Using a fuel line tool can be a useful skill for anyone working on vehicles or machinery that utilizes fuel lines. This tool is designed to help with the installation, repair, and maintenance of fuel lines, ensuring they are properly connected and sealed. It is an essential accessory for mechanics and DIY enthusiasts alike, as it simplifies the process of working with fuel lines, which can be delicate and prone to damage. The tool typically consists of a set of specialized connectors and seals that can be easily attached to fuel lines, ensuring a secure and leak-free connection. By following a few simple steps, you can effectively use this tool to make your fuel line work more efficient and reliable.

What You'll Learn

- Fuel Line Tool Basics: Understand the tool's function and its components

- Fuel Line Inspection: Learn to identify issues with fuel lines

- Fuel Line Cleaning: Techniques for removing contaminants from fuel lines

- Fuel Line Replacement: Steps to replace damaged or worn fuel lines

- Fuel Line Maintenance: Regular care to ensure optimal fuel system performance

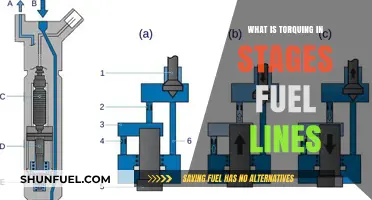

Fuel Line Tool Basics: Understand the tool's function and its components

The fuel line tool is a specialized device designed to facilitate the maintenance and repair of fuel systems in vehicles. It is an essential tool for mechanics and car enthusiasts who work with fuel-related issues, offering a comprehensive solution for diagnosing and addressing problems within the fuel system. This tool is particularly useful for identifying and resolving issues related to fuel pressure, flow, and quality, ensuring optimal engine performance.

At its core, the fuel line tool consists of several key components that work in harmony to provide accurate readings and efficient troubleshooting. The primary element is the pressure gauge, which measures the fuel pressure within the system. This gauge is crucial for identifying potential issues, such as low or fluctuating fuel pressure, which can lead to engine misfires or poor performance. The tool also includes a fuel flow meter, which measures the volume of fuel passing through the system, helping to detect blockages or restrictions in the fuel lines.

Additionally, the fuel line tool is equipped with a fuel sample port, allowing for the collection of fuel samples for analysis. This feature enables users to check for contamination, water content, or other impurities that might affect engine operation. The tool may also incorporate a display unit that provides real-time data, including pressure, flow rates, and fuel quality indicators, making it easier to interpret the results and make informed decisions.

Understanding the function of each component is essential for effective use. The pressure gauge provides critical information about the fuel system's performance, helping to pinpoint issues related to fuel delivery. The fuel flow meter ensures that the fuel is flowing correctly, identifying potential blockages or leaks. The sample port and display unit work together to offer a comprehensive view of the fuel system's health, enabling users to make necessary adjustments or repairs.

Mastering the fuel line tool requires practice and familiarity with its various functions. Users should familiarize themselves with the tool's calibration process, ensuring accurate readings. Regular maintenance and cleaning of the tool are also vital to ensure its longevity and reliability. By grasping the fundamentals of this tool, mechanics can efficiently diagnose and resolve fuel-related problems, ultimately improving the overall performance and longevity of vehicles.

Understanding the Role of Fuel Line Hoses in the Evaporative Emissions System

You may want to see also

Fuel Line Inspection: Learn to identify issues with fuel lines

Fuel lines are a critical component of any vehicle's fuel system, and regular inspections can help prevent costly repairs and ensure optimal engine performance. Identifying issues with fuel lines early on can save you from potential breakdowns and expensive engine replacements. Here's a guide on how to inspect your fuel lines and what to look for:

Understanding the Fuel Line System: Before you begin the inspection, it's essential to understand the basic components of your vehicle's fuel line system. This system typically includes a fuel tank, a fuel pump, a fuel filter, and a network of fuel lines that carry gasoline from the tank to the engine. Each part plays a crucial role in delivering fuel efficiently. Familiarize yourself with the layout of these components in your vehicle to locate the fuel lines easily.

Visual Inspection: Start by visually examining the fuel lines for any visible damage or deterioration. Look for cracks, leaks, bulges, or any signs of corrosion. Fuel lines are often made of rubber or plastic, and over time, they can degrade due to heat, sunlight, and chemical exposure. Check for any discoloration or softening of the material, as this could indicate a compromised line. Pay close attention to bends and fittings, as these areas are more susceptible to damage. If you notice any issues, it's best to replace the affected fuel line promptly.

