Bending a plastic fuel line is a common task in automotive repairs and modifications, but it requires careful technique to ensure a secure and durable connection. This guide will provide a step-by-step process for bending a plastic fuel line, including the necessary tools, safety precautions, and tips for achieving a precise bend that meets the specific requirements of your project. By following these instructions, you can ensure a professional-looking installation that will stand the test of time.

What You'll Learn

- Preparation: Clean and inspect the fuel line for damage before bending

- Measuring: Determine the desired bend angle and mark the line accordingly

- Bending Tools: Use a pipe bender or a pair of pliers for precise bends

- Safety: Wear protective gear and work in a well-ventilated area when bending

- Testing: Ensure the bent fuel line is secure and free of leaks

Preparation: Clean and inspect the fuel line for damage before bending

Before attempting to bend a plastic fuel line, it is crucial to ensure that the line is in optimal condition to avoid any potential issues. Start by thoroughly cleaning the fuel line to remove any dirt, debris, or contaminants that may interfere with the bending process. Use a mild detergent or a specialized fuel line cleaner, ensuring you follow the manufacturer's instructions. Rinse the line thoroughly to eliminate any residue. This step is essential as any remaining contaminants could lead to corrosion or damage during bending.

Once the cleaning process is complete, inspect the fuel line for any signs of damage or wear. Look for cracks, tears, or any visible imperfections. Check for flexibility and ensure it is not brittle or showing signs of aging. If you notice any damage, it is best to replace the fuel line entirely to avoid potential leaks or failures during the bending process. This inspection is a critical safety measure to prevent accidents and ensure the longevity of your vehicle's fuel system.

Pay close attention to the bends and kinks in the fuel line, as these areas may require extra care. Check for any sharp bends or kinks that could indicate previous damage or stress points. These areas might be more susceptible to further issues when bending, so it's important to handle them with care. If you find any problematic sections, consider replacing those parts to ensure a smooth and safe bending process.

After cleaning and inspecting, you should have a clear understanding of the fuel line's condition. This preparation step is vital to guarantee a successful and safe bending process, minimizing the risk of damage to the fuel line and your vehicle's system. It also ensures that any bends you make will be clean and precise, contributing to a professional-looking installation.

Fuel Line Flexibility: Can A1-15 Handle Coolant?

You may want to see also

Measuring: Determine the desired bend angle and mark the line accordingly

To begin the bending process, you must first determine the desired bend angle and mark the plastic fuel line accordingly. This step is crucial to ensure the bend is accurate and meets your requirements. Here's a detailed guide on how to measure and mark the line:

- Assess the Bend Requirements: Start by understanding the specific needs of your project. Consider the angle at which you want to bend the fuel line. This angle will depend on the layout of your vehicle's fuel system, the desired positioning of the line, and any constraints you might have. Make sure you have a clear idea of the bend's purpose and the desired outcome.

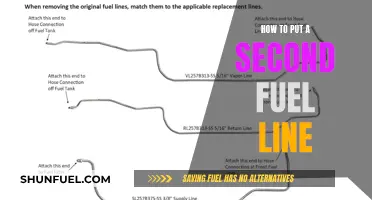

- Measuring the Line: Take the plastic fuel line and lay it out according to the bend angle you've decided on. Use a flexible measuring tape or a ruler to measure the length of the line that needs to be bent. Ensure that the line is taut and straight to get an accurate measurement. Mark this length on the line itself using a permanent marker or a piece of chalk. This mark will serve as your starting point for the bend.

- Creating a Guide: To ensure precision, create a guide for the bend. You can use a straight edge, such as a straight piece of metal or a ruler, and place it along the marked length of the line. Adjust the straight edge to form the desired angle, and mark the point where the line meets the edge. Repeat this process for the other end of the line, creating two marks that represent the start and end points of the bend.

- Marking the Bend: Now, you can clearly see the bend's path. Mark the line between the two guide marks to indicate the bend's location. You can use a pencil or a marker to make a light mark, ensuring that it's visible but not permanent, as you may need to adjust the bend if needed. This step provides a visual reference for the desired bend, allowing you to proceed with the actual bending process with confidence.

