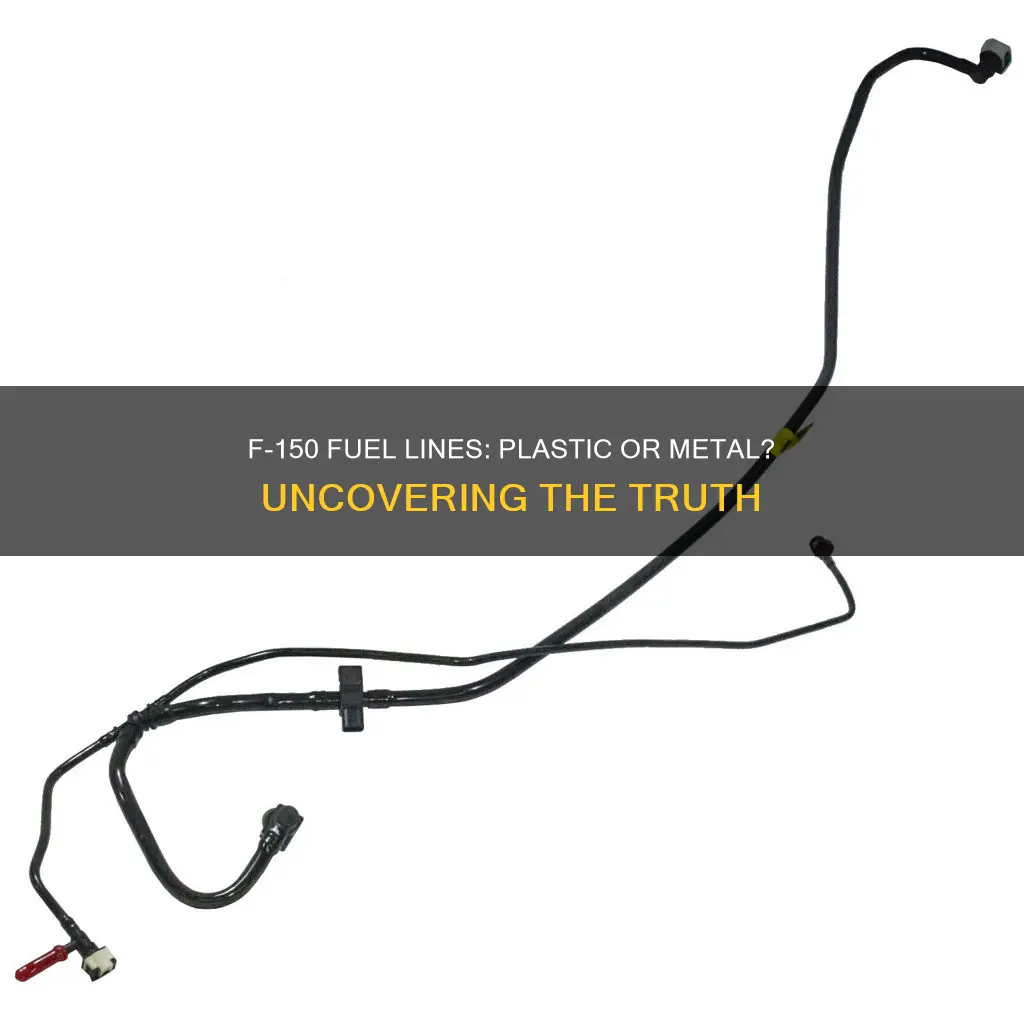

The Ford F-150, a popular pickup truck, has been a staple in the automotive industry for decades. One of the key components of its fuel system is the fuel lines, which are crucial for delivering fuel from the tank to the engine. Traditionally, these fuel lines were made of metal, but in recent years, some F-150 models have incorporated plastic fuel lines as an alternative to metal ones. This innovation has sparked curiosity among vehicle owners and enthusiasts, leading to the question: Does the F-150 have plastic fuel lines? This paragraph aims to explore this topic and provide insights into the reasons behind the switch to plastic and its potential benefits and drawbacks.

What You'll Learn

- Material Comparison: Plastic vs. rubber fuel lines: pros and cons

- Durability: Plastic fuel lines: resistance to heat and corrosion

- Performance: Impact on engine performance and fuel efficiency

- Maintenance: Ease of replacement and maintenance for plastic fuel lines

- Cost: Price comparison and long-term savings of plastic fuel lines

Material Comparison: Plastic vs. rubber fuel lines: pros and cons

When it comes to fuel lines in vehicles like the Ford F-150, the choice of material is crucial for performance, safety, and longevity. The debate between plastic and rubber fuel lines has been a long-standing one, with each material offering distinct advantages and disadvantages. Let's delve into this comparison to understand why one might be preferred over the other.

