Removing fuel lines can be a necessary step during vehicle maintenance or repairs, but it requires careful execution to avoid spills and damage. This guide will provide a step-by-step process for safely disconnecting fuel lines, ensuring you have the right tools and safety gear before beginning. It's important to understand the specific make and model of your vehicle to locate the fuel lines correctly and use the appropriate tools for a clean and secure removal.

What You'll Learn

- Prepare the Vehicle: Ensure the engine is off and the car is in a stable position

- Locate the Fuel Lines: Identify the specific fuel lines you want to remove

- Use the Right Tools: Employ appropriate tools like fuel line cutters or pliers

- Loosen Connections: Carefully loosen the connections between the fuel lines and other components

- Cut and Remove: Carefully cut and remove the fuel lines, being mindful of any residual fuel

Prepare the Vehicle: Ensure the engine is off and the car is in a stable position

Before attempting to remove the fuel lines, it's crucial to ensure the vehicle is in a safe and controlled environment. Start by turning off the engine and allowing it to cool down. This step is essential to prevent any accidental starting of the engine during the process, which could lead to injury or damage to the fuel system. Once the engine is off, it's important to engage the parking brake to keep the car stationary. This simple action provides stability and prevents the vehicle from moving unexpectedly, especially on uneven surfaces or slopes.

Next, locate the fuel lines that you intend to remove. These lines typically run from the fuel tank to the engine, and their exact positions may vary depending on the vehicle's make and model. It's important to identify the correct lines to avoid disconnecting other critical components. Often, fuel lines are secured with clips or brackets, so you may need to carefully remove these fasteners to free the lines. Take your time and be gentle to avoid damaging the lines or the surrounding areas.

While preparing the vehicle, it's also a good practice to put down a large, flat piece of cloth or a tarp under the car. This simple step will help catch any spilled fuel and protect your work area from potential stains. Additionally, ensure that the surrounding area is clear of any obstacles or hazards that could interfere with your work or cause accidents.

With the engine off and the vehicle secure, you can now proceed with the specific steps to remove the fuel lines. Remember to work systematically, taking notes or photographs if necessary, to ensure you reconnect the lines in the correct order. This is especially important if you're working on a complex vehicle or if it's your first time dealing with fuel lines.

By following these initial preparation steps, you'll create a safe and controlled environment for removing the fuel lines, ensuring a more efficient and secure process. Always prioritize safety and take the necessary precautions to protect yourself and your vehicle.

Dodge Cummins Fuel Line Removal: A Step-by-Step Guide

You may want to see also

Locate the Fuel Lines: Identify the specific fuel lines you want to remove

To begin the process of removing fuel lines, it's crucial to first identify the specific lines you intend to disconnect. This step is essential to ensure you don't accidentally remove the wrong lines, which could lead to fuel leaks and potential safety hazards. Here's a detailed guide on how to locate and identify the fuel lines:

Locate the Fuel Tank and Lines: Start by locating your vehicle's fuel tank. This is typically found in the trunk or beneath the vehicle, depending on the car model. Once you've located the tank, you'll see several fuel lines connected to it. These lines are usually made of rubber or plastic and carry fuel from the tank to the engine.

Identify the Lines: Each fuel line has a specific function. The primary lines include the fuel supply line, which delivers fuel from the tank to the engine, and the return line, which returns unused fuel from the engine back to the tank. There may also be lines for the fuel pump and other components. Identify the lines you want to remove by checking your vehicle's manual or consulting a repair guide specific to your car model. This will help you understand the layout and function of each line.

Mark the Lines: To avoid confusion, it's a good practice to mark the lines you intend to remove. You can use tape, labels, or even a permanent marker to identify them. For example, you could label the fuel supply line as "Line A" and the return line as "Line B." This simple step will make the disconnection process much easier and reduce the risk of errors.

Prepare the Necessary Tools: Before you start, ensure you have the right tools for the job. You'll likely need a fuel line disconnect tool, which is a specialized tool designed to release the pressure and allow for the safe removal of fuel lines. Additionally, have a container ready to catch any fuel that may spill during the process.

By following these steps, you'll be well-prepared to safely and efficiently remove the specific fuel lines you've identified, ensuring a clean and organized workspace. Remember, always exercise caution when working with fuel to prevent any accidents or environmental damage.

