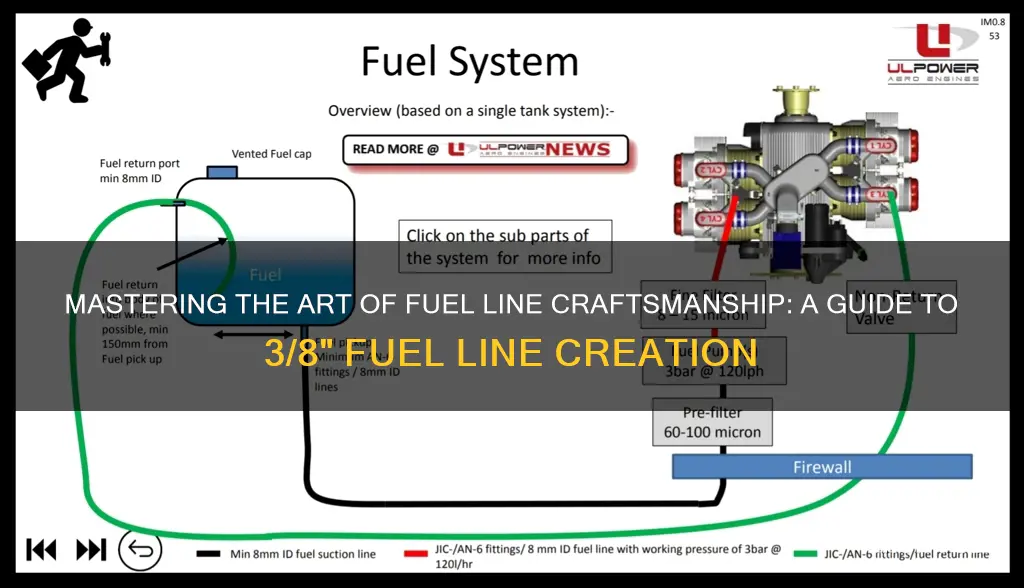

Making a 3/8-inch fuel line is a useful skill for anyone working on a vehicle's fuel system. This guide will provide a step-by-step process to create a custom fuel line, ensuring a secure and reliable connection. From selecting the right materials to using the appropriate tools, you'll learn how to measure, cut, and assemble the line, ensuring it meets the required specifications for your vehicle's fuel needs.

What You'll Learn

- Materials and Tools: Gather necessary supplies like fuel line, connectors, and crimping tools

- Preparation: Clean and prepare the fuel line and connectors for assembly

- Assembly: Connect the fuel line to the fuel source and engine using appropriate connectors

- Testing: Inspect the fuel line for leaks and ensure proper fuel flow

- Safety: Follow safety guidelines to prevent fuel leaks and ensure proper installation

Materials and Tools: Gather necessary supplies like fuel line, connectors, and crimping tools

Before you begin, it's crucial to gather all the necessary materials and tools to ensure a successful and safe fuel line installation. Here's a comprehensive list of what you'll need:

Materials:

- 3/8" fuel line: Select a high-quality fuel line specifically designed for automotive applications. Ensure it is compatible with your vehicle's fuel system and meets the required pressure and temperature specifications.

- Connectors: You'll need various types of connectors to join the fuel line to the fuel pump, injectors, and other components. Common connector types include quick-connect fittings, barbed fittings, and compression fittings. Choose connectors that are compatible with your fuel line diameter and vehicle's fuel system.

- Fuel line clips or ties: These are used to secure the fuel line and prevent it from rubbing against other components, which could cause damage or leaks.

- Fuel line sealant (optional): If you're replacing an existing fuel line, consider using a fuel line sealant to ensure a secure and leak-free connection.

Tools:

- Crimping tool: This specialized tool is essential for installing connectors onto the fuel line. It applies the necessary force to create a secure and leak-resistant connection. Ensure you have the appropriate crimping tool for the connector type you've chosen.

- Pliers: Standard pliers can be useful for gripping and manipulating fuel line components during the installation process.

- Hose clamp tool (optional): If you're using hose clamps instead of fuel line clips, a hose clamp tool will make the installation process easier.

- Cleaning supplies: Have some cleaning solutions and rags ready to clean the fuel line and connectors before assembly. This ensures a proper connection and prevents contamination.

- Safety equipment: Wear appropriate personal protective equipment, such as gloves and safety goggles, to protect yourself during the fuel line installation process.

By gathering these materials and tools, you'll be well-prepared to tackle the task of installing or replacing a 3/8" GM fuel line. Remember to follow manufacturer instructions and safety guidelines throughout the process.

Understanding the Car's Fuel Line: A Comprehensive Guide

You may want to see also

Preparation: Clean and prepare the fuel line and connectors for assembly

Before you begin the process of creating a 3/8" GM fuel line, it is crucial to ensure that all components are in optimal condition. Start by gathering the necessary tools and materials, including a fuel line kit, a fuel pump, connectors, and any required fittings. This initial step is essential to guarantee a smooth and efficient assembly process.

