Bleed air from a motorcycle's fuel line to ensure optimal performance and prevent engine issues. This process involves releasing trapped air bubbles that can restrict fuel flow, leading to poor engine operation. By following a few simple steps, you can easily bleed the air from the fuel line, ensuring a smooth and efficient ride. This guide will provide a step-by-step process to safely and effectively remove air from the fuel line, allowing your motorcycle to run smoothly and reliably.

What You'll Learn

Locate the fuel line and identify the bleeder screw

To begin the process of bleeding air from your motorcycle's fuel line, you'll need to locate the fuel line itself and then identify the bleeder screw. This screw is specifically designed to allow you to release any air bubbles that may have entered the system. Here's a step-by-step guide to help you with this task:

Start by inspecting your motorcycle's fuel system. The fuel line is typically a flexible tube that runs from the fuel tank to the engine, delivering gasoline to the carburetor or fuel injection system. It's important to locate the point where the fuel line connects to the engine, as this is where the bleeder screw is usually found. Look for any visible screws or fittings along the length of the fuel line. The bleeder screw is often a small, flat-head screw, and it might be located near the fuel tank or close to the engine block. It is usually marked with a small 'B' or 'Bleeder' on the fuel line or the engine casing to indicate its purpose.

Once you've identified the fuel line, carefully follow its path to find the bleeder screw. It is often positioned in a convenient location for maintenance, such as near the fuel tank or under the engine cover. The screw might be accessible without removing any panels, or it could require you to carefully lift or remove a small section of the engine cover to gain access. Take note of the position of the bleeder screw relative to the fuel line to ensure you can easily locate it again during the bleeding process.

When you've found the bleeder screw, you'll need to ensure that the motorcycle is in a stable position. Park it on a level surface and engage the parking brake for added safety. Now, you're ready to proceed with the bleeding process, which will be covered in the next steps of the guide. Remember to be cautious when working with fuel lines, as they can be under pressure, and always refer to your motorcycle's manual for specific instructions tailored to your bike's make and model.

Ford Pink Fuel Line Clip Removal: A Step-by-Step Guide

You may want to see also

Remove the screw and attach a vacuum pump

To begin the process of bleeding air from your motorcycle's fuel line, you'll need to locate the appropriate screw and prepare the necessary tools. This step is crucial as it allows access to the fuel line, enabling you to remove air bubbles and ensure a smooth fuel flow. Start by identifying the specific screw that connects the fuel line to the engine or fuel tank. This screw is typically located near the fuel line's entry point into the engine compartment. Once you've found it, use a screwdriver to carefully remove the screw, being mindful of any small parts or debris that might fall out.