Pressure Testing: Conducting a pressure test is an effective way to identify potential fuel line leaks. You can use a fuel line pressure tester or a simple pump and gauge set. Start by ensuring the engine is off and the vehicle is in a stable position. Connect the pressure tester to the fuel line, ensuring a secure connection. Turn on the engine and gradually increase the pressure, listening for any hissing sounds, which indicate a leak. If you hear a leak, locate the source and consider replacing the affected section. Remember to release the pressure safely after the test.

Leak Detection: Fuel line leaks can be challenging to detect due to the fuel's volatile nature. Always exercise caution when inspecting for leaks. Use a soapy water solution to coat the fuel lines and look for bubbles, which indicate a leak. Alternatively, you can use a fuel line dye, available at auto parts stores, to make the detection process easier. Apply the dye to the fuel lines and check for any discoloration in the engine compartment or under the vehicle. Leaks can cause engine misfires, reduced performance, and even dangerous situations, so addressing them promptly is crucial.

Regular Maintenance: Preventive maintenance is key to keeping your fuel lines in good condition. Regularly inspect the fuel lines during routine vehicle maintenance checks. Keep an eye out for any changes in engine performance, such as reduced power or fuel efficiency, which could be indicators of fuel line issues. Additionally, ensure that the fuel filter is regularly replaced according to the manufacturer's recommendations to prevent contaminants from entering the fuel lines.

Understanding Fuel Filter Lines: A Comprehensive Guide

You may want to see also

Fuel Line Cleaning: Techniques for removing contaminants from fuel lines

Fuel lines are crucial components of a vehicle's fuel system, and over time, they can accumulate contaminants such as fuel varnish, water, and debris, which can lead to reduced engine performance, poor fuel economy, and even engine damage. Cleaning these fuel lines is essential to maintain the health and longevity of your vehicle's engine. Here's a comprehensive guide on how to use a fuel line cleaning tool and the techniques to effectively remove contaminants:

Understanding the Fuel Line Cleaning Process: Before you begin, it's important to understand the process and the tools involved. Fuel line cleaning tools are designed to remove contaminants without causing damage to the fuel lines. These tools typically use a combination of pressure, air, and sometimes chemicals to dislodge and flush out the contaminants. The process involves inserting the tool into the fuel line and creating a controlled flow of air or a cleaning solution to push the contaminants out.

Gathering the Necessary Tools and Materials: To clean fuel lines, you'll need a few essential tools and materials. Firstly, acquire a fuel line cleaning tool, which can be rented or purchased from automotive supply stores. These tools often consist of a flexible hose, a pressure regulator, and a nozzle for controlled cleaning. Additionally, you'll require a fuel line cleaner or a fuel system cleaner, which can be in the form of a concentrate or a ready-to-use spray. It's recommended to use a product specifically designed for fuel system cleaning to ensure effectiveness.

Pre-Cleaning Preparation: Prior to the cleaning process, it's crucial to prepare your vehicle. Park the car on a level surface and ensure it is in a safe, well-ventilated area. Turn off the engine and allow it to cool down to prevent any potential hazards. Locate the fuel lines and identify the points where the cleaning tool can be inserted. Typically, this is done by removing the fuel line clips or brackets to access the fuel lines.

Cleaning Technique: Start by attaching the fuel line cleaning tool to the fuel line at the identified insertion points. Connect the tool's hose to the fuel line cleaner's spray nozzle. Turn on the tool's power source and adjust the pressure to a moderate setting. Begin the cleaning process by spraying the fuel line cleaner into the line, ensuring an even distribution. The tool's pressure will help dislodge contaminants, and the cleaner will dissolve any built-up deposits. Allow the cleaner to work for a specified duration, which may vary depending on the product and the severity of contamination.

Flushing and Rinsing: After the cleaning process, it's essential to flush the fuel lines to remove any remaining contaminants and cleaning solution. Turn on the vehicle's engine and allow it to idle for a few minutes. This will create a flow of fuel through the lines, helping to push out any residual cleaner. Once the engine is running smoothly, continue idling for a while to ensure a thorough flush. Finally, shut off the engine and disconnect the fuel line cleaner to rinse the tool and any remaining contaminants.

Post-Cleaning Maintenance: After the fuel lines are clean, it's a good practice to perform a few maintenance steps. Check the fuel lines for any signs of damage or wear, especially if you've used a high-pressure cleaning tool. Replace any damaged sections and ensure all connections are secure. Additionally, consider using a fuel stabilizer to prevent future contamination and maintain the cleanliness of the fuel system.

