Bending RV-12 fuel lines can be a delicate process, but with the right tools and techniques, it can be done safely and effectively. This guide will provide a step-by-step approach to bending fuel lines, ensuring a secure and reliable connection for your RV's fuel system. By following these instructions, you can avoid common pitfalls and ensure a professional-looking installation.

What You'll Learn

- Fuel Line Routing: Plan optimal paths for RV-12 fuel lines, avoiding sharp bends and tight spaces

- Flexibility: Use flexible materials to create gentle bends, reducing stress on the fuel lines

- Support: Install brackets or clips to support fuel lines, preventing excessive bending

- Pressure Testing: Ensure fuel lines can withstand pressure changes without bending or leaking

- Safety: Follow manufacturer guidelines to avoid damage to fuel lines during RV-12 installation

Fuel Line Routing: Plan optimal paths for RV-12 fuel lines, avoiding sharp bends and tight spaces

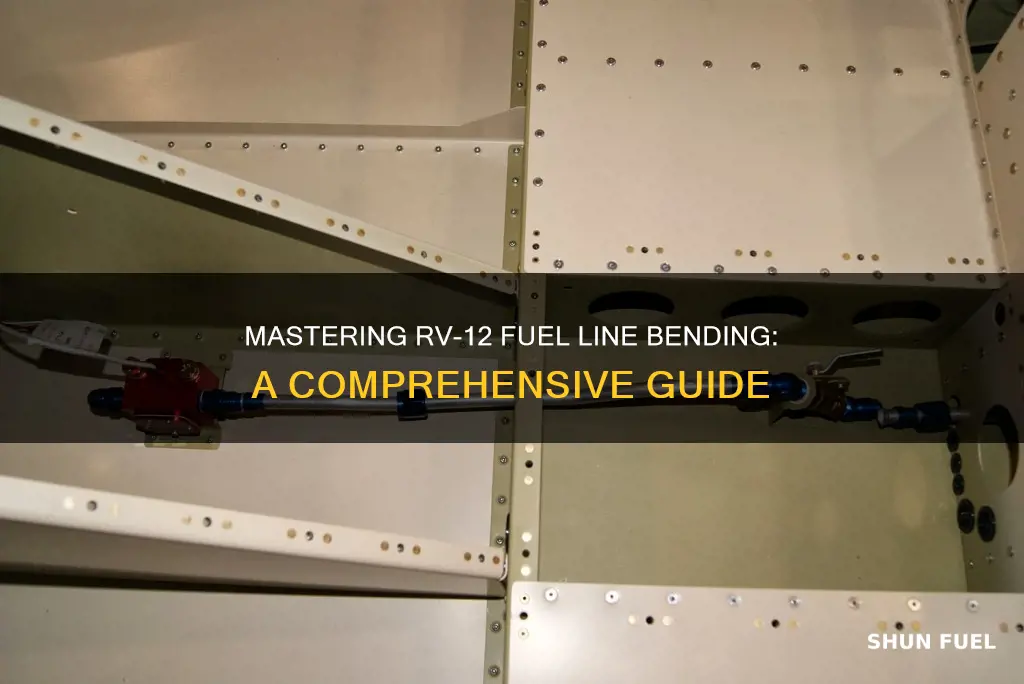

When it comes to routing fuel lines for the RV-12 engine, careful planning is essential to ensure optimal performance and longevity. The goal is to create a path that minimizes stress on the fuel lines while avoiding sharp bends and tight spaces that could lead to damage or reduced flow efficiency. Here's a step-by-step guide to achieving this:

- Understand the Layout: Begin by studying the engine bay layout of your RV-12. Identify the available space and any constraints, such as the position of the engine, transmission, and other components. Understanding the overall structure will help you make informed decisions about the fuel line routes.

- Route Planning: Design a route for the fuel lines, keeping in mind the need to avoid sharp bends. A gentle, gradual curve is ideal. Consider the length of the fuel lines and the distance they need to travel from the fuel tank to the engine. Aim for a path that is as straight as possible, allowing for slight adjustments to accommodate the engine's layout.

- Material Selection: Choose the right fuel line material to ensure flexibility and durability. Rubber or synthetic materials are commonly used for their ability to withstand fuel pressures and temperatures. Ensure the chosen material can accommodate the desired bend radius without kinking or becoming brittle.

- Bending Techniques: When bending the fuel lines, employ the following techniques:

- Use a fuel line bender tool to create smooth, consistent bends. This tool helps maintain the line's integrity and prevents sharp, abrupt changes in direction.

- Aim for a bend radius that is at least four times the diameter of the fuel line to avoid stress concentrations.

- If a sharp bend is unavoidable, consider using a flexible joint or a bend radius adapter to reduce the angle.

- Securement: Properly secure the fuel lines to prevent movement and potential damage. Use fuel line clips or ties to attach the lines to the engine bay's structural members, ensuring they are not tight enough to cause strain. Allow for some slack to accommodate thermal expansion and contraction.

