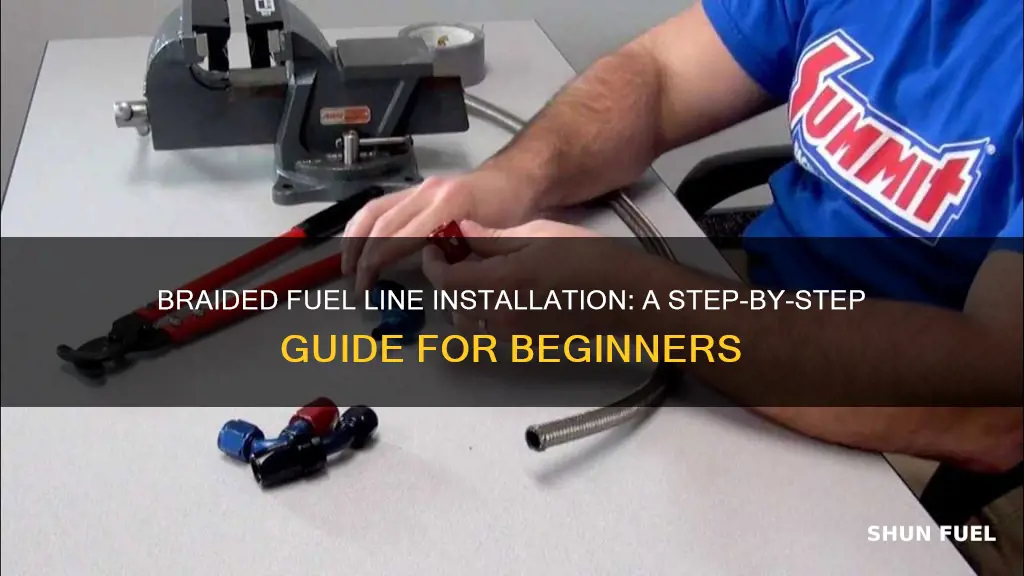

Installing a fuel braided line connector is a crucial step in ensuring your vehicle's fuel system operates efficiently and safely. This process involves replacing the stock rubber fuel lines with braided steel lines, which offer improved flexibility, durability, and resistance to fuel contamination. The connector acts as a crucial link between the fuel pump and the engine, ensuring a steady and reliable fuel supply. This guide will provide a step-by-step process for installing the connector, covering everything from preparing the necessary tools and materials to the final adjustments, ensuring your vehicle's performance and longevity.

| Characteristics | Values |

|---|---|

| Step 1: Gather Tools and Materials | - Fuel braided line connector - Hose clamp - Cleaning supplies (e.g., solvent, cloth) |

| Step 2: Prepare the Fuel Line | - Disconnect the fuel line from the fuel tank or source. - Clean the fuel line and the connector to remove any dirt or debris. |

| Step 3: Slide the Connector onto the Fuel Line | - Ensure the connector is the correct size and type for your fuel line. - Slide the connector over the fuel line, aligning the threads or locking mechanism. |

| Step 4: Secure the Connector | - Tighten the connector by hand, then use a tool to ensure a secure fit. - Check for any leaks around the connector. |

| Step 5: Test for Leaks | - Reconnect the fuel line to the fuel tank or source. - Start the vehicle and check for any fuel leaks at the connector. |

| Step 6: Final Adjustments | - If leaks are found, tighten the connector further or adjust the hose clamp. - Ensure the connector is properly aligned and secure. |

| Precautions | - Always work on a level surface to avoid fuel spills. - Wear protective gear, such as gloves and goggles, to prevent contact with fuel. |

| Note | - Regularly inspect and replace fuel connectors to maintain optimal fuel system performance. |

What You'll Learn

- Prepare Tools: Gather necessary tools like fuel line connectors, pliers, and a fuel filter

- Clean Hoses: Ensure both hoses are clean and free of debris for a secure connection

- Cut and Measure: Accurately cut the fuel line to the correct length for a snug fit

- Connect Hoses: Slide the connector onto the hose, tightening it securely with pliers

- Test for Leaks: Check for any leaks by starting the engine and inspecting for any fuel loss

Prepare Tools: Gather necessary tools like fuel line connectors, pliers, and a fuel filter

Before you begin the installation process, it's crucial to have the right tools ready to ensure a smooth and efficient job. Here's a breakdown of the essential tools you'll need:

Fuel Line Connectors: These are the primary components you'll be working with. Ensure you have the specific connectors that match your fuel line's diameter and type. Different vehicles may require different connector styles, so double-check the compatibility. Having a variety of connector sizes and types in your kit will be beneficial for various applications.