The first step in the preparation phase is to thoroughly clean the fuel line and connectors. Over time, fuel lines can accumulate dirt, debris, and contaminants, which can lead to performance issues. Use a fuel line cleaner or a high-pressure water jet to remove any built-up grime. Pay close attention to the connectors, as they are prone to accumulating contaminants. Ensure that all surfaces are free from any residue or debris.

Next, inspect the fuel line for any signs of damage or wear. Look for cracks, punctures, or any other visible defects. If you notice any issues, it is best to replace the fuel line to ensure a safe and reliable setup. Check the flexibility and overall condition of the fuel line to ensure it can withstand the required pressure and movement.

Once the fuel line is clean and inspected, it's time to prepare the connectors. Ensure that all connectors are in good condition and properly aligned. Use a connector cleaning tool or a small brush to remove any debris from the threads and ports. This step is crucial to ensure a tight and secure connection during the assembly process.

Additionally, consider lubricating the fuel line and connectors with a suitable fuel line lubricant. This will facilitate the assembly process and ensure a smooth connection. However, be cautious not to over-lubricate, as excess lubricant can lead to leaks. Follow the manufacturer's guidelines for the appropriate amount of lubricant to use.

By following these detailed preparation steps, you will have a clean and ready-to-use fuel line and connectors, setting a strong foundation for the rest of the assembly process.

Deep Clean Your 4Runner's Fuel System: A Step-by-Step Guide

You may want to see also

Assembly: Connect the fuel line to the fuel source and engine using appropriate connectors

When connecting the 3/8" GM fuel line to the fuel source and engine, it's crucial to follow a systematic approach to ensure a secure and reliable assembly. Here's a step-by-step guide to help you through this process:

Step 1: Prepare the Components

Before you begin, ensure you have all the necessary components. This includes the 3/8" fuel line, appropriate fuel connectors, and any required fittings or adapters. Check the compatibility of the connectors with your specific fuel source and engine model to ensure a proper fit.

Step 2: Prime the Fuel System

Start by priming the fuel system to remove any air bubbles. Prime the fuel line by attaching one end to the fuel source and the other to a test gauge or a temporary connection point. Open the fuel source and allow the fuel to flow through the line, ensuring it is free-flowing and without any obstructions. This step is essential to ensure the line is ready for fuel delivery.

Step 3: Connect the Fuel Line to the Fuel Source

Locate the fuel source, which could be a fuel pump, a fuel tank, or a fuel injectors' port. Carefully connect one end of the 3/8" fuel line to the fuel source using the appropriate connector. Ensure a tight and secure connection by following the manufacturer's instructions for the specific connector type. Use thread seal tape or pipe compound on the threads to prevent leaks.

Step 4: Route the Fuel Line to the Engine

Carefully route the fuel line from the fuel source to the engine, following the recommended path. Ensure the line is not kinked or pinched, as this can restrict fuel flow. Use fuel line clips or ties to secure the line in place, allowing it to hang freely without any sharp bends.

Step 5: Connect to the Engine

At the engine, locate the fuel injectors or carburetor, depending on your engine setup. Connect the other end of the fuel line to the engine's fuel delivery system using the appropriate connector. Again, ensure a tight connection and consider using thread sealants for added security.

Step 6: Test the Assembly

After completing the connections, start the engine and monitor for any leaks. Check all connections for tightness and ensure there are no visible signs of fuel escaping. If everything is secure, the engine should start smoothly, indicating a successful assembly.

Remember, when working with fuel lines, it's essential to prioritize safety and precision. Take your time, double-check connections, and seek professional advice if needed to ensure a reliable and safe fuel system.

Modern Diesel Evolution: Heated Fuel Lines for Improved Performance

You may want to see also

Testing: Inspect the fuel line for leaks and ensure proper fuel flow

When testing the fuel line for your 3.8L GM engine, it's crucial to ensure there are no leaks and that the fuel is flowing correctly. Here's a step-by-step guide to help you with this process:

- Prepare the Necessary Tools: Before you begin, gather the required tools and materials. You'll need a fuel pressure gauge, a fuel line inspection kit (which may include a flexible light source and a camera for internal inspection), and some cleaning supplies like a degreaser and a cloth. Additionally, have some new fuel line connectors and a supply of fuel ready for testing.

- Locate the Fuel Line: Identify the fuel line that connects the fuel pump to the engine. This line is typically located under the vehicle, running along the frame rail. Carefully inspect the line for any visible signs of damage, cracks, or corrosion. Look for any areas where the line might be pinched or kinked, as these can cause issues.