- Testing and Inspection: After installation, test the fuel system to ensure proper flow and pressure. Inspect the fuel lines for any signs of damage, kinking, or excessive wear. Regular maintenance and inspections will help identify issues early on and ensure the long-term reliability of the fuel system.

By following these guidelines, you can effectively plan and implement fuel line routing for the RV-12 engine, ensuring a reliable and efficient fuel supply while minimizing the risk of damage due to sharp bends or tight spaces.

Fuel Line Connection: DIY Tips for a Seamless Installation

You may want to see also

Flexibility: Use flexible materials to create gentle bends, reducing stress on the fuel lines

When working with RV-12 fuel lines, one of the most critical aspects is ensuring flexibility to avoid stress and potential damage. The fuel lines in an RV-12 engine are designed to transmit fuel efficiently, and any bends or kinks can lead to reduced performance and potential safety hazards. To achieve this, it is essential to use flexible materials that can accommodate the natural movement and expansion of the engine components.

Flexible materials, such as braided stainless steel or high-temperature rubber hoses, are ideal for creating gentle bends in the fuel lines. These materials have the inherent ability to conform to the engine's contours without putting excessive pressure on the lines. By using flexible hoses, you can ensure that the fuel lines remain in optimal shape, even during the engine's operation and when it undergoes various movements.

The process of bending the fuel lines requires careful consideration of the engine's layout and the available space. It is crucial to identify the areas where the lines need to be bent and plan the bends accordingly. Gentle, gradual bends are preferable to sharp, abrupt ones, as they reduce the risk of stress concentration and potential cracking. When bending, it is recommended to use a pair of pliers or a specialized hose bending tool to apply consistent pressure and create a smooth curve.

Additionally, it is essential to consider the length and placement of the fuel lines. Longer lines may require multiple bends to accommodate the engine's design, and each bend should be carefully measured to ensure it is gentle and not overly tight. Proper alignment and support of the fuel lines are also crucial to prevent any unnecessary strain.

By incorporating flexible materials and employing gentle bending techniques, you can significantly reduce the stress on the RV-12 fuel lines. This approach ensures the longevity of the fuel system and contributes to the overall reliability and performance of the RV-12 engine. It is a vital step in maintaining a well-functioning fuel system and preventing potential issues related to fuel line damage.

Understanding In-Line Fuel Filters: Benefits and Maintenance Tips

You may want to see also

Support: Install brackets or clips to support fuel lines, preventing excessive bending

When working with RV-12 fuel lines, it's crucial to prioritize safety and ensure that the fuel lines are securely supported to prevent excessive bending, which can lead to potential leaks or damage. One effective method to achieve this is by installing brackets or clips specifically designed for this purpose. These accessories play a vital role in maintaining the structural integrity of your fuel system.

The process begins with identifying the sections of the fuel lines that are prone to bending, often due to their route through the engine bay or under the vehicle's body. These areas require extra protection to withstand the constant movement and potential stress caused by engine vibrations. Once the vulnerable spots are located, you can proceed with the installation.

Brackets and clips are typically made from durable materials such as steel or aluminum, ensuring they can withstand the rigors of the fuel system. The brackets are designed to securely fasten around the fuel lines, providing a rigid support structure. Clips, on the other hand, are smaller and more discreet, allowing for a neater installation. They are often used in conjunction with brackets to secure the fuel lines at various points along their length.

To install these support mechanisms, carefully route the fuel lines to the designated positions where the brackets or clips will be attached. Ensure that the brackets or clips are firmly attached to the vehicle's frame or other sturdy components, providing a solid anchor point. Tighten the fasteners securely, but be cautious not to overtighten, as it may damage the fuel lines. The goal is to create a stable and secure environment for the fuel lines, minimizing the risk of excessive bending.

By implementing this support system, you create a protective barrier around the fuel lines, allowing them to maintain their shape and integrity. This is particularly important when dealing with high-pressure fuel systems, as it helps prevent leaks and potential hazards associated with fuel line failures. Proper support ensures that your RV-12 fuel system operates reliably and safely, providing peace of mind during your travels.

Understanding Saturn Fuel Line Inner Diameter: A Comprehensive Guide

You may want to see also

Pressure Testing: Ensure fuel lines can withstand pressure changes without bending or leaking

Pressure testing is a critical step in ensuring the integrity and safety of RV-12 fuel lines. This process involves subjecting the fuel lines to various pressure changes to simulate real-world conditions and assess their ability to withstand these forces without any issues. Here's a detailed guide on how to perform this test:

Preparation: Before initiating the pressure test, it is essential to gather the necessary equipment and tools. You will need a pressure gauge, a source of compressed air or nitrogen, a fuel line connector, and a suitable testing environment. Ensure that the fuel lines are clean and free of any debris or contaminants that could affect the test results.

