Installing a rubber fuel line is a crucial step in maintaining the integrity of your vehicle's fuel system. This process involves replacing worn-out or damaged lines with new, high-quality rubber fuel lines to ensure optimal performance and safety. The installation process typically begins with disconnecting the old fuel line from the engine and fuel tank, carefully removing any debris or old parts, and then securely attaching the new rubber fuel line, ensuring a tight and leak-free connection. This guide will provide a step-by-step overview of the installation process, offering valuable insights for vehicle owners looking to enhance their car's reliability and longevity.

| Characteristics | Values |

|---|---|

| Preparation | Clean the fuel line and ensure it is free of debris and old fuel. Inspect for any damage or leaks before installation. |

| Materials | New rubber fuel line, fuel line connectors, fuel filter, and fuel pump. |

| Tools | Wrenches, pliers, fuel line cutting tool, tape measure, and cleaning supplies. |

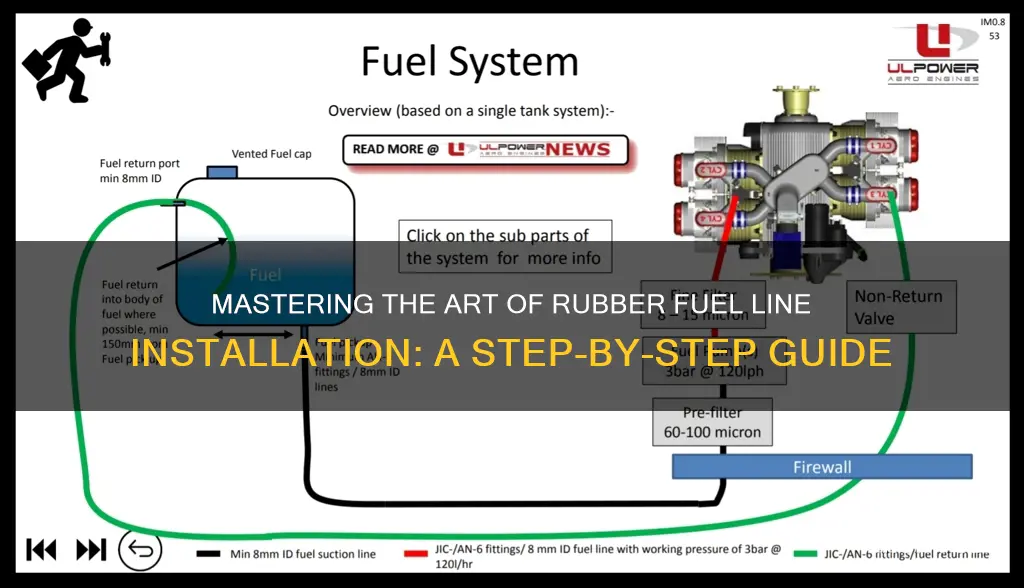

| Steps | 1. Cut the new fuel line to the desired length. 2. Connect the fuel line to the fuel pump and filter, ensuring a secure fit. 3. Route the fuel line through the engine compartment, following the manufacturer's diagram. 4. Secure the fuel line with clips or ties. 5. Test for leaks by starting the engine and checking for any fuel seepage. |

| Safety | Wear protective gear, including gloves and eye protection, when handling fuel. Ensure proper ventilation in the work area. |

| Maintenance | Regularly inspect the fuel line for wear and tear, especially after long periods of use or exposure to extreme temperatures. Replace if any damage is detected. |

What You'll Learn

- Prepare Tools: Gather necessary tools: wrench, fuel line cutter, tape measure, and safety gear

- Inspect Vehicle: Check for existing fuel lines, ensuring compatibility with new rubber lines

- Cut and Fit: Measure and cut rubber fuel line to length, then slide onto vehicle's fuel lines

- Secure Connections: Use clamps or ties to fasten new line securely, avoiding sharp bends

- Test and Inspect: Start engine, check for leaks, and ensure proper fuel flow

Prepare Tools: Gather necessary tools: wrench, fuel line cutter, tape measure, and safety gear

Before you begin the process of installing a rubber fuel line, it's crucial to gather all the necessary tools and equipment to ensure a smooth and efficient job. Here's a detailed guide on what you need to prepare:

Wrench: A wrench is an essential tool for any fuel line installation. You'll need a adjustable wrench or a pair of channel locks to grip and tighten the fuel line fittings securely. Make sure it fits your hand comfortably and is the appropriate size for the fittings you'll be working with.

