Bleed fuel lines on a small Yanmar diesel engine to ensure a consistent and reliable fuel supply. This process involves removing air bubbles from the fuel lines, which can cause engine misfires or poor performance. By following a few simple steps, you can safely and effectively bleed the fuel lines, ensuring your Yanmar diesel engine runs smoothly and efficiently.

What You'll Learn

- Preparation: Gather tools, safety gear, and a clean workspace

- Fuel System Inspection: Check for blockages, leaks, and proper fuel flow

- Bleeding Procedure: Open fuel line bleeder valves sequentially, releasing air

- Pressure Testing: Use a gauge to ensure system integrity and correct pressure

- Cleaning: Remove contaminants with fuel system cleaner for optimal performance

Preparation: Gather tools, safety gear, and a clean workspace

Before you begin the process of bleeding fuel lines on a small Yanmar diesel engine, it's crucial to ensure you have the necessary tools, safety equipment, and a well-prepared workspace. This preparation will not only make the task safer but also more efficient. Here's a detailed guide on what you need to do:

Gather the Tools:

Start by collecting all the tools required for the job. You'll need a fuel pump primer bulb, which is essential for priming the fuel lines and ensuring a steady flow. A fuel filter bypass tool or a small container with a tight-fitting lid will be useful for collecting any fuel that needs to be drained. Additionally, have a fuel line cleaner or a suitable solvent to flush out any contaminants. Other basic tools like a wrench, pliers, and a fuel gauge (if available) can be helpful for monitoring the fuel level during the bleeding process.

Safety Gear:

Personal protection is vital when working on any engine. Wear safety goggles to protect your eyes from potential fuel splashes. Gloves are essential to prevent skin contact with fuel, and a respirator mask should be worn to avoid inhaling any fumes. Consider wearing old clothing that you don't mind getting stained, as fuel can be difficult to remove.

Clean Workspace:

Designate a clean and well-lit area for the work. Ensure the workspace is free from any clutter or obstacles that might interfere with your movements. Cover the ground with a drop cloth or old newspapers to catch any spills. It's a good idea to have a small workbench or a stable surface to place the engine on, ensuring it remains steady during the bleeding process. Keep a bucket or container nearby to catch any fuel that may drain from the engine.

Additionally, it's a good practice to have a second person assist you, especially when dealing with small engines. They can help monitor the engine's performance and provide support if needed. With the right preparation, you'll be well-equipped to tackle the task of bleeding fuel lines on your Yanmar diesel engine safely and effectively.

Mastering Motorcycle Fuel Lines: A Step-by-Step Guide to Tearing and Installing

You may want to see also

Fuel System Inspection: Check for blockages, leaks, and proper fuel flow

Fuel system inspection is a crucial step in maintaining the performance and longevity of your Yanmar diesel engine. It ensures that the fuel is being delivered efficiently and effectively to the engine, preventing potential issues and costly repairs. Here's a comprehensive guide on how to inspect the fuel system for blockages, leaks, and proper fuel flow:

Checking for Blockages:

Start by examining the fuel lines for any visible signs of damage, such as cracks, kinks, or punctures. These issues can lead to blockages and reduced fuel flow. Pay close attention to the lines where they connect to the fuel tank, pump, and injectors. If you notice any damage, it's essential to replace the affected lines immediately. Additionally, inspect the fuel filter for any clogs or debris. A clogged filter can restrict fuel flow and may require cleaning or replacement. Use a fuel filter cleaner or a compressed air gun to gently blow out any built-up contaminants. Remember to follow the manufacturer's guidelines for filter maintenance to ensure optimal performance.

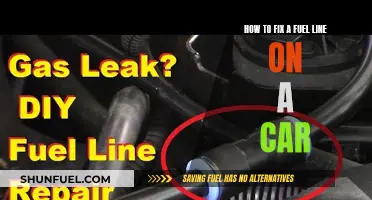

Leak Detection:

Fuel system leaks can cause significant problems, including engine misfires and reduced power. Inspect all connections and fittings for any signs of fuel leakage. Start with the fuel pump and lines, checking for wet spots or fuel residue around the connections. If you find any leaks, tighten the fittings or consider replacing the affected components. It's also crucial to inspect the fuel tank for any corrosion or damage. Over time, fuel tanks can develop rust or small holes, leading to fuel loss. Inspect the tank's interior and exterior for any signs of corrosion or damage, and address any issues promptly.

Fuel Flow Assessment:

Ensuring proper fuel flow is vital for engine operation. Check the fuel pressure using a fuel pressure gauge. Low pressure could indicate a clogged filter, damaged lines, or an issue with the fuel pump. If the pressure is below the recommended range, investigate the potential causes and take appropriate action. Additionally, listen for any unusual noises while the engine is running. Strange sounds, such as hissing or roaring, might suggest a fuel-related issue, including leaks or blockages. Addressing these noises promptly can prevent further complications.

