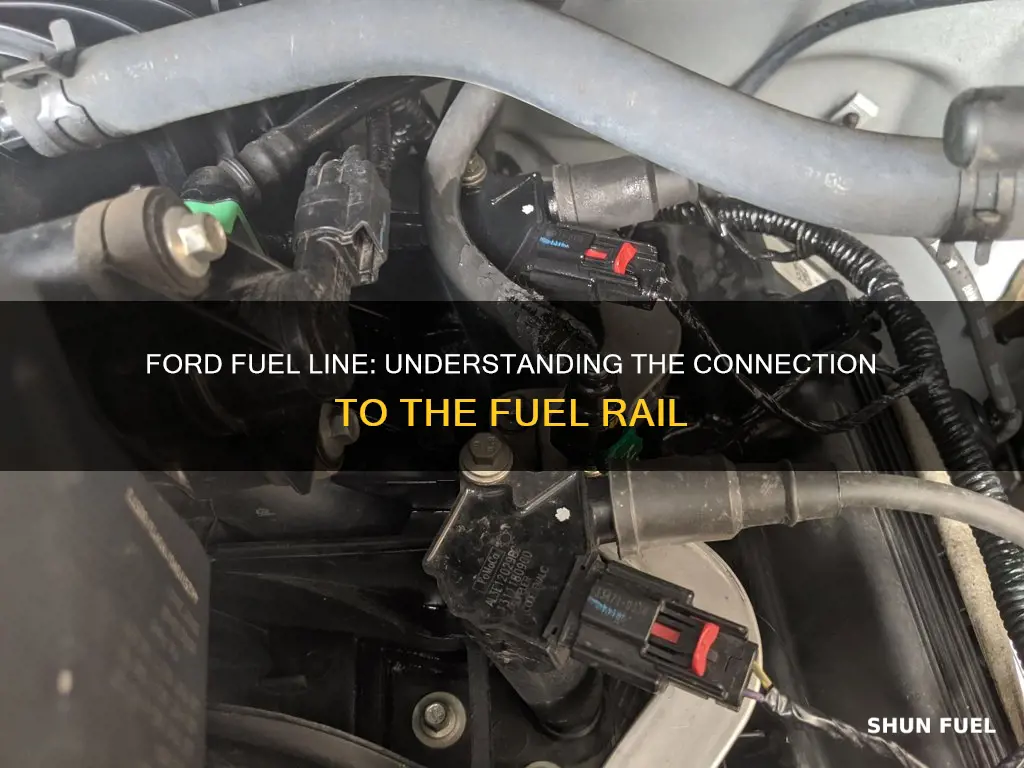

The Ford fuel line plays a crucial role in the fuel delivery system of Ford vehicles, connecting the fuel tank to the fuel rail. Understanding the connection between these components is essential for maintaining optimal engine performance and fuel efficiency. The fuel line is typically made of durable materials such as steel or rubber and is designed to withstand the pressure and temperature variations encountered during driving. It is connected to the fuel rail, which is a critical component that regulates the fuel pressure and ensures a steady supply of fuel to the engine. This connection is vital for the proper functioning of the fuel injection system, allowing the engine to receive the correct amount of fuel for efficient combustion.

What You'll Learn

- Fuel Rail Design: Ford fuel rails are designed to hold fuel under pressure, ensuring a steady supply to the engine

- Fuel Line Material: The fuel lines are typically made of durable materials like steel or rubber to withstand pressure and temperature

- Connection Methods: Ford uses various connection methods like quick-connect fittings or threaded adapters for secure fuel line attachment

- Pressure Regulation: Fuel lines are crucial for maintaining the correct fuel pressure, which is regulated by the fuel rail

- Engine Compatibility: Different Ford engines may require specific fuel line connections to ensure optimal performance and fuel delivery

Fuel Rail Design: Ford fuel rails are designed to hold fuel under pressure, ensuring a steady supply to the engine

The fuel rail is a critical component in Ford's fuel system design, playing a vital role in delivering fuel to the engine under pressure. This design ensures a consistent and reliable supply of fuel, which is essential for optimal engine performance. Ford engineers have carefully crafted the fuel rail to accommodate the specific requirements of their engines, considering factors such as fuel pressure, flow rate, and engine size.

At its core, the fuel rail is a metal structure designed to hold and distribute fuel. It is typically made from durable materials such as aluminum or steel to withstand the high-pressure environment within the fuel system. The rail features a series of ports or outlets strategically positioned to connect to the individual fuel injectors. These injectors are responsible for precisely metering and injecting the fuel into the engine's cylinders.

One of the key design considerations is the ability to maintain fuel pressure. Ford fuel rails are engineered with a specific pressure rating to ensure that the fuel remains under the required pressure throughout the system. This pressure is crucial as it enables the fuel to flow efficiently and rapidly to the injectors when demanded by the engine's operating conditions. The rail's design incorporates a series of passages and chambers to manage the fuel flow, ensuring a steady and consistent supply.

