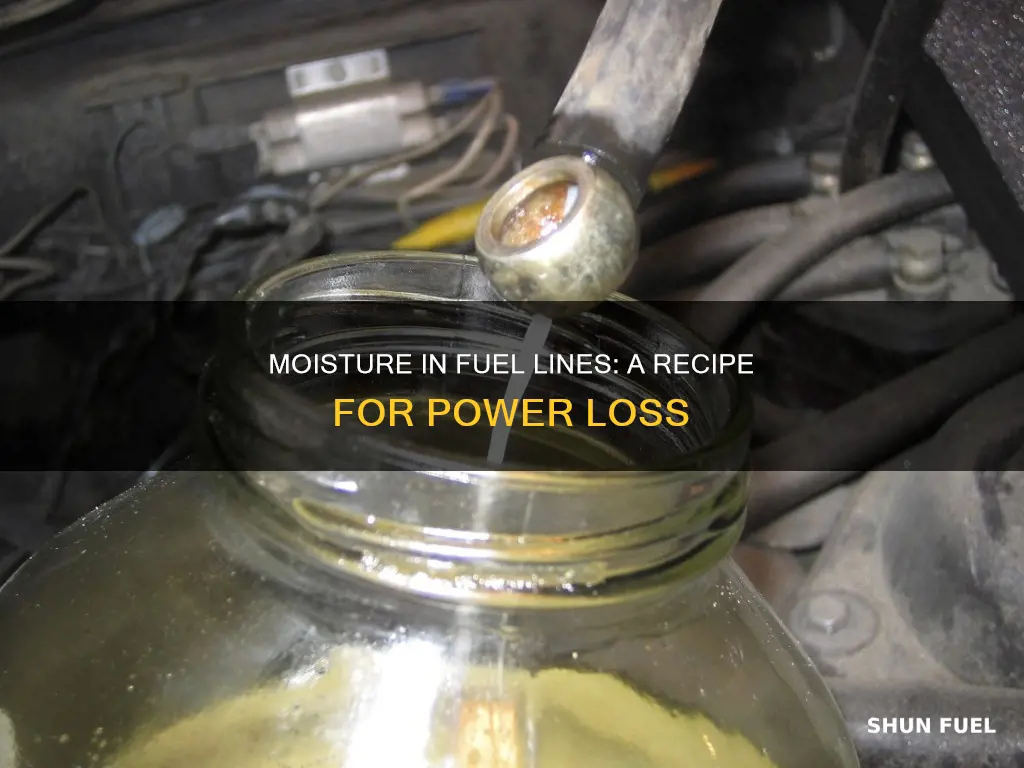

Moisture in fuel lines can have a significant impact on engine performance. When water enters the fuel system, it can lead to a variety of issues, including a loss of power. This occurs because the moisture can cause the fuel to become less efficient, leading to reduced combustion and, consequently, a decrease in power output. Understanding the causes and effects of moisture in fuel lines is crucial for maintaining optimal engine performance and preventing potential damage.

| Characteristics | Values |

|---|---|

| Cause | Moisture in the fuel line can lead to fuel degradation, which may result in engine misfires, reduced power, and poor performance. |

| Symptoms | Engine stalling, hesitation, rough idling, reduced acceleration, and increased fuel consumption. |

| Effects | Moisture can cause corrosion in the fuel system, leading to blockages, fuel pump issues, and potential engine damage over time. |

| Prevention | Using a fuel drier or fuel line separator can help remove moisture. Regularly checking and replacing fuel filters is essential. |

| Solution | Draining and replacing the contaminated fuel, cleaning the fuel system, and ensuring proper fuel storage and handling practices. |

| Common Causes | Poor fuel storage, fuel tank leaks, faulty fuel pumps, and engine overheating can introduce moisture into the fuel line. |

| Repair Cost | The cost of repairs can vary depending on the extent of the damage, but it may include fuel system cleaning, parts replacement, and professional services. |

What You'll Learn

Moisture Ingress: Water Contamination in Fuel Lines

Moisture ingress, or the presence of water in fuel lines, is a common issue that can lead to significant performance problems in internal combustion engines. When water enters the fuel system, it can cause a range of symptoms, including reduced power, poor fuel economy, and even engine failure in extreme cases. This phenomenon is particularly prevalent in regions with high humidity or during the rainy season, but it can occur at any time, especially if the fuel system is not properly maintained.

