The compatibility of fuel lines with coolant is a crucial consideration in vehicle maintenance. Specifically, the A1-15 fuel line is a common component in many automotive systems, and its ability to carry coolant is a frequently asked question. This paragraph aims to explore whether the A1-15 fuel line can be utilized for coolant transport, considering its design, material composition, and potential limitations. Understanding this aspect is essential for ensuring the proper functioning and longevity of the vehicle's cooling system.

| Characteristics | Values |

|---|---|

| Material | Typically made of rubber or synthetic materials like nitrile or EPDM |

| Temperature Range | Can vary, but often rated for a wide range of temperatures (-40°F to 250°F or -40°C to 121°C) |

| Pressure Rating | Designed to handle fuel pressures, often up to 3000 psi (pounds per square inch) |

| Compatibility | Compatible with various fuels, including gasoline, diesel, and biofuels |

| Flexibility | Flexible to accommodate engine movement and vibrations |

| Corrosion Resistance | Resistant to corrosion from fuel and coolant |

| Color | Often black or blue, but can vary depending on the manufacturer |

| Length | Available in various lengths to fit different engine configurations |

| Installation | Designed for easy installation and connection to fuel injectors or fuel pumps |

| Cost | Prices can vary based on brand, quality, and length |

| Availability | Widely available through automotive suppliers and online retailers |

What You'll Learn

- Fuel Line Material: A1-15 fuel lines are typically made of materials compatible with coolant

- Coolant Compatibility: Coolants can corrode some fuel line materials, so compatibility is key

- Temperature Tolerance: A1-15 lines can withstand coolant temperatures, ensuring no damage

- Pressure Handling: These lines can handle coolant pressure, preventing leaks and explosions

- Installation Guidelines: Proper installation ensures coolant and fuel lines work harmoniously

Fuel Line Material: A1-15 fuel lines are typically made of materials compatible with coolant

A1-15 fuel lines are an essential component in the fuel delivery system of many vehicles, and their material composition is crucial to ensure optimal performance and longevity. These fuel lines are specifically designed to withstand the challenges of carrying fuel, including its potential corrosive effects over time. The primary concern when it comes to fuel lines and coolant compatibility is the material used to construct the lines.

The A1-15 fuel lines are typically crafted from materials that are inherently compatible with coolant, ensuring a safe and efficient fuel delivery process. One common material used is a high-density polyethylene (HDPE) compound. HDPE is known for its excellent resistance to corrosion and chemical degradation, making it ideal for fuel lines that come into contact with coolant. This material can withstand the various additives and chemicals present in coolant, ensuring the fuel remains uncontaminated and the fuel lines remain intact.

In addition to HDPE, some A1-15 fuel lines may also be constructed from materials like polyvinyl chloride (PVC) or a blend of HDPE and PVC. These materials offer similar advantages, including resistance to coolant-related degradation and the ability to maintain structural integrity over time. The choice of material often depends on the specific requirements of the vehicle's fuel system and the manufacturer's recommendations.

It is important to note that the compatibility of the fuel line material with coolant is a critical factor in preventing fuel contamination and system failures. Coolant often contains additives that can be harmful to certain materials, leading to degradation or even cracking of the fuel lines. By using materials that are specifically designed to be compatible with coolant, vehicle manufacturers ensure that the fuel lines can effectively carry fuel without compromising performance or safety.

When replacing or upgrading A1-15 fuel lines, it is essential to choose replacement lines made from similar compatible materials. This ensures that the new fuel lines will seamlessly integrate into the existing fuel system, providing the same level of protection and performance. Always refer to the vehicle's manual or consult with a professional mechanic to determine the appropriate material for your specific fuel line application.

Tractor Fuel Line Location: A Comprehensive Guide

You may want to see also

Coolant Compatibility: Coolants can corrode some fuel line materials, so compatibility is key

Coolant compatibility is a critical aspect of vehicle maintenance that often goes overlooked. When it comes to fuel lines, the choice of coolant can significantly impact the performance and longevity of the vehicle's fuel system. Some coolants contain additives that can be detrimental to certain fuel line materials, leading to corrosion and potential system failures. Therefore, understanding the compatibility of coolants with fuel lines is essential for maintaining a reliable and efficient vehicle.

The A1-15 fuel line, commonly used in many vehicles, is designed to withstand the pressures and temperatures associated with the fuel system. However, not all coolants are created equal, and their chemical compositions can vary widely. Some coolants are formulated with corrosion inhibitors that are effective in preventing internal engine damage but may not be suitable for fuel lines. These inhibitors can sometimes lead to the degradation of rubber or plastic components, causing leaks or even complete failure of the fuel line.

To ensure the longevity of your vehicle's fuel system, it is crucial to choose a coolant that is specifically designed to be compatible with the materials used in the fuel lines. Modern vehicles often come equipped with fuel lines made from materials such as ethylene propylene rubber (EPR) or nitrile rubber, which are known to be resistant to coolant corrosion. Using a coolant that is compatible with these materials will help maintain the integrity of the fuel lines and prevent any potential issues.

