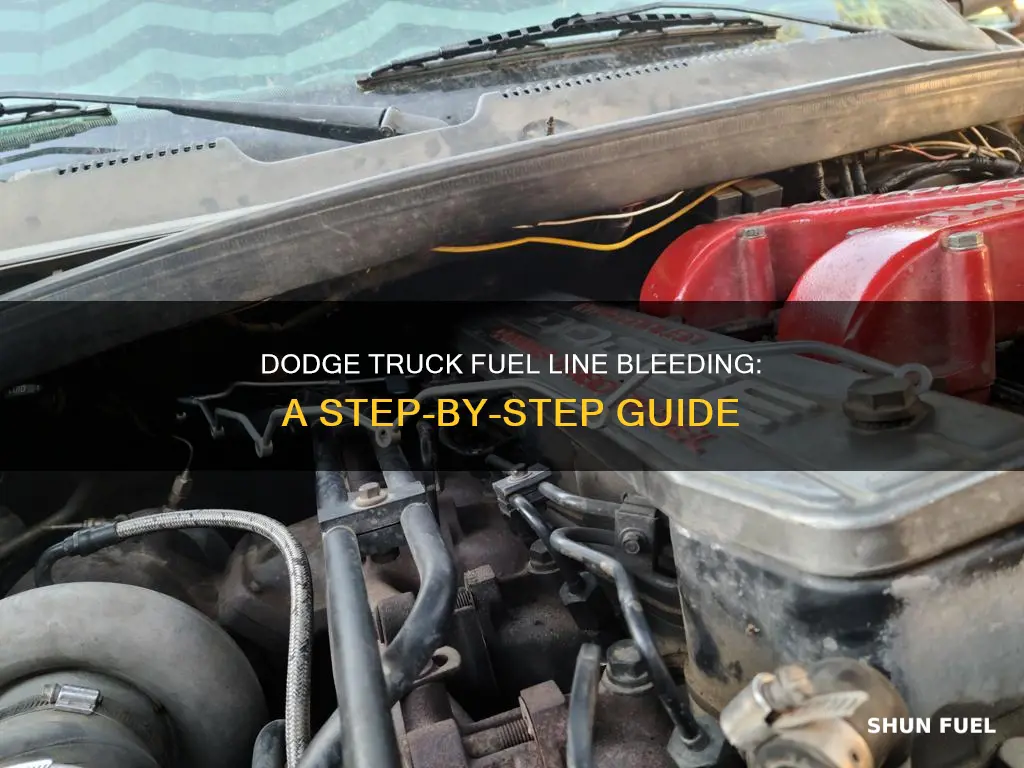

Bleed fuel lines on a Dodge truck to ensure a steady and reliable fuel supply to the engine. This process involves removing the fuel tank cap, opening the fuel line, and allowing air to enter the system to remove any trapped gas. It's important to follow the manufacturer's guidelines and use the correct tools to avoid damage to the fuel system. This step-by-step guide will provide instructions on how to safely and effectively bleed the fuel lines on your Dodge truck.

What You'll Learn

Preparation: Ensure truck is off, and park on level ground

To begin the process of bleeding fuel lines on your Dodge truck, it's crucial to ensure a safe and controlled environment. Start by locating the fuel tank and identifying the fuel lines that need to be bled. These lines typically run from the fuel tank to the engine, and you'll want to focus on the sections that are easily accessible.

Park your truck on a level surface to facilitate the bleeding process. It is essential that the vehicle is completely stationary and not in gear to avoid any accidental movement during the procedure. Engage the parking brake as an extra safety measure to prevent the truck from rolling.

Before proceeding, it's recommended to have a clean and well-lit workspace. Remove any obstacles or items that might obstruct your view or access to the fuel lines. This step ensures a smooth and efficient bleeding process, allowing you to identify and address any issues promptly.

Additionally, gather the necessary tools and equipment. You will likely need a fuel line bleeding kit, which includes a specialized tool for creating a vacuum or a small pump to draw air out of the lines. Having a supply of clean fuel and a container to collect any debris or contaminants is also advisable.

By following these preparation steps, you'll be well-equipped to safely and effectively bleed the fuel lines on your Dodge truck, ensuring optimal fuel delivery to the engine. Remember, taking the time to properly prepare can make the entire process smoother and more efficient.

Fuel Line Swap: Can You Use It for Coolant?

