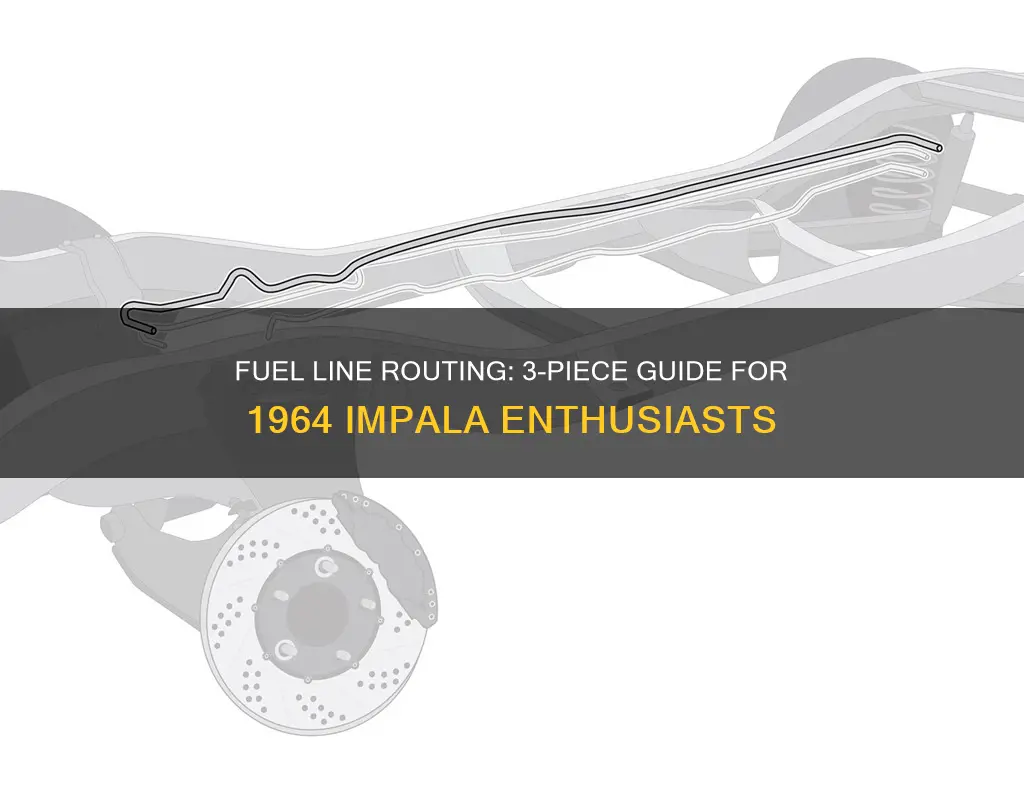

Routing a three-piece fuel line on a 1964 Impala can seem daunting, but with the right tools and a bit of patience, it's a manageable task. This guide will walk you through the process, ensuring your fuel system is secure and efficient. You'll learn the best practices for installation, including how to properly secure the lines and adapt them to the unique contours of your vehicle. By the end, you'll have a reliable fuel supply system that enhances your Impala's performance and longevity.

What You'll Learn

- Fuel Line Routing Basics: Understand the layout and angles of the engine bay

- Clamps and Connections: Secure the line with appropriate clamps and fittings

- Fuel Pump Placement: Position the pump for optimal fuel flow

- Hose Length and Flexibility: Ensure hoses are long enough and flexible for easy installation

- Testing and Adjustments: Verify fuel flow and make necessary adjustments

Fuel Line Routing Basics: Understand the layout and angles of the engine bay

When working on fuel line routing for a classic car like the 1964 Impala, understanding the engine bay layout and angles is crucial. This knowledge ensures a clean, efficient, and safe installation. Here's a breakdown of the key considerations:

Engine Bay Layout:

- Familiarize yourself with the Impala's engine bay: Study the factory diagrams and photographs specific to your 64 Impala. This will reveal the exact locations of the fuel tank, fuel pump, injectors (or carburetor if applicable), and other relevant components.

- Identify clearance zones: Note areas with limited space due to engine components, wiring harnesses, and other accessories. These areas will dictate where you can and cannot route the fuel lines.

Angle Considerations:

- Slope and orientation: The engine bay likely has a slight slope from front to back. Consider this when routing the fuel lines to ensure they drain properly and avoid air bubbles.

- Vertical and horizontal angles: Fuel lines should be routed at optimal angles to minimize pressure drops and ensure smooth fuel flow. Generally, horizontal lines are preferred over vertical ones to prevent excessive tension and potential leaks.