Fuel Line Cutter: This specialized tool is designed to cut through fuel lines with precision. It ensures a clean and accurate cut, which is vital for a successful installation. Look for a fuel line cutter that can handle the thickness of the rubber fuel line you are working with.

Tape Measure: Accurate measurements are critical when installing fuel lines. A tape measure will help you determine the length of fuel line required and ensure a proper fit. It's best to opt for a flexible measuring tape that can bend around curves and tight spaces.

Safety Gear: Working with fuel lines requires caution to ensure your safety and the integrity of the system. Safety gear includes gloves to protect your hands from sharp edges and potential fuel spills. Safety goggles are essential to shield your eyes from any debris or splashes. Additionally, consider wearing old clothing or an apron to avoid stains from fuel.

Having these tools ready will make the installation process much more manageable and efficient. It's always a good practice to double-check your tool kit before starting any automotive project to avoid any last-minute hassles.

Fuel Line Installation: A Step-by-Step Guide to Success

You may want to see also

Inspect Vehicle: Check for existing fuel lines, ensuring compatibility with new rubber lines

Before you begin the installation of new rubber fuel lines, it's crucial to inspect your vehicle's existing fuel system to ensure compatibility and avoid any potential issues. This step is often overlooked but is essential for a successful and safe installation. Here's a detailed guide on how to inspect your vehicle for existing fuel lines and ensure compatibility with the new rubber lines:

Locate the Existing Fuel Lines: Start by familiarizing yourself with your vehicle's engine bay. Locate the fuel tank, which is typically located at the front or rear of the vehicle, depending on the model. From the fuel tank, you will find the fuel lines that run to the engine. These lines are usually made of rubber or a similar flexible material. Carefully trace the path of these lines to identify their connections and endpoints.

Check for Damage and Wear: Inspect the existing fuel lines for any signs of damage, cracks, or wear. Rubber fuel lines can degrade over time due to exposure to heat, sunlight, and chemicals in the fuel. Look for any soft spots, bulges, or areas where the line has become brittle. Also, check for any signs of leaks or corrosion at the connections. If you notice any significant damage, it may indicate that the line needs to be replaced, and you should consider using the new rubber lines for a fresh installation.

Measure and Compare: Take accurate measurements of the existing fuel lines, especially the length and diameter. This information is vital to ensure that the new rubber lines are compatible. Measure the distance from the fuel tank to the engine and any additional lengths required for connections. Compare these measurements with the specifications provided by the manufacturer of the new rubber fuel lines. Ensure that the new lines have the correct length and diameter to fit seamlessly into your vehicle's fuel system.

Identify Connections and Fittings: Pay close attention to the connections and fittings of the existing fuel lines. Note the types of connectors used, such as quick-release clips, screws, or clamps. Understanding these connections will help you choose the appropriate fittings for the new rubber lines. Ensure that the new lines have compatible fittings to securely attach to the existing system.

Consider Fuel Type and Compatibility: Different types of fuel, such as gasoline or diesel, may require specific fuel line materials and specifications. Check your vehicle's manual or consult the manufacturer's guidelines to ensure the new rubber fuel lines are compatible with the type of fuel your vehicle uses. This step is crucial to prevent any potential issues related to fuel compatibility.