To achieve this steady supply, Ford employs various design techniques. One approach is to use a fuel pump that generates the necessary pressure to push fuel through the rail. This pump is strategically located to ensure efficient fuel delivery. Additionally, the fuel rail may incorporate a pressure regulator to maintain the desired pressure, especially during varying engine loads.

In summary, Ford fuel rail design focuses on creating a robust and efficient system for delivering fuel under pressure to the engine. This design ensures that the engine receives a consistent and reliable fuel supply, contributing to its overall performance and responsiveness. The careful engineering of the fuel rail, including its material choice, port placement, and pressure management, showcases Ford's commitment to delivering a well-engineered and high-performing fuel system.

Thawing Fuel Lines: Tips for Cold Climates

You may want to see also

Fuel Line Material: The fuel lines are typically made of durable materials like steel or rubber to withstand pressure and temperature

The fuel lines in a Ford vehicle are an essential component of the fuel system, responsible for transporting fuel from the tank to the engine. These lines are designed to be robust and durable, capable of withstanding the high pressure and temperature fluctuations that occur within the system. The choice of material for these lines is crucial to ensure optimal performance and longevity.

Fuel lines are typically constructed from materials that offer excellent resistance to wear and tear. Steel is a common choice for its strength and ability to handle pressure. It provides a rigid structure, ensuring the lines can withstand the force exerted by the fuel pump and maintain a secure connection to the fuel rail. However, steel lines may be less flexible, which can be a consideration during installation.

Rubber, on the other hand, is another popular material for fuel lines due to its flexibility and resilience. It can accommodate slight movements and vibrations within the engine bay, reducing the risk of damage or leaks. Rubber lines are often preferred for their ease of installation and the ability to conform to various shapes, making them a versatile choice. The flexibility of rubber also contributes to its durability, as it can withstand temperature changes without becoming brittle or cracking.

In some cases, a combination of steel and rubber may be used. For instance, a steel inner core could be encased in a rubber outer layer, providing the strength of steel while maintaining the flexibility required for a secure connection. This hybrid approach ensures the fuel lines can handle the demanding conditions of the fuel system.

When selecting the material for fuel lines, Ford engineers consider factors such as engine power, operating temperatures, and the overall design of the vehicle. The chosen material must not only withstand the physical demands but also resist corrosion and chemical degradation, ensuring a long-lasting and reliable fuel supply to the engine. Proper material selection is a critical aspect of vehicle design, contributing to the overall performance and safety of the Ford fuel system.

Optimizing Fuel Line Safety: Where to Install the Check Valve

You may want to see also

Connection Methods: Ford uses various connection methods like quick-connect fittings or threaded adapters for secure fuel line attachment

When it comes to connecting the fuel line to the fuel rail in Ford vehicles, the company employs a range of connection methods to ensure a secure and reliable fuel supply. These methods are designed to withstand the demands of the automotive environment, providing a robust and efficient fuel delivery system.

One of the primary connection techniques used by Ford is the quick-connect fitting. This method involves using specialized fittings that allow for a rapid and secure attachment of the fuel line to the fuel rail. Quick-connect fittings are typically made of durable materials such as brass or stainless steel, ensuring they can withstand the pressure and temperature variations within the fuel system. These fittings often feature a threaded design, allowing for a tight and leak-free connection. By using quick-connect fittings, Ford engineers ensure that the fuel line is firmly attached to the fuel rail, minimizing the risk of fuel leaks and ensuring optimal performance.

In addition to quick-connect fittings, Ford also utilizes threaded adapters as a connection method. Threaded adapters provide a secure and customizable way to attach the fuel line. These adapters are designed with internal threads that match the external threads of the fuel line, creating a tight seal. By using threaded adapters, Ford allows for easy installation and adjustment, ensuring that the fuel line is properly aligned and secured to the fuel rail. This method is particularly useful when dealing with different fuel line diameters or when retrofitting older vehicles with new fuel systems.

The choice of connection method depends on various factors, including the vehicle model, engine requirements, and the specific design of the fuel system. Ford's engineers carefully select these connection techniques to ensure compatibility, reliability, and ease of maintenance. By employing quick-connect fittings and threaded adapters, Ford achieves a secure and efficient attachment of the fuel line to the fuel rail, contributing to the overall performance and longevity of the vehicle's fuel system.

It is important to note that proper installation and maintenance of these connections are crucial to ensure the vehicle's optimal performance and safety. Regular checks and inspections of the fuel line connections should be conducted to identify any potential issues, such as leaks or loose fittings, which could lead to fuel system malfunctions.

Poulin Chainsaw Fuel Line: Size Guide for Optimal Performance

You may want to see also

Pressure Regulation: Fuel lines are crucial for maintaining the correct fuel pressure, which is regulated by the fuel rail

The fuel lines in a Ford vehicle play a critical role in ensuring optimal engine performance by maintaining the appropriate fuel pressure, which is regulated by the fuel rail. This pressure regulation is essential for efficient combustion and power generation. Here's a detailed explanation of how this system works:

Fuel lines are designed to carry gasoline from the fuel tank to the engine, and their diameter and material are carefully chosen to handle the pressure requirements. When the engine is running, the fuel pump creates a specific pressure, typically around 4-6 psi, which is then transmitted through the fuel lines. This pressure is crucial as it ensures that the fuel reaches the engine's injectors at the right rate and with the correct force.