Routing Techniques:

- Use the factory routing as a guide: Start by tracing the original fuel line paths. This provides a solid foundation and helps maintain the integrity of the vehicle's design.

- Prioritize functionality over aesthetics: While a clean appearance is desirable, the primary goal is to ensure proper fuel flow and safety.

Materials and Protection:

- Choose appropriate fuel line material: Select fuel lines made from durable materials like stainless steel or high-temperature rubber that can withstand fuel pressure and engine heat.

- Insulate vulnerable sections: Protect fuel lines from heat sources and potential damage by using heat shields, rubber sleeves, or other insulation materials.

Remember, proper fuel line routing is essential for optimal performance, fuel efficiency, and safety. Take the time to carefully plan and execute the routing to ensure a successful and long-lasting installation.

1956 Chevy Fuel Line: Size Matters for Performance

You may want to see also

Clamps and Connections: Secure the line with appropriate clamps and fittings

When it comes to routing the fuel lines on your 64 Impala, ensuring secure and reliable connections is crucial for optimal performance. Here's a detailed guide on how to achieve this:

Choosing the Right Clamps: Select high-quality fuel line clamps that are compatible with the material of your fuel lines. For a classic car like the Impala, you might opt for stainless steel or brass clamps to ensure longevity and resistance to corrosion. These materials offer excellent durability and can withstand the demands of fuel systems. Look for clamps with a smooth interior surface to prevent any damage to the fuel lines.

Fitting Installation: Begin by carefully cutting the fuel lines to the desired length, ensuring precise measurements. Then, slide the clamps over the fuel lines, positioning them securely. The clamps should be tight enough to hold the lines in place but not so tight that they cause any damage or restrict flow. Use a small amount of fuel line adhesive or tape inside the clamp to provide an additional layer of protection and ensure a secure connection.

Routing and Placement: Route the fuel lines away from high-heat areas and sharp edges to prevent damage. Consider the engine's layout and choose a path that allows for easy access during maintenance. Secure the lines to the body or frame using appropriate mounting hardware, ensuring they remain taut and free from any obstructions. Proper routing will not only enhance performance but also contribute to a clean and professional appearance under the hood.

Fittings and Connections: When connecting the fuel lines to the fuel pump, carburetor, or other components, use fittings that match the fuel line diameter. Tighten the fittings securely, ensuring a leak-free connection. Consider using fuel line connectors with gaskets or O-rings for an extra layer of protection against fuel leaks. Regularly inspect these connections to ensure they remain tight and intact over time.

By following these steps and paying close attention to the quality of clamps and fittings, you can ensure a reliable and efficient fuel system for your 64 Impala. Remember, proper routing and secure connections are essential for maintaining the vehicle's performance and longevity.

Will Deasil Fuel Lines Freeze? Unraveling Winter Fuel Line Mysteries

You may want to see also

Fuel Pump Placement: Position the pump for optimal fuel flow

When it comes to routing the fuel lines on a 64 Impala, proper fuel pump placement is crucial for optimal performance and longevity. The fuel pump's position directly impacts fuel flow, pressure, and overall engine operation. Here's a detailed guide on how to position the pump for the best results:

- Engine Bay Layout: Familiarize yourself with the engine bay layout of your 64 Impala. Identify the areas where you have easy access and sufficient space to work with. Typically, the fuel pump is located near the front of the engine, often mounted on the firewall or within the engine compartment. Understanding the layout will help you make informed decisions about the pump's placement.

- Optimal Height and Angle: The fuel pump should be positioned at an optimal height and angle to ensure smooth fuel flow. Aim for a height that allows the fuel line to maintain a slight downward slope from the pump to the fuel tank. This slight angle prevents air from entering the system and promotes a consistent fuel supply. A good rule of thumb is to have the pump as low as possible while still allowing easy access for maintenance.

- Proximity to the Tank: Position the fuel pump as close as possible to the fuel tank. This reduces the length of the fuel line, minimizing potential pressure drops and ensuring a more efficient fuel delivery system. The shorter the line, the less resistance to fuel flow, resulting in improved performance and reduced stress on the pump.

- Secure Mounting: Ensure the fuel pump is securely mounted to prevent movement or vibration during engine operation. Use appropriate mounting brackets or hardware to attach the pump to the firewall or a suitable surface. A stable mounting system helps maintain the pump's position and prevents potential damage to the fuel lines.

- Consideration of Heat: Take into account the heat generated by the engine. Avoid placing the fuel pump too close to hot engine components, as this can lead to fuel degradation and potential performance issues. A good practice is to provide some insulation or a heat shield to protect the pump and ensure the fuel remains at optimal temperature.

