sleeves or conduits if necessary. |

| Clamps and Connections | Check all clamps and connections for tightness and integrity. Replace any corroded or damaged clamps to ensure a secure seal. |

| Fuel Filter Maintenance | Regularly clean or replace the fuel filter to prevent contamination and ensure clean fuel flow. Clogged filters can lead to pressure buildup and potential leaks. |

| Engine Maintenance | Keep the engine in good condition. Regularly service and tune-up the mower to ensure proper fuel delivery and combustion, reducing the risk of fuel line issues. |

| Fuel Type Compatibility | Use the recommended fuel type for your mower. Different fuels have varying properties, and using the wrong type may cause corrosion or degradation of the fuel line. |

| Fuel Tank Inspection | Inspect the fuel tank for any signs of damage, leaks, or contamination. Ensure the tank is properly sealed and free from debris. |

| Weather Protection | Protect the fuel line from extreme weather conditions, especially if it's exposed to sunlight or extreme temperatures. Consider using protective covers or routing it indoors. |

| Regular Inspection | Perform routine inspections of the fuel system, including the line, tank, and connections. Address any issues promptly to prevent further damage. |

What You'll Learn

- Identify the Source: Locate the damaged section of the fuel line, often near the mower's engine or fuel tank

- Turn Off the Fuel Supply: Stop the leak by disconnecting the fuel line or turning off the fuel valve

- Use Fuel Line Repair Kit: Apply a repair kit for a quick fix, ensuring a tight seal

- Replace the Line: If the damage is severe, replace the entire fuel line for a long-term solution

- Tighten Connections: Ensure all connections are secure and tightened properly to prevent future leaks

Identify the Source: Locate the damaged section of the fuel line, often near the mower's engine or fuel tank

