Understanding how to safely and effectively remove a sleeve from a metal fuel line is crucial for vehicle maintenance and repairs. This process involves carefully disconnecting the sleeve, which acts as a protective covering, to access the fuel line for inspection, repair, or replacement. It requires a systematic approach, including identifying the correct tools and following a step-by-step procedure to ensure the fuel line remains intact and the sleeve is removed without causing damage. This guide will provide a detailed, step-by-step process to help you navigate this task efficiently and safely.

What You'll Learn

- Preparation: Gather tools, wear safety gear, and inspect the fuel line for damage

- Location: Identify the fuel line's position, often under the vehicle's hood

- Access: Loosen fittings, remove any obstructions, and create space for the sleeve

- Removal: Carefully pull the sleeve off, avoiding damage to the fuel line

- Replacement: Install a new sleeve or repair the existing one if necessary

Preparation: Gather tools, wear safety gear, and inspect the fuel line for damage

Before attempting to remove the sleeve from a metal fuel line, it's crucial to prioritize safety and preparation. Here's a step-by-step guide to ensure a safe and efficient process:

Gather the Necessary Tools: Start by assembling the required tools for the job. You'll need a set of adjustable pliers or a fuel line removal tool, designed specifically for this purpose. Additionally, have a pair of gloves and safety goggles ready to protect your hands and eyes from any potential hazards. Consider using a fuel line cutting tool if the sleeve is severely damaged and needs to be removed and replaced.

Wear Appropriate Safety Gear: Safety should always be a top priority. Put on your gloves to protect your hands from sharp edges and potential fuel spills. Safety goggles are essential to shield your eyes from any debris or fuel that may spray during the process. Ensure that you are wearing appropriate clothing, avoiding loose items that could get caught in the fuel line.

Inspect the Fuel Line: Carefully examine the fuel line for any signs of damage or deterioration. Look for cracks, corrosion, or any visible wear and tear. Check for any leaks or spills around the sleeve's connection points. If you notice any significant damage, it might be best to consult a professional mechanic to ensure a safe and proper repair. Take note of the fuel line's condition, as this information will guide your next steps.

Prepare the Work Area: Set up your work area to minimize the risk of accidents. Place a drop cloth or old newspapers on the ground to catch any potential spills. Ensure you have a clear and stable surface to work on, away from any high-traffic areas or potential trip hazards. If possible, work in a well-ventilated area to avoid inhaling any fuel fumes.

By following these preparation steps, you'll be well-equipped to handle the task of removing the sleeve from the metal fuel line, ensuring a safe and controlled environment for the process. Remember, proper preparation is key to a successful and safe repair.

Fixing a Hard Plastic Fuel Line: A Repair Guide

You may want to see also

Location: Identify the fuel line's position, often under the vehicle's hood

When attempting to remove a sleeve from a metal fuel line, it's crucial to first locate the fuel lines under the vehicle's hood. This step is essential to ensure you have the right information and access to the necessary components. Here's a detailed guide on how to identify and locate the fuel lines:

Step 1: Inspect the Engine Bay

Start by opening the hood of your vehicle and taking a comprehensive look at the engine bay. Fuel lines are typically routed through this area to supply fuel from the tank to the engine. Look for any visible metal or rigid plastic lines connected to various parts of the engine. These lines are often color-coded or marked with labels to indicate their purpose.

Step 2: Identify the Fuel Tank and Pump

Locate the fuel tank, which is usually positioned at the front or rear of the vehicle, and the fuel pump, which is responsible for sending fuel through the lines. The fuel pump is often located near the tank or in the engine compartment. Identifying these components will help you understand the path of the fuel lines.

Step 3: Follow the Lines

Carefully trace the metal or rigid fuel lines from the fuel pump to the engine. These lines may be connected to various components such as the fuel injectors, carburetor (in older vehicles), or the engine's fuel rail. Look for any sleeves or protective covers that might be attached to the lines. These sleeves are often used to protect the lines from damage or to provide insulation.

