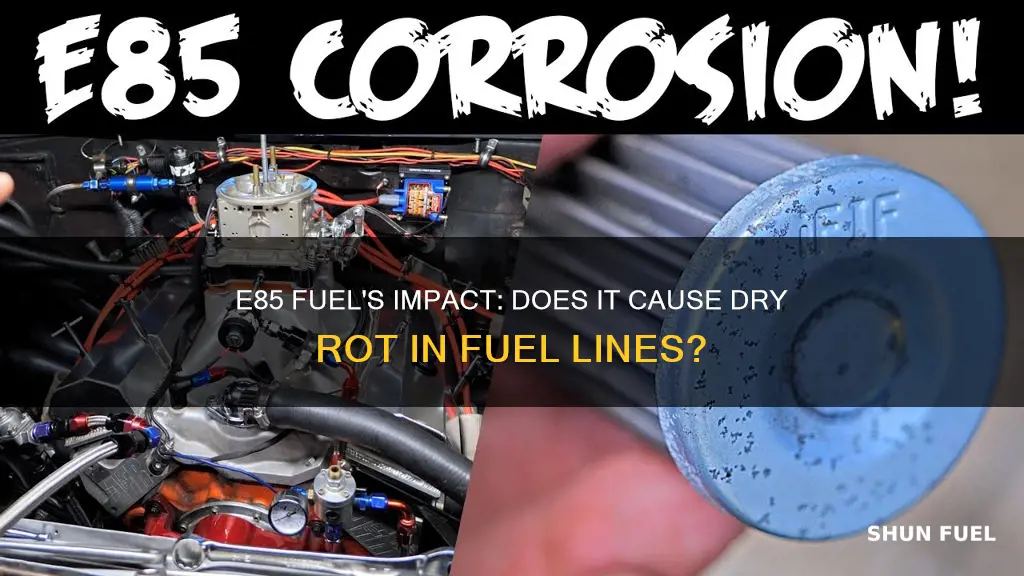

E85, a blend of 85% ethanol and 15% gasoline, is a popular alternative fuel for vehicles. While it offers benefits such as reduced carbon emissions and higher octane levels, its use raises concerns about its impact on fuel system components, particularly fuel lines. This paragraph explores the question of whether E85 can cause fuel lines to dry rot, a potential issue that vehicle owners should be aware of when considering this fuel option.

| Characteristics | Values |

|---|---|

| Fuel Type | Ethanol (E85) |

| Fuel Line Material | Various (e.g., rubber, plastic, steel) |

| Potential for Dry Rot | Yes, especially in materials like rubber |

| Factors Affecting Dry Rot | Temperature, humidity, fuel line age, fuel quality |

| Symptoms of Dry Rot | Cracks, brittleness, fuel leaks, reduced performance |

| Prevention Measures | Regular inspections, using compatible materials, fuel additives |

| Maintenance | Replacing old fuel lines, using lubricants to prevent cracking |

| Environmental Impact | E85 can have higher emissions compared to gasoline |

| Performance Considerations | E85 may require engine modifications for optimal performance |

| Cost Implications | Potential for higher maintenance and repair costs |

What You'll Learn

- Corrosion: E85 can cause rust and deterioration in fuel lines over time

- Rubber Degradation: The ethanol in E85 accelerates the breakdown of rubber components

- Leaks: Fuel line cracks may lead to fuel leaks and engine issues

- Flexibility Loss: E85 can make fuel lines stiff, reducing their flexibility

- Maintenance: Regular inspections and replacements are necessary to prevent damage

Corrosion: E85 can cause rust and deterioration in fuel lines over time

E85, a blend of 85% ethanol and 15% gasoline, is a popular alternative fuel for vehicles designed to run on ethanol. While it offers benefits such as reduced carbon emissions and potential cost savings, it also presents unique challenges, particularly regarding its impact on fuel system components. One of the most significant concerns is the potential for E85 to cause corrosion and deterioration in fuel lines, which can lead to various performance issues and potential safety hazards.

