Installing an aftermarket fuel line is a great way to improve the performance and reliability of your vehicle's fuel system. This process involves replacing the original fuel lines with a high-quality aftermarket version, which can offer better flexibility, durability, and resistance to fuel contamination. Before you begin, ensure you have the necessary tools and safety equipment, including a fuel line cutting tool, a fuel line crimper, and safety gear to protect against fuel spills. Start by disconnecting the fuel lines from the fuel tank and engine, taking note of the positions and connections. Carefully remove the old fuel lines, being mindful of any fuel residue or contaminants. Then, install the new fuel lines, ensuring they are properly aligned and secured with the appropriate fasteners. Finally, double-check all connections and test the fuel system to ensure there are no leaks. With careful planning and attention to detail, you can successfully install an aftermarket fuel line and enhance your vehicle's performance.

What You'll Learn

- Preparation: Gather tools and materials, ensure compatibility, and prepare the vehicle for installation

- Fuel Line Removal: Locate and disconnect the old fuel line, carefully remove it, and inspect for damage

- New Line Installation: Route the new fuel line, secure it with ties, and connect it to the fuel pump

- Bleeding the System: Start the engine, allow air to escape, and check for leaks

- Testing and Safety: Verify fuel flow, check for pressure, and ensure the system is leak-free before driving

Preparation: Gather tools and materials, ensure compatibility, and prepare the vehicle for installation

Before you begin the installation of an aftermarket fuel line, it's crucial to prepare thoroughly to ensure a successful and safe process. Here's a step-by-step guide to the preparation phase:

Gather the Necessary Tools and Materials: Start by collecting all the required tools and components for the installation. This typically includes the new fuel line itself, which should be compatible with your vehicle's make and model. You'll also need basic hand tools such as wrenches, pliers, and a fuel line cutter or kit for precise cutting. Additionally, have a fuel container or pump nearby to ensure a steady supply of fuel during the process.

Research and Ensure Compatibility: Take time to research the specific requirements for your vehicle. Check the vehicle's manual or online resources to identify the correct fuel line specifications, including diameter, length, and any unique features. Ensure that the aftermarket fuel line you've chosen is compatible with your engine type and fuel system. This step is vital to avoid any potential issues or damage during installation.

Prepare the Vehicle: Begin by locating the existing fuel lines and identifying their connections. Park the vehicle on a level surface and engage the parking brake for safety. If there are any old fuel lines that need to be removed, disconnect them carefully, taking note of their positions and connections. Ensure you have a clear understanding of the fuel flow to avoid any spills or accidents. Clean the areas where the new fuel line will be connected to remove any dirt or debris.

Safety Precautions: Before proceeding, ensure you are working in a well-ventilated area to avoid inhaling fuel vapors. Wear protective gear, such as gloves and eye protection, to safeguard yourself from potential fuel splashes. It's also a good practice to have a spill kit nearby in case of any accidents.

By following these preparation steps, you'll be well-equipped to tackle the installation process with confidence, ensuring a successful and safe aftermarket fuel line upgrade.

Fuel Rail Line Repair: A Step-by-Step Guide to Getting Your Engine Running Again

You may want to see also

Fuel Line Removal: Locate and disconnect the old fuel line, carefully remove it, and inspect for damage

When it comes to installing an aftermarket fuel line, the first step is to carefully remove the old one. This process requires a systematic approach to ensure you don't cause any damage to the vehicle or the new fuel line. Here's a step-by-step guide to help you through the removal process:

Locate the fuel line: Start by identifying the old fuel line that you want to replace. It is typically located near the fuel tank and runs along the frame rail to the engine bay. Carefully inspect the fuel line for any visible signs of damage, such as cracks, leaks, or corrosion. Take note of the routing and any attachments or clamps holding it in place.

Disconnect the fuel line: Once you've identified the old fuel line, it's time to disconnect it. Locate the fuel line clamps or fittings and use the appropriate tools to loosen and remove them. Be gentle to avoid damaging the fuel line or the surrounding components. Take off the fuel line from the fuel tank and engine bay connections, ensuring you have a clear view of the entire length.

Remove the fuel line: Carefully pull the old fuel line away from the vehicle's structure, being mindful of any sharp edges or protruding parts. Inspect the fuel line as you remove it for any signs of damage, such as punctures or excessive wear. Take note of the order in which you remove the sections to ensure proper installation of the new fuel line.

Inspect for damage: After removing the old fuel line, thoroughly inspect it for any damage. Check for cracks, kinks, or any signs of deterioration. If you notice any issues, it's crucial to replace the fuel line immediately to prevent potential fuel leaks and ensure the safety of your vehicle. Clean the fuel line and the surrounding areas to prepare for the installation of the new aftermarket fuel line.

Remember, when removing the fuel line, take your time and be methodical. Properly identifying and disconnecting the old fuel line is essential to ensure a successful installation of the new aftermarket fuel line.