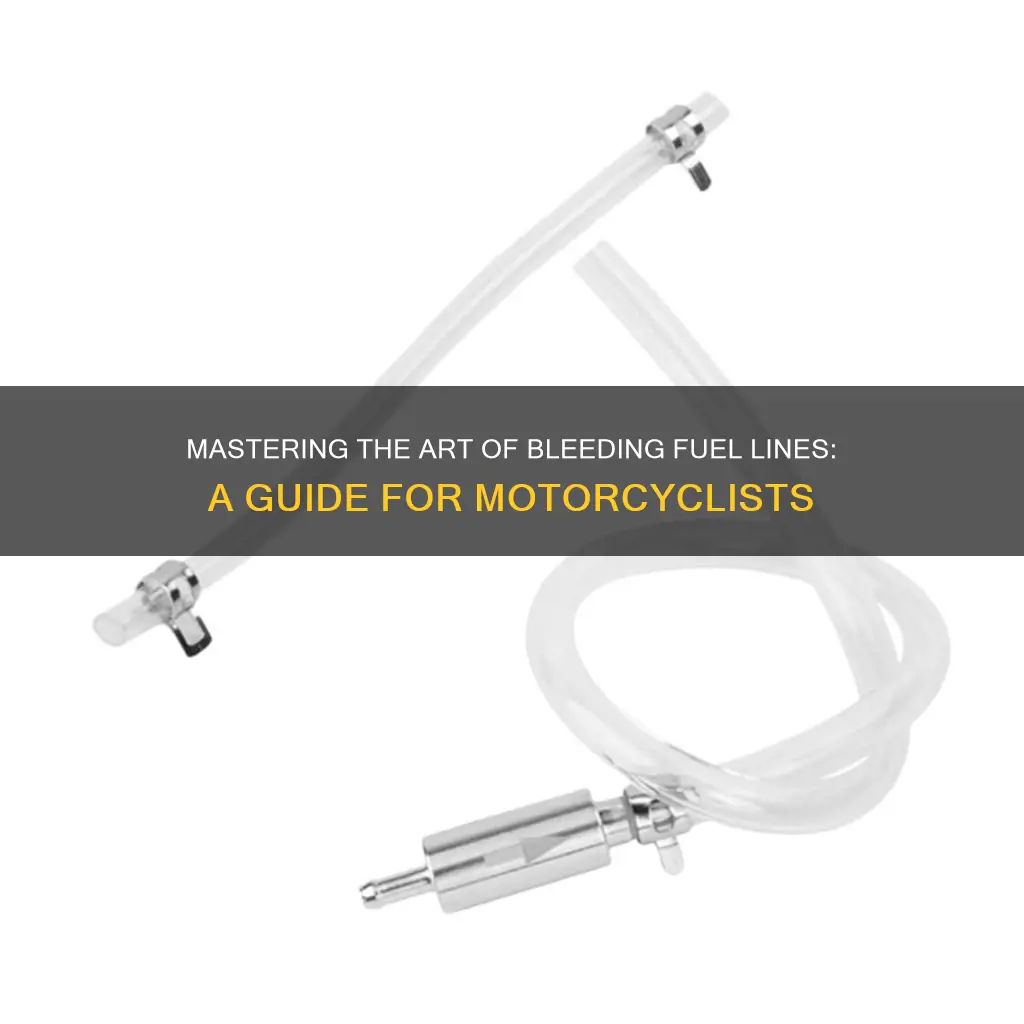

With the screw removed, you'll now have access to the fuel line. It's important to ensure that the fuel line is secure and not damaged during this process. Inspect the fuel line for any signs of wear or damage, and make sure it is in good condition. Now, it's time to attach a vacuum pump. This tool will help create a vacuum, allowing you to draw out the air bubbles from the fuel line. Choose a vacuum pump that is compatible with your motorcycle's fuel system and ensure it has a strong suction capacity.

When attaching the vacuum pump, locate the fuel line's end that is closest to the engine or fuel tank. Carefully slide the vacuum pump's hose over the fuel line, ensuring a secure connection. Make sure the hose is tightly fitted to create an airtight seal. Once the hose is in place, turn on the vacuum pump and allow it to run for a few minutes. This will create a suction force that will draw out any air bubbles present in the fuel line.

As the vacuum pump operates, you might notice some fuel being drawn out along with the air. This is normal and indicates that the pump is effectively removing the air bubbles. Continue running the pump for a sufficient duration, typically a few minutes, to ensure that all the air has been bled out. Keep an eye on the fuel line during this process to ensure no excessive fuel is being drawn out.

After a few minutes, turn off the vacuum pump and carefully remove the hose. Check the fuel line to ensure that it is now free of any air bubbles. Reinsert the screw you removed earlier, ensuring it is tightened securely. With these steps, you've successfully bled the air from your motorcycle's fuel line, ensuring optimal fuel flow and engine performance.

The Ultimate Guide to Choosing the Best 1-2 Fuel Line

You may want to see also

Turn on the pump to draw air out of the line

To effectively bleed air out of your motorcycle's fuel line, it's crucial to understand the process and take the necessary steps. Once you've located the appropriate bleeder screw and prepared the necessary tools, the next step is to turn on the pump to draw air out of the line. This process involves using a fuel pump to create a vacuum that will force any trapped air bubbles to move through the fuel line and out of the bleeder screw.

