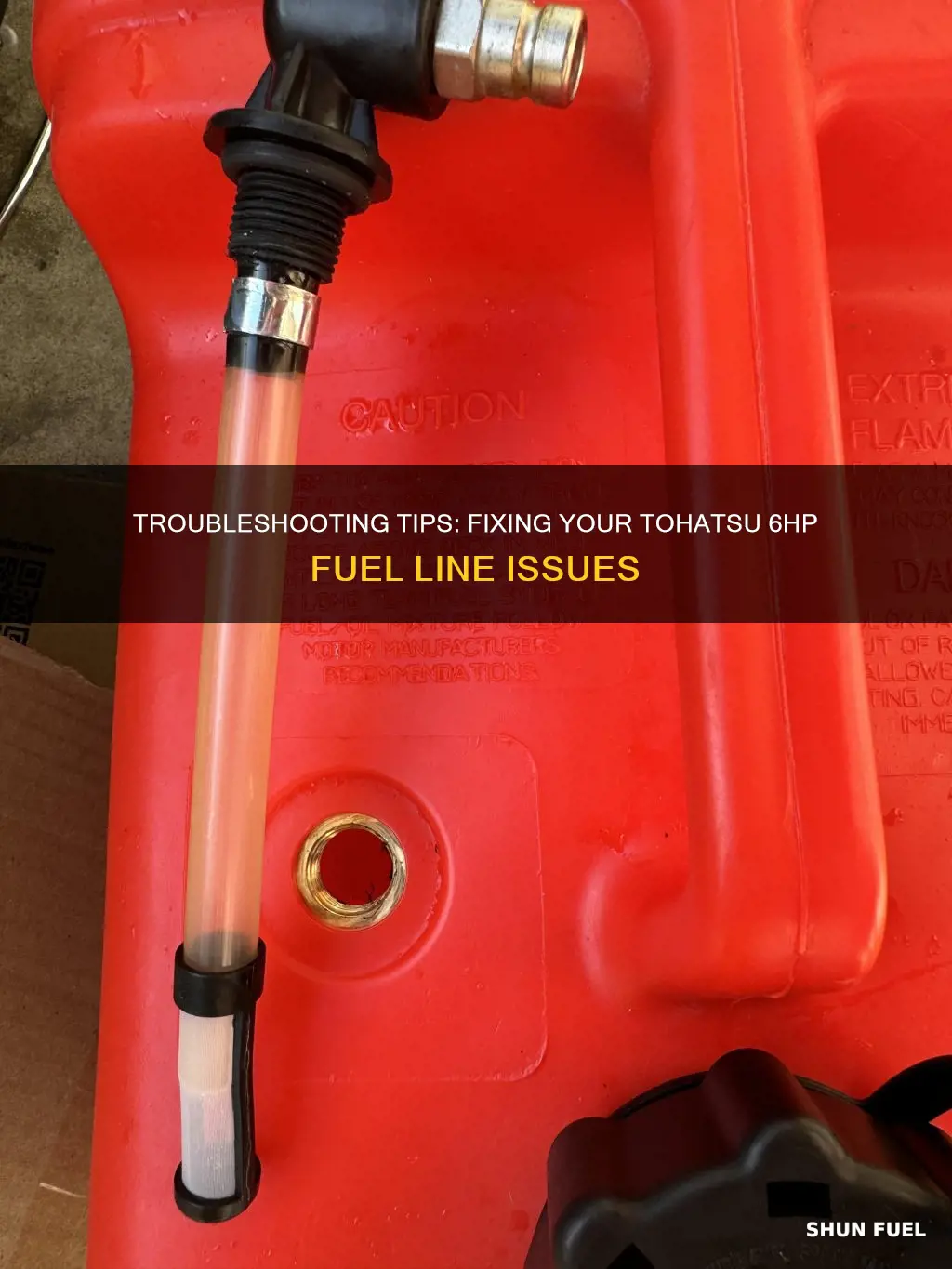

Troubleshooting a Tohatsu 6HP outboard fuel line can be a daunting task, but with the right approach, it can be made manageable. This guide will provide a step-by-step process to help you identify and resolve common issues with the fuel line, ensuring your engine runs smoothly and efficiently. By following these instructions, you'll be able to diagnose problems related to fuel flow, such as poor performance, stalling, or lack of power, and take the necessary actions to get your Tohatsu engine back on track.