The corrosive nature of E85 is primarily due to the high ethanol content. Ethanol is known to be more corrosive to certain metals, especially when in contact with water. Over time, the ethanol in E85 can cause the fuel lines to deteriorate, leading to several problems. One of the most visible signs of this deterioration is the formation of rust and corrosion along the fuel lines. This corrosion can lead to a buildup of deposits, narrowing the fuel lines and reducing the flow of fuel to the engine. As a result, the engine may experience reduced performance, poor fuel efficiency, and even stalling.

The impact of E85 on fuel lines is particularly noticeable in older vehicles or those with less robust fuel systems. The ethanol in E85 can accelerate the degradation of rubber and plastic components, such as fuel hoses and gaskets, which are commonly used in fuel systems. This degradation can lead to leaks, allowing air to enter the fuel system, which can cause engine misfires and reduced performance. In some cases, the corrosion may even lead to the complete failure of the fuel lines, resulting in a complete loss of fuel supply to the engine.

To mitigate these issues, it is essential to use E85-compatible fuel lines and components. Many modern vehicles are designed to handle E85, but it is crucial to ensure that the fuel system has been properly upgraded to accommodate the higher ethanol content. Regular maintenance, such as fuel system flushes and the use of ethanol-safe fuel stabilizers, can also help prevent corrosion and maintain the integrity of the fuel lines. Additionally, drivers should be aware of the potential signs of fuel line issues, such as unusual engine noises, reduced power, or changes in fuel efficiency, and address them promptly to avoid further damage.

In summary, while E85 offers environmental and economic benefits, its potential to cause corrosion and deterioration in fuel lines is a significant consideration for vehicle owners. Understanding the risks and taking appropriate measures can help ensure that E85 vehicles operate efficiently and safely over their lifespan.

Vinyl as Fuel Line: A Creative Alternative or a Recipe for Disaster?

You may want to see also

Rubber Degradation: The ethanol in E85 accelerates the breakdown of rubber components

The use of E85, a fuel blend containing 85% ethanol and 15% gasoline, has become increasingly popular among vehicle enthusiasts and those seeking alternative energy sources. However, one concern that has emerged is the potential impact of ethanol on rubber components in fuel systems. This is particularly relevant for fuel lines, which are crucial for delivering fuel from the tank to the engine.

Ethanol, a polar solvent, has a unique property that sets it apart from gasoline. When ethanol is added to gasoline, it increases the overall octane rating, which can improve engine performance. However, its solvent properties also play a significant role in the degradation of rubber. Rubber, a polymer, is composed of long chains of molecules that are sensitive to various environmental factors. Ethanol's ability to dissolve and penetrate these chains can lead to a process known as "rubber degradation."

In the context of fuel lines, this degradation can have serious consequences. Rubber fuel lines are designed to withstand the pressure and temperature changes associated with fuel flow. However, when exposed to ethanol-rich environments, these lines can deteriorate over time. The ethanol accelerates the breakdown of the rubber's molecular structure, causing it to become brittle, crack, and eventually fail. This failure can result in fuel leaks, which not only pose environmental risks but also lead to engine misfires, reduced performance, and potential safety hazards.

Research has shown that the rate of rubber degradation is significantly higher in ethanol-containing fuels compared to traditional gasoline. This is primarily due to the higher concentration of ethanol, which provides a more aggressive solvent environment. As a result, fuel lines made from natural rubber or synthetic rubbers containing natural rubber components may be particularly susceptible to damage.

To mitigate these issues, some vehicle manufacturers and fuel system designers are exploring alternative materials for fuel lines. These alternatives include synthetic rubbers that are less susceptible to ethanol degradation. Additionally, regular maintenance and inspection of fuel lines, especially in vehicles running on E85, can help identify and address potential issues before they lead to significant problems. Understanding the impact of ethanol on rubber components is crucial for ensuring the longevity and reliability of fuel systems in vehicles using E85 fuel.