- Check for Leaks: Start by applying a small amount of fuel line sealer or a similar product along the length of the fuel line, ensuring you cover all connections. Then, using the fuel pressure gauge, apply pressure to the fuel system while monitoring for any leaks. Check all connections, including the fuel pump, injectors, and the engine's fuel rail. Leaks can occur at these points, so ensure they are tight and secure. If you notice any fuel seeping or dripping, it indicates a potential leak that needs attention.

- Inspect for Proper Fuel Flow: With the fuel line sealed, start the engine and allow it to idle. Monitor the fuel gauge and listen for any unusual noises. The fuel gauge should be steady and not fluctuate, indicating a consistent fuel flow. If the gauge drops or fluctuates, it suggests a potential issue with the fuel pump or the fuel line itself. Additionally, check for any signs of fuel starvation, such as the engine stalling or losing power, which could be caused by a restricted fuel flow.

- Use the Inspection Kit: For a more thorough inspection, utilize the inspection kit. Insert the flexible light source and camera into the fuel line to examine the interior. Look for any blockages, debris, or signs of damage that might affect fuel flow. This step is especially important if you suspect a blockage or internal damage.

- Clean and Reassemble: If any issues are found, address them accordingly. Clean the fuel line and connections to remove any contaminants. Replace any damaged or leaking components, ensuring proper sealing. Reassemble the fuel system, double-checking all connections for tightness.

By following these steps, you can thoroughly test the fuel line, ensuring it is leak-free and functioning correctly, which is essential for optimal engine performance.

Push Lock Fittings: A Guide to Fuel Line Safety

You may want to see also

Safety: Follow safety guidelines to prevent fuel leaks and ensure proper installation

When working with fuel lines, safety should always be the top priority. Fuel is a highly flammable and potentially dangerous substance, so any handling or installation process must be conducted with extreme care. Here are some essential safety guidelines to follow to prevent fuel leaks and ensure a proper installation:

Personal Protective Equipment (PPE): Before beginning any work, ensure you are wearing appropriate PPE, including gloves, safety goggles, and a respirator. This protects you from potential fuel exposure and any sharp edges or debris that might be present during the installation process.

Fuel Line Material and Compatibility: Use only the correct type of fuel line material for your specific application. Different fuels and environments require different materials to withstand pressure, temperature, and chemical resistance. For example, 3/8" GM fuel lines are commonly used in automotive applications, but it's crucial to choose the right material (such as rubber or silicone) that is compatible with the fuel type (gasoline, diesel, etc.) and the vehicle's system.

Fuel Line Inspection and Preparation: Before installation, inspect the fuel line for any signs of damage, cracks, or leaks. Check for any sharp bends or kinks that could lead to stress points and potential failures. Clean the fuel line and the connection points to ensure a secure and leak-free installation.

Proper Installation Techniques: When installing the 3/8" GM fuel line, follow these steps: Start by routing the line away from sharp edges and heat sources. Secure the line with ties or clips to maintain tension and prevent sagging. Use fuel line connectors that are compatible with your fuel type and ensure a tight, leak-free connection. Avoid overtightening, as it can damage the line. After installation, test the system for leaks by applying pressure and checking for any signs of fuel escaping.

Ventilation and Venting: Proper ventilation is crucial when working with fuel. Ensure your workspace is well-ventilated to prevent the buildup of fuel vapors. If working in a confined space, use a fume hood or ventilation system to remove potential hazards. Additionally, always vent fuel lines to the atmosphere to prevent the accumulation of pressure and potential explosions.

Training and Professional Guidance: If you are not experienced in fuel line installation, consider seeking professional guidance or training. Proper installation techniques and knowledge of fuel systems are essential to prevent accidents. Certified technicians can provide valuable insights and ensure that the work is done safely and effectively.

Remember, safety should never be compromised when dealing with fuel. By following these guidelines, you can minimize the risks associated with fuel line installation and ensure a secure and reliable system. Always prioritize safety protocols to protect yourself, those around you, and the environment.

The Cost of Fuel Line Replacement: A Comprehensive Guide

You may want to see also

Frequently asked questions

A 3/8" fuel line is commonly used in automotive applications to transport fuel from the tank to the engine. It is a standard size for fuel lines due to its balance between flow rate and flexibility, making it suitable for various vehicles.

To cut a 3/8" fuel line, you will need a fuel line cutter or a sharp utility knife. Measure and mark the desired length on the fuel line, ensuring you leave enough length for connections. Then, carefully cut along the marked line, using a steady hand and a sharp blade to avoid damaging the line.

Installing a 3/8" fuel line typically requires a few essential tools. You will need a fuel line cutter or a pair of sharp scissors/knives for cutting the line. Additionally, have a fuel line crimping tool or a pair of pliers to secure the connections. It is also recommended to use fuel line adhesive or tape for a secure and leak-free installation.