By following these steps, you'll have accurately measured and marked the plastic fuel line, setting the foundation for a successful bend. This method ensures that you have a clear understanding of the bend's angle and location, making the bending process more efficient and precise.

Unveiling the 1967 Ford LTD's Fuel Line Route

You may want to see also

Bending Tools: Use a pipe bender or a pair of pliers for precise bends

When it comes to bending plastic fuel lines, using the right tools is essential to ensure a clean and precise bend. One of the most effective tools for this task is a pipe bender. Pipe benders are specifically designed to create accurate bends in various materials, including plastic. Here's a step-by-step guide on how to use a pipe bender for bending a plastic fuel line:

- Prepare the Materials: Start by ensuring you have the necessary materials, including the plastic fuel line, a pipe bender, and any required fittings or adapters. Clean the fuel line to remove any dirt or debris that might interfere with the bending process.

- Measure and Mark: Measure the desired bend radius and mark the fuel line accordingly. This step is crucial to ensure the bend is accurate and doesn't damage the material. Use a ruler or a measuring tape to get precise measurements.

- Position the Bender: Place the pipe bender on the marked section of the fuel line. Ensure that the bender is positioned correctly, with the bend axis aligned with the desired bend direction. Pipe benders typically have adjustable jaws or a clamping mechanism to hold the material in place.

- Apply Pressure: Apply pressure to the bender, moving it along the marked line. The amount of pressure required may vary depending on the thickness of the plastic and the desired bend angle. Start with a gentle pressure and increase it gradually if needed. The goal is to create a smooth and continuous bend without kinking or damaging the material.

- Create the Bend: As you move the bender along the marked line, the plastic fuel line will start to bend. Take your time and apply consistent pressure to achieve a precise bend. Avoid applying excessive force, as it may distort the material. For tighter bends, you might need to adjust the bender's settings or use a different type of bender.

Alternatively, if you don't have access to a pipe bender, a pair of pliers can be a temporary solution for simple bends. Here's how to use pliers for bending:

- Grip the Line: Position the pliers around the fuel line, ensuring a secure grip.

- Apply Force: Squeeze the pliers to create a bend. For more complex bends, you might need to use both hands to apply force and guide the bend.

- Adjust and Repeat: If the bend is not precise, carefully adjust the pliers' position and try again. This method is less accurate than a pipe bender but can be useful for quick adjustments.

Remember, when working with plastic fuel lines, it's important to take your time and use the appropriate tools to avoid damaging the material. Practice and precision are key to achieving clean and professional bends.

Will Deasil Fuel Lines Freeze? Unraveling Winter Fuel Line Mysteries

You may want to see also

Safety: Wear protective gear and work in a well-ventilated area when bending

When working with plastic fuel lines, it's crucial to prioritize safety to avoid any potential hazards. Here's a detailed guide on the necessary precautions:

Protective Gear: Before you begin the bending process, ensure you have the appropriate personal protective equipment (PPE). Safety goggles are essential to protect your eyes from any potential splashes or debris that might occur during bending. Additionally, consider wearing gloves to safeguard your hands from any sharp edges or chemicals that the plastic fuel line might contain. A respirator or a dust mask is also recommended to prevent inhaling any harmful fumes or particles that could be released when bending the plastic.

Well-Ventilated Area: Working in a well-ventilated space is critical for your safety and the environment. Plastic fuel lines can release volatile organic compounds (VOCs) when heated or manipulated, which can be harmful if inhaled. Ensure you are working in an area with proper ventilation, such as an outdoor space or a garage with open windows and a functioning exhaust fan. This will help disperse any fumes and reduce the risk of exposure.

Bending Technique: When bending the plastic fuel line, use a gentle and controlled approach. Avoid applying excessive force, as it can lead to cracks or breaks in the material. Instead, use a pair of pliers or a bending tool specifically designed for plastic to create smooth and precise bends. Take your time and work slowly to ensure the line remains intact. Remember, the goal is to manipulate the plastic without causing any damage or releasing harmful substances.

Fire Safety: Plastic fuel lines can be flammable, so it's essential to be cautious of open flames or heat sources. Keep a safe distance from any potential ignition sources while working. If you need to heat the plastic to make it more pliable, use a heat gun or a soldering iron on a low setting, ensuring it doesn't get too hot to avoid melting or charring the material. Always have a fire extinguisher nearby as a precaution.