What You'll Learn

- Fuel Pump Inspection: Check for proper operation, blockages, and leaks

- Fuel Filter Replacement: Clean or replace to ensure clear fuel flow

- Fuel Line Routing: Inspect for damage, kinks, or improper connections

- Carburetor Adjustment: Fine-tune for optimal performance and fuel mixture

- Engine Diagnostics: Use a multimeter to test electrical components

Fuel Pump Inspection: Check for proper operation, blockages, and leaks

When troubleshooting a Tohatsu 6HP outboard fuel line issue, it's crucial to inspect the fuel pump as a key component. The fuel pump is responsible for drawing fuel from the tank and delivering it to the engine, so any malfunction can lead to starting problems or poor performance. Here's a step-by-step guide to inspecting the fuel pump:

- Check for Proper Operation: Start by ensuring the fuel pump is functioning correctly. Turn off the engine and disconnect the fuel line from the pump. Use a fuel gauge or pressure gauge to measure the fuel pressure at the pump outlet. If the pressure is low or inconsistent, it may indicate a pump issue. You can also listen for the pump's operation; it should produce a steady, rhythmic sound when running. If it's silent or makes irregular noises, further investigation is needed.

- Inspect for Blockages: Fuel pump blockages are a common cause of fuel-related problems. Remove the fuel pump strainer and inspect it for debris, dirt, or clogs. Clean or replace the strainer if necessary. Additionally, check the fuel line itself for any blockages or restrictions. Ensure the line is not kinked, twisted, or damaged, as this can impede fuel flow.

- Look for Leaks: Inspect the fuel pump and its connections for any signs of fuel leaks. Check the pump's housing for cracks or damage that might allow fuel to escape. Also, examine the fuel lines for leaks, especially at the pump's inlet and outlet ports. Leaks can lead to fuel wastage and potential engine issues. If you notice any leaks, tighten connections or replace damaged parts.

- Test Pump Performance: To further assess the pump's performance, you can temporarily bypass the fuel line and directly test the pump's ability to deliver fuel. Use a clear container to catch the fuel as you disconnect the pump's outlet line and prime the pump. If fuel flows freely and fills the container, the pump is likely operational. However, if no fuel is delivered or the flow is weak, the pump may need repair or replacement.

Remember, during this inspection, it's essential to work in a well-ventilated area and wear appropriate safety gear, as fuel can be hazardous. If you're unsure about any step, consult the Tohatsu manual or seek professional assistance to ensure the problem is diagnosed and resolved correctly.

Fuel Line Routing: 1969 Chevy Nova Engine Bay Guide

You may want to see also

Fuel Filter Replacement: Clean or replace to ensure clear fuel flow

When dealing with a Tohatsu 6HP outboard fuel line issue, one of the critical components to inspect and potentially replace is the fuel filter. Over time, fuel filters can become clogged or contaminated, leading to reduced engine performance and potential starting difficulties. Here's a step-by-step guide on how to approach fuel filter replacement or cleaning:

Locate the Fuel Filter: Begin by familiarizing yourself with the engine's layout. The fuel filter is typically located near the engine's fuel tank or along the fuel line. It might be a separate component or integrated into a larger assembly. Consult your Tohatsu engine manual for specific locations, as filter placement can vary depending on the model and year.

Prepare for Replacement: Before proceeding, ensure you have the necessary tools and materials. You'll need a fuel filter replacement kit, which often includes the new filter and any required gaskets or seals. Additionally, have a container ready to catch any remaining fuel or debris to prevent contamination. It is recommended to drain the fuel tank or use a fuel pump primer to ensure a clean and dry environment during the replacement process.

Remove the Old Filter: Carefully disconnect the fuel line from the engine and the filter housing. Take note of the connection points and any clips or fasteners holding the filter in place. Gently pull the old filter out, being mindful of any debris or fuel residue that may need to be cleaned or disposed of properly. Inspect the filter for signs of excessive dirt, rust, or damage, which could indicate a longer-term issue.

Clean or Replace the Filter: If the filter is clean and shows no signs of excessive wear, you can attempt to clean it. Rinse the filter with a suitable fuel system cleaner to remove any built-up contaminants. Ensure you follow the manufacturer's instructions for the cleaning process. After cleaning, allow the filter to dry completely before reinstalling. If the filter is damaged or heavily contaminated, it is best to replace it with a new one to ensure optimal performance.

