Hard plastic fuel lines are a common component in many vehicles, but they can be prone to damage over time due to various factors such as age, weather conditions, and accidents. Repairing these lines is a specialized task that requires specific tools and knowledge. In this article, we will explore the process of repairing hard plastic fuel lines, including identifying the signs of damage, the necessary tools and materials, and step-by-step instructions for the repair process. Whether you're a DIY enthusiast or a professional mechanic, understanding how to repair hard plastic fuel lines can save you time and money while ensuring your vehicle's fuel system remains reliable.

What You'll Learn

- Fuel Line Inspection: Check for cracks, brittleness, and damage using a flashlight and gloves

- Fuel Line Replacement: Replace damaged fuel line with new, compatible parts

- Fuel Line Routing: Ensure proper routing to avoid damage from heat or vibration

- Fuel Line Clamps: Inspect and replace clamps to prevent fuel leaks

- Fuel Line Cleaning: Clean fuel lines to remove contaminants and improve performance

Fuel Line Inspection: Check for cracks, brittleness, and damage using a flashlight and gloves

Fuel lines are crucial components of your vehicle's fuel system, and regular inspections are essential to ensure optimal performance and prevent potential issues. When it comes to hard plastic fuel lines, a thorough examination can help identify problems like cracks, brittleness, or damage, allowing for timely repairs or replacements. Here's a step-by-step guide on how to inspect your fuel lines using basic tools and your senses:

Preparation and Safety: Before you begin, ensure you have a well-lit area and a flashlight with a bright, focused beam. Wear gloves to protect your hands and to avoid any potential contaminants. It's also a good idea to have a clean, dry cloth ready to wipe away any fuel spills. Remember to work in a well-ventilated area and take necessary safety precautions, especially when dealing with fuel.

Visual Inspection: Start by visually examining the fuel lines. Look for any visible signs of damage, such as cracks, splits, or brittleness. Hard plastic fuel lines can deteriorate over time due to UV exposure, temperature fluctuations, and fuel contamination. Check for any discolored or softened areas, as these could indicate internal damage or degradation. Pay close attention to bends and fittings, as these areas are more susceptible to wear and tear. Use the flashlight to illuminate dark corners and hard-to-see spots, ensuring no potential issues are overlooked.

Feel and Touch: In addition to visual cues, your sense of touch can provide valuable insights. Run your fingers along the length of the fuel lines, feeling for any bumps, ridges, or unusual textures. Brittle fuel lines may feel dry and crumbly, while cracked lines might show signs of brittleness or flexibility. If you notice any areas that feel significantly different from the rest, it could indicate internal damage or a potential weak spot.

Check for Leaks: While inspecting, also look out for any signs of fuel leakage. Even a small crack or puncture can cause a significant fuel leak, leading to engine performance issues and potential safety hazards. If you suspect a leak, it's crucial to address it immediately. You can use a soapy water solution to test for leaks. Apply the solution to the fuel line connections and observe if any bubbles form, indicating a potential leak.

Document and Compare: As you inspect, take notes or take photos (with your phone) to document any issues found. Compare these notes with the manufacturer's specifications or previous inspection records to identify any changes or deterioration over time. This documentation will be valuable for future reference and can help you track the health of your fuel lines.

Regular fuel line inspections are a proactive approach to vehicle maintenance. By following these simple steps, you can identify potential issues early on and take the necessary actions to ensure your vehicle's fuel system operates efficiently and safely. Remember, if you're unsure or notice significant damage, consulting a professional mechanic is always recommended.

