Installing a dorman nylon fuel line is a straightforward process that can be completed with basic tools and a bit of patience. This guide will walk you through the steps to ensure a successful installation, providing a reliable and durable fuel line for your vehicle. By following these instructions, you can easily replace or upgrade your fuel line, ensuring optimal performance and safety.

| Characteristics | Values |

|---|---|

| Material | Nylon |

| Application | Fuel Line |

| Brand | Dorman |

| Color | Black |

| Compatibility | Universal fit for various vehicles |

| Length | Varies depending on the specific product |

| Diameter | Typically 3/8" or 1/2" |

| Resistance | Heat, oil, gasoline, and UV rays |

| Installation | Straightforward, often requiring no additional tools |

| Advantages | Flexible, durable, and resistant to cracking |

What You'll Learn

- Prepare Tools: Gather necessary tools: wrench, fuel line cutter, and replacement line

- Locate Fuel Tank: Identify the fuel tank and locate the fuel line connection

- Remove Old Line: Carefully disconnect and remove the old, damaged fuel line

- Cut and Install: Measure and cut the new nylon fuel line, then securely install it

- Test and Secure: Test for leaks, ensure proper fit, and secure the new line

Prepare Tools: Gather necessary tools: wrench, fuel line cutter, and replacement line

Before you begin the installation process, it's crucial to have the right tools to ensure a smooth and efficient job. Here's a breakdown of the essential tools you'll need:

Wrench: A wrench is a fundamental tool for any fuel line installation or repair. You'll require a wrench that fits the size of the fuel line you're working with. Common sizes include 1/4-inch, 3/8-inch, and 1/2-inch. Make sure you have a good grip and leverage to tighten or loosen the connections effectively.

Fuel Line Cutter: Cutting the old or damaged fuel line is a critical step. A fuel line cutter will allow you to make a clean and precise cut. Look for a cutter that can handle the thickness of your nylon fuel line. Some cutters may require additional tools or accessories to ensure a smooth cut.

Replacement Fuel Line: Along with the tools, you'll need a replacement nylon fuel line that is compatible with your vehicle's specifications. Ensure you purchase the correct size and length to match the existing line. Check the manufacturer's recommendations or consult a parts catalog to make an informed choice.

Having these tools ready will set you up for success when it's time to install the new Dorman nylon fuel line. It's always a good practice to double-check your tool kit before starting any automotive project to avoid any last-minute surprises.