Temporary Fuel Line Solutions: Quick Fixes for Car Fuel Issues

You may want to see also

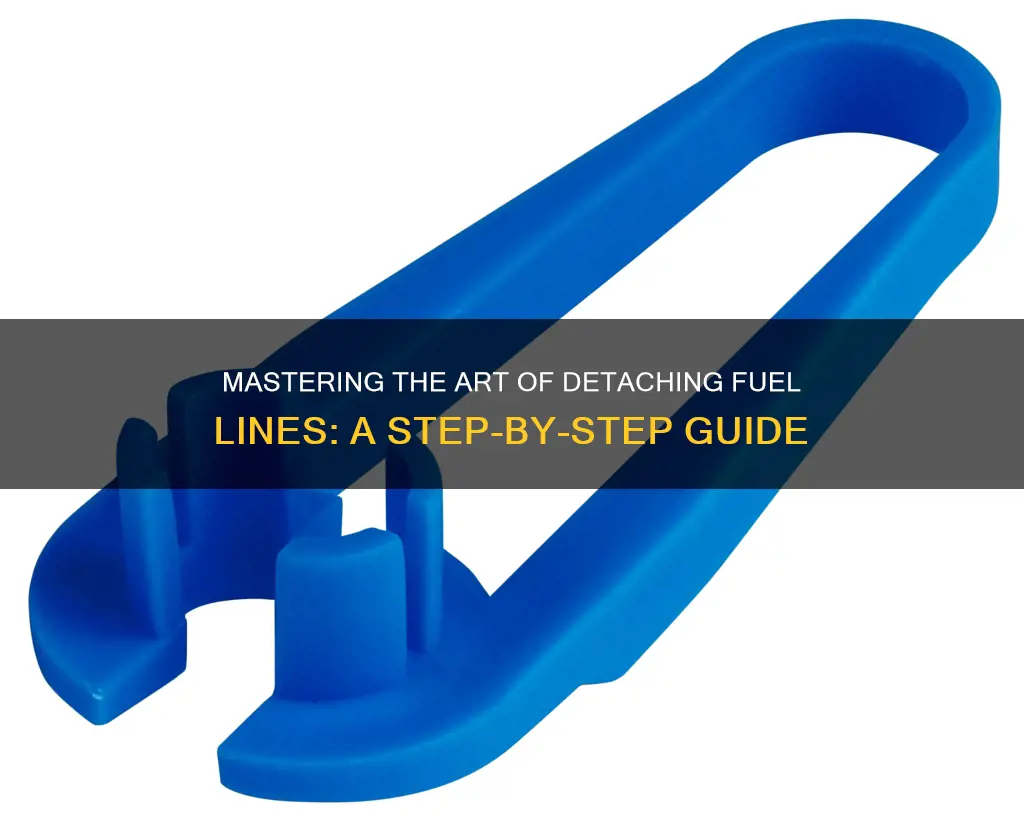

Use the Right Tools: Employ appropriate tools like fuel line cutters or pliers

When it comes to removing fuel lines, using the right tools is crucial to ensure a safe and efficient process. One of the primary tools you'll need is a fuel line cutter, also known as a fuel line cutting tool or fuel line removal kit. These specialized tools are designed to safely and effectively cut through fuel lines without causing damage to the surrounding components. They typically feature a sharp, precision-ground blade that can cleanly sever the fuel line, minimizing the risk of fuel leaks and potential hazards.

In addition to fuel line cutters, having a set of appropriate pliers can be incredibly useful. Pliers provide the necessary grip and leverage to carefully bend or manipulate fuel lines, especially in tight or hard-to-reach areas. Look for pliers with a smooth, non-marring jaw to avoid scratching the fuel lines or surrounding surfaces. Some pliers even have adjustable features, allowing you to grip fuel lines of various sizes securely.

Using the right tools not only makes the job easier but also safer. Fuel lines are typically made of high-pressure hoses that can be dangerous if not handled properly. Without the appropriate tools, you risk damaging the fuel lines or causing them to rupture, leading to potential fuel leaks and fire hazards. By employing fuel line cutters and pliers, you can ensure a clean and controlled cut, reducing the chances of accidents and making the removal process more efficient.

It's important to choose tools that are specifically designed for fuel line work. Generic tools may not provide the necessary precision or safety features. When selecting your tools, consider factors such as the material of the fuel lines, the pressure they carry, and the overall design of the vehicle you're working on. Investing in high-quality, purpose-built tools will pay off in terms of reliability and performance.

Remember, when working with fuel lines, always prioritize safety. Take the time to understand the process, gather the right tools, and follow proper procedures. By using the appropriate fuel line cutters and pliers, you'll be well-equipped to safely remove fuel lines, ensuring a successful and hazard-free repair or maintenance task.

Flare Stainless Steel Fuel Lines: A Comprehensive Guide

You may want to see also

Loosen Connections: Carefully loosen the connections between the fuel lines and other components

When it comes to removing fuel lines, one of the crucial steps is carefully loosening the connections between the fuel lines and other components. This process requires precision and patience to ensure that you don't damage any parts or cause a fuel leak. Here's a detailed guide on how to approach this task:

Start by identifying the connections you need to loosen. Fuel lines are typically connected to various components such as the fuel tank, engine, and fuel injectors. Locate the fittings or clamps that secure these connections. It's important to understand the layout and positioning of these connections to avoid any confusion during the process.

