When it comes to automotive maintenance, choosing the right materials for fuel lines is crucial to ensure the safety and performance of your vehicle. One common question that arises is whether Teflon tape is suitable for fuel lines. Teflon, known for its non-stick properties, is often used in various applications, but its use in fuel lines requires careful consideration. This paragraph will explore the advantages and potential drawbacks of using Teflon tape for fuel lines, examining its compatibility with different fuel types and its ability to withstand the demands of the automotive environment.

| Characteristics | Values |

|---|---|

| Chemical Composition | Polytetrafluoroethylene (PTFE) |

| Temperature Resistance | Up to 500°F (260°C) |

| Flexibility | Good flexibility, can be bent and twisted without breaking |

| Corrosion Resistance | Excellent resistance to corrosion, including from fuels |

| Compatibility | Compatible with most fuels, including gasoline, diesel, and aviation fuels |

| Ease of Application | Easy to apply, can be wrapped around fuel lines without the need for heat or pressure |

| Cost | Relatively inexpensive compared to other sealing materials |

| Environmental Impact | Non-toxic and environmentally friendly |

| Longevity | Long-lasting, can last for many years without degradation |

| Maintenance | Requires minimal maintenance, no need for regular replacement |

What You'll Learn

- Material Compatibility: Teflon tape is generally safe for fuel lines, but check compatibility with the specific fuel type

- Temperature Resistance: Ensure the tape can withstand fuel line temperatures without degradation

- Leak Prevention: Properly applied Teflon tape can effectively prevent leaks in fuel lines

- Durability: Choose a durable Teflon tape for long-lasting protection against fuel line damage

- Installation Guidelines: Follow manufacturer instructions for best results when using Teflon tape on fuel lines

Material Compatibility: Teflon tape is generally safe for fuel lines, but check compatibility with the specific fuel type

Teflon tape, also known as polytetrafluoroethylene (PTFE) tape, is a popular choice for sealing and repairing fuel lines due to its non-stick properties and resistance to heat and chemicals. It is widely used in the automotive industry and is often recommended for fuel line installations. However, while Teflon tape is generally considered safe for fuel lines, it is crucial to consider the compatibility of the tape with the specific fuel type being used.

The compatibility of Teflon tape with fuel lines depends on the type of fuel being transported. Different fuels have varying chemical compositions and properties, and some may react with certain materials, including Teflon. For example, gasoline and ethanol blends can be more corrosive to certain types of plastics and rubbers, so it's essential to ensure that the Teflon tape used is compatible with these fuels. On the other hand, diesel fuel, being less corrosive, may not pose the same compatibility concerns.

When using Teflon tape for fuel lines, it is recommended to check the manufacturer's guidelines and specifications for the specific fuel type. Some fuel lines may require a different type of sealing material or additional precautions to ensure long-term performance and safety. For instance, if the fuel contains additives or has a higher ethanol content, alternative sealing methods might be necessary to prevent degradation or loss of sealing properties over time.

In addition to checking compatibility, it is also important to follow proper installation techniques when using Teflon tape for fuel lines. The tape should be applied correctly, ensuring a secure and tight seal without any wrinkles or folds that could compromise its effectiveness. Proper installation practices include cleaning the fuel line surfaces, applying a generous amount of tape, and ensuring it is firmly wrapped around the connection.

In summary, while Teflon tape is generally safe for fuel lines, it is crucial to consider the specific fuel type and its compatibility with the tape. Checking the manufacturer's guidelines and following proper installation techniques will help ensure the long-term reliability and safety of the fuel line system. Always prioritize the use of materials that are specifically designed for the fuel type being handled to maintain optimal performance and prevent potential issues.

Evo Fuel Line Size: Essential Guide for Optimal Performance

You may want to see also

Temperature Resistance: Ensure the tape can withstand fuel line temperatures without degradation

When it comes to ensuring the integrity of fuel lines in vehicles, the choice of sealing material is critical. One popular option that has gained traction is Teflon tape, known for its versatility and reliability. However, a crucial aspect to consider is the temperature resistance of this tape, especially in the context of fuel lines, which are exposed to varying and often extreme temperatures.