During the inspection, it's essential to refer to your Yanmar diesel engine's manual for specific guidelines and recommended fuel system maintenance procedures. This documentation will provide valuable insights into the unique requirements of your engine model. By following these steps and staying vigilant, you can effectively maintain your fuel system, ensuring optimal performance and reliability from your Yanmar diesel engine.

2008 Cobalt Fuel Line: Size and Compatibility Guide

You may want to see also

Bleeding Procedure: Open fuel line bleeder valves sequentially, releasing air

To bleed the fuel lines on a small Yanmar diesel engine, you'll need to follow a systematic approach to ensure all air bubbles are removed from the system. Here's a detailed guide on the procedure:

Step 1: Preparation

Before you begin, make sure the engine is turned off and cooled down. Locate the fuel line bleeder valves, which are typically small openings along the fuel lines. These valves are designed to release air and allow you to bleed the system. It's crucial to have a clear understanding of the engine's layout to find these valves efficiently.

Step 2: Sequential Bleed

Start the bleeding process by opening the first bleeder valve. This valve is usually located at a convenient point along the fuel line, often near the engine. When you open it, you might hear a hissing sound as air escapes. Keep the valve open for a few seconds to allow the air to escape completely. Then, close the valve and move to the next section of the fuel line. Repeat this process, opening each bleeder valve sequentially. Ensure that you open each valve one at a time, allowing the air to escape, and then close it before moving to the next valve. This sequential approach ensures that you're not introducing new air bubbles into the system.

Step 3: Releasing Air

As you open each valve, pay attention to the sound and feel. You should hear a steady hissing sound as air is released. If you notice any resistance or a sudden stop in the hissing, it might indicate a blockage or a stubborn air pocket. In such cases, you may need to apply gentle pressure to the fuel line near the valve to release the air. Be cautious not to over-tighten or damage the fuel line.

Step 4: Repeat and Inspect

Continue this process until you've opened all the bleeder valves. After completing the sequence, recheck each valve to ensure no air is left in the system. You can do this by listening for any hissing sounds or by using a tool to feel for resistance. If any air bubbles remain, repeat the bleeding process for that specific section.

Remember, patience and a systematic approach are key to successful fuel line bleeding. Take your time, and don't rush the process to ensure a clean and efficient fuel supply to your Yanmar diesel engine.

Mastering Your Engine's Performance: A Guide to Using Protec Fuel Line Cleaner

You may want to see also

Pressure Testing: Use a gauge to ensure system integrity and correct pressure

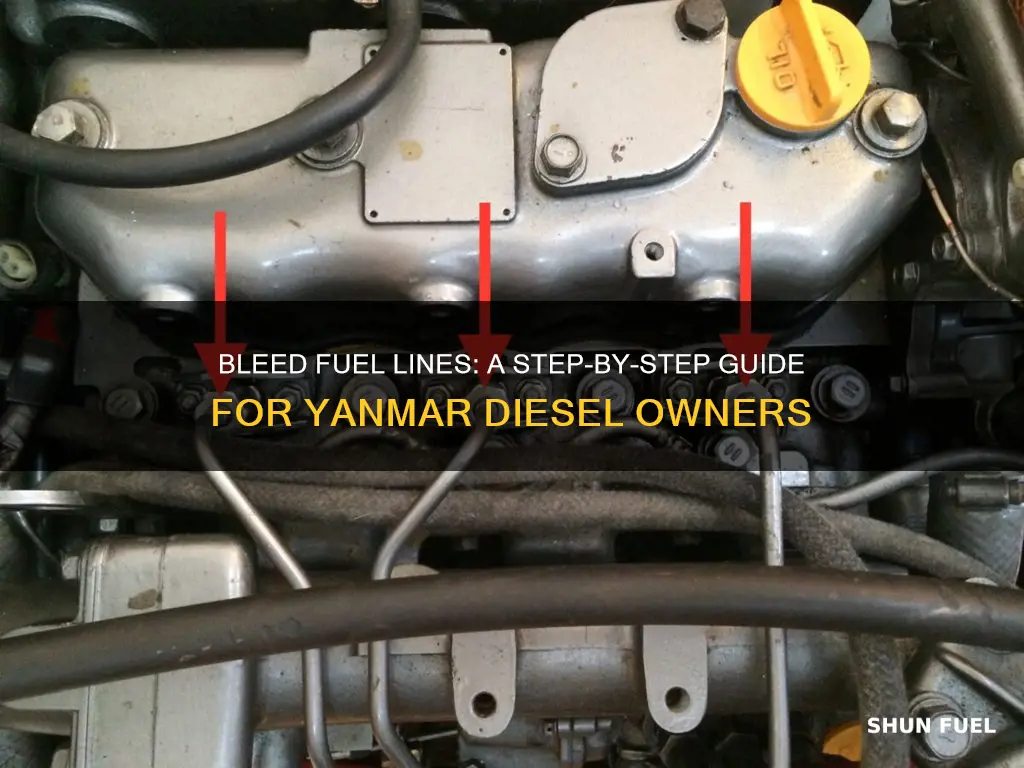

When it comes to pressure testing the fuel system of a small Yanmar diesel engine, it's crucial to ensure the system's integrity and correct pressure to prevent any potential issues. This process involves using a gauge to measure the pressure within the fuel lines and system, allowing you to identify any leaks, blockages, or pressure-related problems. Here's a step-by-step guide on how to perform this critical test:

