Checking the fuel return line on a diesel Kubota engine is an important maintenance task to ensure optimal performance and longevity. This guide will provide a step-by-step process to inspect and verify the condition of the fuel return line, which plays a crucial role in the engine's fuel system. By following these instructions, you can identify potential issues, such as blockages or leaks, and take appropriate measures to keep your Kubota engine running smoothly.

What You'll Learn

- Visual Inspection: Check for cracks, leaks, and debris in the fuel return line

- Pressure Test: Use a gauge to measure pressure and ensure it's within the recommended range

- Flow Rate: Measure the flow rate of fuel to ensure it's functioning properly

- Clogged Filters: Inspect and clean fuel filters to prevent blockages

- Engine Diagnostics: Use diagnostic tools to identify issues with the fuel system

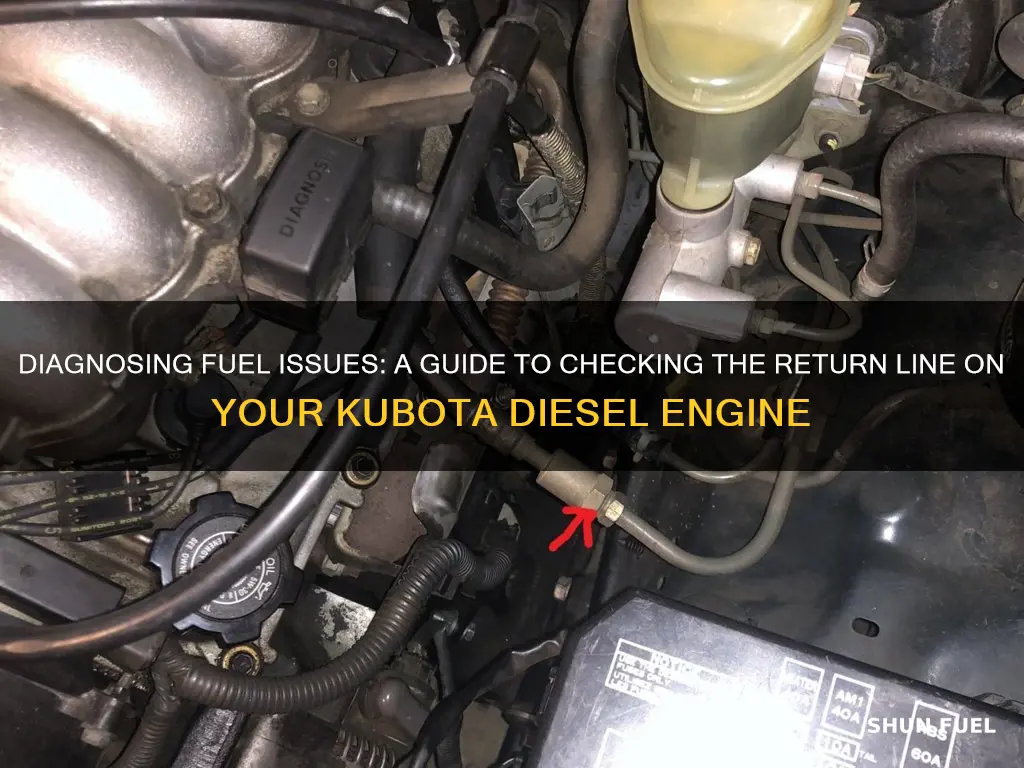

Visual Inspection: Check for cracks, leaks, and debris in the fuel return line

A visual inspection is a crucial step in maintaining the health of your diesel Kubota engine, especially when it comes to checking the fuel return line. This line is responsible for transporting fuel from the engine back to the fuel tank, ensuring a continuous supply of fuel for optimal performance. Here's a detailed guide on how to perform this inspection:

Start by locating the fuel return line, which is typically a black or dark-colored hose that runs from the engine to the fuel tank. It is important to inspect this line regularly as it can be susceptible to damage over time. Look for any visible signs of wear and tear, such as cracks, cuts, or punctures. These defects can lead to fuel leaks, which are not only dangerous but can also cause engine misfires and reduced performance. Inspect the line for any signs of corrosion or rust, especially if the line is exposed to harsh weather conditions or has been in contact with contaminated fuel.

Next, check for any leaks along the length of the fuel return line. Even a small leak can lead to significant issues over time. Look for any wet spots or fuel stains around the line, as these could indicate a leak. It's also a good idea to use a fuel-safe dye to make the inspection easier. Add a small amount of dye to the fuel tank and observe if any fuel appears in the return line, indicating a potential leak. If you notice any leaks, it's essential to address them promptly to prevent further damage.

Additionally, inspect the fuel return line for any debris or contaminants. Over time, dirt, rust, and other particles can accumulate in the line, leading to blockages and reduced fuel flow. Remove the line from the engine and inspect it closely. Use a bright light or a mirror to check for any hidden debris. If you find any debris, carefully remove it to ensure a clear path for fuel flow. It's recommended to clean the line regularly to prevent the buildup of contaminants.

