Multi-port fuel injection (MPFI) is a sophisticated engine management system that delivers fuel to multiple intake ports simultaneously, optimizing combustion and performance. One crucial aspect of MPFI systems is the return fuel line, which plays a vital role in ensuring efficient fuel management. This paragraph will explore the necessity of a return fuel line in multi-port injection systems, examining its function, benefits, and potential challenges. By understanding the role of the return line, we can appreciate how it contributes to the overall efficiency and reliability of modern engines.

| Characteristics | Values |

|---|---|

| Multi-Port Injection | Does not typically require a return fuel line |

| Fuel Delivery System | Uses a fuel rail and injectors to deliver fuel directly to the intake ports |

| Return Fuel Line | Usually present in older systems to recirculate fuel to the carburetor or fuel pump |

| Modern Engine Design | Often employs a high-pressure fuel system with direct injection, eliminating the need for a return line |

| Efficiency and Performance | Multi-port injection systems focus on efficient fuel distribution to multiple cylinders, rather than recirculating fuel |

| Engine Management | Modern engines use sophisticated ECMs to control fuel injection, optimizing performance without a return line |

What You'll Learn

- Fuel Injection Basics: Multi-port fuel injection systems require a return fuel line to manage fuel pressure and ensure efficient operation

- Return Line Function: The return line recycles excess fuel, preventing engine flooding and optimizing fuel-air mixture

- Pressure Regulation: Multi-port injection needs a return line to regulate fuel pressure, ensuring precise fuel delivery

- Engine Performance: A return fuel line enhances engine performance by maintaining optimal fuel levels and combustion

- Maintenance Considerations: Regular maintenance of the return line is crucial for multi-port injection systems to prevent issues

Fuel Injection Basics: Multi-port fuel injection systems require a return fuel line to manage fuel pressure and ensure efficient operation

Multi-port fuel injection (MPFI) systems, commonly found in older engines, have specific requirements for efficient operation, and one of the key components that ensure their proper functioning is a return fuel line. This system is an evolution of the earlier carburetor-based fuel delivery, offering more precise control over the fuel-air mixture. In an MPFI setup, fuel is injected into the intake manifold, which is a network of passages that deliver air to the engine's cylinders. The fuel is injected at a precise rate and timing, ensuring optimal combustion.

The return fuel line is an essential part of this process as it serves multiple purposes. Firstly, it helps regulate and maintain the fuel pressure within the system. When fuel is injected into the manifold, the pressure needs to be carefully controlled to ensure the correct amount of fuel reaches each cylinder. The return line allows excess fuel to be recirculated back to the fuel tank or a reservoir, preventing a buildup of pressure that could lead to inefficient or uneven fuel distribution. This is crucial for maintaining the engine's performance and fuel economy.

Secondly, the return fuel line assists in the efficient operation of the MPFI system by facilitating the mixing of air and fuel. As fuel is injected, it creates a vapor that needs to be evenly distributed throughout the intake manifold. The return line ensures that this vapor is properly dispersed, allowing for a more uniform air-fuel mixture. This uniformity is vital for complete combustion, as it ensures that all cylinders receive the optimal fuel-air ratio, resulting in better engine performance and reduced emissions.

Furthermore, the presence of a return fuel line in MPFI systems provides a safety mechanism. If the engine were to stall or experience a sudden stop, the return line would allow excess fuel to be drained back into the tank, preventing a dangerous accumulation of fuel in the system. This is particularly important in applications where fuel injection is used in high-performance or racing engines, where rapid changes in speed and load can occur.

In summary, multi-port fuel injection systems rely on a return fuel line to manage fuel pressure, ensure proper fuel distribution, and maintain efficient engine operation. This design feature is a critical component of the overall fuel injection system, allowing for precise control of the fuel-air mixture and contributing to the engine's performance and longevity. Understanding these basics is essential for anyone working with or maintaining MPFI engines.

Airdog Fuel Line Routing: A Comprehensive Guide

You may want to see also

Return Line Function: The return line recycles excess fuel, preventing engine flooding and optimizing fuel-air mixture

The return fuel line is a critical component in multi-port fuel injection systems, and its function is often overlooked. This line plays a vital role in maintaining the engine's performance and efficiency by managing the fuel flow and ensuring optimal combustion. When a multi-port fuel injection system is used, it injects fuel into the intake manifold, which is then distributed to the cylinders. However, this process can lead to excess fuel being present in the system, especially during the initial stages of engine operation or when the engine is idling.