Teflon, a brand name for polytetrafluoroethylene (PTFE), is renowned for its exceptional thermal stability. It can withstand temperatures ranging from -459°F to 536°F (-272°C to 275°C) without any significant degradation. This makes it an ideal candidate for applications where temperature fluctuations are common. For fuel lines, which are typically located under the hood and experience engine heat, this temperature range is particularly relevant. The tape's ability to maintain its structural integrity and adhesive properties at these temperatures is essential to prevent fuel leaks and ensure the safety of the vehicle.

The resistance of Teflon tape to high temperatures is attributed to the unique chemical structure of PTFE. It has a low coefficient of friction and excellent chemical resistance, which means it can resist the effects of various fuels, including gasoline and diesel. This property is crucial as it ensures that the tape does not become brittle or lose its adhesive strength over time, even when exposed to the harsh conditions inside an engine compartment.

In addition to its temperature resistance, Teflon tape is also known for its ease of use. It is flexible and can be easily wrapped around fuel lines, providing a secure and reliable seal. This flexibility is particularly advantageous when dealing with fuel lines that may have slight bends or curves, ensuring a snug fit without causing damage to the fuel line itself.

In conclusion, when considering the use of Teflon tape for fuel lines, temperature resistance is a key factor that cannot be overlooked. The tape's ability to withstand extreme temperatures without degradation ensures the long-term reliability and safety of the fuel system. With its thermal stability, chemical resistance, and ease of application, Teflon tape is a strong contender for sealing fuel lines, offering a practical and effective solution for vehicle maintenance and repair.