Unleash Your Engine's Potential: Understanding the 8AM Fuel Line

You may want to see also

Locate Fuel Tank: Identify the fuel tank and locate the fuel line connection

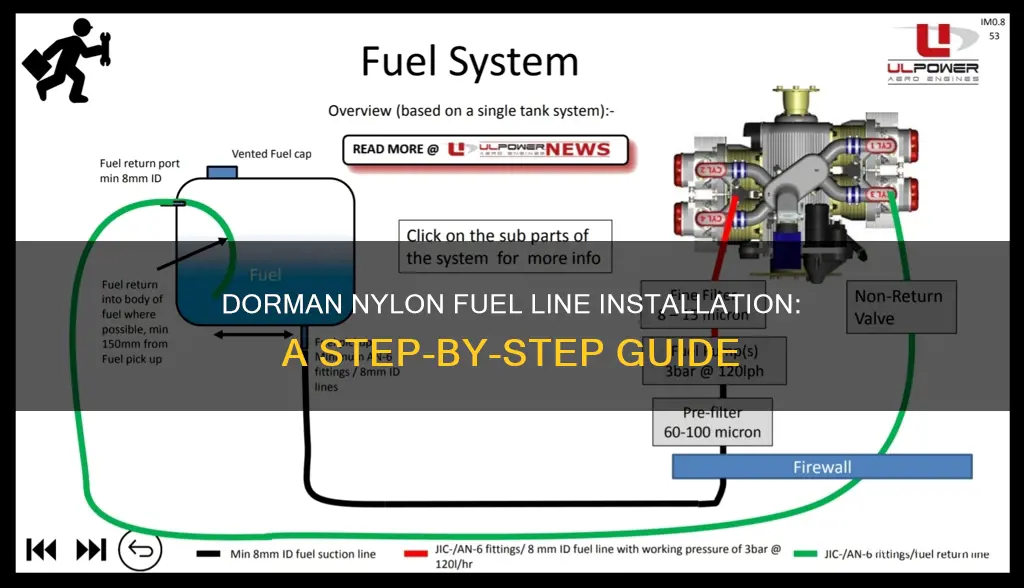

To begin the process of installing a Dorman nylon fuel line, you must first locate the fuel tank. This is a crucial step as it provides the starting point for your fuel line installation. The fuel tank is typically located beneath the vehicle, often in the front or rear area, depending on the vehicle's design. It is usually a large, cylindrical or rectangular container with a fuel filler cap on top.

Once you've identified the fuel tank, the next step is to locate the fuel line connection. This is where the fuel line will be attached to the tank, allowing fuel to flow from the tank to the engine. The fuel line connection is often a small opening or port on the side or bottom of the fuel tank. It is usually covered by a small metal or plastic cover, which can be removed to expose the connection.

When locating the fuel line connection, look for a small, narrow opening that is specifically designed for the fuel line. This opening is often marked with a small arrow or indicator on the fuel tank, making it easier to identify. The connection point may also have a small groove or channel to guide the fuel line into place. It is important to ensure that you are connecting the fuel line to the correct port to avoid any fuel leaks or engine issues.

Take your time to carefully inspect the fuel tank and its surroundings. You may need to refer to your vehicle's manual or online resources for specific details about the fuel tank's location and the fuel line connections. Proper identification of these components is essential to ensure a successful and safe installation of the Dorman nylon fuel line.

Remember, when working with fuel lines, it is crucial to exercise caution and follow safety guidelines. Always disconnect the fuel line from the engine before making any modifications to avoid accidental fuel spills or engine damage.

Mastering Backpack Fuel Lines: A Guide to Echo PB-500T Hook-Up

You may want to see also

Remove Old Line: Carefully disconnect and remove the old, damaged fuel line

Before you begin the process of replacing the fuel line, it's crucial to ensure you have the necessary tools and safety precautions in place. Start by gathering the appropriate tools, such as a fuel line cutter, a wrench, and a new fuel line. Additionally, it's essential to work in a well-ventilated area and wear protective gear, including gloves and safety goggles, to safeguard yourself from any potential fuel spills.

Locate the old fuel line, which is typically a rubber or nylon tube that carries fuel from the tank to the engine. It is often black or dark in color and can be found running along the frame or under the vehicle. Carefully inspect the line for any signs of damage, such as cracks, leaks, or deterioration. If you notice any issues, it's best to replace the entire line to prevent further problems.

To remove the old fuel line, start by disconnecting the fuel line from the fuel tank. Locate the fuel line fitting, which is usually a small metal or plastic clip or a quick-connect fitting. Use the appropriate tool to loosen and remove the clip or fitting, being careful not to damage the surrounding components. Once the fitting is removed, gently pull the fuel line away from the tank, ensuring you don't twist or kink it.

Next, disconnect the fuel line from the engine. This may require removing a small bracket or clip that holds the line in place. Carefully detach the line from the engine's fuel inlet or outlet, ensuring you have a clear view of the connection points. Take note of the orientation of the line to ensure proper installation of the new line.

With the old fuel line now disconnected, you can proceed to remove it entirely. Carefully feed the line through any remaining openings or channels, being mindful of any sharp edges or obstacles. Once the line is free, carefully pull it away from the vehicle, ensuring you don't leave any debris or contaminants behind. Properly dispose of the old fuel line, following local regulations for hazardous waste disposal.

Sealing the Deal: Keeping Air Out of Fuel Lines

You may want to see also

Cut and Install: Measure and cut the new nylon fuel line, then securely install it

Before you begin the installation process, it's crucial to ensure you have the right tools and materials. You'll need a new nylon fuel line, a fuel line cutter, a fuel line crimper, and a fuel line clamp. Additionally, have a fuel line diagram or a manual specific to your vehicle to guide the installation.