The primary function of the return line is to address this excess fuel and prevent engine flooding. Engine flooding occurs when too much fuel is present in the cylinders, leading to poor combustion and reduced engine performance. By recycling excess fuel, the return line ensures that the engine receives the precise amount of fuel required for efficient operation. This is achieved by routing the excess fuel back to the fuel tank or the fuel pump, where it can be reused or replenished as needed.

In a multi-port injection system, the return line is designed to maintain a balanced fuel-air mixture. It helps in achieving the correct air-fuel ratio, which is crucial for optimal engine performance and fuel efficiency. When the engine operates, the return line continuously monitors the fuel levels and adjusts the flow accordingly. This dynamic adjustment ensures that the engine receives the right amount of fuel at all times, preventing rich or lean conditions that can lead to decreased power and increased emissions.

Furthermore, the return line contributes to the overall longevity of the engine. By preventing engine flooding, it reduces the risk of excessive wear and tear on engine components, such as the valves and piston rings. Proper fuel management also minimizes the chances of carbon buildup, which can lead to reduced engine performance and increased maintenance requirements.

In summary, the return fuel line is an essential component in multi-port fuel injection systems. Its primary function is to recycle excess fuel, preventing engine flooding and optimizing the fuel-air mixture. This ensures that the engine operates efficiently, with the correct air-fuel ratio, and contributes to the overall reliability and longevity of the vehicle's powerplant. Understanding the role of the return line is key to maintaining and troubleshooting multi-port injection systems effectively.

Mastering the Art of Fuel Line Removal: A Guide for 02 Avalanche Owners

You may want to see also

Pressure Regulation: Multi-port injection needs a return line to regulate fuel pressure, ensuring precise fuel delivery

Multi-port fuel injection (MPFI) systems, commonly found in modern engines, require a return fuel line to maintain optimal performance and efficiency. This return line plays a crucial role in pressure regulation, which is essential for precise fuel delivery to the engine's cylinders. Here's a detailed explanation of why this component is necessary:

In a multi-port injection system, fuel is injected into the engine's intake ports, which are located at the top of the engine cylinders. This design allows for a more uniform fuel distribution across all cylinders, ensuring that each cylinder receives the correct amount of fuel for efficient combustion. However, to achieve this precise fuel delivery, the system relies on a carefully regulated fuel pressure. The return fuel line is integral to this process.

When the engine is running, the fuel pump supplies high-pressure fuel to the injectors. This pressure is critical to ensure that the fuel can overcome the engine's intake port pressure and be injected effectively. After the fuel is injected and the engine's combustion process has taken place, the used fuel, now in a vaporized state, needs to be returned to the fuel tank or the fuel pump. This is where the return line comes into play. The return line allows the used fuel to flow back to the fuel tank or the pump, creating a closed-loop system. This loop ensures that the fuel pressure remains stable and regulated, as the fuel volume and pressure are constantly being adjusted based on the engine's demand.

Without a return line, the fuel pressure would not be controlled effectively. The fuel would not be able to flow back to the tank or pump, leading to a continuous increase in pressure. This would result in overfilling the engine's cylinders with fuel, causing poor fuel-air mixture quality and potentially leading to engine misfires or reduced performance. Therefore, the return line is essential to maintain the correct fuel pressure and ensure that the engine receives the precise amount of fuel required for optimal operation.

In summary, the return fuel line is a critical component in multi-port injection systems, facilitating pressure regulation and enabling precise fuel delivery. It ensures that the engine operates efficiently and reliably, making it a vital part of modern engine technology. Understanding this process is key to appreciating the complexity and precision required in modern automotive engineering.

Fuel Line Hose: A Viable Power Steering Solution?

You may want to see also

Engine Performance: A return fuel line enhances engine performance by maintaining optimal fuel levels and combustion

The concept of a return fuel line is an essential component in engine design, particularly for those utilizing multi-port fuel injection systems. This system is a sophisticated method of delivering fuel to the engine's cylinders, ensuring precise control over the air-fuel mixture. When a multi-port fuel injection system is employed, it requires a return fuel line to function optimally. This line plays a critical role in maintaining the engine's performance and efficiency.

In a multi-port injection setup, fuel is injected into the intake manifold, which is a network of passages that deliver air to the engine's cylinders. The return fuel line is responsible for transporting excess fuel from the manifold back to the fuel tank or a reservoir. This process ensures that the fuel system remains balanced and that the engine receives the precise amount of fuel required for efficient combustion. By recirculating the fuel, the system prevents fuel accumulation in the manifold, which could lead to inefficient combustion and potential engine misfires.