Remember, a thorough visual inspection can help you identify potential issues before they become major problems. By checking for cracks, leaks, and debris, you can ensure the longevity and optimal performance of your diesel Kubota engine's fuel return system. Regular maintenance and attention to these details will contribute to a reliable and efficient machine.

Mastering RC Fuel Line Twists: A Comprehensive Guide

You may want to see also

Pressure Test: Use a gauge to measure pressure and ensure it's within the recommended range

When performing a pressure test on a diesel Kubota engine's fuel return line, it's crucial to follow a systematic approach to ensure accuracy and safety. Here's a step-by-step guide to help you through the process:

Preparation: Before you begin, ensure you have the necessary tools and equipment. You'll need a fuel pressure gauge specifically designed for diesel engines, as well as a source of compressed air or a pump to create the test pressure. It's also essential to have a clear understanding of the recommended pressure range for your specific Kubota model. Consult the engine manual or manufacturer's guidelines for this information.

Procedure: Start by locating the fuel return line, which is typically a metal or rubber hose connecting the fuel injectors to the fuel tank. Ensure the engine is cool and has been sitting idle for a sufficient period to allow the fuel system to stabilize. Attach the fuel pressure gauge to the fuel return line, ensuring a secure connection. Turn on the engine and allow it to reach operating temperature. With the engine running, slowly increase the pressure using your air source or pump until you reach the recommended maximum pressure for your Kubota engine. This pressure should be stable and consistent.

Measurement and Analysis: During the test, carefully monitor the fuel pressure gauge reading. Record the maximum pressure achieved and compare it to the specified range. If the measured pressure is within the recommended limits, the fuel return line is likely functioning correctly. However, if the pressure is significantly higher or lower than the specified range, it could indicate a potential issue with the fuel system, such as a restricted line, a leaking gasket, or a faulty fuel pump.

Troubleshooting: If the pressure test reveals an abnormal reading, further investigation is necessary. Check for any visible signs of damage or blockage in the fuel return line. Inspect the connections and fittings for leaks or corrosion. In some cases, you may need to remove the line and inspect it for internal damage. If the issue persists, consult a qualified mechanic or refer to the Kubota service manual for specific troubleshooting steps related to your engine model.

Remember, regular maintenance and pressure testing of the fuel return line are essential to ensure optimal engine performance and longevity, especially in diesel engines where fuel system reliability is critical. Always prioritize safety and consult the manufacturer's guidelines for any specific instructions or precautions related to your Kubota diesel engine.

Thread Locker Blue: A Viable Option for Fuel Line Security?

You may want to see also

Flow Rate: Measure the flow rate of fuel to ensure it's functioning properly

To ensure the proper functioning of your diesel Kubota engine, it's crucial to check the fuel return line, as it plays a vital role in the fuel system's performance. One critical aspect of this maintenance is measuring the flow rate of fuel. Here's a step-by-step guide on how to do it:

Step 1: Gather the Necessary Tools

Before you begin, ensure you have the required tools and equipment. You'll need a fuel flow meter, which is a specialized device designed to measure the volume of fuel flowing through a line. It's essential to use a calibrated and accurate flow meter for precise measurements. Additionally, have a fuel gauge and a container to collect the fuel sample for comparison.

Step 2: Locate the Fuel Return Line

Identify the fuel return line on your diesel Kubota engine. This line typically connects the fuel tank to the engine's fuel system, allowing the fuel to return after it has been used. Locate the line where it connects to the engine block or the fuel pump assembly. Make sure you have easy access to this point for the measurement process.

Step 3: Set Up the Flow Meter

Securely attach the fuel flow meter to the fuel return line. Ensure a tight and leak-free connection. Follow the manufacturer's instructions for proper installation. The flow meter will provide real-time data on the fuel flow rate, allowing you to monitor the engine's fuel consumption.

Step 4: Measure the Flow Rate

Start the engine and allow it to idle at a steady speed. This is crucial as it provides a consistent fuel demand. Begin the measurement process and record the flow rate displayed on the flow meter. Keep the engine idling for a sufficient duration to get an accurate reading. Note the volume of fuel flowing through the line during this period.

Step 5: Compare and Analyze

Compare the measured flow rate with the expected or recommended value for your specific Kubota engine model. You can find these values in the engine's manual or consult a technical resource. If the measured flow rate deviates significantly from the expected value, it may indicate a potential issue with the fuel return line or the overall fuel system. Further investigation might be required to identify and resolve the problem.

By following these steps, you can effectively measure the flow rate of fuel and ensure that your diesel Kubota engine is functioning optimally. Regular maintenance and monitoring of the fuel system, including the return line, are essential to prevent potential issues and maintain the engine's performance.

Unveiling the Tvr Tasmin's Fuel Line Mystery: Size Matters!