Pliers: A good pair of pliers is an indispensable tool for any automotive repair. You'll use them to grip and manipulate the fuel line connectors securely. Look for pliers with adjustable jaws to accommodate different connector sizes. Ensure they have a comfortable grip and are made from durable materials to withstand the force required during installation.

Fuel Filter: While not directly related to the connector installation, having a new or cleaned fuel filter is essential for maintaining your vehicle's performance. A clogged or damaged filter can lead to engine issues. Replace it if it's old or consider cleaning it if you're reusing it. This step ensures that your fuel system remains clean and efficient.

Gathering these tools beforehand will make the installation process much more manageable. It's always a good practice to have a well-prepared workspace, ensuring you have everything within reach as you work. With the right tools, you'll be able to tackle the installation with confidence and minimize the risk of errors.

Understanding Fuel Line Direction: The Switch's Crucial Role

You may want to see also

Clean Hoses: Ensure both hoses are clean and free of debris for a secure connection

When preparing to install a fuel braided line connector, it is crucial to prioritize the cleanliness of the hoses to ensure a secure and reliable connection. This step is often overlooked but plays a vital role in the overall performance and safety of the fuel system. Here's a detailed guide on how to ensure your hoses are clean and ready for the installation:

Start by removing the old hoses or any existing connections from the vehicle. This process allows for a thorough inspection and cleaning of the hose ends. Use a hose cleaner or a mild detergent mixed with water to gently clean the interior and exterior of the hoses. Focus on the areas where the connector will be attached, ensuring no dirt, rust, or corrosion is present. Rinse the hoses thoroughly to remove any cleaning agent residue.

For a more thorough cleaning, consider using a hose brush or a small brush with soft bristles to scrub the interior of the hoses, especially where the connector will make contact. This step helps to remove any stubborn dirt or debris that might interfere with the connection. After cleaning, allow the hoses to air dry completely. Ensure there is proper ventilation to prevent moisture buildup, which can lead to corrosion.

Once the hoses are dry, inspect them for any signs of damage or wear. Check for cracks, leaks, or any other imperfections that might affect the installation. If any issues are found, replace the hoses to ensure a clean and secure connection. Proper cleaning and inspection of the hoses are essential to guarantee a tight fit and prevent potential fuel leaks, which could lead to dangerous situations.

By taking the time to clean and prepare the hoses, you create a solid foundation for a successful fuel braided line connector installation. This process ensures that the new connector will function optimally and maintain the integrity of the fuel system. Remember, a clean and well-maintained fuel system is crucial for the performance and longevity of your vehicle.

Troubleshooting Tips: When the Fuel Line Refuses to Uncouple

You may want to see also

Cut and Measure: Accurately cut the fuel line to the correct length for a snug fit

When installing a fuel braided line connector, precise cutting of the fuel line is crucial to ensure a secure and leak-free connection. Here's a step-by-step guide to help you achieve an accurate cut:

- Refer to the Diagram: Before you begin, locate the diagram or illustration provided with the fuel braided line connector. This visual guide will show you the recommended length of the fuel line for your specific application. It's essential to refer to this diagram as it takes into account the connector's design and the vehicle's fuel system.

- Measure and Mark: Using a tape measure, carefully measure the distance between the fuel source and the desired connection point on the engine. Compare this measurement with the length indicated on the diagram. Mark this length on the fuel line with a permanent marker or a piece of tape. Ensure the mark is precise and aligned with the connector's mounting position.

- Prepare the Cutting Tools: You'll need a sharp utility knife or a fuel line cutter for this task. A utility knife with a fine blade will allow for more precise cuts. If using a dedicated fuel line cutter, ensure it is suitable for the diameter of your fuel line.

- Cut with Precision: Place the fuel line on a flat surface and position the cutting tool at the marked length. Apply steady pressure and make a clean cut. For a more professional finish, you can use a fuel line cutter, which often provides a smoother edge. Take your time and be cautious to avoid cutting too much or too little.

- Inspect the Cut: After cutting, inspect the end of the fuel line. It should be smooth and free of any sharp edges that could damage the connector or fuel system. If necessary, use a file or sandpaper to gently smooth the cut end.

Accurate cutting ensures that the fuel braided line connector fits perfectly, minimizing the risk of fuel leaks and maximizing performance. Take your time with this step, as it sets the foundation for a successful installation.