Using the appropriate tools is essential for this step. You will likely need a set of wrenches or fuel line removal tools specifically designed for this purpose. These tools often have a curved or angled design to fit around the connections comfortably. Apply a small amount of force to loosen the connections, but be cautious not to overtighten. Loosen them just enough to create a small gap, allowing you to work on the fuel lines without excessive resistance.

Take your time and work systematically. Loosen one connection at a time, ensuring that you don't over-tighten or force it. If you encounter resistance, back off slightly and try again. It's better to be gentle and patient than to force the connections, as this can lead to damage or stripping of threads. Remember to keep track of the order in which you loosen the connections to avoid confusion when reassembling the system.

As you loosen the connections, inspect the fuel lines for any signs of damage or wear. Look for cracks, leaks, or any signs of deterioration. This inspection is crucial to ensure that the fuel lines are in good condition and won't cause any issues when removed. If you notice any damage, it's best to replace the affected fuel lines to maintain the safety and efficiency of your vehicle's fuel system.

Once all the connections are loosened, you can proceed with the next steps of removing the fuel lines. Remember, this process requires a gentle touch and a systematic approach to ensure a successful and safe fuel line removal.

Fuel Return Line Size for 1998 Honda Civic

You may want to see also

Cut and Remove: Carefully cut and remove the fuel lines, being mindful of any residual fuel

When it comes to removing fuel lines, it's important to approach the task with caution and a methodical mindset. The process requires careful disassembly to ensure no fuel spills or damage to the vehicle's components. Here's a step-by-step guide to help you navigate this process:

Start by identifying the fuel lines you need to remove. These lines are typically made of rubber or a flexible material and are connected to the fuel tank and various fuel-injected components. Locate the specific lines you want to disconnect, as the process may vary depending on the vehicle's make and model. It's crucial to understand the layout of the fuel system to avoid any accidental disconnections.

Using the right tools is essential for a successful removal. You'll likely need a fuel line disconnect tool or a similar device designed for this purpose. These tools help grip and release the fuel lines without causing damage. If you don't have access to such tools, a pair of adjustable pliers or a wrench can be used with caution, but be prepared for a more challenging process.

Now, carefully cut the fuel lines. This step requires precision to avoid cutting into other components or causing fuel leaks. Use a sharp, clean blade or a fuel line cutter to make a clean cut. Ensure you cut the line at a slight angle to create a smooth edge, which will help prevent fraying. Take your time and double-check your measurements to avoid any mistakes.

As you cut the fuel lines, be vigilant for any residual fuel. Fuel is highly flammable, and any spilled fuel can lead to dangerous situations. If you encounter any fuel, immediately wipe it up with a clean, dry cloth or absorbency material. Ensure you work in a well-ventilated area and consider wearing protective gear, such as gloves and safety goggles, to minimize any potential hazards.

Once the fuel lines are cut, carefully remove them from the vehicle. You may need to unclip or unbolt certain components to access the lines. Take your time and be gentle to avoid causing further damage. Properly dispose of the fuel lines or recycle them if possible, following local regulations for hazardous waste disposal. Remember, the key to success is patience and attention to detail throughout the entire process.

Where to Find 5/16 Rigid Metal Fuel Lines

You may want to see also

Frequently asked questions

Removing fuel lines can be a delicate process, and it's important to take safety precautions. First, ensure the engine is cool and parked on a level surface. Locate the fuel lines, which are typically made of rubber or plastic and run from the fuel tank to the engine. Use a fuel line disconnect tool or a pair of pliers to carefully loosen and remove the fittings. Be cautious not to damage the lines or the surrounding components. If the lines are corroded or difficult to remove, consider using a fuel line cleaner or a thin-walled socket to gently pry them off.

Yes, you can often reuse the old fuel lines if they are in good condition. Inspect the lines for any cracks, leaks, or signs of damage. If they are intact and not showing any wear, you can reconnect them to the new fuel pump or engine. However, if the lines are old or have been damaged, it's best to replace them with new ones to ensure a reliable fuel supply.

If the fuel lines are stubborn and not coming off easily, there are a few things you can try. First, ensure you have the correct tools and apply gentle force. Sometimes, a thin-walled socket or a fuel line disconnect tool can help pry the lines off. If the lines are stuck due to corrosion, consider using a fuel line cleaner or a lubricant to loosen the fittings. Be patient and avoid forcing anything to prevent damage. If the issue persists, it might be best to seek professional assistance to avoid any further complications.