Honda vs Mercury: Unraveling the Outboard Fuel Line Connector Mystery

You may want to see also

Fuel Line Replacement: Replace damaged fuel line with new, compatible parts

Fuel lines are an essential component of any vehicle's fuel system, and over time, they can become damaged or worn out. When this happens, it's crucial to replace the damaged fuel line promptly to ensure optimal performance and prevent potential issues. Here's a step-by-step guide on how to replace a damaged fuel line with new, compatible parts:

Step 1: Inspect and Identify the Damage

Before you begin the replacement process, thoroughly inspect the fuel line for any signs of damage. Look for cracks, splits, kinks, or any other visible defects. Check the entire length of the fuel line, as damage can occur at various points, especially where it connects to the fuel tank, engine, and other components. Identifying the exact location and extent of the damage is crucial for a successful repair.

Step 2: Gather the Necessary Tools and Parts

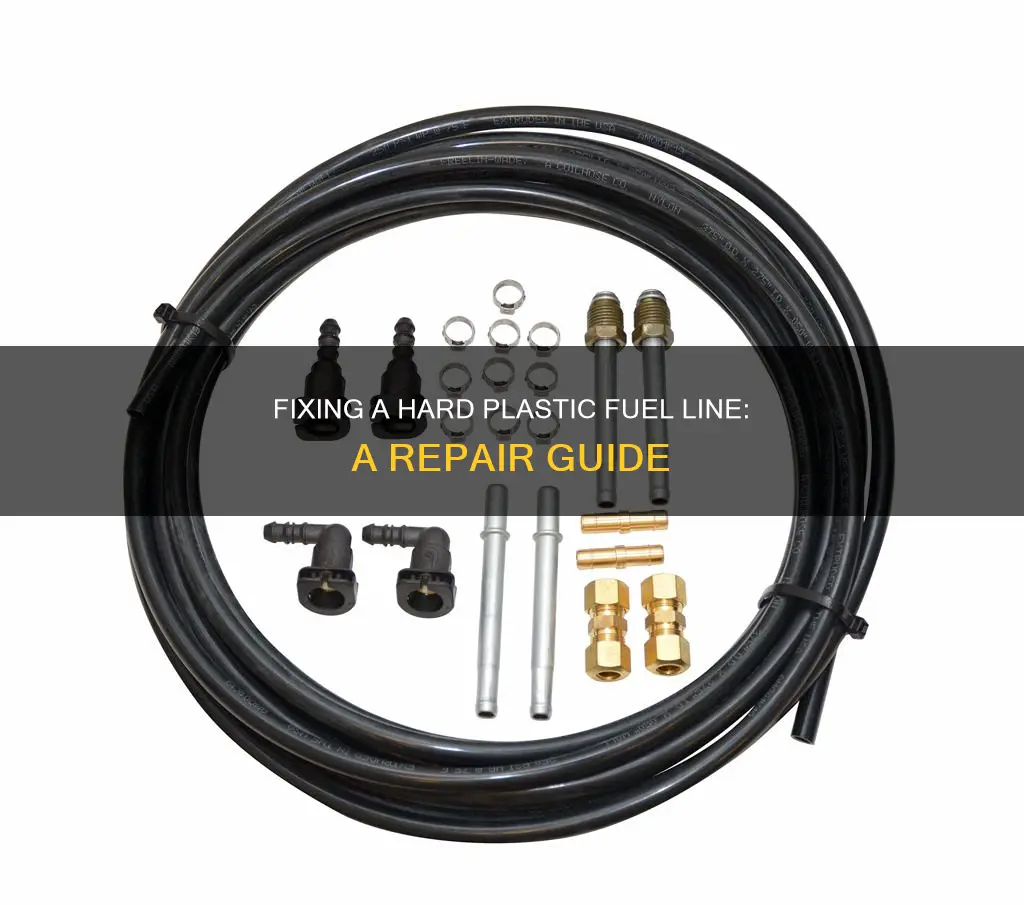

Obtain a new fuel line that is compatible with your vehicle's make and model. Ensure it meets the required specifications and is made of high-quality, durable materials. Along with the new fuel line, you'll need various tools, including a fuel line cutter, a fuel line crimper, a wrench set, and possibly a fuel line cleaner or solvent. Having all the necessary tools and parts ready will make the replacement process smoother.