By following these safety measures, you can effectively bend the plastic fuel line while minimizing the risks associated with the task. It's important to stay focused and take the necessary precautions to ensure a safe working environment.

Rubber Hose for Fuel Line Fixes: A Viable Option?

You may want to see also

Testing: Ensure the bent fuel line is secure and free of leaks

After you've successfully bent the plastic fuel line to fit your specific needs, it's crucial to thoroughly test its integrity to ensure it functions safely and efficiently. Here's a step-by-step guide to testing the bent fuel line for leaks and security:

- Visual Inspection: Begin by carefully examining the bent fuel line for any visible signs of damage or imperfections. Look for cracks, tears, or any discolored areas on the plastic material. Even small cracks can potentially lead to fuel leaks over time. Pay close attention to the bends themselves, as sharp bends might cause stress on the material.

- Pressure Test: This is the most critical step to ensure the fuel line's security. You'll need a fuel pressure gauge and some compressed air or a small pump. Connect the gauge to the fuel line, ensuring it's properly sealed. Apply pressure gradually and observe the gauge reading. The pressure should hold steady without any drops, indicating a secure connection. If you notice any fluctuations or drops in pressure, it could be a sign of a potential leak.

- Leak Detection: To identify leaks, you can use a soapy water solution. Fill a spray bottle with a mixture of dish soap and water. Spray the soapy water onto the fuel line connections, bends, and any areas where the line might be exposed. If you see bubbles forming, it indicates a leak. Make sure to check all connections thoroughly, including where the fuel line joins the fuel tank and any other components it connects to.

- Functional Testing: Once you've confirmed the fuel line is leak-free, it's time to test its functionality. Start the vehicle's engine and monitor it closely. Listen for any unusual noises, such as hissing or whistling, which could indicate a leak. Check for any fuel odors around the engine bay, as this could also be a sign of a leak. If the engine runs smoothly without any issues, your bent fuel line is likely secure and ready for use.

- Long-Term Monitoring: Even after passing these tests, it's essential to monitor the fuel line's performance over time. Regularly inspect the line for any signs of wear and tear, especially in areas that experience the most stress due to vibrations or movement. Address any issues promptly to prevent potential fuel leaks and ensure the safety and efficiency of your vehicle's fuel system.

Carbureted Engine Fuel Return Line: Essential or Optional?

You may want to see also

Frequently asked questions

When bending form-plastic fuel lines, it's crucial to use the right tools and techniques to avoid any potential harm. Start by using a pair of sharp, fine-tipped pliers or a fuel line bender to carefully shape the line. Apply gentle pressure and make small, controlled bends, ensuring the line remains flexible throughout the process. Avoid excessive force or sharp bends that could lead to cracks or tears in the plastic material.

Yes, using a heat gun can make bending form-plastic fuel lines more manageable. Apply the heat gun to the section you want to bend, being careful not to overheat the plastic. This will make the material more pliable, allowing you to create the desired bend. However, be cautious and monitor the temperature to prevent melting or warping the fuel line.

To avoid kinks and cracks, maintain a consistent bending radius and avoid sharp bends. Keep the fuel line as straight as possible during the bending process. Use a mandrel or a small diameter rod to guide the bend, ensuring a smooth and uniform curve. Take your time and apply steady pressure to achieve the desired angle without putting excessive strain on the material.

Absolutely! Working with fuel lines requires caution due to the potential hazards associated with fuel. Always wear protective gear, including gloves and safety goggles, to prevent any accidental contact with the fuel. Ensure proper ventilation in the workspace to avoid inhaling fuel vapors. Additionally, double-check all connections and bends to ensure they are secure and free from damage before reassembling the system.

If you come across a section that resists bending, try applying a small amount of fuel line solvent or a thin layer of petroleum jelly to the area. This can help lubricate the plastic, making it more flexible. However, be cautious and test a small portion first to ensure it doesn't affect the fuel line's integrity. Always work slowly and patiently, allowing the material to adjust and bend without forcing it.