Reinstall and Test: Once you've cleaned or replaced the fuel filter, carefully reconnect the fuel line and secure the filter housing. Ensure all connections are tight and secure. Start the engine and let it run for a few minutes to allow the fuel system to prime. Observe for any unusual noises or vibrations, and check for smooth operation. If the engine starts and runs smoothly, you've successfully addressed the fuel filter issue. However, if problems persist, further troubleshooting may be required.

Mastering the Art of Fuel Line Removal: A Guide for 1998 Sierra 2500 Owners

You may want to see also

Fuel Line Routing: Inspect for damage, kinks, or improper connections

When troubleshooting a Tohatsu 6HP outboard fuel line, one of the critical steps is to inspect the fuel line routing for any potential issues. This process involves a thorough examination of the fuel line's path, ensuring it is free from damage, kinks, or improper connections that could disrupt the fuel flow. Here's a detailed guide on how to approach this task:

Start by locating the fuel line, which typically runs from the fuel tank to the engine's fuel intake. Carefully trace the path of the fuel line, ensuring you inspect every inch of its route. Look for any visible signs of damage, such as cracks, punctures, or frayed areas. Over time, fuel lines can deteriorate due to exposure to the elements, UV radiation, or physical impacts. Inspect the line for any signs of wear and tear, especially where it connects to the fuel tank and engine.

Next, check for kinks or bends in the fuel line. Kinking can occur due to sharp turns, tight spaces, or improper installation. Kinks in the fuel line can restrict fuel flow and potentially cause engine performance issues. Gently straighten the line if you notice any kinks, ensuring it is laid out smoothly without any sharp bends. Make sure the line is not pinched or compressed, as this can also impede fuel flow.

Pay close attention to the connections between the fuel line, fuel filter, and engine. Improper connections can lead to fuel leaks or restricted flow. Ensure all fittings are tight and secure. Check for any signs of corrosion or damage around the connection points. If you find any loose or damaged connections, tighten them or replace the affected components to ensure a proper seal.

Additionally, inspect the fuel line for any signs of contamination or debris. Over time, fuel lines can accumulate dirt, rust, or other contaminants, which can clog the line and affect engine performance. Use a fuel line cleaner or a compressed air gun to blow out any debris or contaminants you find. This step is crucial to ensure that the fuel line is free from any obstructions that might impact the engine's operation.

By thoroughly inspecting the fuel line routing for damage, kinks, and improper connections, you can identify and rectify potential issues that may be causing problems with your Tohatsu 6HP outboard engine. Regular maintenance and inspection of the fuel line will help ensure optimal engine performance and longevity.

Choosing the Right Fuel Line for Your 25 HP Mercury Outboard

You may want to see also

Carburetor Adjustment: Fine-tune for optimal performance and fuel mixture

Troubleshooting a Tohatsu 6HP outboard fuel line issue often involves addressing the carburetor, as it plays a critical role in controlling the fuel-air mixture. Here's a step-by-step guide to fine-tuning the carburetor for optimal performance:

Step 1: Access the Carburetor

Start by removing the fuel line from the engine's fuel inlet and temporarily disconnecting the carburetor from the engine. This allows for easy access to the carburetor for inspection and adjustment.

Step 2: Inspect the Carburetor Components

Carefully examine the carburetor for any signs of damage, debris, or excessive wear. Check the float bowl for proper water separation and ensure the float is functioning correctly. Inspect the jetting, including the main jet, pilot jet, and needle valve, for any blockages or damage.

Step 3: Adjust the Carburetor Settings

- Fuel-Air Ratio: The carburetor's primary function is to mix air and fuel. Adjust the throttle stop screw to control the idle speed and mixture. Turning it clockwise increases the fuel mixture, while counterclockwise decreases it. Fine-tune this adjustment to achieve a balanced idle.

- Idle Speed: Set the idle speed screw to control the engine's idle speed. Turn it clockwise to increase speed and counterclockwise to decrease it. Aim for a smooth, stable idle.

- Pilot Jet: The pilot jet controls the idle mixture. If the engine idles too fast or stalls, consider adjusting the pilot jet. A larger jet number will enrichen the mixture, while a smaller number will lean it.

- Main Jet: Adjust the main jet to control the engine's performance at higher RPMs. A larger main jet will increase power but may also cause engine backfire.

Step 4: Test and Fine-tune

After making adjustments, reattach the carburetor and reconnect it to the engine. Start the engine and observe its performance. Adjust the carburetor settings slightly at a time, testing after each change. This iterative process ensures you find the optimal fuel-air ratio for your specific conditions.