6AN 3/8 Stainless Braided Fuel Line: Ultimate Upgrade for Your Engine

You may want to see also

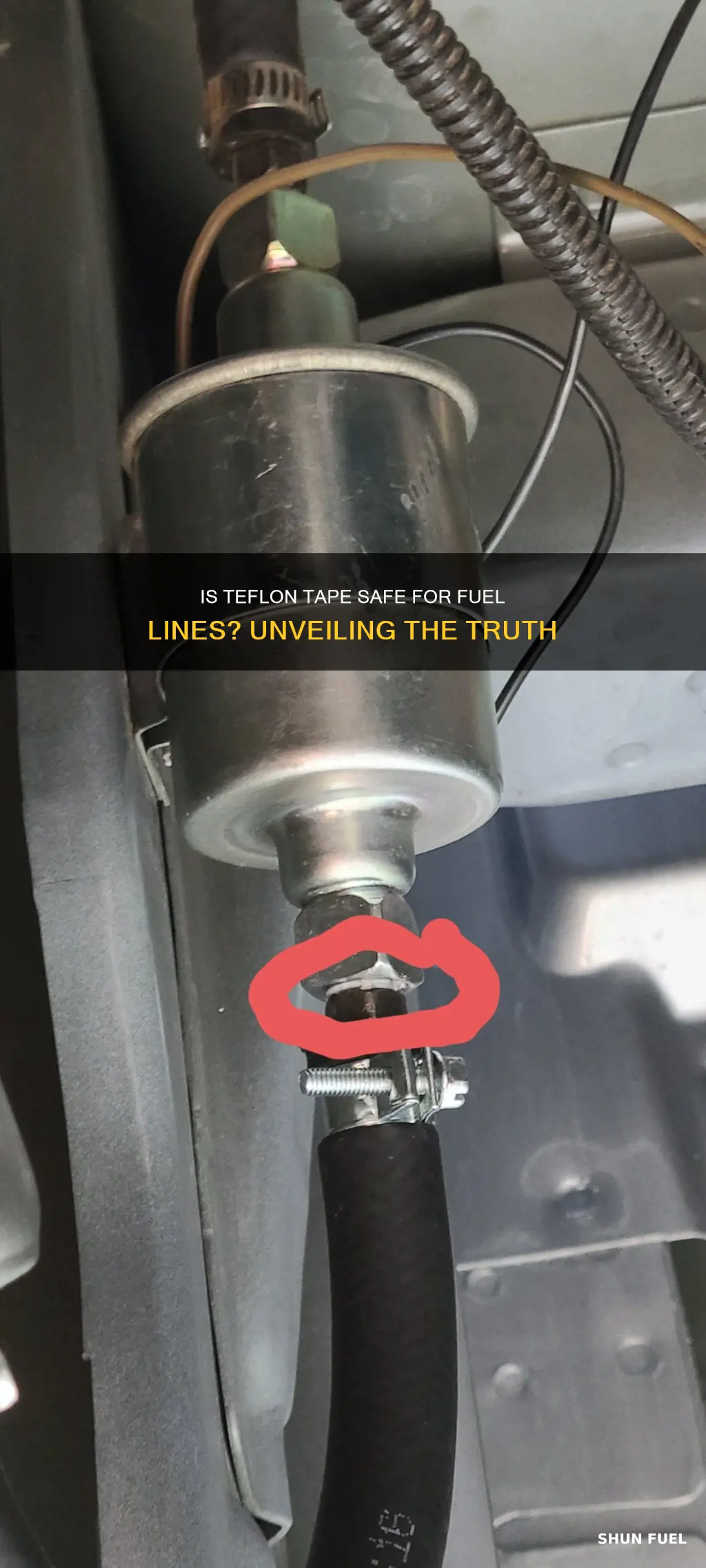

Leak Prevention: Properly applied Teflon tape can effectively prevent leaks in fuel lines

Teflon tape, also known as PTFE (polytetrafluoroethylene) tape, is a popular choice for sealing and repairing fuel lines due to its unique properties. When applied correctly, it can provide an effective and long-lasting solution for preventing leaks in these critical automotive components. Here's a detailed guide on how to use Teflon tape for leak prevention in fuel lines:

Understanding the Material: Teflon tape is renowned for its non-stick and non-corrosive nature. It is chemically inert, meaning it doesn't react with most substances, including fuels. This property makes it ideal for fuel lines, as it ensures that the tape doesn't compromise the integrity of the fuel or the pipe. The tape's smooth surface also allows for easy installation, creating a tight seal without the risk of damage to the fuel line.

Preparation is Key: Before applying Teflon tape, ensure that the fuel line is clean and free of any debris or old tape. Start by wrapping the tape around the fuel line, ensuring that it is applied in a clockwise direction. The tape should be wrapped tightly, but not too tightly, as this can cause damage to the line. A good rule of thumb is to wrap the tape at least three times, overlapping the edges slightly, to create a secure bond.

Creating a Secure Bond: The key to effective leak prevention is a strong bond between the tape and the fuel line. When applying the tape, apply firm pressure as you wrap it. This pressure helps create a tight seal, ensuring that there are no gaps or air bubbles. It's important to avoid over-tightening, as this can lead to damage. Instead, focus on applying consistent and firm pressure throughout the wrapping process.

Multiple Layers for Extra Strength: For added security, especially in high-pressure or high-temperature environments, consider using multiple layers of Teflon tape. Wrap the tape in the same direction, overlapping the previous layer by about 50%. This technique provides a stronger bond and increases the tape's ability to withstand stress. However, be cautious not to wrap too tightly, as this can restrict fuel flow.

Testing and Maintenance: After applying the Teflon tape, it's essential to test the fuel line for leaks. Start the engine and check for any signs of fuel leakage around the connection points. If no leaks are found, regular maintenance checks are recommended to ensure the tape remains intact. Over time, the tape may degrade, so periodic inspections are crucial to identify any signs of wear and replace the tape if necessary.

By following these steps and understanding the unique properties of Teflon tape, you can effectively prevent leaks in fuel lines, ensuring the safe and efficient operation of your vehicle's fuel system. Proper application and regular maintenance will contribute to a reliable and long-lasting solution for fuel line sealing.

Troubleshooting Fuel Vapor Issues: A Guide for 2004 Trailblazer Owners

You may want to see also

Durability: Choose a durable Teflon tape for long-lasting protection against fuel line damage

When it comes to ensuring the longevity and safety of your fuel lines, durability is a critical factor to consider. Teflon tape, known for its exceptional heat resistance and non-stick properties, can be an excellent choice for providing long-lasting protection against fuel line damage. This is especially important in automotive applications where fuel lines are exposed to varying temperatures and potential hazards.

The durability of Teflon tape lies in its ability to withstand extreme conditions. It can resist high temperatures, which are common in engine compartments, without compromising its structural integrity. This heat resistance is crucial as it prevents the tape from melting or degrading over time, ensuring that it maintains its protective function. Additionally, Teflon tape is known for its flexibility, allowing it to conform to the shape of fuel lines, providing a secure and tight seal.

In the context of fuel lines, durability is essential to prevent leaks and potential engine damage. Fuel lines are susceptible to wear and tear, especially when exposed to vibrations and temperature fluctuations. A durable Teflon tape can offer a reliable barrier against these potential issues. It helps to protect the fuel lines from corrosion, chemical damage, and physical abrasion, ensuring that the fuel remains contained and safe.