Test Procedure: Begin by connecting the pressure gauge to the fuel line at the point where it is intended to be used. This could be at the fuel pump, the engine, or any other relevant location. Gradually increase the pressure in the fuel line using the compressed air or nitrogen source. Start with a low pressure and gradually build up to a level that simulates the maximum pressure the fuel lines will experience during operation. Maintain this pressure for a specified duration, typically around 15-20 minutes, to ensure a thorough test.

During the test, closely monitor the fuel lines for any signs of bending, kinking, or damage. Check for leaks at the connections and along the length of the fuel lines. Even a small leak can indicate potential issues with the fuel line's integrity. If any issues are detected, immediately release the pressure and inspect the fuel lines further.

Analysis and Results: After the test, carefully examine the fuel lines for any visible damage or weaknesses. Document any findings, including the pressure levels at which issues were observed. Compare these results with the manufacturer's specifications and guidelines for the RV-12 fuel lines. If the fuel lines pass the test without any issues, they are likely to perform well in real-world conditions.

Safety Considerations: It is crucial to prioritize safety during pressure testing. Always work in a well-ventilated area and ensure that the compressed air or nitrogen source is properly secured to prevent accidental release. Wear appropriate personal protective equipment, such as gloves and eye protection, to safeguard against any potential hazards.

By following this pressure testing procedure, you can effectively evaluate the strength and reliability of RV-12 fuel lines, ensuring they can handle pressure changes without compromising their structural integrity or leaking fuel. This process is a vital part of the overall fuel line installation and maintenance process.

Choosing the Right Fuel Line: A Comprehensive Guide

You may want to see also

Safety: Follow manufacturer guidelines to avoid damage to fuel lines during RV-12 installation

When installing an RV-12 engine, it's crucial to prioritize safety and take the necessary precautions to prevent any damage to the fuel lines. Fuel lines are a critical component of the fuel system, and any damage can lead to fuel leaks, engine performance issues, and potential safety hazards. Here's a detailed guide on how to ensure safety during the installation process:

Understand the Fuel System: Before attempting any modifications or installations, it's essential to have a comprehensive understanding of the RV's fuel system. Familiarize yourself with the layout of the fuel lines, the location of the fuel tank, and the various components connected to the engine. This knowledge will help you identify potential areas of risk and ensure that you don't accidentally damage any critical parts.

Refer to the Manufacturer's Guidelines: The manufacturer of your RV-12 engine will provide detailed installation manuals and guidelines specific to your model. These documents are invaluable resources that include precise instructions on how to handle and install the engine while maintaining the integrity of the fuel system. Pay close attention to the sections related to fuel line installation, as they will provide specific instructions on bending and routing the lines.

Bending Fuel Lines with Care: When bending fuel lines, it's crucial to use the right techniques to avoid kinks or sharp bends that could compromise the line's integrity. Here are some key points to remember:

- Use a fuel line bender tool specifically designed for this purpose. These tools allow you to apply the necessary force to bend the line without causing damage.

- Start by identifying the desired bend radius and mark the line accordingly. Ensure that the bend is gradual and not sharp.

- Avoid forcing the line if it doesn't bend smoothly. You might need to adjust the tool's pressure or angle to achieve the desired bend.

- Always bend the line in the direction indicated by the manufacturer's guidelines to maintain the line's structural integrity.

Routing and Support: Proper routing of fuel lines is essential to prevent damage during installation and operation.

- Route the lines away from moving parts, such as engine components or suspension elements, to avoid potential impacts or friction.

- Consider using fuel line protectors or sleeves to shield the lines from sharp edges or potential impacts.

- Ensure that the lines are securely fastened and supported at regular intervals to prevent excessive movement or stress.

Regular Inspection: After the installation, it's a good practice to regularly inspect the fuel lines for any signs of damage or wear. Look for cracks, kinks, or any signs of fuel leakage. Regular maintenance and inspections can help identify potential issues early on and ensure the long-term reliability of your RV's fuel system.

By following the manufacturer's guidelines and exercising caution during the installation process, you can minimize the risk of damage to the fuel lines. This approach ensures a safer and more reliable RV-12 engine installation, providing peace of mind for any vehicle owner.

Fuel Line Compression: A Comprehensive Testing Guide

You may want to see also

Frequently asked questions

A fuel line bender or a hydraulic bender is ideal for bending RV-12 fuel lines. These tools provide precise control and ensure a clean, professional bend.

It's not recommended. Regular metal benders may not have the necessary flexibility and control required for fuel lines. They can also damage the lines due to their rigidity.

Always clean the fuel line and ensure it is free of any debris or contaminants. Use a fuel line cleaner or a mild solvent to remove any old fuel residue. This ensures a smooth and accurate bend.

The bend angle can vary depending on the specific application and RV-12 model. Typically, a 90-degree bend is common, but it's essential to refer to the manufacturer's guidelines or diagrams for precise angles.

Yes, safety is crucial. Always wear protective gear, such as gloves and safety goggles, to prevent injury. Ensure you work in a well-ventilated area, and be cautious of any fuel leaks. It's also a good practice to test the bent line for leaks before installation.