The fuel rail is a component that houses the injectors and acts as a distribution point for fuel. It is connected to the fuel lines via high-pressure lines, which are typically made of durable materials like steel or aluminum. These lines are designed to withstand the elevated pressure, ensuring a secure and reliable connection. The fuel rail is strategically positioned to allow for even fuel distribution to all the injectors, ensuring precise control over the fuel-air mixture.

Pressure regulation is maintained through a combination of factors. Firstly, the fuel pump's output pressure is carefully calibrated to provide the required amount of fuel. Secondly, the fuel lines' design and material properties contribute to pressure stability. For instance, some fuel lines may have a larger diameter to reduce pressure drop over longer distances. Additionally, the fuel rail's design incorporates pressure-regulating mechanisms, such as pressure-relief valves, to prevent excessive pressure buildup and maintain a steady fuel supply.

In summary, the fuel lines and fuel rail work in harmony to regulate fuel pressure, ensuring that the engine receives the correct amount of fuel for optimal performance. This system's precision is vital for maintaining engine efficiency, power output, and overall reliability, especially in high-performance Ford vehicles. Understanding this pressure regulation mechanism is key to appreciating the intricate design of modern fuel injection systems.

Fuel Line Plug: Location on 2002 Elantra Injector Rail

You may want to see also

Engine Compatibility: Different Ford engines may require specific fuel line connections to ensure optimal performance and fuel delivery

When it comes to Ford engines, understanding the compatibility of fuel line connections is crucial for maintaining optimal performance and ensuring efficient fuel delivery. Different Ford engines have unique specifications and requirements, and using the correct fuel line connections is essential to avoid potential issues. Here's an overview of engine compatibility and the specific fuel line connections needed for various Ford engines:

V8 Engines: Ford's iconic V8 engines, such as the 5.0L V8 found in the Mustang GT, require precise fuel line connections. The fuel rail is typically located near the engine's front, and the fuel lines must be connected to the rail's injectors. These engines often use a high-pressure fuel system, so the connections should be secure and tight to prevent fuel leaks. It is recommended to refer to the Ford service manual for the specific bolt patterns and fittings required for your V8 engine model.

EcoBoost Engines: Ford's EcoBoost engines, known for their fuel efficiency and performance, also have unique fuel line requirements. The 2.3L EcoBoost engine, commonly found in the Ford Escape and Fusion, utilizes a different fuel rail design. The fuel lines are connected to the rail's injectors, but the connection process may vary. It is essential to follow the manufacturer's guidelines, as some EcoBoost engines may require specialized fuel line fittings to ensure proper fuel pressure and delivery.

Duratorq Engines: Ford's Duratorq diesel engines, such as the 3.2L and 4.5L variants, have their own set of fuel line connection requirements. These engines often feature a common rail fuel system, which provides high-pressure fuel to the injectors. The fuel lines must be securely connected to the common rail, and the connections should be tight to maintain optimal fuel delivery. Ford provides detailed instructions in their service manuals for connecting the fuel lines to the Duratorq engines, ensuring proper functionality.

Engine Family Compatibility: It's important to note that some Ford engines share similar fuel line connection principles but may have slight variations. For example, the 4.6L V8 engine family, used in various Ford models, may have different fuel rail locations and connection methods. Always refer to the specific engine's service manual, as it will provide the most accurate and compatible fuel line connection instructions.

By understanding the engine compatibility and following the manufacturer's guidelines, Ford vehicle owners can ensure that their fuel lines are correctly connected, promoting optimal engine performance and fuel efficiency. Proper fuel line connections are vital to avoid potential issues, such as fuel leaks or improper fuel pressure, which can lead to reduced engine power and efficiency.

Diesel Fuel Line Repair: A Step-by-Step Guide to Fixing Leaks

You may want to see also

Frequently asked questions

The fuel line in Ford vehicles is typically connected to the fuel rail through a series of fittings and connectors. The process involves attaching the fuel line to the fuel rail using specific fasteners or clips, ensuring a secure and tight connection. This connection allows the fuel to be delivered from the fuel tank to the engine's fuel injectors or carburetor.

Yes, it is recommended to use the appropriate tools and techniques to ensure a proper connection. This may include fuel line connectors, fuel rail adapters, and the right type of fuel line material. It is essential to follow the manufacturer's guidelines and specifications to avoid any potential issues with fuel delivery and engine performance.

While some fuel line replacement tasks can be performed by vehicle owners, it is generally advised to seek professional assistance for this specific connection. The fuel rail and its associated components can be complex, and improper installation may lead to fuel leaks or engine misfires. It is best to consult a qualified mechanic or refer to Ford's service manual for detailed instructions tailored to your vehicle model.