Step 4: Check for Sleeve Attachment

Once you've identified the fuel lines, look for any sleeves or protective covers that are attached to the metal lines. Sleeves are typically made of a flexible material and are designed to fit over the metal line. They might be secured in place with clips, ties, or screws. Carefully inspect the lines to find the sleeve you want to remove.

Step 5: Prepare for Removal

Before attempting to remove the sleeve, ensure you have the necessary tools, such as a sleeve removal tool or a pair of pliers, depending on the design of the sleeve. If the sleeve is tightly secured, you might need to use a gentle yet firm force to loosen it. Take your time to avoid causing any damage to the fuel line or the surrounding components.

Mastering the Art: Fuel Line Removal Guide for 05 WRX

You may want to see also

Access: Loosen fittings, remove any obstructions, and create space for the sleeve

To access the metal fuel line and remove the sleeve, you'll need to follow a systematic approach to ensure a smooth process. Start by identifying the fittings that connect the fuel line to other components. Loosen these fittings using the appropriate tools, such as wrenches or pliers, being careful not to overtighten to avoid damage. It's crucial to work systematically, loosening one fitting at a time, especially if they are corroded or tightly secured.

Once the fittings are loosened, inspect the fuel line for any obstructions or debris that might be hindering the sleeve removal process. Clear any visible obstructions carefully to ensure a smooth path for the sleeve. This step is essential to prevent damage to the fuel line or the sleeve itself during removal.

Creating space for the sleeve is the next critical step. This might involve gently pulling the fuel line away from the fittings or using a soft-bristled brush to create a gap. Be cautious not to apply excessive force, as it could lead to damage. The goal is to create enough space to allow the sleeve to slide off without resistance.

If the sleeve is particularly stubborn, consider using a lubricant on the fittings and the fuel line to reduce friction. This can make the removal process easier and less likely to cause damage. Remember to wipe away any excess lubricant to prevent contamination of the fuel system.

By following these steps, you'll be well-prepared to safely and effectively remove the sleeve from the metal fuel line, ensuring the process is efficient and minimizes the risk of any issues during the operation.

Understanding 3/8 Fuel Line Dimensions: Inside Diameter Explained

You may want to see also

Removal: Carefully pull the sleeve off, avoiding damage to the fuel line

When it comes to removing a sleeve from a metal fuel line, it's crucial to approach the task with caution and precision to avoid any potential damage to the fuel line. Here's a step-by-step guide to ensure a successful and safe removal process:

Preparation: Before you begin, ensure you have the necessary tools, including a pair of gloves to protect your hands and a set of adjustable pliers or a fuel line removal tool. These tools will provide the grip and leverage needed to carefully extract the sleeve. It's also advisable to have a clean, dry workspace to prevent any contamination or damage to the fuel line.

Location and Access: Locate the sleeve you want to remove. Metal fuel lines are often found under the vehicle, near the engine compartment. Carefully inspect the sleeve to identify any unique markings or features that could aid in its removal. Ensure you have access to all necessary areas by lifting or moving any obstructions that might interfere with your work.

Grip and Pull: Position yourself comfortably, maintaining a stable stance. Place one hand on the sleeve, using your thumb and forefinger to create a secure grip. Apply gentle but firm pressure while pulling the sleeve away from the fuel line. If the sleeve is stubborn, use the pliers or fuel line removal tool to assist in the extraction process, applying steady pressure in the opposite direction of the sleeve's movement. Avoid sudden, forceful pulls that could lead to damage.

Avoiding Damage: As you carefully pull the sleeve off, pay close attention to the fuel line. Ensure that the sleeve is removed without causing any bends, kinks, or cuts in the metal fuel line. If you encounter resistance or feel the fuel line straining, adjust your grip or use the tool to ease the removal. Take your time; rushing could result in accidental damage.