By following these techniques and using the appropriate tools, you can effectively clean your fuel lines, ensuring optimal engine performance and longevity. Regular maintenance of the fuel system is a vital aspect of vehicle care.

Clear Tubing: A Viable Fuel Line Solution?

You may want to see also

Fuel Line Replacement: Steps to replace damaged or worn fuel lines

Fuel lines are crucial components of a vehicle's fuel system, responsible for transporting fuel from the tank to the engine. Over time, these lines can become damaged or worn due to factors like age, corrosion, or accidents. When this happens, it's essential to replace the fuel lines to ensure optimal engine performance and prevent potential issues. Here's a step-by-step guide on how to replace damaged or worn fuel lines using the appropriate tools:

Step 1: Prepare the Vehicle and Gather Tools

Before you begin, ensure you have the necessary tools and equipment. You'll need a fuel line tool, which is a specialized device designed to cut and connect fuel lines. This tool typically has a cutting mechanism and a fitting that allows for secure connections. Additionally, gather the replacement fuel lines, which should be compatible with your vehicle's make and model. It's also advisable to have a fuel pump bypass tool or a similar device to temporarily disconnect the fuel pump during the replacement process. Prepare your workspace by laying down a clean, flat surface and ensuring you have good lighting.

Step 2: Locate the Fuel Lines

Locate the fuel lines that need replacement. These lines are usually located under the vehicle, running from the fuel tank to the engine. Carefully inspect the lines for any visible damage, such as cracks, leaks, or corrosion. Take note of the positions of the fuel lines relative to other components, as this will help with the installation of the new lines.

Step 3: Cut and Remove the Old Fuel Lines

Using the fuel line tool, carefully cut the damaged or worn fuel lines. The tool's cutting mechanism should be aligned with the line's diameter to ensure a clean cut. Once cut, remove the old fuel lines by pulling them away from the connections. Be cautious not to damage surrounding components during this process. If the lines are difficult to remove, you may need to use a fuel line brush to clear any debris or corrosion.

Step 4: Prepare the New Fuel Lines

Take the replacement fuel lines and inspect them for any manufacturing defects or damage. Ensure that the lines are the correct size and length for your vehicle. If necessary, use a fuel line primer to ensure a secure connection. Prepare the ends of the new lines by cutting them to the appropriate length using the fuel line tool again.

Step 5: Install the New Fuel Lines

Begin installing the new fuel lines by connecting one end to the fuel pump or the existing fuel lines. Use the fuel line tool's fitting to create a secure and leak-free connection. Work your way along the fuel lines, connecting each end to the corresponding port or fitting. Ensure that the lines are routed correctly and securely fastened to prevent any movement.

Step 6: Test and Inspect

Once the new fuel lines are installed, it's crucial to test the system. Start the vehicle and check for any leaks at the connections. Listen for any unusual noises from the fuel system. If everything is functioning correctly, you can proceed to the final step. Inspect the entire fuel line system for any signs of damage or improper installation.

Remember, working with fuel lines requires caution and precision. Always refer to your vehicle's manual for specific instructions and ensure you have the necessary experience or guidance when dealing with fuel system repairs.

Mastering Fuel Line Sleeving: A Concrete Guide

You may want to see also

Fuel Line Maintenance: Regular care to ensure optimal fuel system performance

Fuel line maintenance is a crucial aspect of vehicle care that often goes overlooked, yet it plays a significant role in ensuring your engine operates at its best. Regular maintenance of the fuel lines is essential to prevent issues that can lead to reduced performance, costly repairs, and even engine failure. Here's a comprehensive guide on how to maintain your fuel lines and keep your fuel system in top shape.

Understanding the Fuel Line System: Before diving into maintenance, it's essential to understand the fuel line system's function. Fuel lines are responsible for transporting gasoline or diesel from the fuel tank to the engine. They are typically made of durable materials like rubber or plastic and are designed to withstand the pressure and temperature changes associated with fuel. Over time, however, these lines can deteriorate due to factors like age, heat, and chemical exposure.

Regular Inspection: One of the simplest yet most effective maintenance practices is regular inspection. Check the fuel lines for any signs of damage, cracks, leaks, or corrosion. Inspect the lines for any visible wear, especially where they connect to the fuel tank and the engine. Look for any signs of moisture or condensation inside the lines, as this could indicate a leak. If you notice any issues, address them promptly to prevent further damage.