Step 3: Drain the Fuel System

Safety should always be a priority. Before you start working on the fuel line, ensure the vehicle is parked on a level surface and the engine is turned off. Locate the fuel tank and drain valve, and use a suitable container to catch any remaining fuel. Open the drain valve to release the fuel from the system, allowing you to work on the fuel line without the risk of fuel spills or explosions.

Step 4: Cut and Remove the Old Fuel Line

Using the fuel line cutter, carefully cut the damaged section of the fuel line, ensuring a clean and precise cut. Take note of the positioning of the cut to facilitate proper connection of the new fuel line. Remove any remaining sections of the old fuel line, being cautious not to damage surrounding components. Clean the areas where the old fuel line was attached to ensure a proper seal for the new parts.

Step 5: Install the New Fuel Line

Start by attaching the new fuel line to the fuel tank, ensuring it is securely connected and aligned correctly. Use the fuel line crimper to create a tight seal at the connection points. Follow the manufacturer's instructions for the specific crimping technique required. Continue installing the new fuel line, connecting it to the engine and other relevant components, ensuring all connections are tight and secure.

Step 6: Test and Inspect the System

Once the new fuel line is installed, carefully replace the fuel tank and secure it in place. Start the vehicle and check for any leaks around the connections. Ensure that the engine runs smoothly and that there are no fuel-related issues. Inspect the entire fuel system to verify that the replacement was successful and that all components are functioning as they should.

Remember, working on fuel lines requires attention to detail and a systematic approach. Always refer to your vehicle's manual for specific instructions and safety guidelines. If you're unsure about any step, consult a professional mechanic to ensure a safe and successful fuel line replacement.

Ethanol Fuel Line: Can It Support Gasoline?

You may want to see also

Fuel Line Routing: Ensure proper routing to avoid damage from heat or vibration

When it comes to maintaining your vehicle's fuel system, proper fuel line routing is crucial to ensure the longevity and reliability of your engine's performance. Fuel lines, especially those made from hard plastic, can be susceptible to damage if not installed and routed correctly. This is primarily due to the potential for heat and vibration to cause wear and tear over time. Here's a comprehensive guide to help you understand the importance of proper routing and how to achieve it.

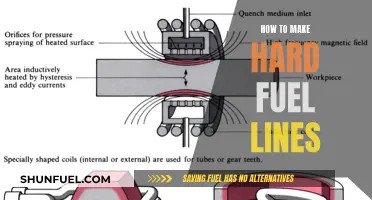

The primary goal of fuel line routing is to protect the lines from excessive heat and mechanical stress. Hard plastic fuel lines are designed to be rigid and durable, but they can still be compromised if they are subjected to continuous strain or exposed to high temperatures. Proper routing ensures that the lines are not kinked, twisted, or subjected to unnecessary pressure, which could lead to cracks, leaks, or even complete failure.

To ensure optimal routing, start by referring to your vehicle's manual. It will provide specific guidelines and diagrams that illustrate the ideal path for the fuel lines. Typically, fuel lines should be routed away from high-temperature areas, such as the exhaust manifold and the engine's hot components. Keep the lines as straight as possible to minimize the risk of damage from vibration during engine operation. Avoid sharp bends or sharp turns that could restrict flow or cause the lines to rub against other components.

One effective method for proper routing is to use rubber or plastic line protectors. These protectors can be slipped over the fuel lines and secured in place. They provide an extra layer of insulation and protection, especially in areas where the lines are more susceptible to damage, such as near the fuel tank or under the vehicle's body. Ensure that the protectors are securely fastened to prevent them from coming loose during operation.

Additionally, consider the use of fuel line clips or ties to secure the lines in place. These clips can be attached to the frame or other stable components, providing a fixed point for the fuel lines. This helps to reduce movement and potential damage caused by vibration. Regularly inspect the routing and clips to ensure they remain intact and effective, especially after any repairs or modifications to the vehicle's structure.