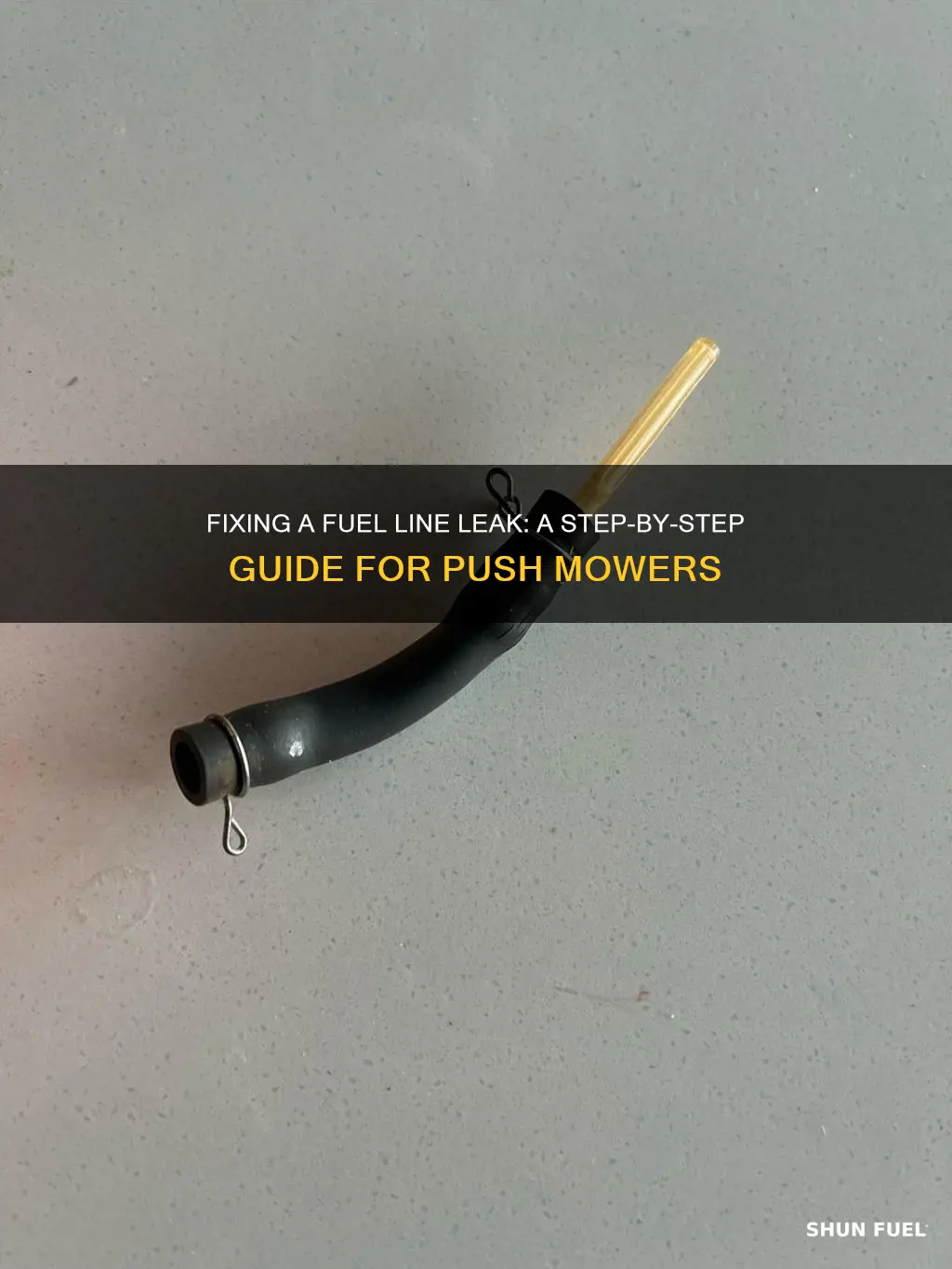

When dealing with a fuel line leak on a push mower, the first step is to identify the source of the issue. This is crucial as it helps you understand the nature of the problem and guides your repair efforts. The fuel line, a critical component responsible for delivering fuel from the tank to the engine, can develop leaks over time due to various factors such as wear and tear, damage from debris, or improper installation.

Locate the fuel line, which is typically a flexible tube running from the fuel tank to the engine. It is often positioned near the engine or the fuel tank, depending on the mower's design. Inspect the line for any visible signs of damage, such as cracks, punctures, or kinks. These visual indicators can provide valuable clues about the location of the leak. For instance, if you notice a bulge or a split in the line, that area is likely the source of the leak.

In some cases, the leak might not be immediately visible. If you suspect a hidden issue, it's essential to listen for any unusual sounds, such as hissing or fuel escaping, which could indicate a leak. Additionally, check for any fuel accumulation around the engine or under the mower, as this could be a sign of a leak.

Once you've identified the damaged section, it's important to act promptly. Delays in addressing the issue can lead to further complications and potential engine damage. If the damage is minor, you might be able to repair it by replacing the affected part of the fuel line. However, if the damage is extensive, you may need to replace the entire line.

Remember, proper identification of the leak source is the first step towards a successful repair. It ensures that you target the right issue and prevents further complications. Always exercise caution when working with fuel lines and consider seeking professional assistance if you're unsure about any part of the process.

Ford Fuel Pump: A Step-by-Step Guide to Removing the Fuel Line

You may want to see also

Turn Off the Fuel Supply: Stop the leak by disconnecting the fuel line or turning off the fuel valve

If you're dealing with a fuel line leak on your push mower, it's crucial to act quickly to prevent further damage and ensure safety. One of the most effective methods to stop the leak is by turning off the fuel supply. Here's a step-by-step guide to help you through the process:

- Locate the Fuel Line and Tank: Begin by identifying the fuel line, which is typically a flexible hose connecting the fuel tank to the engine. Locate the fuel tank, which is usually a small, cylindrical container attached to the mower's frame.

- Disconnect the Fuel Line: Carefully disconnect the fuel line from the fuel tank. This step requires caution as it involves handling potentially hazardous fuel. Ensure you are working in a well-ventilated area, and wear protective gear if necessary. When disconnecting, twist the fuel line counterclockwise to loosen the connection.

- Turn Off the Fuel Valve (if applicable): Some mowers are equipped with a fuel valve, often located near the fuel tank or engine. This valve controls the flow of fuel to the engine. If your mower has this feature, locate and turn it to the 'off' position. This will further restrict the fuel supply and help stop the leak.