When selecting Teflon tape for fuel lines, it is important to choose a high-quality, reputable brand. These brands often provide tapes specifically designed for automotive applications, ensuring they meet the necessary durability standards. Look for tapes that are reinforced with additional layers or materials to enhance their strength and longevity. Proper installation is also key; ensure the tape is applied tightly and securely to avoid any gaps that could lead to fuel leakage.

In summary, for long-lasting protection against fuel line damage, durability is paramount. Teflon tape, with its heat resistance and flexibility, can provide an effective solution. By choosing a durable option and ensuring proper installation, you can maintain the integrity of your fuel system and avoid potential issues related to fuel line damage. This simple yet effective method of protection is a valuable consideration for any vehicle owner.

Mastering Fuel Line Installation: A Guide to Slipping On Outboard Fittings

You may want to see also

Installation Guidelines: Follow manufacturer instructions for best results when using Teflon tape on fuel lines

When working with fuel lines, it's crucial to prioritize safety and ensure that all components are properly installed to prevent any potential hazards. One common question that arises is whether Teflon tape is suitable for securing fuel lines. The answer is yes, but with a crucial emphasis on following manufacturer instructions.

Teflon tape, also known as PTFE (polytetrafluoroethylene) tape, is renowned for its non-stick properties and ability to provide a reliable seal. It is commonly used in plumbing applications due to its resistance to heat and chemicals. However, when it comes to fuel lines, the installation process requires careful attention to detail.

The manufacturer's guidelines are essential as they provide specific instructions tailored to the product's unique characteristics. These instructions often include recommendations on the number of wraps, the tightness of the application, and the type of fuel to be used. For instance, some manufacturers suggest a specific number of wraps to ensure a secure bond without compromising the tape's integrity.

Here's a step-by-step guide to ensure a successful installation:

- Prepare the Surface: Start by cleaning the fuel line threads and ensuring they are free from any debris or contaminants. This step is crucial for a strong bond.

- Apply the Tape: Wrap the Teflon tape around the fuel line threads in a clockwise direction. Follow the manufacturer's recommended number of wraps. Tighten the tape securely, but be careful not to overtighten, as this can damage the threads.

- Secure the Connection: After the desired number of wraps, use a wrench to tighten the fuel line fitting. Ensure it is snug and secure. Check for any leaks at this point.

- Final Checks: Once the connection is made, inspect the entire assembly. Look for any signs of tape coming loose or any gaps that might allow fuel to leak. If everything appears secure, your fuel line is now ready for use.

Remember, adhering to the manufacturer's instructions is vital to guarantee the safety and reliability of your fuel line installation. Teflon tape, when used correctly, can provide an effective and long-lasting solution for sealing fuel lines.

Mastering Dorman Steel Fuel Lines: A Guide to Secure Connections

You may want to see also

Frequently asked questions

Yes, Teflon tape, also known as PTFE (polytetrafluoroethylene) tape, is commonly used for fuel lines due to its non-stick properties and ability to provide a secure seal. It is an excellent choice for fuel line repairs as it offers good heat resistance and chemical stability, ensuring a reliable connection.

Teflon tape has several benefits for fuel line applications. It provides a strong, flexible bond, allowing for easy installation and adjustments. The non-stick nature of PTFE prevents the tape from damaging the fuel line material, ensuring a clean and secure seal. Additionally, it can withstand high temperatures and is resistant to most chemicals, making it a reliable choice for fuel systems.

While Teflon tape is versatile, it is generally recommended for fuel lines made of metal or plastic. It may not be suitable for very thin or delicate fuel lines, as the tape's thickness could cause damage or restrict flow. Always consider the specific requirements and material of your fuel lines before applying any tape.

Applying Teflon tape is a straightforward process. Start by cleaning the fuel line surfaces to ensure a good bond. Wrap the tape tightly around the connection, ensuring full coverage. Use a light, even pressure as you wrap, and avoid overlapping or bunching the tape. Finish by wrapping the tape in the opposite direction to create a secure, leak-free seal.

Yes, there are alternative methods for fuel line repairs. Some people prefer using fuel line cement or adhesive tape specifically designed for fuel systems. These options may offer different advantages, such as faster drying times or enhanced chemical resistance. However, Teflon tape remains a popular choice due to its versatility and proven track record in various applications.