Start by locating the fuel pressure gauge, which is typically connected to the fuel system's high-pressure port. Ensure the gauge is calibrated and functioning correctly. You can use a mechanical or digital gauge, but ensure it has the appropriate range for your Yanmar engine's fuel pressure specifications. Connect the gauge securely to the fuel line, making sure there are no leaks or loose connections.

Next, locate the fuel pump and ensure it is operational. Start the engine and allow it to idle for a few minutes to ensure the fuel system reaches a stable pressure. With the engine running, slowly open the fuel line valve or use a bleed screw (if available) to release any excess pressure. This step is essential to ensure an accurate reading and to prevent any fuel from being forced out of the system during the test.

Now, carefully observe the gauge reading. The pressure should be within the specified range for your Yanmar engine. If the pressure is too low, it may indicate a problem with the fuel pump or a restricted fuel line. If the pressure is too high, it could suggest a potential issue with the fuel injection system or a malfunctioning pressure regulator. Make a note of the pressure reading and compare it to the engine's manual for reference.

To further ensure system integrity, you can perform a visual inspection of the fuel lines for any signs of damage, corrosion, or blockages. Check for any kinks, cracks, or obstructions that might affect the fuel flow and pressure. If any issues are found, address them before proceeding with further testing.

Remember, pressure testing is a critical aspect of maintaining a small Yanmar diesel engine's fuel system. It helps identify potential problems early on, ensuring the engine operates efficiently and reliably. Always refer to the engine's manual for specific pressure ranges and guidelines tailored to your Yanmar model.

Can Fuel Oil Lines Safely Run Under Your Floor?

You may want to see also

Cleaning: Remove contaminants with fuel system cleaner for optimal performance

To ensure your Yanmar diesel engine operates at its best, it's crucial to maintain the fuel system, including the fuel lines. Over time, fuel lines can accumulate contaminants such as water, dirt, and varnish, which can lead to reduced performance and potential engine issues. Cleaning the fuel system with a dedicated fuel system cleaner is an effective way to remove these contaminants and restore optimal performance.

The process begins with the use of a fuel system cleaner, which is specifically designed to dissolve and remove the buildup of contaminants. These cleaners are typically available in concentrated liquid form and are often used in conjunction with a fuel system flush. When using a cleaner, it's important to follow the manufacturer's instructions carefully, as different products may have specific application methods and guidelines.

Start by disconnecting the fuel lines from the engine and the fuel tank. This step is essential to ensure that the cleaner can access all parts of the fuel system without interference. After disconnecting, attach the cleaner's supply line to the fuel line and the return line to a suitable drain point, such as a bucket or a drain pan. This setup allows the cleaner to flow through the system and remove contaminants.

Run the engine for a short period, typically a few minutes, allowing the cleaner to circulate. During this time, the engine's fuel pump will help distribute the cleaner throughout the system, including the injectors and the fuel lines. After the engine has run, shut it off and allow the cleaner to sit for a recommended period, usually around 15-20 minutes, to ensure thorough contact with the contaminants.

Finally, restart the engine and allow it to run for a while to ensure that all the contaminants have been flushed out. Check for any leaks or unusual behavior, and if everything appears normal, your fuel system has been effectively cleaned. This process is a critical maintenance step to keep your Yanmar diesel engine in top condition, ensuring reliable performance and longevity.

Moisture in Fuel Lines: A Recipe for Power Loss

You may want to see also

Frequently asked questions

Bleeding fuel lines is a process to remove air bubbles from the fuel system, ensuring a smooth and efficient flow of fuel to the engine. This is crucial for optimal performance and to prevent potential issues caused by air in the fuel.

It is recommended to bleed the fuel lines whenever you notice a drop in engine performance, such as rough idling, reduced power, or unusual noises. Additionally, it's a good practice to bleed the lines before and after long storage periods to maintain the fuel system's health.

Bleeding fuel lines is a task that can be accomplished by the owner with some mechanical knowledge and the right tools. However, if you're unsure or uncomfortable with the process, it's best to consult a qualified technician or refer to the Yanmar diesel engine's manual for specific instructions and guidance.