Plastic Fuel Lines:

Plastic fuel lines have gained popularity due to their lightweight and flexibility. They are often made from high-density polyethylene (HDPE) or polyvinyl chloride (PVC), which are durable plastics. One of the key advantages is their resistance to corrosion, making them ideal for vehicles exposed to harsh weather conditions or those with high humidity levels. Plastic lines can withstand temperature fluctuations without becoming brittle, ensuring a longer lifespan. Additionally, their lightweight nature can contribute to improved fuel efficiency, which is a significant benefit for trucks like the F-150. However, a potential drawback is their lower pressure resistance compared to rubber, which might be a concern for high-performance applications.

Rubber Fuel Lines:

Rubber fuel lines have been a traditional choice for many years, and for good reasons. They offer excellent flexibility, allowing for easy installation and routing around engine components. Natural rubber is known for its ability to withstand high pressure, making it suitable for high-performance vehicles. Moreover, rubber lines are highly resistant to fuel leaks and can absorb vibrations, providing a smoother ride. This material is also less susceptible to temperature changes, ensuring consistent performance. On the downside, rubber can be more prone to cracking over time, especially in environments with extreme temperatures. It may also be heavier than plastic, which could impact the overall weight of the vehicle.

Pros and Cons Summary:

- Plastic: Lightweight, corrosion-resistant, and flexible, making installation easier. Suitable for vehicles in diverse climates.

- Rubber: Excellent pressure resistance, vibration damping, and leak prevention. Long-lasting and temperature-resistant.

In the context of the F-150, both materials have their merits. Plastic lines might be preferred for their lightweight and corrosion-resistant properties, ensuring a longer-lasting system. Meanwhile, rubber could be chosen for its superior pressure handling and vibration absorption, catering to those seeking a more robust solution. Ultimately, the decision should be based on the specific needs of the vehicle and the environmental conditions it will encounter.

Mastering the Art of Fuel Line Removal: A Guide for 1998 Sierra 2500 Owners

You may want to see also

Durability: Plastic fuel lines: resistance to heat and corrosion

The use of plastic fuel lines in vehicles like the Ford F-150 is a design choice that has sparked some debate among enthusiasts and mechanics. While some argue that plastic lines are a cost-effective and lightweight solution, others express concerns about their long-term durability, particularly regarding heat and corrosion resistance. However, it's important to understand the specific advantages and limitations of plastic fuel lines in the context of the F-150.

One of the key benefits of plastic fuel lines is their resistance to heat. Plastic materials, such as polyethene or polypropylene, can withstand higher temperatures compared to rubber or metal lines. This is crucial for vehicles like the F-150, which may be exposed to varying environmental conditions, including hot engines and outdoor temperatures. Plastic lines are less likely to degrade or become brittle over time when exposed to heat, ensuring a longer lifespan and reduced risk of fuel leaks.

Corrosion resistance is another critical aspect of fuel line durability. Plastic lines are inherently less susceptible to corrosion compared to metal lines. They do not rust or corrode, which is essential for maintaining the integrity of the fuel system. This is particularly important in vehicles that operate in harsh conditions or are exposed to saltwater, as corrosion can lead to fuel contamination and potential engine damage.

Furthermore, the flexibility of plastic fuel lines is a significant advantage. Plastic lines can bend and move with the vehicle's structure without becoming stiff or brittle. This flexibility is crucial for accommodating the natural movement and expansion of the vehicle's components during operation, reducing stress on the fuel lines and minimizing the risk of damage or breakage.

In summary, while there are valid concerns about the initial installation and potential for damage, plastic fuel lines in the F-150 offer excellent resistance to heat and corrosion. Their ability to withstand higher temperatures and resist corrosion makes them a reliable choice for fuel delivery systems, ensuring a longer-lasting and more dependable vehicle performance. Understanding these durability factors is essential for making informed decisions regarding vehicle maintenance and upgrades.

Fuel Line Sizing for Optimal Performance: Lohler Lawnmower Guide

You may want to see also

Performance: Impact on engine performance and fuel efficiency

The presence of plastic fuel lines in an F150 can have a significant impact on engine performance and fuel efficiency. Plastic lines are often used in modern vehicles due to their lightweight and cost-effectiveness, but they can also introduce some challenges. Firstly, plastic fuel lines may not be as flexible as metal ones, which can lead to increased stress on the lines over time, especially during acceleration and deceleration. This can result in potential fuel leaks or even line failure, causing performance issues and potential safety hazards.

In terms of engine performance, the material of the fuel lines can affect the overall efficiency of the fuel delivery system. Plastic lines might not provide the same level of precision and control as metal lines, which could lead to inconsistent fuel flow. This inconsistency can cause the engine to run less efficiently, resulting in reduced power output and potential performance losses. Additionally, the heat resistance of plastic lines is generally lower compared to metal, which means they may degrade faster under high-temperature conditions, further impacting engine performance.

Fuel efficiency is another critical aspect influenced by plastic fuel lines. When fuel lines are not optimized for the vehicle's specifications, it can lead to increased fuel consumption. Plastic lines might not maintain a consistent pressure and flow rate, causing the engine to work harder to compensate for the inconsistent fuel delivery. Over time, this can result in a noticeable decrease in fuel efficiency, leading to higher fuel costs for the vehicle owner.