Here's a detailed guide on how to do this:

- Secure the Motorcycle: Ensure your motorcycle is in a stable position, either on a stand or securely rested on its kickstand. This will prevent any accidental movement during the process.

- Locate the Fuel Pump: Identify the fuel pump, which is typically located near the fuel tank. It might be a separate unit or integrated into the tank. The pump is responsible for sending fuel through the lines to the carburetor or fuel injection system.

- Turn on the Pump: Depending on your motorcycle model, there are a few ways to activate the fuel pump. Some bikes have a dedicated button or switch for this purpose, while others may require you to turn the ignition key to the 'on' position. Make sure the engine is not running during this process to avoid any fuel-related hazards.

- Monitor the Bleeder Screw: As you turn on the pump, keep a close eye on the bleeder screw. You should notice a slight hissing sound as air is drawn out of the line. This is a good sign, indicating that the air is being bled out. If you don't hear any sound, it might mean that the pump is not functioning correctly, and you should check the connections and the pump's power supply.

- Adjust the Pump's Position (if necessary): In some cases, you might need to adjust the position of the pump or the fuel line to ensure optimal air removal. This could involve slightly lifting or moving the pump to create a more direct path for air to escape.

- Continue Bleeding: Keep the pump running and monitor the bleeder screw for a few minutes. You might need to repeat the process a few times to ensure all air bubbles are eliminated. If you notice any air returning to the line, it's a sign that you need to continue bleeding.

Remember, the key to successful bleeding is patience and attention to detail. Take your time, and don't rush the process. If you encounter any issues or have doubts about your motorcycle's specific model, consult the owner's manual or seek professional advice to ensure you're following the correct procedure.

Hydraulic Hose for Diesel Fuel: A Practical Guide

You may want to see also

Check for leaks and repeat if necessary

When dealing with a motorcycle's fuel system and addressing air in the fuel lines, it's crucial to ensure that the process is done correctly to avoid any potential issues. One of the most critical steps in this process is checking for leaks, as it helps identify any potential problems and ensures the system's integrity. Here's a detailed guide on how to check for leaks and repeat the bleeding process if needed:

Step 1: Prepare the Motorcycle

Before you begin, ensure the motorcycle is in a stable and secure position. Turn off the engine and allow it to cool down, especially if it has been running recently. This step is essential for your safety and the accuracy of the leak test. Locate the fuel tank and identify the fuel lines, which are typically made of rubber or plastic and run from the tank to the carburetor or fuel injection system.

Step 2: Inspect for Visual Leaks

Start by visually inspecting the fuel lines and connections. Look for any signs of damage, cracks, or tears in the rubber or plastic. Check for loose fittings and connections, as these can also cause leaks. Pay close attention to the areas where the fuel lines connect to the tank, the carburetor, and any other components. Even small cracks or punctures can lead to significant issues, so ensure you examine every inch of the lines.

Step 3: Use a Bubble Test

A simple yet effective method to check for leaks is the bubble test. Fill the fuel tank with a small amount of fuel, ensuring it is not overfilled. Then, remove the fuel line connections at various points and hold the lines under the surface of the fuel. Submerge the lines until you can no longer see any bubbles rising. If bubbles appear, it indicates a potential leak, and you should investigate further. This test helps identify any air or fuel escaping from the system.

Step 4: Repeat and Secure Connections

If you detect any leaks, it's essential to repeat the bleeding process to ensure the air is properly expelled. Start by disconnecting the fuel lines and attaching a vacuum pump or a large syringe to one end of each line. Apply suction to draw the fuel through the line, which will also pull out any air. Ensure you bleed the system multiple times to remove any remaining air pockets. Once the bleeding process is complete, securely reconnect all the fuel lines and fittings, ensuring they are tight and properly sealed.

