Patching a hole in a rubber fuel line is a common automotive repair that can be accomplished with the right tools and a bit of patience. This guide will walk you through the process of identifying the damaged area, gathering the necessary supplies, and applying a patch to restore the integrity of the fuel line. By following these steps, you can ensure that your vehicle's fuel system remains leak-free and operates efficiently.

What You'll Learn

- Prepare the Tools: Gather necessary tools: fuel line clamp, pipe cutter, sandpaper, and rubber cement

- Locate the Hole: Inspect the fuel line for the hole, ensuring it's accessible and not blocked

- Cut and Prepare: Use a pipe cutter to cut a new section, then smoothen the edges with sandpaper

- Apply Rubber Cement: Carefully apply rubber cement around the hole, ensuring an even layer

- Install the Clamp: Slide the clamp over the prepared section, tightening it securely to seal the hole

Prepare the Tools: Gather necessary tools: fuel line clamp, pipe cutter, sandpaper, and rubber cement

Before you begin the process of repairing a hole in a rubber fuel line, it's crucial to gather the necessary tools to ensure a successful and secure fix. Here's a step-by-step guide on preparing your toolkit:

Fuel Line Clamp: This is the primary tool for sealing the hole. A fuel line clamp is designed to create a tight, leak-proof connection around the damaged area. Choose a clamp that is appropriate for the diameter of your fuel line to ensure a proper fit.

Pipe Cutter: You'll need a pipe cutter to precisely cut the fuel line to the desired length. This tool allows for a clean and accurate cut, ensuring that the exposed edges are smooth and free of debris. It's essential to have a sharp and reliable pipe cutter to make the most of your repair.

Sandpaper: Sandpaper is used to roughen the surface of the fuel line and the clamp. This step is crucial as it provides a better bonding surface for the rubber cement. Lightly abrade the area around the hole to create a textured finish, allowing the cement to adhere more effectively.

Rubber Cement: This is the adhesive that will bond the clamp to the fuel line. Rubber cement is specifically formulated to create a strong, flexible seal between rubber and similar materials. Ensure you have a high-quality rubber cement to guarantee the longevity of the repair.

By gathering these tools, you'll be well-prepared to tackle the task of patching a hole in a rubber fuel line. Each item plays a vital role in ensuring a secure and long-lasting repair, so make sure to have them readily available before starting the process.

Fuel Line Injection: Unlocking Engine Power with Liquid Magic

You may want to see also

Locate the Hole: Inspect the fuel line for the hole, ensuring it's accessible and not blocked

Locate the Hole: Inspecting the fuel line for any holes is the first crucial step in repairing a damaged rubber fuel line. Start by carefully examining the line for any visible punctures or tears. You want to ensure that the hole is easily accessible and not obscured by any surrounding components or debris. This initial inspection will help you determine the size and location of the hole, which is essential for choosing the appropriate repair method.

When searching for the hole, consider the fuel line's path and any potential obstacles. Rubber fuel lines are often routed through engine compartments, which can be cluttered with various parts and components. Carefully navigate through this area, feeling for any protruding objects that might have caused the hole. Ensure you have a clear view and access to the damaged section.

If the hole is partially covered or hidden, you might need to remove some components to gain better access. This could involve taking off certain parts of the engine or removing insulation around the line. Take your time and be methodical to avoid causing further damage. Remember, the goal is to expose the hole fully so that you can proceed with the repair effectively.

In some cases, the hole might be small and difficult to spot. In such instances, consider using a bright flashlight or a mirror to illuminate the area and make the hole more visible. You can also use a thin, flexible probe to carefully navigate the fuel line and locate the damage. The key is to be thorough and patient during this inspection phase to ensure an accurate repair.

Once you've identified the hole, take detailed notes or make a sketch of its location and size. This documentation will be valuable when selecting the appropriate repair technique and gathering the necessary materials. By thoroughly inspecting and locating the hole, you set the foundation for a successful repair, ensuring that the fuel line is safely and effectively patched.

Backflushing Fuel Lines: A DIY Guide to Unclogging Tank Screens

You may want to see also

Cut and Prepare: Use a pipe cutter to cut a new section, then smoothen the edges with sandpaper

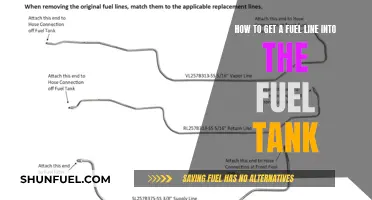

Before you begin the patching process, it's crucial to gather the necessary tools and materials. You'll need a pipe cutter, which is a specialized tool designed for cutting various types of pipes and hoses. This tool will ensure a clean and precise cut. Additionally, you'll require a piece of replacement rubber fuel line that matches the diameter and length of the damaged section. It's essential to measure and cut the replacement line carefully to avoid any unnecessary material.

Once you have your tools ready, locate the hole in the rubber fuel line. Use a marker or a piece of chalk to outline the damaged area, ensuring you mark the spot accurately. Then, position the pipe cutter at the marked location and apply firm pressure while cutting through the line. Take your time and apply steady pressure to achieve a clean cut. After cutting, inspect the edges to ensure they are smooth and free of any sharp or jagged edges that could compromise the patch's integrity.