Dodge Hellcat Fuel Line Sizing: A Comprehensive Guide

You may want to see also

Connect Hoses: Slide the connector onto the hose, tightening it securely with pliers

When connecting the fuel braided line to the connector, it's important to ensure a tight and secure fit to prevent any fuel leaks. Here's a step-by-step guide to help you through the process:

Start by laying out all the necessary components: the fuel braided line, the connector, and a pair of adjustable pliers. Ensure that the connector is the correct size and shape to match the hose. Slide the connector onto the end of the fuel braided line, aligning the threads or locking mechanism of the connector with the hose. Take note of the direction; some connectors might have a specific orientation to ensure a proper seal.

Gently push the connector onto the hose until it is fully seated. You should feel a slight resistance when the connector is in place. Use the pliers to tighten the connector further. Hold the connector in one hand and the hose in the other. Squeeze the pliers onto the connector, applying firm pressure to tighten it securely. Be careful not to overtighten, as this can damage the hose or connector. The goal is to create a snug fit that prevents any movement or potential fuel leakage.

Once tightened, inspect the connection for any signs of leakage. You can do this by gently pressing around the connector and looking for any fuel seeping out. If there's no leakage, your connection is secure. If you notice any issues, carefully loosen the pliers and try again, ensuring that the connector is properly aligned and seated.

Remember, taking your time and applying the right amount of force will result in a successful and leak-free installation. Always refer to the manufacturer's instructions for specific guidelines, as different connectors may have unique requirements.

2007 Hyundai Accent Fuel Lines: Location Guide

You may want to see also

Test for Leaks: Check for any leaks by starting the engine and inspecting for any fuel loss

Before you begin the installation process of a fuel braided line connector, it's crucial to ensure that the fuel system is leak-free. This step is often overlooked but is essential to prevent potential issues and ensure the safety and performance of your vehicle. Here's a detailed guide on how to test for leaks:

Step 1: Engine Preparation

Start by turning off the engine and allowing it to cool down. This is important to avoid any potential burns or damage during the inspection. Locate the fuel tank and ensure it is securely attached. You might want to drain the fuel system temporarily to make the inspection easier. This can be done by disconnecting the fuel pump and allowing the fuel to drain from the lines.

Step 2: Inspect the Fuel Lines

Visually examine the fuel braided lines for any signs of damage, cracks, or brittleness. Look for any visible fuel leaks around the connections, especially where the lines connect to the fuel pump, filter, and the engine itself. Check for any signs of corrosion or deterioration, as these can lead to fuel leaks over time. Ensure that all connections are tight and secure.

Step 3: Engine Startup and Leak Test

With the engine off, start the vehicle and listen for any unusual sounds, especially hissing or roaring noises, which could indicate a fuel leak. Carefully observe the engine's behavior. If you notice any fuel loss, such as fuel dripping or a visible mist around the engine bay, it's a clear sign of a leak. You can also use a fuel leak detector spray or a simple soapy water solution to create a visual indicator of any potential leaks. Apply the solution to the fuel lines and connections, then start the engine. If bubbles appear, it confirms the presence of a leak.

Step 4: Addressing Leaks

If you identify any leaks, it's crucial to address them immediately. Tighten any loose connections and ensure all fittings are secure. If the damage is extensive, consider replacing the affected fuel line. Always refer to your vehicle's manual for specific guidance on replacement parts and procedures.

By following these steps, you can ensure that your fuel braided line connector installation is not only successful but also safe and reliable. Regular maintenance and leak testing are vital to maintaining a healthy fuel system in your vehicle.

Universal Yamaha Fuel Line Fittings: A Comprehensive Guide

You may want to see also

Frequently asked questions

A fuel braided line connector is a crucial component in a vehicle's fuel system, designed to connect the fuel pump to the engine. It is made of a durable braided material that withstands high pressure and temperature, ensuring a reliable and efficient fuel supply.

Signs that you might need a replacement include fuel pump noise, reduced engine performance, or fuel leaks. Regular maintenance and checking for any damage or wear can help identify the need for a new connector.

While it is possible to install a fuel braided line connector yourself, it is recommended to have some mechanical knowledge and experience. The process involves removing the old connector, cutting the new one to the appropriate length, and securely attaching it to the fuel pump and engine. Professional assistance is advised for complex installations or if you are unsure about any step.

You will typically require a fuel pump, a new braided line connector, a wrench or socket set, a fuel filter, and possibly a fuel pressure gauge. It is essential to have the correct specifications and sizes for your vehicle's fuel system to ensure a proper fit.

Yes, safety is crucial. Make sure the engine is cool to avoid burns. Wear protective gear, such as gloves and goggles, to prevent fuel spills. Ensure the vehicle is on a level surface, and follow the manufacturer's instructions for any specific safety guidelines related to your vehicle model.