By thoroughly inspecting your vehicle's existing fuel lines and considering the compatibility factors, you can ensure a smooth and successful installation of the new rubber fuel lines. This process requires attention to detail and a systematic approach to guarantee the safety and efficiency of your vehicle's fuel system.

Efficient EFI Systems: No Return Fuel Line Required

You may want to see also

Cut and Fit: Measure and cut rubber fuel line to length, then slide onto vehicle's fuel lines

Before you begin the installation process, it's crucial to measure the rubber fuel line accurately to ensure a proper fit. Start by inspecting the vehicle's existing fuel lines to determine the length required. Use a tape measure or a flexible measuring tool to carefully measure the distance between the fuel tank and the engine's fuel injection system or the desired connection point. Take note of any bends or angles in the line to ensure the new rubber fuel line can accommodate these. Accurate measurements are essential to avoid any unnecessary adjustments or potential leaks.

Once you have the measurements, it's time to cut the rubber fuel line. Using a sharp utility knife or a dedicated fuel line cutter, carefully slice through the rubber material. Ensure you cut straight and accurately, as any deviations could lead to an improper fit. If you're using a cutter, follow the manufacturer's instructions for the best results. It's important to cut the line slightly longer than the measured length to allow for any adjustments during the installation process.

After cutting the rubber fuel line to the desired length, carefully slide it onto the vehicle's existing fuel lines. Start by aligning one end of the new line with the corresponding fuel line on the vehicle. Use your hands or a soft cloth to gently push the new line onto the existing line, ensuring a secure connection. Take note of any O-rings or seals that may need to be aligned or inserted to create a watertight seal.

When sliding the rubber fuel line onto the vehicle's lines, be mindful of any bends or angles. You may need to gently flex or shape the new line to match the existing route. Ensure that the line is not kinked or twisted, as this could affect its performance and durability. Take your time during this process to avoid any damage to the fuel line or the vehicle's components.

Finally, once the rubber fuel line is securely in place, double-check all connections and ensure there are no sharp bends or kinks. Test the vehicle's fuel system to confirm that the new line is functioning correctly and that there are no leaks. Properly installed rubber fuel lines will ensure optimal fuel delivery and contribute to the overall performance and reliability of your vehicle's engine.

Frozen Fuel Lines: The Silent Culprit Behind Your Car's Failure to Start

You may want to see also

Secure Connections: Use clamps or ties to fasten new line securely, avoiding sharp bends

When installing a new rubber fuel line, ensuring secure connections is crucial to maintain the integrity of the fuel system and prevent potential leaks. One effective method to achieve this is by using clamps or ties to fasten the new line securely. This technique not only provides a reliable hold but also helps to avoid sharp bends, which can compromise the flexibility and longevity of the rubber material.

Start by identifying the appropriate clamp or tie suitable for the fuel line's diameter and the application. Clamps are typically used for larger fuel lines, offering a robust and adjustable grip. Ensure the clamp is made of a durable material, such as metal or heavy-duty plastic, to withstand the pressure and temperature variations associated with fuel systems. For smaller lines or in situations where a more discreet installation is preferred, ties or straps can be an excellent alternative. These are often made of sturdy materials like nylon or polyester and can be easily adjusted to secure the line.

To begin the installation, locate the point where the new fuel line connects to the existing system. Carefully feed the new line through any necessary fittings or adapters, ensuring it is aligned correctly. Once the line is in place, start applying the clamps or ties. For clamps, position them at regular intervals along the length of the line, ensuring they are tight enough to prevent any movement but not so tight as to cause damage to the rubber. The goal is to create a secure yet flexible connection that can accommodate slight movements without compromising the seal.

When using ties or straps, wrap them around the fuel line in a figure-eight pattern, ensuring the tension is even. This method is particularly useful for smaller lines or in confined spaces where clamps might be impractical. The key is to maintain a consistent tension, avoiding sharp bends that could lead to stress concentrations in the rubber. Regularly check the tension and adjust as needed to ensure the line remains secure over time.