The primary concern with water contamination in fuel lines is its impact on the combustion process. Water has a higher specific heat capacity than gasoline or diesel, which means it absorbs and retains heat more effectively. When water is introduced into the fuel, it can cause the fuel to become less volatile, leading to a less efficient combustion process. This results in reduced power output and, in some cases, can even cause the engine to stall.

One of the most noticeable effects of water in the fuel system is the loss of power. As water enters the fuel lines, it can create a layer of moisture around the fuel injectors or carburetor, leading to poor atomization of the fuel-air mixture. This results in incomplete combustion, where the fuel doesn't burn efficiently, leading to a decrease in power and performance. Engine misfires, reduced torque, and a general loss of power are common symptoms that indicate water contamination in the fuel.

To address this issue, it is essential to understand the sources of moisture ingress. Water can enter the fuel system through various means, including condensation, leaks in the fuel tank or lines, and improper fuel storage. Condensation occurs when the temperature of the fuel system drops, causing the fuel to cool and condense, especially in older vehicles with less efficient fuel systems. Leaks in the fuel tank or lines can also introduce water, especially if the vehicle has been exposed to rain or if the fuel system has not been properly sealed.

Preventing moisture ingress is crucial to maintaining engine performance. Regular maintenance, such as checking for leaks and ensuring proper fuel storage, can help mitigate this issue. Using fuel additives designed to inhibit water absorption can also be beneficial. In cases where water contamination has already occurred, draining and replacing the affected fuel lines and injectors may be necessary to restore optimal engine performance.

Fuel Lines: Unveiling the Differences and Their Impact

You may want to see also

Engine Performance: Power Loss from Moisture in Fuel

Moisture in fuel lines is a common issue that can lead to a significant loss of engine power and performance. When water enters the fuel system, it can cause a multitude of problems, affecting the engine's ability to run efficiently and produce power. This issue is often overlooked, but it can be a major culprit behind sudden drops in engine performance.

The presence of moisture in the fuel can be a result of several factors. One common cause is the condensation of water vapor in the fuel tank, especially when the fuel is exposed to colder temperatures. This is particularly prevalent in regions with varying climates, where the fuel tank may experience temperature fluctuations. Over time, water can accumulate in the tank, and if not addressed, it can find its way into the fuel lines and injectors. Another source of moisture could be old or contaminated fuel, which may have absorbed water during storage, especially if left unattended for extended periods.

When moisture enters the fuel system, it can lead to several detrimental effects. Firstly, water has a lower energy content compared to gasoline, so it burns less efficiently. This results in a decrease in power output as the engine struggles to ignite the fuel effectively. Additionally, moisture can cause the fuel to become more viscous, leading to reduced flow rate through the injectors. This can result in poor atomization of the fuel-air mixture, further exacerbating the power loss issue.

The impact of moisture on engine performance is often noticeable during acceleration. The engine may hesitate or stall momentarily when the throttle is opened, indicating a lack of power. This is because the moisture-laden fuel struggles to ignite promptly, causing a temporary loss of power. Over time, the engine may also experience rough idling, misfires, and a general loss of performance, making it less responsive and less efficient.

To address this issue, it is essential to identify and eliminate the source of moisture. Regularly inspecting the fuel tank for any signs of water accumulation and ensuring proper ventilation can help prevent condensation. Using fuel stabilizers or additives can also aid in reducing moisture content in older fuel. Additionally, maintaining a consistent fuel temperature and using fuel line heaters can minimize the chances of moisture-related power loss. By taking these precautions, vehicle owners can ensure their engines remain reliable and powerful, even in the presence of moisture in the fuel system.

Is a Larger Return Fuel Line Necessary for Your Chevy Lumina?