Step 5: Consider Fuel Type

Different fuels may require slight adjustments. If using ethanol-blended fuel, you might need to slightly lean the mixture to compensate for the higher octane. Always refer to the fuel manufacturer's guidelines for any specific recommendations.

Remember, carburetor adjustment is a delicate process, and small changes can significantly impact engine performance. Take your time, make incremental adjustments, and test thoroughly to ensure you achieve the best results for your Tohatsu 6HP outboard engine.

Fuel Line Removal: A Guide for 87 Crown Victoria Owners

You may want to see also

Engine Diagnostics: Use a multimeter to test electrical components

When dealing with engine diagnostics, especially for a Tohatsu 6HP outboard motor, using a multimeter is an essential tool for testing electrical components. This process involves checking for continuity, voltage, and resistance to identify any issues within the electrical system. Here's a step-by-step guide on how to use a multimeter for engine diagnostics:

Understanding the Multimeter: Before beginning, ensure you have a basic understanding of how a multimeter works. A multimeter is a versatile device that can measure current, voltage, and resistance. For engine diagnostics, you'll primarily use it to check for continuity and voltage. Set the multimeter to the appropriate range; for small engines like the Tohatsu 6HP, the 200-2000 ohms range is usually sufficient.

Safety Precautions: Always prioritize safety. Disconnect the battery or the main power source before starting any electrical tests. This prevents accidental short circuits or electrical shocks. Wear protective gear, such as gloves and safety goggles, to minimize any potential hazards.

Testing for Continuity: Start by identifying the electrical components you want to test. For the fuel line issue, you might want to check the wiring connected to the fuel pump, fuel filter, and the engine's control unit. Set the multimeter to the continuity setting and touch the probes to the corresponding wires. If the multimeter beeps or shows a low resistance value, it indicates a good connection. If there's no beep or a high resistance reading, it suggests a possible break in the wire or a faulty component.

Measuring Voltage: Voltage testing is crucial to determine if the electrical system is receiving the correct power. Locate the battery and the engine's starter circuit. Set the multimeter to the voltage setting and touch the probes to the battery terminals and the starter circuit wires. Compare the voltage reading with the expected value for your engine. A healthy voltage reading indicates a stable power supply, while an abnormally low or high voltage could indicate a problem with the battery or wiring.

Testing Sensors and Actuators: If the fuel line issue is suspected to be related to sensors or actuators, you can use the multimeter to test them. For example, check the fuel level sensor by touching the probes to the sensor wires and observing the multimeter's response. Similarly, test the engine's sensors, such as the crankshaft position sensor, by connecting the probes to the sensor wiring.

Troubleshooting Tips: When using the multimeter, pay attention to any unusual sounds, smells, or engine behavior. Combine the multimeter readings with these observations to narrow down the problem. For instance, if you detect a break in the wiring but also notice a burning smell, it might indicate a more serious issue that requires professional attention.

Remember, engine diagnostics can be complex, and using a multimeter is just one part of the process. It's essential to understand the engine's electrical system and the specific components related to the fuel line issue. If you're unsure, consult a mechanic or refer to the Tohatsu service manual for further guidance.

Honda CR-V '98 Fuel Line Cut-Off: Causes and Fixes

You may want to see also

Frequently asked questions

Clogging in the fuel line is often caused by debris, dirt, or a fuel contaminant. You can check for this by removing the fuel line and examining it for any blockages. If you notice any obstructions, use a fuel line cleaner or a small brush to carefully clear the path.

If your engine fails to start, it could be due to a restricted fuel supply. Check the fuel line for any clogs or kinks. Ensure the fuel tank has sufficient fuel and that the fuel filter is clean. If the issue persists, consider consulting a technician to inspect the fuel system for any further issues.

Fuel leaks can occur due to damaged or loose connections. Inspect the fuel line for any cracks, punctures, or loose fittings. Tighten any loose connections and replace any damaged parts. It is recommended to use fuel-resistant sealant or tape to ensure a secure and leak-free connection.

Power loss can be caused by various factors, including a restricted fuel supply or a problem with the fuel injection system. Check the fuel line for any clogs and ensure the fuel filter is clean. If the issue is related to the injection system, it may require professional diagnosis to identify if there are any faulty sensors or valves affecting the engine's performance.