Post-Removal Inspection: Once the sleeve is successfully removed, inspect the fuel line for any signs of damage. Check for bends, cracks, or any other abnormalities. If any issues are found, it may be necessary to repair or replace the fuel line to ensure optimal performance and safety. Properly dispose of the removed sleeve and any other waste materials in an environmentally friendly manner.

Ford Fuel Line Removal: Tips for a Tool-Free Process

You may want to see also

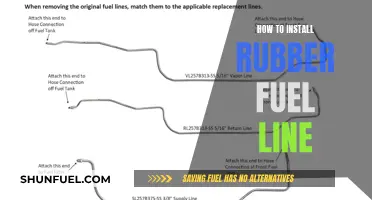

Replacement: Install a new sleeve or repair the existing one if necessary

When dealing with a metal fuel line that requires sleeve replacement or repair, it's essential to approach the task with precision and care. Here's a step-by-step guide to ensure a successful installation or repair:

Preparation: Begin by gathering the necessary tools and materials. You'll need a new sleeve that matches the fuel line's diameter and length, a set of wrenches or pliers for gripping, and possibly a fuel line cutter or a file for shaping. Ensure you have a clean workspace to avoid any contamination during the process.

Removing the Old Sleeve: Start by carefully cutting or slicing the old sleeve from the metal fuel line. Use a fuel line cutter or a sharp tool to make clean cuts. Take your time to avoid damaging the fuel line itself. Once the sleeve is removed, inspect the fuel line for any signs of damage or wear that may have contributed to the sleeve's deterioration.

Installing the New Sleeve: Now, it's time to fit the new sleeve. Slide the new sleeve onto the fuel line, ensuring it covers the entire damaged area. Use your hands or a pair of pliers to gently push the sleeve onto the fuel line, making sure it is securely in place. Test the fit by trying to move the sleeve; it should be snug but not overly tight. If necessary, use a file to gently shape the sleeve to ensure a perfect fit.

Securing the Connection: After the sleeve is in place, secure the connection. Use a suitable adhesive or sealant designed for fuel line applications to ensure a reliable bond. Apply the adhesive according to the manufacturer's instructions, being careful not to overapply. Allow the adhesive to cure as per the instructions before proceeding.

Testing and Final Checks: Once the adhesive is set, test the fuel line's functionality. Check for any leaks around the sleeve connection. Ensure that the fuel line is properly pressurized and that the sleeve is securely in place. If everything is in order, you've successfully replaced or repaired the sleeve, restoring the fuel line's integrity.

Fuel Line Cleaning: A Step-by-Step Guide to Restore Engine Performance

You may want to see also

Frequently asked questions

Removing a sleeve from a metal fuel line requires careful handling to avoid any fuel leaks or damage. Start by ensuring the fuel source is turned off and the line is depressurized. Use a pair of pliers or a sleeve removal tool designed for this purpose. Insert the tool into the sleeve and gently pull it off, being mindful of any sharp edges.

If the sleeve is difficult to remove, try applying a thin layer of lubricant around the sleeve and the fuel line. This can help reduce friction and make it easier to pull off. However, be cautious and ensure the lubricant doesn't come into contact with any electrical components nearby.

Yes, there are specialized tools available for sleeve removal, such as sleeve pullers or sleeve extraction kits. These tools often feature a curved or angled design to fit around the sleeve and provide a firm grip. They can make the process less strenuous and more controlled.

Reusing the sleeve depends on its condition. If the sleeve is still intact and free of any cracks or damage, it might be reusable. However, it's essential to inspect it thoroughly for any signs of wear and tear before reinstalling. Ensure proper cleaning and preparation of the fuel line before reusing the sleeve.

Safety is crucial when working with fuel lines. Always wear protective gloves and eye protection to guard against any potential splashes or debris. Be cautious of sharp edges on the fuel line and sleeve to avoid cuts. Keep a fire extinguisher nearby as a precaution, especially when working with metal components that may generate sparks.