Dodge Truck Fuel Line Bleeding: A Step-by-Step Guide

You may want to see also

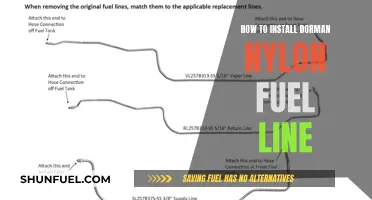

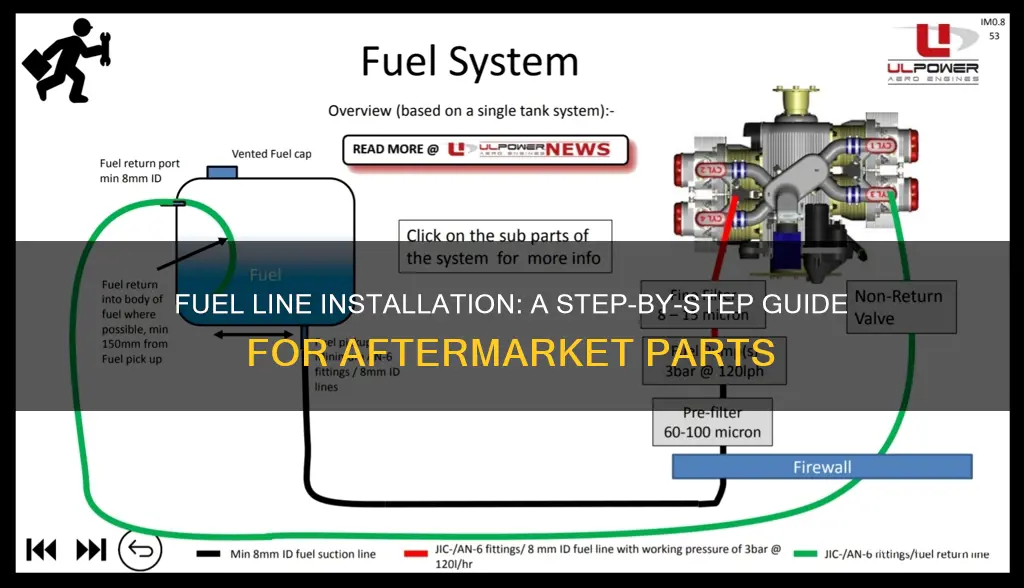

New Line Installation: Route the new fuel line, secure it with ties, and connect it to the fuel pump

When installing an aftermarket fuel line, proper routing and securement are crucial to ensure optimal performance and safety. Here's a step-by-step guide for the installation process, focusing on routing the new line, securing it with ties, and connecting it to the fuel pump:

Routing the New Fuel Line:

Begin by carefully tracing the path of the original fuel line. This will help you determine the best route for the new line, ensuring it follows a similar path to minimize potential interference with other components. Typically, the fuel line should be routed close to the engine bay firewall to maintain a clean and organized appearance. Use flexible fuel line with a suitable inner diameter to accommodate the fuel flow rate of your vehicle. Avoid sharp bends and kinks, as these can restrict fuel flow and potentially damage the line over time.

Securing the Fuel Line with Ties:

Once you've routed the new fuel line, it's essential to secure it in place using ties or clips. This prevents the line from moving or becoming caught under the vehicle's components. Secure the line at regular intervals, ensuring it's taut but not overly tight, as this can restrict fuel flow. Use ties that are appropriate for the fuel line material to avoid any potential damage. Consider using heat-resistant ties if your vehicle operates in high-temperature environments.

Connecting the Fuel Line to the Fuel Pump:

Locate the fuel pump, which is typically found near the fuel tank. Carefully disconnect the old fuel line from the pump, ensuring you have the correct fittings and adapters if necessary. Clean the fuel pump's inlet port to remove any debris or old fuel residue. Now, connect the new fuel line to the pump. Use a fuel line connector or clamp to secure the connection, ensuring a tight and leak-free fit. Double-check the connection to ensure it is secure and aligned properly.

After connecting the fuel line to the pump, test the system for any leaks. Start the engine and monitor for any unusual noises or vibrations. If everything is functioning correctly, you've successfully installed the aftermarket fuel line. Remember to regularly inspect the fuel lines for any signs of wear or damage, especially in areas prone to heat or vibration. Proper maintenance will ensure the longevity of your fuel system.

Mastering the Art of Fuel Line Clip Disconnection: A Step-by-Step Guide

You may want to see also

Bleeding the System: Start the engine, allow air to escape, and check for leaks

When installing an aftermarket fuel line, it's crucial to ensure that the system is bled properly to eliminate any air bubbles that could cause issues. Here's a step-by-step guide to bleeding the system:

Step 1: Start the Engine

Begin by starting your vehicle's engine. Let it run for a few minutes to allow the fuel to circulate and reach the engine. This initial step is essential as it helps to warm up the fuel system and ensures that any air pockets are more likely to rise to the surface.

Step 2: Locate the Bleed Points

Identify the bleed points on your aftermarket fuel line. These are typically small openings or valves strategically placed along the line to facilitate the bleeding process. The exact locations may vary depending on the specific fuel line design, so consult the manufacturer's instructions or online resources for guidance.