Metal Fuel Line Flaring Frustration: Common Issues and Solutions

You may want to see also

Leaks: Fuel line cracks may lead to fuel leaks and engine issues

E85 fuel, a blend of 85% ethanol and 15% gasoline, is known for its higher octane content and potential benefits for performance and fuel economy. However, it's crucial to understand the potential drawbacks, especially regarding fuel line maintenance. One significant concern is the possibility of fuel line cracks, which can lead to various engine issues and safety hazards.

Fuel lines are responsible for transporting fuel from the tank to the engine, and they are designed to withstand the pressure and temperature changes that occur during engine operation. However, E85's higher ethanol content can have a detrimental effect on these lines over time. Ethanol is more corrosive to certain materials, including rubber and plastic, which are commonly used in fuel lines. This corrosion can lead to the deterioration of the fuel lines, causing cracks and eventual leaks.

When a fuel line cracks, it creates a direct path for fuel to escape into the engine compartment or even under the vehicle. This can result in several problems. Firstly, fuel leaks can lead to dangerous situations, as gasoline is highly flammable. Even a small leak can pose a significant fire hazard, especially in enclosed spaces or areas with a spark source. Secondly, the loss of fuel can cause the engine to run poorly or even stall. The engine may not receive the correct amount of fuel, leading to reduced performance, decreased power, and potential damage to internal components.

Regular maintenance and inspections are essential to prevent fuel line issues. Drivers who use E85 should pay close attention to their fuel lines and look for any signs of damage, such as cracks, brittleness, or corrosion. If any issues are detected, immediate action should be taken to repair or replace the affected fuel lines. This may involve consulting a professional mechanic who has experience with E85 fuel systems.

In summary, while E85 offers advantages in terms of performance and fuel economy, it's essential to be aware of the potential risks associated with fuel line cracks. Proper maintenance and regular inspections can help identify and address these issues, ensuring the safe and efficient operation of the vehicle. By understanding the potential consequences of fuel line leaks, drivers can take proactive measures to protect their engines and themselves.

Efficient Conversion: Who Crafts the Perfect EFI-to-Carb Fuel Line Adaptor?

You may want to see also

Flexibility Loss: E85 can make fuel lines stiff, reducing their flexibility

E85, a blend of 85% ethanol and 15% gasoline, is a popular alternative fuel for vehicles, especially those with flexible-fuel capabilities. While it offers numerous benefits, such as reduced emissions and potential cost savings, there is a lesser-known drawback associated with its use: the potential for fuel lines to become stiff and lose flexibility. This issue can have significant implications for the overall performance and longevity of a vehicle's fuel system.

The primary concern with E85 is its higher ethanol content compared to conventional gasoline. Ethanol is known to have a higher water solubility, which means it can attract and hold moisture. When E85 is used regularly, the ethanol can cause the fuel lines to absorb moisture, leading to a process known as "fuel line swelling." Over time, this swelling can result in the fuel lines becoming stiffer and less flexible. The flexibility of fuel lines is crucial for their proper function, as it allows them to expand and contract with temperature changes and engine movement.

The loss of flexibility in fuel lines can lead to several problems. Firstly, it may cause fuel pressure issues. As the lines stiffen, they can restrict the flow of fuel, leading to reduced engine performance and potential starting difficulties. This is particularly problematic for vehicles that rely on precise fuel pressure for optimal operation. Secondly, the reduced flexibility can result in fuel line cracks or even ruptures, especially during temperature fluctuations. These failures can lead to fuel leaks, which not only cause environmental concerns but also pose a safety hazard.