By carefully considering the fuel pump's placement, you can optimize fuel flow, enhance engine performance, and ensure a reliable fuel supply for your 64 Impala. Remember, proper routing and positioning are key to maintaining a healthy fuel system.

Ford 91 E350 Fuel Line: Size Unveiled

You may want to see also

Hose Length and Flexibility: Ensure hoses are long enough and flexible for easy installation

When it comes to routing the fuel lines on a 1964 Impala, one crucial aspect to consider is the hose length and flexibility. This is an important factor to ensure a smooth and efficient installation process. Here's a detailed guide on how to approach this:

Firstly, measure the distance between the fuel tank and the engine compartment, as well as the desired positions for the fuel lines. It is essential to have hoses that are long enough to accommodate these measurements. Insufficient length can lead to tight bends and potential damage to the hoses during installation. Aim for a comfortable fit, allowing for some extra length to facilitate easy routing.

Flexibility is another key attribute of the hoses. The fuel lines need to be able to bend and twist without kinking or putting excessive strain on the connections. Look for hoses with a good range of motion and consider the materials used. Rubber or silicone hoses often offer better flexibility compared to rigid plastic ones. This flexibility will make the installation process less cumbersome and reduce the risk of damage to the fuel system.

To ensure optimal hose length and flexibility, consider the following: cut the hoses to the appropriate length, allowing for a few extra inches at each end for connections. Then, use hose clamps or ties to secure the hoses in place, ensuring they remain taut and free from any sharp bends. This approach provides a neat and functional installation.

Additionally, when routing the hoses, aim for a path that minimizes sharp turns and potential stress points. Smooth curves and gentle bends will contribute to the overall longevity of the fuel lines. Remember, the goal is to create an installation that is not only functional but also aesthetically pleasing.

By paying close attention to hose length and flexibility, you can ensure a successful and hassle-free fuel line routing process for your 1964 Impala. This attention to detail will result in a well-organized and efficient fuel system, contributing to the overall performance and reliability of your classic car.

T100 Fuel Line Guide: Choosing the Right Option

You may want to see also

Testing and Adjustments: Verify fuel flow and make necessary adjustments

Before you begin the installation, it's crucial to test the fuel flow to ensure the system is functioning correctly. This step is often overlooked but is essential to guarantee that your classic Impala gets the fuel it needs for optimal performance. Here's a detailed guide on how to verify fuel flow and make any necessary adjustments:

Step 1: Fuel Flow Testing

- Start by locating the fuel pump and the fuel pressure gauge. The fuel pump is typically found behind the driver's side front seat, and the gauge can be installed in various locations, often near the fuel tank or along the fuel line.

- With the engine off, connect the fuel pressure gauge to the fuel line. Ensure a tight connection to avoid any leaks.

- Turn on the ignition and listen for the fuel pump to prime. It should come on for a few seconds, indicating it's drawing fuel from the tank.

- Check the gauge reading. A healthy fuel pressure for a 1964 Impala should typically range between 40-60 psi (pounds per square inch). If the pressure is too low, it may indicate a restricted fuel line or a faulty pump.

Step 2: Adjusting the Fuel Line Route

- If the fuel flow test reveals any issues, it's time to adjust the fuel line route. Refer to the initial research you conducted on routing a three-piece fuel line for specific guidance.

- Carefully examine the fuel line's path. Ensure it is not kinked, twisted, or pinched anywhere along its length. These obstructions can restrict fuel flow.

- Consider the line's angle and position. It should be routed in a way that minimizes bends and twists, as sharp turns can reduce flow efficiency.

- If you find any tight spots or areas where the line can be realigned, gently adjust it to improve the flow path.

Step 3: Verifying Fuel Delivery

- After making adjustments, restart the engine and retest the fuel pressure. You should notice an improvement if your changes were effective.

- Pay attention to the engine's behavior during this test. A well-functioning fuel system should provide smooth and consistent power delivery.

- If the engine hesitates or stalls, it might indicate a persistent issue with fuel flow, and further investigation is required.

Step 4: Fine-Tuning and Final Checks

- If the fuel flow is still not satisfactory, you may need to make additional adjustments or consider other factors like fuel filter cleanliness or pump performance.

- Ensure all connections are secure and free from corrosion. A loose connection can lead to reduced fuel flow.

- Consult the Impala's service manual for specific troubleshooting tips related to fuel delivery issues.

Remember, proper fuel flow is critical for the performance and reliability of your classic car. Take the time to test and adjust the fuel line route to ensure your 1964 Impala runs smoothly and efficiently.

1988 F150 Fuel Line Sizes: A Comprehensive Guide

You may want to see also