By following these guidelines and paying close attention to fuel line routing, you can significantly reduce the risk of damage to your hard plastic fuel lines. Proper maintenance and careful installation will contribute to a reliable and efficient fuel system, ensuring your vehicle's performance and longevity. Remember, taking the time to route the fuel lines correctly is an investment in your vehicle's overall health and reliability.

Fuel Filter Placement: Understanding the Fuel Return Line

You may want to see also

Fuel Line Clamps: Inspect and replace clamps to prevent fuel leaks

Fuel line clamps play a crucial role in maintaining the integrity of your fuel system, ensuring that fuel is delivered efficiently and safely to the engine. Over time, these clamps can wear out or become damaged, leading to potential fuel leaks and other issues. Regular inspection and timely replacement of fuel line clamps are essential to prevent such problems. Here's a comprehensive guide on how to inspect and replace these clamps:

Inspection Process:

- Visual Inspection: Start by visually examining the fuel line clamps. Look for any signs of damage, such as cracks, brittleness, or visible wear. Check for any signs of corrosion or degradation, especially if the fuel line is exposed to harsh environmental conditions. Inspect the clamps for any signs of looseness or movement, as this could indicate that the clamp is no longer securely holding the fuel line in place.

- Flexibility and Condition: Check the flexibility of the clamps. Over time, plastic clamps can harden and lose their flexibility, making it difficult to tighten or secure the fuel line. If you notice any stiffness or rigidity in the clamps, they may need to be replaced. Additionally, inspect the overall condition of the clamps. Any visible signs of deterioration or deformation should be addressed promptly.

- Tightness Check: Ensure that the fuel line clamps are tight enough to prevent any movement or slippage. Looseness can lead to fuel leaks and potential engine issues. You can use a wrench or a specialized tool to check and adjust the clamp's tightness. Make sure it is secure but not overly tight, as this could cause damage to the fuel line.

Replacement Steps:

- Gather Tools and Materials: Before starting the replacement process, gather the necessary tools and materials. You will typically need a wrench or a specialized fuel line clamp tool, a new replacement clamp (ensure it is the correct size and material for your fuel line), and possibly a fuel line cleaner or solvent for post-replacement cleaning.

- Locate the Clamp: Identify the fuel line clamp that needs replacement. These clamps are usually located where the fuel line connects to the fuel tank, fuel pump, or other components. Carefully inspect the area to locate the clamp and ensure you have access to all necessary parts.

- Remove the Old Clamp: Carefully remove the old clamp by loosening the connections or using the appropriate tool. Be cautious not to damage the fuel line during this process. Take note of how the old clamp was positioned and secured to ensure a proper fit for the new clamp.

- Install the New Clamp: Slide the new fuel line clamp onto the fuel line, ensuring it is positioned correctly and securely in place. Use the appropriate tool to tighten the clamp, following the manufacturer's specifications for the correct amount of torque. Make sure the clamp is tight enough to prevent any movement but not overly tight, causing damage.

- Post-Replacement Care: After replacing the clamp, clean the fuel line and surrounding areas to remove any dirt or debris. This step ensures that the fuel system remains clean and free from contaminants. Additionally, check the fuel line for any signs of damage or leaks, especially around the newly installed clamp.

Regular maintenance and inspection of fuel line clamps are vital to prevent fuel leaks and maintain the overall health of your vehicle's fuel system. By following these steps, you can ensure that your fuel lines remain secure and leak-free, contributing to a reliable and efficient engine performance. Remember, if you encounter any challenges or are unsure about the process, consulting a professional mechanic is always an option to ensure the job is done correctly.