- Secure the Disconnected Parts: Once the fuel line is disconnected, place it in a secure location away from the mower's moving parts to prevent accidental contact. If the fuel valve is turned off, ensure it remains in the 'off' position until the leak is completely resolved.

- Test and Reassemble: After disconnecting the fuel supply, test the mower to ensure the engine doesn't start. If the leak has stopped, you can reassemble the fuel line and secure it with the appropriate clamps. Ensure all connections are tight and secure to prevent future leaks.

Remember, when working with fuel, always prioritize safety. If you're unsure about any step, consult the mower's manual or seek assistance from a qualified mechanic to ensure the job is done correctly and safely.

Poulan Pro 4620 AVHD Fuel Line Size: Expert Guide

You may want to see also

Use Fuel Line Repair Kit: Apply a repair kit for a quick fix, ensuring a tight seal

If you're dealing with a fuel line leak on your push mower, a fuel line repair kit can be a convenient and effective solution. These kits are designed to provide a temporary fix, allowing you to get your mower back in operation while you consider more permanent repairs or replacements. Here's a step-by-step guide on how to use a fuel line repair kit to stop the leak:

Step 1: Prepare the Kit

Start by gathering all the components of the repair kit. Typically, it will include a specialized adhesive or sealant, a cleaning cloth, and possibly a small brush or applicator. Ensure you have the right amount of product for the size of the leak.

Step 2: Clean the Fuel Line

Before applying the repair, it's crucial to ensure the fuel line is clean and free of any debris or contaminants. Use the cleaning cloth provided in the kit to wipe down the affected area. This step ensures that the adhesive will bond effectively.

Step 3: Apply the Sealant

Take the sealant from the kit and carefully apply it to the leak. Follow the manufacturer's instructions for the specific product you are using. Typically, you will need to squeeze the sealant onto the leak and then use the provided applicator or your finger to spread it evenly. Make sure to cover the entire damaged area.

Step 4: Allow it to Set

After applying the sealant, let it set according to the instructions. This process might involve waiting for a specified amount of time or ensuring the area is dry. Avoid operating the mower or placing any weight on it during this time to prevent the sealant from curing prematurely.

Step 5: Test and Monitor

Once the sealant has set, test the mower to ensure the leak has stopped. Run the engine and check for any signs of fuel leakage. If the leak persists, you may need to consider more extensive repairs or consult a professional. However, for a quick fix, this method can be highly effective.

Remember, while a fuel line repair kit can provide a temporary solution, it's essential to address the underlying issue to prevent further leaks. If the leak is frequent or severe, it might be best to consult a lawn care expert or a mechanic to ensure a safe and long-lasting repair.

80 CB750 Fuel Line: Location and Connection Guide

You may want to see also

Replace the Line: If the damage is severe, replace the entire fuel line for a long-term solution

If you've identified a severe fuel line leak on your push mower, it's crucial to address the issue promptly to prevent further damage and ensure safe operation. Replacing the fuel line is a recommended long-term solution when the damage is extensive. Here's a step-by-step guide to help you through the process:

- Prepare the Necessary Tools and Materials: Before you begin, ensure you have the required tools and components. You'll need a new fuel line that is compatible with your mower model, a fuel filter (if applicable), and basic hand tools such as wrenches, screwdrivers, and a fuel pump primer bulb. It's also a good idea to have a clean workspace and some rags to catch any spills.

- Drain the Fuel Tank: Safety should be your top priority. Start by draining the fuel tank to prevent any potential hazards. Locate the drain valve, which is usually found at the bottom of the tank, and open it to release the fuel. Allow the tank to drain completely, and consider using a fuel container to collect the drained fuel for proper disposal or recycling.

- Locate and Remove the Old Fuel Line: Access the fuel line that needs to be replaced. This line typically runs from the fuel tank to the engine's fuel inlet. Carefully cut or sever the damaged section of the fuel line, ensuring you leave enough length to connect the new line. Remove any clamps or brackets holding the old line in place, and set the old fuel line aside for disposal.

- Install the New Fuel Line: Take your new fuel line and carefully route it from the fuel tank to the engine's fuel inlet, following the original path. Ensure the line is not pinched or kinked, as this can cause future issues. Secure the new line with the appropriate clamps or brackets, making sure it is tightly fastened but not overly tight, which could restrict fuel flow.