To mitigate these issues, vehicle owners should be aware of the potential impact of E85 on fuel lines. Regular maintenance, including fuel system inspections and the use of ethanol-free gasoline for occasional topping up, can help prevent or minimize the effects of fuel line swelling. Additionally, keeping the vehicle's fuel system clean and dry is essential, as moisture can exacerbate the problem. While E85 offers an attractive alternative fuel option, it is crucial to understand and address its potential impact on fuel system components like the lines to ensure optimal vehicle performance and longevity.

Unveiling the Fuel Line Mystery: Boeing 747's Fuel Line Size Explained

You may want to see also

Maintenance: Regular inspections and replacements are necessary to prevent damage

Maintaining your vehicle's fuel system is crucial, especially when using E85 fuel, which contains higher levels of ethanol compared to conventional gasoline. Ethanol can have a drying effect on certain components, including fuel lines, which can lead to cracking, brittleness, and eventual failure. Regular inspections and replacements are essential to prevent damage and ensure optimal performance.

During routine maintenance, it is recommended to inspect the fuel lines for any signs of deterioration. Look for cracks, splits, or any visible damage along the length of the lines. Pay close attention to the connections and fittings, as these areas are more susceptible to wear and tear. If you notice any issues, it is best to replace the affected fuel lines promptly to avoid further complications. Over time, the ethanol in E85 can cause the rubber or plastic material of the fuel lines to dry out and become brittle, leading to potential leaks or blockages.

In addition to visual inspections, it is beneficial to consider the age and condition of the fuel lines. Older fuel lines may be more prone to degradation, especially if they have been exposed to the elements for an extended period. Regularly checking the fuel lines' condition and replacing them every few years can help prevent unexpected failures. It is also advisable to use high-quality fuel line materials that are more resistant to ethanol's drying effects.

When performing inspections, ensure that the vehicle is in a secure and level position. Use a flashlight to examine the fuel lines thoroughly, especially in hard-to-reach areas. If you are unsure about the condition of the fuel lines or the extent of the damage, consult a professional mechanic who has experience with E85-compatible vehicles. They can provide expert advice and ensure the necessary replacements are made.

Remember, proper maintenance and regular attention to the fuel system will help extend the lifespan of your vehicle and ensure reliable performance. By incorporating these inspection and replacement practices into your vehicle's care routine, you can minimize the risks associated with E85 fuel and maintain a well-functioning engine.

Optimizing Fuel Flow: Choosing the Right Size Fuel Line for Your Monte Carlo

You may want to see also

Frequently asked questions

E85 is a type of ethanol fuel, specifically a blend of 85% ethanol and 15% gasoline. It is a higher-octane fuel that can cause some unique challenges when it comes to fuel system maintenance. While E85 is less likely to cause immediate corrosion or drying out of fuel lines compared to pure gasoline, it can still have an impact over time.

Yes, E85 can potentially lead to fuel line drying and cracking. Ethanol is more volatile than gasoline, which means it can attract moisture from the air. Over time, this moisture can cause the fuel lines to swell and potentially crack, especially if the fuel lines are not made of materials that can withstand ethanol.

Regular maintenance is key to preventing issues with E85. Here are some recommendations:

- Use ethanol-compatible fuel lines: Ensure your fuel lines are made of materials like stainless steel or nylon, which can handle ethanol blends.

- Add a fuel stabilizer: Consider using a fuel stabilizer designed for ethanol fuels. These products can help maintain the moisture content in the fuel, reducing the risk of drying out the fuel lines.

- Regularly inspect and replace fuel lines: Periodically check for any signs of cracking or swelling in your fuel lines. If any issues are found, replace the affected lines promptly.

Yes, there are a few other factors to keep in mind:

- Engine compatibility: Not all engines are designed to run on E85. Ensure your vehicle's engine is compatible with ethanol blends.

- Moisture content: E85 can attract moisture, so it's important to use a fuel filter that can handle ethanol and to regularly check and maintain the fuel system to remove any accumulated moisture.

- Storage and handling: When storing E85, ensure it is in a sealed container to prevent moisture absorption. Always handle the fuel with clean equipment to avoid introducing contaminants.