You may want to see also

Safety: Wear gloves and safety goggles to protect from fuel splashes

When working on a vehicle's fuel system, it's crucial to prioritize safety to avoid any potential hazards. One of the most important safety measures to take when bleeding fuel lines on a Dodge truck is to wear protective gear, specifically gloves and safety goggles. These simple yet essential items can provide a crucial barrier between you and the potentially harmful substances you'll be dealing with.

Fuel is a highly flammable and corrosive substance, and any splashes or spills can be dangerous. Gloves act as a protective shield, safeguarding your hands from direct contact with fuel. Opt for heavy-duty gloves made from durable materials like leather or thick synthetic fabrics to ensure they can withstand the harsh environment. Look for gloves that offer a snug fit to prevent any fuel from seeping through the seams.

Safety goggles are equally vital as they protect your eyes from any fuel that might spray or splatter during the bleeding process. Fuel can cause severe irritation and even temporary blindness if it comes into contact with your eyes. Goggles provide a clear, unobstructed view while keeping your eyes safe. Ensure you choose a pair that fits comfortably over your prescription glasses, if applicable, to maintain clear vision throughout the procedure.

By wearing gloves and safety goggles, you create a protective barrier that minimizes the risk of fuel-related injuries. This simple safety precaution is often overlooked but can significantly reduce the chances of accidents and long-term health issues associated with fuel exposure. It is a fundamental step in ensuring a safe and successful fuel line bleeding process.

Painting Fuel Lines: A Pre-Install Guide

You may want to see also

Locate Lines: Identify fuel lines under the truck's body or hood

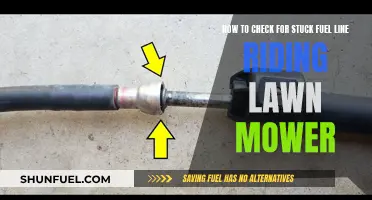

When working on a Dodge truck to bleed the fuel lines, the first crucial step is to locate the fuel lines themselves. These lines can be found under the truck's body or hood, depending on the specific model and year. For the body, you'll typically find the fuel lines running along the frame rails, often protected by rubber or plastic covers. These covers may be removed to expose the lines, but be cautious as they can be fragile. Under the hood, the fuel lines are usually more accessible and can be identified by their color-coded or labeled ends.

For the body, start by inspecting the area along the frame rails. The fuel lines may be bundled together, and you might need to carefully move aside any obstructions like wiring harnesses or engine mounts to get a clear view. Look for any signs of damage, such as cracks or leaks, as these could be indicators of previous issues. If you find any issues, it's best to replace the affected lines to ensure optimal performance.

Under the hood, the process is generally simpler. The fuel lines are often more exposed and can be easily identified by their distinct colors or labels. These labels might indicate the type of fuel they carry, such as gasoline or diesel. Carefully inspect each line for any signs of corrosion, damage, or leaks. If you notice any issues, it's important to address them promptly to prevent further complications.

In some cases, you might find that the fuel lines are bundled together with other components, such as hoses and wiring. If this is the case, be gentle when separating them to avoid any damage. Take note of the positions of the lines to ensure you can reattach them correctly during the bleeding process. Remember, the goal is to locate the fuel lines, assess their condition, and prepare them for the bleeding procedure.

Braided Fuel Line: A Viable Substitute for Oil Lines?

You may want to see also

Bleeding Process: Open bleeder valves at each line's end

The bleeding process is a crucial step in ensuring that your Dodge truck's fuel lines are functioning properly and delivering fuel efficiently. When you open the bleeder valves at each line's end, you're essentially allowing air to escape from the fuel lines, which can cause issues with fuel pressure and performance. Here's a detailed guide on how to do this:

Locate the Bleeder Valves: Start by familiarizing yourself with the fuel lines on your Dodge truck. These lines are typically located under the hood and may require some maneuvering to access. The bleeder valves are usually small, screw-on caps or valves at the ends of the fuel lines. They are often marked with a small 'B' or 'V' to indicate their purpose.

Prepare the Tools: You'll need a few basic tools for this process. A wrench or pliers will be used to loosen and tighten the bleeder valves. It's also a good idea to have a container or rag nearby to catch any fuel that may spill during the bleeding process.

Locate the Fuel Tank: Before you begin, ensure that the fuel tank is empty or at least partially empty. This is an important safety precaution as it prevents fuel from spilling during the bleeding process. If your truck has a fuel pump, you may need to disconnect it temporarily to access the fuel lines.