The primary benefit of a return fuel line is its ability to maintain optimal fuel levels. In a multi-port injection system, fuel is distributed to multiple cylinders simultaneously. Without a return line, excess fuel in the manifold could lead to a rich air-fuel mixture, causing incomplete combustion and increased emissions. The return line mitigates this issue by ensuring that the fuel is properly managed, allowing for a leaner mixture and improved engine performance. This is especially crucial in high-performance engines where precise fuel control is essential for optimal power output.

Additionally, the return fuel line contributes to better combustion quality. By recirculating fuel, it helps to maintain a consistent fuel-air mixture throughout the engine's operation. This consistency ensures that each cylinder receives the correct amount of fuel, promoting efficient combustion and reducing the chances of engine knock or pre-ignition. As a result, the engine operates more smoothly, with improved power delivery and reduced emissions.

In summary, the return fuel line is a vital component in multi-port fuel injection systems, directly impacting engine performance and efficiency. It ensures optimal fuel management, prevents fuel accumulation, and promotes consistent combustion. By incorporating this design feature, engineers can create engines that deliver superior performance while maintaining a balanced and controlled fuel-air mixture. Understanding the role of the return fuel line is essential for anyone looking to optimize their engine's potential.

91 Mustang GT Fuel Line Removal: A Step-by-Step Guide

You may want to see also

Maintenance Considerations: Regular maintenance of the return line is crucial for multi-port injection systems to prevent issues

The return fuel line is an essential component of multi-port injection systems, and its maintenance is often overlooked but critical to the overall performance and longevity of the engine. Regular upkeep of this line is crucial to prevent various issues that can arise over time.

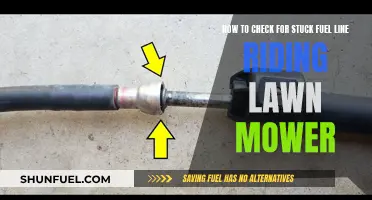

One of the primary reasons for maintaining the return fuel line is to ensure optimal fuel pressure regulation. Multi-port injection systems rely on precise fuel pressure to deliver the correct amount of fuel to each cylinder. Over time, the return line can develop restrictions or blockages, leading to a buildup of pressure. This can result in poor engine performance, reduced power, and even potential engine damage. Regular inspections and cleaning of the return line can prevent these issues, ensuring the system operates efficiently.

Another critical aspect is the prevention of fuel contamination. The return line is responsible for returning excess fuel from the injectors back to the fuel tank or reservoir. If this line becomes clogged or damaged, it can lead to fuel contamination. Contaminated fuel may contain water, debris, or other impurities, which can cause engine misfires, reduced fuel efficiency, and even permanent engine damage. Regular maintenance, including replacing the line when necessary, helps to keep the fuel clean and ensures the engine operates smoothly.

Furthermore, the return line's condition directly impacts the engine's fuel economy. A well-maintained return line ensures that the fuel system operates at its most efficient level. Clogged or damaged lines can lead to increased fuel consumption, as the engine may not be receiving the correct amount of fuel at the right time. Regular checks and maintenance can help identify and rectify these issues, improving the overall fuel efficiency of the vehicle.

In summary, regular maintenance of the return fuel line is vital for the proper functioning of multi-port injection systems. It helps prevent fuel pressure-related problems, fuel contamination, and ensures optimal fuel economy. By incorporating routine inspections and timely replacements, vehicle owners can extend the life of their engines and maintain reliable performance.

Maximizing Fuel Efficiency: The Role of Return Lines in Pumps

You may want to see also

Frequently asked questions

A return fuel line is an essential component in multi-port fuel injection (MPFI) systems. It serves the critical function of recirculating excess fuel back to the fuel tank or reservoir, ensuring efficient fuel management and preventing fuel accumulation in the system.

Yes, a return fuel line is typically required in most multi-port injection systems. It helps maintain proper fuel pressure, prevents fuel wastage, and ensures that the engine receives the correct fuel-air mixture for optimal performance.

By recirculating excess fuel, the return line helps regulate fuel pressure, reducing the risk of fuel starvation during high-load conditions. This ensures a consistent fuel supply, promoting better engine performance, especially during acceleration and high-speed driving.

Omitting the return fuel line is generally not recommended. It can lead to fuel pressure fluctuations, reduced engine efficiency, and potential performance issues. The return line plays a vital role in maintaining the overall health and performance of the MPFI system.

Regular inspection and maintenance of the return fuel line are essential. Over time, the line can become clogged with debris or fuel contaminants, requiring cleaning or replacement. It is also important to check for any leaks or damage to the line to ensure the system's proper functioning.