Fixing a fuel line on a car can seem daunting, but with the right tools and a bit of know-how, it's a manageable task. Whether you're dealing with a small tear or a complete break, the process involves identifying the damaged section, gathering the necessary supplies, and following a step-by-step repair guide. This guide will walk you through the process, ensuring you have the confidence to tackle the job and get your car back on the road safely.

What You'll Learn

- Locate the Fuel Line: Identify the damaged section using a visual inspection or diagnostic tools

- Prepare the Tools: Gather necessary tools like a fuel line cutter, crimping tool, and replacement line

- Cut and Remove: Carefully cut the damaged section and disconnect the fuel line from the engine

- Install New Line: Slide the new fuel line into place, ensuring proper alignment and secure it

- Test and Bleed: Bleed the fuel system to remove air, then test for leaks and proper fuel flow

Locate the Fuel Line: Identify the damaged section using a visual inspection or diagnostic tools

Locating the fuel line in your car is the first crucial step in repairing any damage. Fuel lines are typically made of rubber or plastic and carry gasoline from the fuel tank to the engine. They are often located beneath the car, running along the frame and near the wheels. A visual inspection is usually the first step to identify any issues. Start by examining the fuel lines for any visible signs of damage, such as cracks, punctures, or leaks. Look for areas where the line might have been damaged by sharp objects, road debris, or previous repairs. Check for any discolouration or swelling, which could indicate a potential issue. Pay close attention to areas where the line bends around sharp corners or where it is close to hot engine components. These areas are more prone to damage.

If a visual inspection doesn't reveal any obvious issues, you may need to use diagnostic tools. A fuel pressure gauge is a useful tool for this purpose. It measures the pressure of the fuel in the system and can help identify if there is a blockage or if the fuel pump is not functioning correctly. Connect the gauge to the fuel line and check the pressure. Low pressure could indicate a problem with the fuel pump or a restricted fuel line. You can also use a fuel leak detector, which is a spray that, when applied to the fuel line, will temporarily seal any small leaks. This can help pinpoint the exact location of a leak, making it easier to identify the damaged section.

In some cases, you might need to use a fuel system diagnostic scanner, which is a more advanced tool. These scanners can provide detailed information about the fuel system's performance, including pressure, temperature, and flow rates. They can help identify issues like clogged fuel filters, faulty injectors, or problems with the fuel pump. When using these tools, it's essential to consult the vehicle's manual to ensure you are using them correctly and interpreting the results accurately.

Remember, proper safety precautions should always be taken when working with fuel lines. Ensure the engine is cool before starting any repairs, and always disconnect the battery to prevent any electrical issues. If you are unsure about any step or suspect a more complex issue, it is best to consult a professional mechanic who can provide expert guidance and ensure the job is done safely and effectively.

Unconventional Engine: Exploring the Possibility of a Car Running Without a Fuel Line

You may want to see also

Prepare the Tools: Gather necessary tools like a fuel line cutter, crimping tool, and replacement line

Before you begin the process of repairing or replacing a fuel line on your car, it's crucial to ensure you have the right tools and materials ready. This preparation will make the repair process smoother and more efficient. Here's a step-by-step guide on what you need to gather:

Fuel Line Cutter: This tool is essential for cutting the damaged or old fuel line to the appropriate length. It allows you to create a clean and precise cut, ensuring a proper fit for the replacement line. Look for a cutter that can handle the specific diameter of the fuel line you are working with.