To mitigate these potential issues, it is recommended to use high-quality, vehicle-specific plastic fuel lines that are designed to withstand the rigors of the automotive environment. Upgrading to metal lines, if possible, can provide a more reliable and efficient fuel delivery system, ensuring optimal engine performance and fuel economy. Regular inspections and maintenance of the fuel system can also help identify and address any potential issues caused by plastic fuel lines.

Understanding Honda's Fuel Line Pulsation Dampener: A Comprehensive Guide

You may want to see also

Maintenance: Ease of replacement and maintenance for plastic fuel lines

The ease of maintenance and replacement is a significant advantage of plastic fuel lines in vehicles like the Ford F-150. Plastic lines are generally more flexible and less rigid compared to their metal counterparts, which makes them less prone to damage from engine movement and vibrations over time. This flexibility also allows for easier installation and removal during routine maintenance or when replacing the lines.

When it comes to maintenance, plastic fuel lines are often less susceptible to corrosion and degradation caused by fuel chemicals. This is particularly beneficial for older F-150 models or those with higher mileage, as the lines may have been exposed to fuel for an extended period. Regular inspections can help identify any signs of wear or damage, and replacing the lines proactively can prevent potential fuel leaks and ensure optimal engine performance.

In terms of replacement, the process is relatively straightforward. The plastic fuel lines are typically designed with quick-connect fittings or threaded ends, making them easy to disconnect and remove. This accessibility simplifies the replacement process, especially for those with some mechanical knowledge or experience. It is recommended to use high-quality replacement lines that meet or exceed the original specifications to ensure compatibility and optimal performance.

For DIY enthusiasts, replacing plastic fuel lines can be a manageable task. It involves disconnecting the old lines, cleaning the fuel system, and then carefully installing the new lines, ensuring secure connections. However, it is crucial to follow the manufacturer's instructions and take necessary safety precautions, such as using fuel containment devices to avoid spills during the replacement process.

In summary, the plastic fuel lines in the Ford F-150 offer ease of maintenance and replacement due to their flexibility and resistance to corrosion. Regular inspections and proactive replacement can help ensure the vehicle's fuel system remains reliable and efficient throughout its lifespan. With the right tools and knowledge, even those without extensive mechanical experience can perform this maintenance task successfully.

Fuel Line Sources for 2000 Mercury Mountaineer: Quick and Easy Access

You may want to see also

Cost: Price comparison and long-term savings of plastic fuel lines

When considering the installation of plastic fuel lines in your Ford F-150, one of the most significant factors to evaluate is the cost. Plastic fuel lines are generally more affordable than their metal counterparts, offering a cost-effective solution for vehicle owners. The initial price difference can be substantial, with plastic lines often costing 20-50% less than metal lines. This reduced cost is primarily due to the materials and manufacturing processes involved. Plastic is a lighter and more flexible material, which can simplify the installation process and reduce labor costs.

However, it's essential to consider the long-term savings that plastic fuel lines can provide. While the upfront cost may be lower, the durability and longevity of plastic lines are often questioned. Plastic is known to be more susceptible to degradation over time, especially when exposed to certain chemicals in fuel and the harsh conditions under the hood. This can lead to potential issues such as cracking, brittleness, and fuel leaks, which may require costly repairs or replacements.

To ensure long-term savings, it's crucial to choose high-quality plastic fuel lines and install them correctly. Opting for reputable brands that offer warranties or guarantees can provide peace of mind. Additionally, proper maintenance and regular inspections can help identify and address any potential issues early on, preventing more significant and expensive problems down the line.

In comparison to metal fuel lines, plastic lines offer a more budget-friendly option, but the trade-off might be in the form of reduced durability. Metal lines, while more expensive initially, are known for their strength and resistance to corrosion, ensuring a longer lifespan. The decision should be based on a comprehensive understanding of the vehicle's specific needs and the potential risks associated with fuel line material.

In summary, while plastic fuel lines may offer an initial cost advantage, the long-term savings and reliability should be carefully considered. It is a decision that requires balancing the immediate budget constraints with the potential long-term benefits and drawbacks of the chosen material.

Fixing a Fuel Line: A Step-by-Step Guide to Repair

You may want to see also

Frequently asked questions

Yes, the F-150, like many other vehicles, has plastic fuel lines as part of its fuel system. These lines are used to transport fuel from the tank to the engine and are designed to be lightweight and flexible.

Absolutely! Plastic fuel lines are a standard component in the F-150's fuel system across various models and years. They are cost-effective and help reduce the overall weight of the vehicle, which is beneficial for performance and fuel efficiency.

While plastic fuel lines are generally durable, it's still important to inspect them regularly for any signs of damage or deterioration. Over time, exposure to fuel, heat, and vibration can cause the lines to crack or become brittle. It is recommended to replace the fuel lines every 10-15 years or as advised by the vehicle manufacturer to ensure optimal performance and prevent fuel leaks.