Locate the Fuel Line: 2001 Monte Carlo Guide

You may want to see also

Fuel Line Cleaning: Clean fuel lines to remove contaminants and improve performance

Fuel lines play a crucial role in delivering fuel from the tank to the engine, and over time, they can accumulate contaminants that hinder their performance. Cleaning these fuel lines is an essential maintenance task to ensure optimal engine operation and longevity. Here's a comprehensive guide on how to clean fuel lines effectively:

Identifying the Problem: Before you begin the cleaning process, it's important to understand the signs of contaminated fuel lines. Engine misfires, reduced power, poor fuel economy, and even strange noises during operation could indicate the presence of contaminants. If you notice any of these symptoms, it's a clear sign that your fuel lines need attention.

Gathering the Right Tools: Cleaning fuel lines requires specific tools to ensure a thorough job. You'll need a fuel line cleaner, which is a specialized solvent designed to dissolve and remove contaminants. These cleaners are typically available in spray bottles or concentrated forms. Additionally, have a fuel filter cleaner and a fuel pressure gauge on hand to help with the process. It's also advisable to wear protective gear, such as gloves and goggles, to safeguard yourself during the cleaning process.

Step-by-Step Cleaning Process: Start by locating the fuel lines under the hood. Carefully inspect the lines for any visible signs of contamination, such as deposits or corrosion. Then, disconnect the fuel lines from the fuel tank and engine to gain access to the entire length of the lines. Apply the fuel line cleaner directly to the inside of the lines, ensuring complete coverage. Allow the cleaner to sit for the recommended time, which usually ranges from 10 to 20 minutes, to allow it to dissolve the contaminants. Use a brush or a small tool to gently scrub the inside of the fuel lines to remove any built-up deposits. Rinse the lines thoroughly with clean water to remove the cleaner and any dislodged contaminants.

Fuel Filter and Pressure Check: After cleaning the fuel lines, it's essential to inspect and clean the fuel filter. Remove the filter and use the fuel filter cleaner to remove any debris or contaminants. Check the fuel pressure using the gauge to ensure it meets the manufacturer's specifications. Low fuel pressure can be a result of contaminated lines or a clogged filter.

Reassembly and Testing: Once the cleaning and inspection are complete, reassemble the fuel lines and filter. Start the engine and monitor its performance. A clean fuel system should result in improved engine response, better fuel efficiency, and reduced emissions. If you notice any lingering issues, further investigation may be required to identify and address any remaining problems.

Regular maintenance and cleaning of fuel lines can prevent costly engine repairs and ensure your vehicle's overall reliability. By following these steps, you can effectively clean and maintain the fuel lines, promoting a healthier and more efficient engine.

Mastering the Art of Splice: Rubber Fuel Line Repair Guide

You may want to see also

Frequently asked questions

Hard plastic fuel lines can be susceptible to damage from various factors. Over time, the plastic can become brittle due to exposure to sunlight, extreme temperatures, or chemical degradation. Physical impact, such as from a collision or a sharp object, can also cause cracks or splits in the fuel line. Additionally, fuel contamination with water or other impurities can lead to corrosion and weakening of the plastic material.

Repairing a hard plastic fuel line can be challenging, but it is possible. The most common method is to replace the damaged section with a new fuel line. This process involves identifying the broken area, cutting out the damaged portion, and inserting a new section. It is crucial to ensure a proper seal and use appropriate fuel line connectors. If the damage is extensive, it might be more cost-effective to replace the entire fuel line.

While it is not recommended for long-term use, a temporary fix can be applied in emergencies. You can use a fuel line repair kit that includes a flexible, durable material to create a temporary seal. This kit typically involves cleaning the damaged area, applying a primer, and then wrapping the repair tape or sleeve around the line. However, this fix is only a temporary solution and should be replaced as soon as possible.

Repairing a hard plastic fuel line can be a complex task, especially if the damage is extensive. It requires specialized knowledge and tools to ensure a proper repair. If you are not confident in your DIY skills, it is best to consult a professional mechanic or a fuel system specialist. They have the expertise to diagnose the issue accurately and perform the necessary repairs, ensuring the fuel system's safety and functionality.