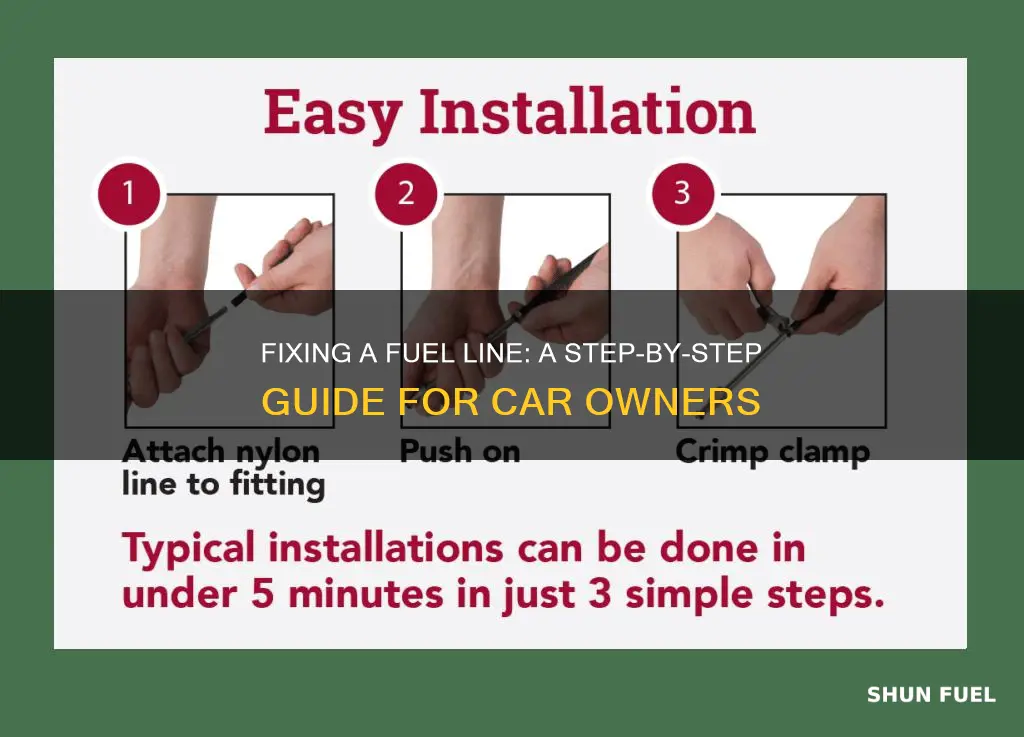

Crimping Tool: Crimping is a critical step in fuel line repair as it ensures a secure and leak-free connection. A crimping tool will enable you to create a reliable joint by deforming the fuel line's end around a fitting or connector. Make sure to choose a crimping tool that matches the size and type of fittings you'll be using.

Replacement Fuel Line: Always have a new fuel line ready that is compatible with your vehicle's specifications. Measure the damaged line to determine the correct length, ensuring it's slightly longer than the required length to allow for any adjustments. It's advisable to get a replacement line from the same make and model to guarantee a perfect fit.

Additionally, consider having some fuel line connectors, seals, and possibly a fuel line inspection camera (if you plan to inspect the existing line). These items can be useful for making temporary repairs or for ensuring a thorough job. Having all these tools and materials prepared beforehand will save you time and effort during the repair process.

Thawing Frozen Fuel Lines: A Guide to Winter Car Care

You may want to see also

Cut and Remove: Carefully cut the damaged section and disconnect the fuel line from the engine

When dealing with a damaged fuel line on your car, the first step is to carefully assess the situation and ensure you have the necessary tools and safety precautions in place. It's crucial to wear protective gear, such as gloves and safety goggles, to shield yourself from any potential fuel spills or splashes. Additionally, make sure the car is parked on a level surface and the engine is cool to avoid any accidents.

Locate the damaged section of the fuel line. This can often be identified by visual inspection, as fuel lines are typically visible under the car. Look for any signs of wear, cracks, or corrosion. Once you've identified the problem area, you'll need to cut the fuel line. Using a sharp, clean pair of cutting pliers or a fuel line cutter, carefully sever the damaged section, ensuring you don't damage any surrounding components. Take your time and make precise cuts to avoid any unnecessary damage.

After cutting the fuel line, you must disconnect it from the engine. Locate the fuel line connectors, which are usually metal or plastic fittings. Loosen the connectors by hand, then use a pair of pliers or a fuel line wrench to remove them. Be gentle to avoid stripping the threads or damaging the fittings. Once the connectors are removed, you should be able to pull the fuel line away from the engine.

It's important to note that fuel lines are often connected to various components, such as the fuel pump, fuel tank, and engine. When disconnecting the fuel line, be mindful of these connections to prevent any accidental disconnections or damage. Take your time and ensure you understand the layout of the fuel system in your specific vehicle. If you're unsure, consult the car's manual or seek guidance from a professional mechanic.

Once the damaged section is removed and the fuel line is disconnected, you can proceed with the necessary repairs or replacements. This may involve soldering a new section of fuel line, using a fuel line repair kit, or replacing the entire fuel line, depending on the severity of the damage. Always ensure that all connections are secure and properly sealed to prevent any fuel leaks.

Signs of Frozen Fuel Lines: A Winter Checklist

You may want to see also

Install New Line: Slide the new fuel line into place, ensuring proper alignment and secure it

When replacing a damaged or leaking fuel line on your car, the installation process involves a few crucial steps to ensure the system is secure and functional. Here's a detailed guide on how to install a new fuel line:

Slide the New Line into Place: Begin by carefully removing the old fuel line from the vehicle. Take note of the path it follows and the specific connections it makes. Now, take the new fuel line and slide it into the same route, ensuring it follows the same path as the old one. Proper alignment is key to a successful installation. Make sure the new line is positioned correctly, matching the original's route and connections.