You may want to see also

Clogged Filters: Inspect and clean fuel filters to prevent blockages

When dealing with a diesel engine, ensuring that the fuel system is clean and free of debris is crucial for optimal performance. One common issue that can arise is clogged fuel filters, which can lead to reduced power, poor fuel efficiency, and even engine failure if left unattended. Here's a step-by-step guide on how to inspect and clean fuel filters to prevent blockages, specifically tailored to the diesel Kubota engine.

Identifying Clogged Filters:

Start by locating the fuel filter on your Kubota diesel engine. It is typically found near the engine's fuel tank or along the fuel lines. Inspect the filter for any signs of contamination. Over time, dirt, rust, and other particles can accumulate, leading to blockages. Look for a dirty or discolored appearance, as this may indicate the need for cleaning or replacement. If the filter is easily accessible, you can remove it and examine it more closely.

Cleaning the Fuel Filter:

If you find that the filter is clogged or dirty, it's essential to clean it properly. Here's the process:

- Filter Removal: Carefully remove the fuel filter from its mounting position. Take note of the filter's orientation to ensure proper reinstallation.

- Cleaning: Soak the filter in a fuel filter cleaner or a mixture of diesel fuel and a suitable solvent. This will dissolve any accumulated contaminants. Allow it to soak for the recommended time, usually a few minutes to an hour.

- Rinsing: After soaking, rinse the filter thoroughly with clean diesel fuel to remove any remaining cleaner. Ensure that no debris or cleaner residue is left behind.

- Reinstallation: Once the filter is clean, reinstall it in the original position, ensuring a secure and proper fit.

Preventive Maintenance:

Regular maintenance is key to preventing clogged fuel filters. Here are some tips:

- Routine Checks: Periodically inspect the fuel filter during routine engine maintenance checks. Look for any signs of damage, corrosion, or excessive dirt accumulation.

- Filter Replacement: Consider replacing the fuel filter at regular intervals, as recommended by the manufacturer. This proactive approach ensures that the filter remains clean and efficient.

- Fuel Quality: Using high-quality diesel fuel can reduce the risk of contamination. Keep an eye on fuel stability and consider using fuel stabilizers if storing fuel for extended periods.

By following these steps, you can effectively manage and prevent clogged fuel filters in your diesel Kubota engine. Regular inspection and cleaning will contribute to the overall longevity and performance of your engine, ensuring it runs smoothly and efficiently. Remember, proper maintenance is essential to avoid costly repairs and downtime.

Marine Fuel Line Valves: When and Why to Replace

You may want to see also

Engine Diagnostics: Use diagnostic tools to identify issues with the fuel system

When it comes to diagnosing issues with the fuel system in a diesel engine, such as the Kubota, using diagnostic tools is an essential step to identify and resolve problems efficiently. The fuel system is a complex network, and any malfunction can lead to reduced performance, increased emissions, or even engine failure. Here's a guide on how to approach engine diagnostics with a focus on the fuel system:

Fuel Pressure Testing: Start by checking the fuel pressure using a pressure gauge. Connect the gauge to the fuel line and measure the pressure at idle. The ideal pressure range varies by engine model and specifications, so consult the Kubota's manual for reference. Low fuel pressure could indicate a restricted fuel filter, a faulty fuel pump, or issues with the injection pump. If the pressure is too high, it might suggest a clogged return line or a malfunctioning pressure regulator.

Fuel Filter Inspection: The fuel filter is a critical component that can become clogged over time, leading to reduced flow and potential engine issues. Locate the fuel filter and inspect it for any signs of contamination or blockage. If it appears dirty or clogged, replace it with a new one. Regularly scheduled filter changes are essential to maintain optimal engine performance.

Return Line Inspection: The fuel return line is responsible for sending excess fuel back to the tank. Inspect this line for any signs of damage, leaks, or blockages. Start by checking for visible signs of corrosion or damage, especially if the engine has been operating in harsh conditions. You can also use a fuel-colored dye to trace the return line and identify any potential leaks or restricted areas. If a blockage is found, it may require cleaning or replacement of the affected section.

Using Diagnostic Scanners: Modern diesel engines are equipped with onboard computers that can provide valuable diagnostic information. Connect a diagnostic scanner to the engine's OBD-II port to access error codes and live data. Look for any error codes related to the fuel system, such as fuel pump control module errors or injection pump issues. The scanner can also provide real-time data on fuel pressure, injection timing, and other critical parameters, helping you pinpoint the source of the problem.

Engine Test Modes: Many diesel engines have test modes that can be activated to simulate specific conditions and provide diagnostic information. For example, the 'fuel cut-off' test can help identify issues with the fuel injection system. By temporarily disabling the fuel supply, you can observe the engine's response and check for any abnormal behavior. This test can reveal problems with the injection pump, injectors, or fuel management system.

By utilizing these diagnostic tools and techniques, you can systematically identify and address issues within the fuel system of a diesel Kubota engine. Remember, proper maintenance and regular diagnostics are key to ensuring the engine's longevity and optimal performance.

Braided Fuel Line Clamping: A Comprehensive Guide

You may want to see also