In summary, securing connections when installing a rubber fuel line is essential for safety and performance. Clamps and ties provide effective solutions, offering both strength and flexibility. By following these installation techniques, you can ensure a reliable fuel system that operates efficiently and safely, minimizing the risk of leaks and potential engine issues. Remember, proper installation and regular maintenance are key to the long-term success of any fuel line system.

Shell Station Fuel Reward Line: Location and Access

You may want to see also

Test and Inspect: Start engine, check for leaks, and ensure proper fuel flow

Once you've installed the rubber fuel line, it's crucial to test and inspect the system to ensure it's functioning correctly and safely. Here's a step-by-step guide to help you through this process:

Starting the Engine: Begin by starting the engine. This initial step is essential as it allows you to check the fuel system under actual operating conditions. Turn the ignition key to the 'on' position, ensuring the engine doesn't start immediately. This is to allow the fuel system to prime and prepare for operation. Once the engine starts, let it run for a few moments to ensure it's running smoothly.

Checking for Leaks: After the engine has been running for a while, it's time to inspect for any leaks. Turn off the engine and immediately check all connections, especially where the rubber fuel line joins the fuel pump, the fuel filter, and any other components. Look for any signs of fuel dripping or leaking. If you notice any leaks, it could indicate a faulty connection or a damaged component, requiring immediate attention and potential replacement.

Ensuring Proper Fuel Flow: With the engine off, it's important to check the fuel flow to ensure it's adequate and consistent. Locate the fuel pump and listen for a steady, continuous flow of fuel. If the flow seems intermittent or weak, it might indicate a problem with the fuel pump or the fuel line itself. You can also use a fuel pressure gauge to measure the pressure at the fuel injectors or carburetor (depending on your vehicle's setup). Proper fuel flow is critical to ensure the engine receives the required amount of fuel for efficient operation.

Visual Inspection: While the engine is running, perform a visual inspection of the rubber fuel line. Check for any signs of damage, such as cracks, brittleness, or punctures. Ensure that the line is securely attached to all connections and that there are no kinks or twists that could restrict fuel flow. A thorough visual inspection will help identify any potential issues before they cause problems during operation.

Post-Drive Inspection: After driving the vehicle for a short period, it's beneficial to repeat the leak check and fuel flow inspection. Driving the vehicle will put additional stress on the fuel system, allowing you to identify any potential issues that may have arisen during operation. This comprehensive approach ensures that the rubber fuel line installation is secure and the system is functioning as intended.

Propane Engine Fueling: Rubber Fuel Line Compatibility Explained

You may want to see also

Frequently asked questions

To install a rubber fuel line, you will need a variety of tools and materials. These include a fuel line cutter or a pair of sharp scissors or a utility knife, a fuel line crimping tool or a pair of pliers, a fuel line clamp or a hose clamp, and a cleaning rag or cloth. It's also recommended to have a fuel line primer or adhesive, especially if you're working with a new or replacement line.

Cutting the fuel line to the right length is crucial for a proper installation. Start by measuring the distance between the fuel source and the engine, ensuring you account for any bends or turns the line will take. Use the fuel line cutter or scissors to carefully cut the line, making sure to cut straight and not at an angle. If needed, you can file or sand the edges to create a smooth finish.

Crimping the fuel line connector is a critical step to ensure a secure connection. Place the connector over the fuel line, ensuring it is centered and aligned with the crimping tool. Apply firm pressure to the tool, following the manufacturer's instructions, to create a tight crimp. Make sure the crimp is flush and even, without any gaps, to prevent fuel leaks.

Absolutely, safety is essential when working with fuel lines. Always wear protective gloves and eye protection to avoid any potential splashes or spills. Ensure you are in a well-ventilated area, especially when using any primers or adhesives. It's also important to double-check all connections and ensure no fuel is leaking before starting the engine. Properly dispose of any fuel line waste and follow local regulations for fuel-related waste management.