Ensure Proper Alignment: As you slide the new fuel line into place, pay close attention to its alignment. The line should be straight and not kinked or bent excessively. Check that it doesn't rub against any sharp edges or interfere with other components. Proper alignment ensures optimal performance and prevents potential damage to the new line.

Secure the Line: Once the new fuel line is in the correct position, it's time to secure it. Use the appropriate fasteners, such as clips, ties, or brackets, provided by the manufacturer. These fasteners should be attached to the vehicle's body or frame to provide a solid anchor point. Tighten the fasteners securely but be careful not to overtighten, as this can damage the fuel line. Ensure the line is taut and cannot move or sag, as this could lead to leaks or damage over time.

Final Checks: After securing the fuel line, perform a few final checks. Inspect the line for any signs of strain or damage. Ensure all connections are tight and there are no leaks. Start the engine and check for any unusual noises or vibrations, especially around the fuel line. If everything is in order, your new fuel line is now installed and ready to function efficiently. Remember, proper installation and regular maintenance are essential to keeping your vehicle's fuel system reliable and safe.

Mastering Fuel Line Fixes: A Comprehensive Guide to Using Repair Kits

You may want to see also

Test and Bleed: Bleed the fuel system to remove air, then test for leaks and proper fuel flow

Bleed the fuel system to ensure it is free of air bubbles and to test its integrity. This process is crucial as air in the fuel can cause engine misfires and performance issues. Here's a step-by-step guide to performing this procedure:

- Locate the fuel tank and identify the fuel lines leading to the engine. Typically, there will be a primary fuel line connecting the tank to the engine and smaller lines branching off to individual cylinders or injectors.

- Start the engine and allow it to idle. You'll need the engine to be running to simulate the conditions it operates under.

- Locate the fuel pressure regulator, which is usually found near the engine's intake manifold. This component regulates the fuel pressure to ensure optimal engine performance.

- Connect a fuel pressure gauge to the regulator's outlet port. This gauge will allow you to measure the fuel pressure and ensure it meets the manufacturer's specifications.

- Open the fuel tank's vent valve, which is often located near the fuel pump. This valve allows air to enter the tank, simulating the breathing process of the fuel system.

- With the engine running, slowly open the fuel tank's vent valve and close it again. This action should cause a slight increase in fuel pressure, indicating that the system is drawing fuel from the tank. If the pressure remains stable or drops significantly, it may indicate a blockage or issue with the fuel pump.

- Next, you'll need to bleed the system to remove any air bubbles. Turn the engine off and locate the fuel line that connects the fuel pump to the engine.

- Using a fuel line bleeder kit or a similar tool, locate the bleeder valve on the fuel line. This valve is designed to allow air to escape from the line.

- Open the bleeder valve and listen for any hissing or bubbling sounds, which indicate the release of air. If you hear these sounds, continue to open the valve slightly until the hissing stops, ensuring all air is bled from the line.

- Once the air is bled, close the bleeder valve and start the engine again. Check for any leaks around the connections and ensure the fuel pressure is stable.

- Test for leaks by inspecting all fuel lines and connections for any signs of fuel seepage. Even a small leak can lead to engine performance issues and potential safety hazards.

- Finally, ensure that the fuel flow is proper by monitoring the engine's performance. Rev the engine to its maximum RPM and check for any unusual noises or hesitation. Proper fuel flow should result in a smooth, responsive engine.

By following these steps, you can effectively test and bleed the fuel system, ensuring it is free of air bubbles and ready for optimal performance. This process is a critical part of diagnosing and resolving fuel-related issues in a vehicle.

Understanding the Role of the Diesel Leak Off Fuel Line

You may want to see also

Frequently asked questions

A fuel line leak can be identified by the presence of fuel residue or a strong gasoline smell around the car's underbody. You might also notice a hissing sound or see fuel spraying from the line when the engine is running.

Fuel lines can fail due to age, corrosion, or damage from accidents. Over time, rubber can degrade, leading to cracks and leaks. Corrosion from fuel contamination or moisture can also weaken the line.

Temporary fixes are not recommended as they may not be effective in the long run. It's best to replace the entire fuel line to ensure a proper repair. However, if you need a quick solution, you can use a fuel line sealant or tape to temporarily cover small holes, but this should be followed by a professional repair.

Replacing a fuel line requires several steps. First, locate the old line and disconnect it from the fuel tank and engine. Then, cut the line at a clean break and install a new line, ensuring it is the correct size and type. Secure the new line with clamps or brackets, and test the fuel system for leaks before starting the car.

Yes, one common mistake is not using the correct type of fuel line. Different vehicles require specific types of lines, so it's crucial to identify the correct part. Another error is not properly securing the line, which can lead to leaks. Always ensure a tight and secure connection to prevent fuel leaks.