Step 3: Allow Air to Escape

With the engine running, locate the bleed points and use a small tool or your finger to open them one by one. As you do this, you should hear or feel air escaping from the line. This air is what needs to be bled out of the system. Be patient and methodical, as you may need to repeat this process for each bleed point. Allow the engine to idle during this process to ensure a steady flow of fuel and air.

Step 4: Check for Leaks

After you've bled all the identified points, carefully inspect the fuel line for any signs of leaks. Look for any fuel dripping or seeping around the connections or along the line. Additionally, check for any visible damage or wear that could be causing the leaks. If you notice any leaks, tighten connections or replace damaged sections as necessary.

Step 5: Re-check and Repeat (if needed)

Once you've addressed any leaks, start the engine again and repeat the bleeding process. This ensures that any remaining air bubbles are eliminated. Continue this process until no more air is heard escaping from the line, and the engine runs smoothly without any hesitation or stalling.

Remember, proper bleeding is critical to the performance and longevity of your aftermarket fuel line. Take the time to follow these steps carefully, and don't hesitate to consult the manufacturer's instructions or seek professional advice if needed.

Mastering the Art of Fuel Line Installation: A Step-by-Step Guide

You may want to see also

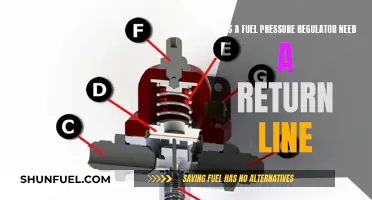

Testing and Safety: Verify fuel flow, check for pressure, and ensure the system is leak-free before driving

After installing an aftermarket fuel line, it's crucial to conduct thorough testing and safety checks to ensure the system's reliability and prevent potential hazards. Here's a step-by-step guide to verifying the fuel flow, checking pressure, and confirming the system's integrity:

Fuel Flow Verification: Start by checking the fuel flow rate to ensure it meets the required specifications. You can use a fuel flow meter or a calibrated bucket to measure the volume of fuel passing through the line per unit of time. Compare the measured flow rate with the expected value based on the engine's requirements. If the flow rate is significantly lower than expected, it may indicate a restriction or blockage in the line, requiring further investigation.

Pressure Testing: Fuel systems operate under specific pressure requirements. Use a pressure gauge to measure the fuel pressure at the engine's fuel rail or pump. The pressure should align with the manufacturer's recommendations. Low pressure could suggest a faulty pump or restricted lines, while abnormally high pressure might indicate potential issues with the fuel injectors or return line. Adjustments or further diagnostics may be necessary based on these pressure readings.

Leakage Inspection: Ensuring the system is leak-free is paramount for safety. Visually inspect all connections, fittings, and joints for any signs of fuel leakage. Apply a small amount of diesel fuel or soapy water around the connections to make it easier to identify leaks. If any fuel drips or bubbles are noticed, tighten the connections or replace faulty components immediately. Properly sealing the system is essential to prevent fuel loss and potential engine damage.

Before Driving: Once you've completed the testing and identified any necessary adjustments or repairs, allow sufficient time for the fuel system to stabilize. Start the engine and monitor its performance, ensuring it runs smoothly and efficiently. Test drive the vehicle to assess the fuel line's functionality under various driving conditions. Pay attention to any unusual noises or vibrations, as these could indicate potential issues with the newly installed fuel line. Regularly check the fuel gauge and ensure the tank is refilled to maintain optimal fuel levels.

Remember, proper testing and safety measures are critical to the successful installation of aftermarket fuel lines. By following these steps, you can ensure the system's performance, reliability, and compliance with safety standards, providing peace of mind during your vehicle's operation.

Can Plastic Air Lines Be Used for Fuel? Uncovering the Potential

You may want to see also

Frequently asked questions

An aftermarket fuel line is an alternative to the original equipment (OE) fuel line, often made by a third-party manufacturer. It can offer improved performance, durability, or customization options. You might consider installing an aftermarket fuel line if you want to enhance the fuel delivery system's efficiency, upgrade the material for better resistance to heat or chemicals, or simply personalize the appearance of your vehicle.

There are several signs that may indicate your fuel line requires replacement. These include fuel leaks, reduced engine performance, engine misfires, or strange noises from the fuel system. If you notice any of these symptoms, it's essential to inspect the fuel line for damage, cracks, or deterioration.

Many aftermarket fuel lines are designed for easy installation and can be a DIY project. However, the complexity of the installation process can vary depending on the vehicle model and the specific fuel line. If you're unsure or uncomfortable with the task, it's recommended to seek the help of a professional mechanic to ensure a proper and safe installation.

The required tools and materials may include fuel line cutters or shears, fuel line connectors or fittings, a fuel line inspection mirror (for hard-to-reach areas), a fuel pump primer (if necessary), and a fuel line cleaner. It's essential to have the correct tools for your specific fuel line type and vehicle to ensure a proper fit and seal.

Yes, safety is crucial when working with fuel lines. Always ensure the engine is cool to the touch before starting the installation to avoid burns. Wear protective gloves and goggles to prevent fuel from splashing into your eyes. Additionally, make sure to drain the fuel tank or disable the fuel pump before working on the fuel system to prevent accidental fuel release and potential hazards.