Step 5: Test Ride and Monitor

After completing the leak check and repeating the bleeding process, it's time for a test ride. Start the motorcycle and let it idle for a few minutes. Monitor the engine's performance and listen for any unusual noises. Check for any signs of fuel leakage around the connections and under the motorcycle. If everything appears normal, you've successfully bled the air from the fuel lines. However, if any issues arise, repeat the leak-checking process and secure the connections tightly.

Remember, taking the time to thoroughly inspect for leaks and repeating the bleeding process is vital to ensuring your motorcycle's fuel system operates efficiently and reliably. Always exercise caution when working on fuel lines, and if you're unsure, consult a professional mechanic.

Unveiling Alabama's Rustic Fuel Lines: A Comprehensive Guide

You may want to see also

Reinstall the screw and tighten securely

Reinstalling the screw and tightening it securely is a crucial step in the process of bleeding air out of your motorcycle's fuel line. This step ensures that the fuel line is properly sealed and that no air can enter the system, which is essential for optimal performance. Here's a detailed guide on how to do it:

Step-by-Step Process:

- Locate the Fuel Line and Screw: Start by identifying the fuel line on your motorcycle. It is typically a thin, flexible tube that runs from the fuel tank to the engine. Find the screw that is responsible for securing the fuel line to the engine or a nearby component. This screw is often located near the fuel line's connection to the engine block or a fuel injection system.

- Remove the Old Screw: Carefully remove the existing screw using a screwdriver or a specialized tool designed for this purpose. Be gentle to avoid damaging the fuel line. Take note of the screw's orientation and position, as you might need to reattach it in the same way.

- Clean the Fuel Line and Connection: Before reinstalling the screw, ensure that the fuel line and the connection area are clean and free of any debris or old fuel residue. You can use a soft cloth or a small brush to wipe away any contaminants. This step is important to ensure a tight and secure connection.

- Reinstall the Screw: Now, carefully reinstall the screw, ensuring that it is aligned correctly with the fuel line. Tighten the screw by hand first to get a sense of the required force. Then, using a wrench or a socket, tighten the screw securely. Make sure it is tight enough to hold the fuel line in place but be careful not to overtighten, as it might damage the fuel line or the surrounding components.

- Final Check: After tightening the screw, give it a final check to ensure it is secure. You can gently tug on the fuel line to verify that it is firmly attached and that there is no excessive play. If everything feels snug, you're ready to move on to the next step in the bleeding process.

Remember, when working on your motorcycle's fuel system, it's crucial to exercise caution and follow safety guidelines. If you're unsure about any step, consult a professional mechanic or refer to your motorcycle's manual for specific instructions tailored to your bike's make and model.

Optimizing Performance: Choosing the Right Fuel Line for Your CT70 Engine

You may want to see also

Frequently asked questions

One common sign of air in the fuel line is a lack of power or stalling of the engine when you try to start it. You might also notice a sputtering or backfiring sound when riding.

You'll typically need a fuel line bleed kit, which includes a specialized nozzle or adapter that fits over the fuel line. Some kits also come with a vacuum pump or a compressed air source to assist in the bleeding process.

Yes, you can bleed the fuel line without completely removing it. You'll need to locate the fuel line's bleeder valve, which is usually a small screw or fitting. This valve allows you to release the air pressure and remove the air from the line.

Start by ensuring the motorcycle is in a level position and the engine is off. Locate the bleeder valve and attach the bleed kit's nozzle. Open the valve to release the air, then slowly close it to trap the air in the line. Repeat this process a few times, and you should hear the air being expelled.

Yes, it's important to wear protective gear, such as gloves and eye protection, as fuel and air can be released under pressure. Ensure the motorcycle is in a safe, stable position, and be cautious of any fuel leaks. It's also a good idea to have a clean, dry area to work in to avoid any fuel-related hazards.