- Test and Adjust: After installing the new fuel line, it's essential to test the system. Reconnect the fuel pump and prime the engine according to the manufacturer's instructions. Start the mower and let it run for a few minutes to ensure the fuel is flowing correctly. Check for any leaks at the connections and make adjustments as needed.

- Finalize and Dispose of Old Parts: Once you've confirmed that the new fuel line is functioning properly, dispose of the old line responsibly. Fuel lines often contain hazardous materials, so check local regulations for proper disposal methods.

Replacing the fuel line is a more involved process, but it ensures a long-lasting solution to the leak. Always refer to your mower's manual for specific instructions and safety guidelines when performing any maintenance or repairs.

Beetle Fuel Supply Line: Frame Type 1 Unveiled

You may want to see also

Tighten Connections: Ensure all connections are secure and tightened properly to prevent future leaks

When dealing with fuel line leaks on a push mower, one of the most critical steps is ensuring that all connections are secure and tightened properly. This process is essential to prevent future leaks and maintain the integrity of your mower's fuel system. Here's a detailed guide on how to tighten connections effectively:

Start by identifying all the fuel lines and connections on your mower. These are typically located near the fuel tank and the engine. Look for any loose fittings, fittings that have become corroded, or those that show signs of damage. It's important to inspect both the fuel lines and the corresponding fittings or connectors. Over time, vibrations from the engine and movement during use can cause connections to loosen, leading to potential leaks.

Use the appropriate tools to tighten these connections. A standard socket or wrench is usually sufficient for most fuel line fittings. However, some may require a specialized tool, especially if they have a unique design or are made of a specific material. When tightening, apply firm pressure but be careful not to overtighten, as this can damage the fittings or fuel lines. The goal is to achieve a secure connection without forcing anything, ensuring that the threads or locking mechanisms are engaged properly.

Pay close attention to the direction of tightening. Many fuel line connections have a specific orientation to ensure a proper seal. Follow the manufacturer's guidelines or consult the mower's manual if available. This ensures that you are tightening the connections in the correct direction, which is crucial for a reliable seal.

After tightening, check the connections again to ensure they are secure. You can do this by gently wiggling the fittings to see if they feel tight and stable. If any connections still feel loose, re-tighten them using the appropriate force. It's better to be thorough and double-check all connections to avoid any future issues.

By following these steps, you can effectively tighten the connections on your push mower's fuel lines, preventing leaks and ensuring a reliable fuel supply to the engine. Regular maintenance and inspection of these connections will also contribute to the overall longevity of your mower.

Mastering the Art: A Step-by-Step Guide to Removing Fuel Line Connectors from Nylon Hoses

You may want to see also

Frequently asked questions

A leaking fuel line can be a common issue with push mowers, often caused by damage, corrosion, or improper installation. To fix this, start by identifying the source of the leak. If the line is cracked or damaged, replace it with a new one of the same diameter and material. Ensure a tight connection by using the appropriate fittings and tightening them securely. Check for any clogs or blockages in the line and clear them if necessary. If the issue persists, consider consulting a professional for further assistance.

Fuel lines can leak due to several reasons. Over time, the lines can become brittle and crack due to exposure to sunlight, heat, or cold temperatures. Corrosion from fuel contamination or moisture can also weaken the line. Additionally, improper installation, such as tight connections or kinks, can lead to leaks. Regular maintenance and inspection of the fuel system are essential to prevent such issues.

While duct tape can provide a temporary solution, it is not recommended for a permanent fix. Duct tape may offer a quick fix by sealing the leak temporarily, but it is not designed for fuel lines and may not be compatible with the materials used. It can also lose its adhesive properties over time, leading to further issues. For a long-lasting solution, it's best to replace the fuel line or seek professional repair.

Regular maintenance and inspections are crucial to prevent fuel line leaks. It is recommended to inspect the fuel system at least once a month, or more frequently if you use your mower regularly or in varying weather conditions. Look for any signs of damage, corrosion, or disconnection. Check for fuel leaks by applying a small amount of soapy water to the fuel lines and observing for bubbles. Promptly address any issues to ensure safe and efficient operation of your push mower.