Measuring and Cutting the Fuel Line:

Start by locating the existing fuel line and identifying the point where the new line will be installed. Use the fuel line diagram to determine the exact length required. Measure and mark the new line accordingly. It's essential to get the length precise to avoid any future issues. Once marked, use the fuel line cutter to carefully cut the new line to the measured length.

Securing the Installation:

Now, it's time to install the new nylon fuel line. Begin by inserting the new line through the appropriate openings, ensuring it follows the path indicated by the fuel line diagram. Once in place, use the fuel line crimper to create a secure connection. Apply firm pressure to the crimper to ensure a tight seal. After crimping, use the fuel line clamp to further secure the connection and provide additional support. Tighten the clamp according to the manufacturer's instructions to ensure a reliable bond.

Repeat this process for any additional fuel lines you need to install. Remember to double-check your connections and ensure all lines are securely in place before proceeding with further vehicle maintenance or driving. Properly installed nylon fuel lines will ensure a reliable fuel supply and contribute to the overall performance and longevity of your vehicle's fuel system.

Unrusting Fuel Line Bolts: A Step-by-Step Guide to Success

You may want to see also

Test and Secure: Test for leaks, ensure proper fit, and secure the new line

Once you've installed the new Dorman nylon fuel line, it's crucial to test and secure it to ensure optimal performance and prevent any potential issues. Here's a step-by-step guide to help you through this process:

Testing for Leaks: After installation, the first critical step is to check for any leaks. Start by applying a small amount of diesel fuel or a suitable fuel line sealer to the connections and bends of the new line. This will help identify any potential leak points. Then, carefully observe the fuel line for any signs of fuel escaping. You can use a rag or paper towel to wipe the line and check for wet spots, which could indicate a leak. If you notice any leaks, carefully remove the fuel source and tighten any loose connections or clamps. Reapply the sealer and test again.

Ensuring Proper Fit: It's essential to verify that the fuel line is correctly routed and fits snugly against the fuel tank and engine. Check that there are no sharp bends or kinks in the line, as these can restrict fuel flow and cause issues. Ensure the line is not rubbing against any sharp edges or components that could damage it. Adjust the routing as needed to achieve a smooth and secure path.

Securing the Line: Properly securing the fuel line is vital to prevent movement and potential damage. Use the appropriate fuel line clips or ties provided with the Dorman nylon fuel line to fasten the line to the frame or other secure mounting points. Ensure the clips are tight and secure, but be careful not to overtighten, as this can restrict fuel flow. Distribute the line's weight evenly to avoid excessive strain on any single point.

Final Inspection: Once the line is installed, secured, and you've confirmed there are no leaks, perform a final inspection. Check for any signs of damage, such as cracks or frayed areas, especially at the connections. Ensure all clips and ties are intact and in place. A thorough inspection will give you peace of mind and help identify any potential issues before they become problems.

Remember, taking the time to properly test and secure the fuel line is essential for the safety and performance of your vehicle's fuel system. Always refer to the manufacturer's guidelines and safety instructions for any specific requirements or recommendations.

Fuel Line Failure: Causes, Symptoms, and Solutions

You may want to see also

Frequently asked questions

Before you begin, ensure you have the necessary tools and materials, including the nylon fuel line, fuel line connectors, and a fuel line cutter. Inspect the line for any defects or damage, and if found, replace it with a new one.

Measure the length required for your specific application using a tape measure. Then, using the fuel line cutter, carefully cut the line at a 45-degree angle to ensure a clean and precise cut.

Start by inserting the fuel line into the connector, ensuring it is aligned correctly. Use the appropriate connector type (e.g., quick-connect or threaded) and tighten it securely according to the manufacturer's instructions. Double-check the connection to make sure it is tight and leak-free.

Yes, regular inspection is key. Check for any signs of wear, cracks, or damage, especially at bends and connections. Keep the fuel line away from heat sources and sharp objects to prevent deterioration. It's also a good practice to replace the line periodically, especially after extended periods of use, to ensure optimal performance and safety.