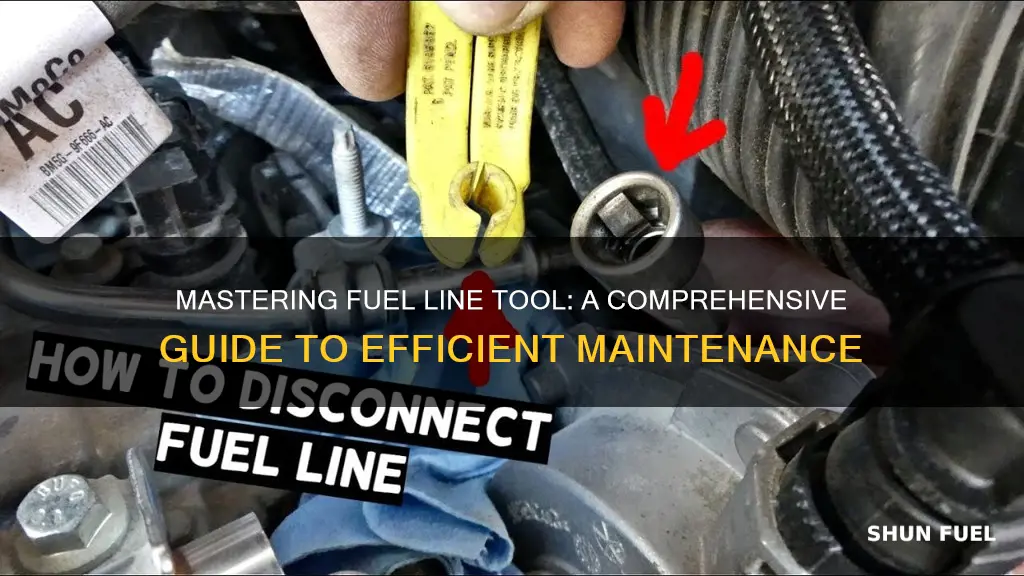

Using a Fuel Line Tool: A fuel line tool, also known as a fuel line cleaner or fuel line brush, is a handy device designed to clean and maintain fuel lines. These tools are particularly useful for reaching tight spaces and removing built-up deposits and contaminants. Here's how to use it effectively: First, ensure the vehicle is parked on a level surface and the engine is cool. Locate the fuel lines and identify the areas that need cleaning. Apply the fuel line tool, which often consists of a flexible brush or a cleaning solution, to the inside of the lines. Work the tool through the lines, paying extra attention to any bends or restrictions. This process helps remove old fuel, varnish, and debris, ensuring a clean and smooth flow of fuel.

Routine Cleaning and Flushing: Regular cleaning and flushing of the fuel system are vital. You can use a fuel system cleaner, available at most auto parts stores, to flush out any contaminants. Follow the manufacturer's instructions for the cleaning process. This routine maintenance helps prevent the buildup of deposits and ensures that the fuel lines remain clear and efficient.

Addressing Common Issues: Common problems with fuel lines include leaks, clogs, and corrosion. If you notice a leak, it's crucial to replace the affected line promptly. Clogs can be addressed by using a fuel line brush to clear any blockages. Corrosion is often caused by moisture, so ensure the fuel tank is dry and consider using a fuel stabilizer to prevent corrosion.

By following these maintenance practices, you can ensure that your fuel lines remain in excellent condition, promoting optimal engine performance and longevity. Regular care and attention to the fuel system will save you from potential headaches and costly repairs in the long run.

Unveiling the Materials Behind Fuel Tank Lines

You may want to see also

Frequently asked questions

A fuel line tool is a specialized device used to remove and install fuel lines in vehicles. It is essential for mechanics and car enthusiasts when working on fuel system repairs or replacements. This tool helps to ensure a secure and leak-free connection, making it a crucial component in maintaining a vehicle's fuel efficiency and performance.

To remove a fuel line using this tool, start by positioning the tool over the fuel line connection. Apply firm pressure and rotate the tool counterclockwise to loosen the connection. Once loosened, gently pull the fuel line away from the fitting. Take note of the orientation of the fuel line to ensure proper reinstallation.

Yes, fuel line tools are typically designed to accommodate various fuel line sizes. They often feature adjustable or interchangeable components to fit different diameters. However, it's essential to check the specifications of your particular tool and ensure it matches the size of the fuel line you are working with. Using the correct tool size is crucial for a successful and safe removal process.