To smoothen the edges, grab a piece of fine-grit sandpaper. Gently rub the cut edges, following the direction of the material's grain. This process helps to remove any roughness and prepares the surface for the patch. Ensure you sandpaper the entire length of the cut to create a seamless transition between the old and new sections. The goal is to create a smooth, even surface that will allow the patch to adhere properly.

As you work, take care not to apply too much pressure, as it might distort the shape of the line. Instead, use gentle, controlled movements to achieve the desired smoothness. Once you've sanded the entire length, inspect the edges once more to confirm they are smooth and ready for the next step. This preparation process is vital to ensure a successful and long-lasting repair.

With the cut and smoothed edges, you're now ready to proceed with the patching process, ensuring a robust and reliable repair for your rubber fuel line.

Mastering Fuel Line Clip Removal: A Step-by-Step Guide

You may want to see also

Apply Rubber Cement: Carefully apply rubber cement around the hole, ensuring an even layer

Before you begin the patching process, it's crucial to ensure that the fuel line is completely dry and free from any debris. This step is often overlooked but is essential for the success of the repair. Once the area is prepared, you can proceed with the application of rubber cement.

Rubber cement is a specialized adhesive designed to bond rubber materials. It creates a strong, flexible seal that can withstand the pressure and movement associated with fuel lines. When applying the cement, take your time and be meticulous. Start by laying a thin, even layer of cement around the hole, ensuring that you cover the entire damaged area. It's important to use a steady hand to avoid any uneven or lumpy application.

The key to a successful repair is to apply the cement in a way that it forms a smooth, continuous layer. You can use a small brush or a clean finger (after wearing gloves) to spread the cement evenly. Make sure there are no air bubbles or gaps in the cement layer, as these can compromise the integrity of the repair. Aim for a thin, consistent coat that fills the hole and adheres well to the surrounding rubber.

Allow the rubber cement to dry completely according to the manufacturer's instructions. This drying process is crucial to ensure a strong bond. Once dry, the patch should be secure and ready to withstand the pressure of the fuel line. Remember, this method provides a temporary fix, and for long-term solutions, professional assistance is recommended.

Unveiling the Material Secrets of Metal Fuel Lines

You may want to see also

Install the Clamp: Slide the clamp over the prepared section, tightening it securely to seal the hole

To effectively patch a hole in a rubber fuel line, you'll need to follow a systematic approach. Once you've gathered the necessary tools and materials, the next step is to install the clamp. This process involves carefully sliding the clamp over the prepared section of the fuel line, ensuring that it covers the hole completely. The clamp should be positioned in a way that it aligns with the damaged area, providing a seamless and secure fit.

When sliding the clamp into place, it's crucial to maintain a steady and controlled motion. Apply gentle force to ensure the clamp slides smoothly without any kinks or bends. The goal is to create a tight seal, so the clamp must be snug against the fuel line. Take your time with this step, as a proper fit is essential for the patch's longevity.

After positioning the clamp, the next action is to tighten it securely. Use a wrench or a pair of pliers to apply firm pressure and tighten the clamp further. The amount of force required may vary depending on the size and material of the clamp, but the key is to ensure it doesn't slip or loosen over time. A secure clamp will prevent any fuel leakage and provide a robust repair.

It's important to check the tightness of the clamp regularly, especially after the initial installation. Over time, the clamp might loosen due to fuel line movement or vibration. By periodically tightening the clamp, you can ensure the patch remains effective and reliable. This simple maintenance step can significantly extend the life of your fuel line repair.

Remember, the success of this repair heavily relies on the proper installation of the clamp. Take your time, use the right tools, and ensure a tight, secure fit. With these steps, you'll be able to effectively patch a hole in your rubber fuel line, ensuring a safe and efficient fuel system.

Tig Welding Fuel Lines: A Comprehensive Guide

You may want to see also

Frequently asked questions

Inspect the fuel line carefully for any visible tears, punctures, or signs of damage. Often, the hole will be noticeable due to the exposed fuel inside the line. You can also use a flashlight to examine the line from different angles if it's in a hard-to-see location.

Yes, temporary fixes are possible. You can use a rubber fuel line repair kit, which includes a patch and adhesive. Clean the area around the hole, apply the adhesive, and carefully place the patch over it. Ensure it's secure and sealed properly. This will provide a temporary solution until you can get a more permanent fix.

For a more permanent solution, you'll need a few tools. A fuel line cutter or a sharp knife can be used to carefully cut away the damaged section of the line. You'll also need a fuel line crimper to create a new fitting and ensure a tight seal. Additionally, have the necessary adhesives and sealants for the specific fuel line material.

Absolutely. When working with fuel lines, safety is crucial. Ensure you are in a well-ventilated area and wear protective gear, including gloves and safety goggles. Fuel is flammable, so it's essential to avoid sparks and open flames. Also, make sure to drain the fuel system or disconnect the fuel source before starting the repair to prevent accidental fuel release.

Regular maintenance and inspection can help prevent future issues. Keep an eye out for any signs of wear, such as cracks or brittleness, and address them promptly. Avoid running the fuel line through tight spaces or areas where it could be damaged by sharp objects. Properly securing the line and using protective covers can also help extend its lifespan.