You may want to see also

Fuel System Maintenance: Preventing Moisture-Related Engine Issues

Moisture in the fuel line is a common issue that can lead to a variety of engine problems, including a significant loss of power. When water enters the fuel system, it can cause a multitude of issues that affect engine performance and longevity. Understanding the causes and consequences of this problem is essential for any vehicle owner to ensure optimal engine operation.

One of the primary reasons moisture forms in the fuel line is due to condensation. As fuel vaporizes in the tank, it leaves behind water droplets, especially in colder climates or when the vehicle is parked for extended periods. Over time, this moisture can accumulate and travel through the fuel lines, leading to potential engine damage. The presence of water in the fuel can cause several symptoms, such as rough idling, reduced power output, and even engine misfires. These issues often arise because water is not an ideal lubricant for the internal engine components and can disrupt the combustion process.

To prevent moisture-related engine problems, regular fuel system maintenance is crucial. One effective method is to use a fuel additive designed to eliminate water from the fuel system. These additives typically contain compounds that attract and bind to water molecules, allowing them to be safely drained from the system. It is recommended to use these additives periodically, especially during seasonal changes, to ensure the fuel system remains dry. Additionally, keeping the fuel tank as full as possible can help minimize the formation of condensation, as a full tank leaves less room for air and moisture to accumulate.

Another important practice is to regularly check and replace the fuel filter. Over time, the fuel filter can become clogged with contaminants, including water, which can restrict fuel flow and introduce moisture into the engine. By replacing the fuel filter at recommended intervals, you can ensure that the fuel system remains clean and free-flowing, reducing the chances of water-related issues.

In summary, moisture in the fuel line is a serious concern that can lead to engine power loss and other performance problems. By implementing simple maintenance practices, such as using fuel additives and regularly replacing filters, vehicle owners can effectively prevent moisture-related engine issues. Staying proactive with fuel system maintenance will help ensure a reliable and efficient engine performance.

Optimizing Performance: Choosing the Right Fuel Line for Your 2005 Johnson 90 HP

You may want to see also

Fuel Injection: Impact of Moisture on Injection Systems

Moisture in fuel lines can have a significant impact on the performance of fuel injection systems, leading to a range of issues that can affect engine operation and overall vehicle performance. When water enters the fuel system, it can cause a variety of problems, from reduced engine power and efficiency to potential long-term damage to the engine. Understanding these issues is crucial for vehicle owners and mechanics alike to ensure proper maintenance and troubleshooting.

One of the primary concerns with moisture in the fuel line is its effect on fuel atomization and injection. Fuel injectors are designed to spray a precise amount of fuel into the engine's intake manifold or directly into the combustion chamber. When moisture is present, it can cause the fuel to become less volatile, leading to poor atomization. This results in a less efficient combustion process, as the fuel doesn't vaporize properly, causing a loss of power and potential misfires. Over time, this can also lead to increased emissions and reduced engine performance.

The presence of moisture can also lead to the formation of fuel-water emulsions, which can block fuel filters and injectors. As water and fuel mix, they create a slurry that can clog the small passages within fuel injectors and filters. This blockage can restrict fuel flow, further exacerbating the loss of power and potentially causing the injectors to malfunction. Regular maintenance, including fuel filter changes, is essential to prevent this issue and ensure the longevity of the fuel injection system.

In addition to the immediate effects, moisture in the fuel line can also contribute to long-term engine damage. Water can enter the engine through various means, such as condensation in the fuel tank or improper fuel handling. Once inside, it can lead to corrosion of internal engine components, especially in areas where fuel comes into contact with metal surfaces. This corrosion can result in worn-out valves, damaged cylinder heads, and other critical engine parts, ultimately leading to engine failure.

To mitigate the impact of moisture, it is essential to employ preventative measures. Regularly checking and replacing fuel filters is a simple yet effective way to remove water and contaminants from the fuel system. Additionally, using fuel additives that help prevent moisture accumulation can be beneficial. Proper fuel storage and handling practices, such as ensuring fuel tanks are dry and using fuel stabilizers, can also reduce the likelihood of moisture-related issues. By being proactive and addressing potential moisture problems, vehicle owners can maintain optimal engine performance and extend the life of their fuel injection systems.