Open the Bleeder Valves: Now, carefully locate the bleeder valves at each end of the fuel lines. Use your tools to loosen and remove the valves. When you open them, you might hear a hissing sound as air escapes. This is normal, and you should see a small stream of fuel coming out of the valve. If no fuel is visible, it may indicate a blockage, and you should investigate further.

Catch and Dispose of Fuel: As you open the valves, be prepared to catch any fuel that may spill. This is an important step to prevent fuel wastage and potential environmental hazards. Use the container or rag to collect the fuel, and ensure you dispose of it according to local regulations.

Reinstall and Tighten: Once you've bled the fuel lines, carefully reinstall the bleeder valves and tighten them securely. Make sure they are properly aligned and tightened to avoid any leaks.

Remember, this process requires patience and a methodical approach. Take your time to locate the valves, and ensure you have the necessary tools and safety precautions in place. Bleeding the fuel lines is an essential maintenance task to keep your Dodge truck's fuel system in optimal condition.

Dirt Bike Fuel Line Attachment: A Comprehensive Guide

You may want to see also

Testing: Check for leaks and ensure fuel flows freely

Before you begin the process of bleeding the fuel lines on your Dodge truck, it's crucial to understand the importance of testing for leaks and ensuring proper fuel flow. This step is essential to guarantee that the fuel system is functioning correctly and to prevent any potential issues down the line. Here's a detailed guide on how to test for leaks and ensure free fuel flow:

Leak Testing:

- Prepare the Vehicle: Park your Dodge truck in a well-ventilated area, preferably an open field or a garage with the door ajar. Ensure the engine is off and allow the fuel system to cool down if it has been recently used.

- Gather Materials: You will need a few basic tools and materials. Firstly, a fuel line bleeding kit or a simple setup with a syringe and a clear container. Additionally, have some rags or paper towels ready to wipe up any spills.

- Locate the Fuel Lines: Identify the fuel lines that you have bled. These are typically located near the engine and may require some disassembly of the engine bay components to access them.

- Connect the Bleeding Kit: Attach the syringe or the clear container to the end of the fuel line you want to test. Ensure a secure connection to prevent any fuel from escaping.

- Apply Pressure: With the engine off, slowly squeeze the fuel line to create a slight pressure. This will force any air bubbles or residual fuel out of the line. Listen and feel for any hissing or dripping sounds, which indicate a potential leak. If you detect a leak, immediately stop and address the issue.

- Check for Spills: Inspect the area around the fuel lines and the engine bay for any fuel spills. Even small leaks can lead to contamination and potential engine damage over time.

Ensuring Free Fuel Flow:

- Prime the System: After leak testing, it's essential to prime the fuel system to ensure proper fuel flow. Start the engine and let it idle for a few minutes. This will allow the fuel pump to prime the system and ensure a steady supply of fuel to the engine.

- Monitor Fuel Pressure: While the engine is running, use a fuel pressure gauge to check the pressure. The pressure should be within the recommended range specified in your Dodge truck's manual. If the pressure is too low, it may indicate a restricted fuel flow or a problem with the fuel pump.

- Check for Engine Performance: Observe the engine's behavior during this test. A well-functioning fuel system should provide smooth and consistent engine operation. Any rough idling, stalling, or unusual noises could indicate a fuel-related issue.

- Repeat the Process: If any issues are detected, repeat the bleeding and testing process, focusing on specific areas that may require further attention.

Remember, proper testing and maintenance of the fuel system are vital for the overall performance and longevity of your Dodge truck. By following these steps, you can ensure that the fuel lines are bled correctly and that the fuel flows freely, contributing to a reliable and efficient vehicle.

Optimizing Performance: Choosing the Right Fuel Line for Your 350 Chevy

You may want to see also

Frequently asked questions

Bleeding fuel lines is a process to remove air bubbles from the fuel system, ensuring that the engine receives a consistent and uninterrupted supply of fuel. This is crucial for optimal engine performance and can help prevent issues like stalling or poor acceleration.

It is recommended to bleed the fuel lines whenever you add a new fuel tank, make significant modifications to the fuel system, or notice any issues with fuel delivery. Regular maintenance, especially before long trips, can ensure the engine runs smoothly.

Signs that your fuel lines may need bleeding include engine misfires, rough idling, reduced power, or unusual noises from the fuel system. If you experience any of these symptoms, it's best to check and bleed the fuel lines to maintain the truck's performance.

Bleeding fuel lines is a task that can be accomplished by experienced DIY enthusiasts. However, if you're unsure or uncomfortable with the process, it's advisable to consult a professional mechanic. They have the tools and expertise to ensure the job is done correctly and safely.