Understanding the Purpose of the Smaller Fuel Line on a Trimmer

You may want to see also

Engine Diagnostics: Identifying Moisture-Related Power Loss

Moisture in the fuel line can indeed lead to a loss of power in an engine, and it's a common issue that many vehicle owners face. When water enters the fuel system, it can cause a range of problems, from reduced performance to potential engine damage. Identifying and addressing this issue is crucial for maintaining your vehicle's efficiency and longevity. Here's a step-by-step guide to diagnosing and resolving moisture-related power loss:

Step 1: Visual Inspection

Start by visually inspecting the fuel lines and the engine bay. Look for any signs of water accumulation, such as wet spots, condensation, or water droplets. Check the fuel lines for any visible damage, cracks, or leaks. Moisture in the fuel line can be a result of a damaged line, a faulty fuel pump, or even a poorly sealed fuel tank.

Step 2: Check the Fuel Filter

The fuel filter is an essential component that traps contaminants, including water, from entering the engine. Remove the fuel filter and inspect it for any signs of moisture or sediment buildup. If the filter is clogged or shows signs of water, it may need to be replaced. A dirty or damaged fuel filter can restrict fuel flow, leading to power loss.

Step 3: Inspect the Fuel Pump

The fuel pump is responsible for delivering fuel from the tank to the engine. Over time, the pump can develop issues, especially if it's located in an area prone to moisture accumulation. Inspect the fuel pump for any signs of corrosion or damage. If the pump is faulty, it may not be able to deliver the required fuel volume, resulting in reduced power.

Step 4: Test the Fuel Pressure

Low fuel pressure can be a symptom of moisture-related issues. Use a fuel pressure gauge to measure the pressure at the fuel rail or injectors. Compare the readings to the manufacturer's specifications. If the pressure is significantly lower than the expected range, it could indicate a problem with the fuel pump or a clogged line.

Step 5: Check for Fuel Contamination

Moisture in the fuel can lead to contamination, which may cause engine misfires and reduced power. Remove the fuel tank and inspect the inside for any signs of corrosion or water accumulation. If necessary, drain and clean the tank to remove any contaminants. Ensure that the fuel tank is properly sealed to prevent future moisture issues.

Step 6: Dry the Fuel System

If moisture is detected in the fuel system, it's essential to dry it out thoroughly. Use a fuel vapor extractor or a desiccant-based drying agent to remove excess moisture from the fuel lines, filter, and tank. This process ensures that the fuel system is free from water, which can help restore engine performance.

Step 7: Monitor and Prevent Future Issues

After addressing the moisture-related problems, monitor your engine's performance regularly. Keep an eye on fuel consumption, engine idle quality, and overall power output. Consider using a fuel additive that inhibits corrosion and helps maintain the dryness of the fuel system. Regular maintenance, such as fuel system flushes and filter replacements, can also prevent future moisture-related power loss.

By following these diagnostic steps, you can effectively identify and resolve moisture-related power loss in your engine. Remember, addressing fuel system issues promptly is crucial to ensure optimal engine performance and prevent potential damage.

Brake Fluid's Impact on Fuel Lines: A Comprehensive Guide

You may want to see also

Frequently asked questions

Yes, moisture in the fuel line can lead to a significant reduction in engine performance. When water enters the fuel system, it can cause several issues, including fuel contamination, which can result in a loss of power.

Moisture in fuel can lead to phase separation, where water and fuel separate, creating a layer of water at the bottom of the fuel tank. This water can then enter the fuel lines and injectors, causing issues.

Common symptoms include a decrease in engine power, rough idling, poor acceleration, and even stalling. The engine may also produce a knocking or rattling sound, indicating potential fuel-related problems.

Yes, several measures can be taken to prevent moisture-related issues. These include using fuel additives that inhibit water absorption, ensuring proper fuel tank ventilation, and regularly checking for any signs of water accumulation in the fuel system.

In some cases, draining the fuel tank may be necessary to remove accumulated water. However, it is best to consult a professional mechanic to assess the situation and determine the appropriate course of action.