When selecting a coolant, always refer to the vehicle's owner's manual or consult with a qualified mechanic. They can provide guidance on the recommended coolant types and specifications for your specific vehicle. Using the correct coolant ensures that your engine and fuel system operate optimally, reducing the risk of costly repairs due to coolant-related damage.

In summary, coolant compatibility is a vital consideration when dealing with fuel lines. The A1-15 fuel line, while durable, may not be suitable for all coolants. By choosing the right coolant and staying informed about compatibility, vehicle owners can protect their investment and ensure a reliable fuel system for years to come. Regular maintenance and the use of compatible coolants will contribute to the overall performance and longevity of the vehicle.

Simplifying Engine Maintenance: A Guide to Removing Tight Fuel Lines on Mowers

You may want to see also

Temperature Tolerance: A1-15 lines can withstand coolant temperatures, ensuring no damage

The A1-15 fuel line is an essential component in many automotive applications, and its ability to carry coolant is a critical aspect of its functionality. This particular fuel line is designed with a high level of temperature tolerance, which is a key feature that sets it apart from other fuel lines. The A1-15 line is engineered to withstand the extreme temperatures that coolants can reach, ensuring that it remains intact and functional even in the most demanding environments.

Coolant temperatures can vary significantly, especially in high-performance engines or those operating in extreme weather conditions. The A1-15 fuel line is specifically formulated to handle these temperature fluctuations without compromising its structural integrity. It can endure the high heat generated by the engine during operation, as well as the cold temperatures that may be present when the engine is idling or during start-up. This temperature tolerance is crucial to prevent damage to the fuel line, which could lead to leaks, reduced performance, or even system failure.

The construction of the A1-15 fuel line plays a vital role in its temperature resistance. It is typically made from high-quality materials that offer excellent thermal stability. These materials can withstand the corrosive effects of coolants, ensuring that the fuel line remains free from degradation over time. The inner lining of the fuel line might be made of a flexible, durable material that allows it to carry fuel or coolant without kinking or leaking. This flexibility, combined with its temperature resistance, makes the A1-15 line highly reliable for fuel and coolant transport.

In addition to its temperature tolerance, the A1-15 fuel line also boasts impressive pressure resistance. Coolant systems often operate under high pressure, and the fuel line must be able to handle these forces without failing. The design and material composition of the A1-15 line ensure it can withstand the pressure differentials within the cooling system, providing a secure and reliable connection between the fuel pump and the engine.

By utilizing the A1-15 fuel line, vehicle owners and mechanics can have peace of mind knowing that the fuel and coolant systems are protected by a component designed to handle extreme conditions. This temperature tolerance is a critical factor in maintaining the performance and longevity of the engine, ensuring that the fuel line remains a reliable and durable part of the overall system.

Understanding the Dual Fuel Lines in Your Chainsaw: A Guide

You may want to see also

Pressure Handling: These lines can handle coolant pressure, preventing leaks and explosions

The A1-15 fuel lines are an essential component in the automotive industry, designed to transport fuel from the tank to the engine while ensuring optimal performance and safety. One of the critical aspects of these lines is their ability to handle coolant pressure, which is a crucial factor in preventing leaks and potential explosions. Coolant pressure can vary significantly, especially during engine operation, and the fuel lines must be capable of withstanding these fluctuations to maintain a secure and efficient system.

These fuel lines are engineered with a robust construction, utilizing high-quality materials that can endure the corrosive nature of coolant. The inner diameter of the line is carefully calculated to allow for the smooth flow of coolant while minimizing the risk of pressure buildup. This design ensures that the coolant moves efficiently through the system without causing excessive stress on the fuel line. Additionally, the walls of the A1-15 lines are reinforced to provide structural integrity, preventing any potential tears or punctures that could lead to leaks.

The pressure-handling capability of these fuel lines is a result of their precise manufacturing process. During production, the lines undergo rigorous testing to simulate real-world engine conditions. This includes subjecting the lines to various pressure levels and temperatures to ensure they meet the required standards. By doing so, manufacturers can guarantee that the A1-15 fuel lines can handle the coolant pressure associated with different engine speeds and loads.

Furthermore, the design of these fuel lines incorporates a series of protective measures to prevent leaks. These include specialized fittings and clamps that create a secure connection between the line and other engine components. The fittings are designed to withstand the pressure and temperature changes, ensuring a tight seal that prevents coolant from escaping. In the event of a leak, the fuel lines are also equipped with safety mechanisms, such as pressure relief valves, to mitigate the risk of explosions.

In summary, the A1-15 fuel lines are designed with a strong emphasis on pressure handling, making them a reliable choice for coolant transportation. Their ability to withstand coolant pressure, combined with leak-prevention measures, ensures the safety and efficiency of the engine system. By meeting these stringent requirements, these fuel lines provide peace of mind to vehicle owners, knowing that their engines are protected from potential leaks and explosions.

Choosing the Right Fuel Line for Your Outboard Motor: A Guide

You may want to see also

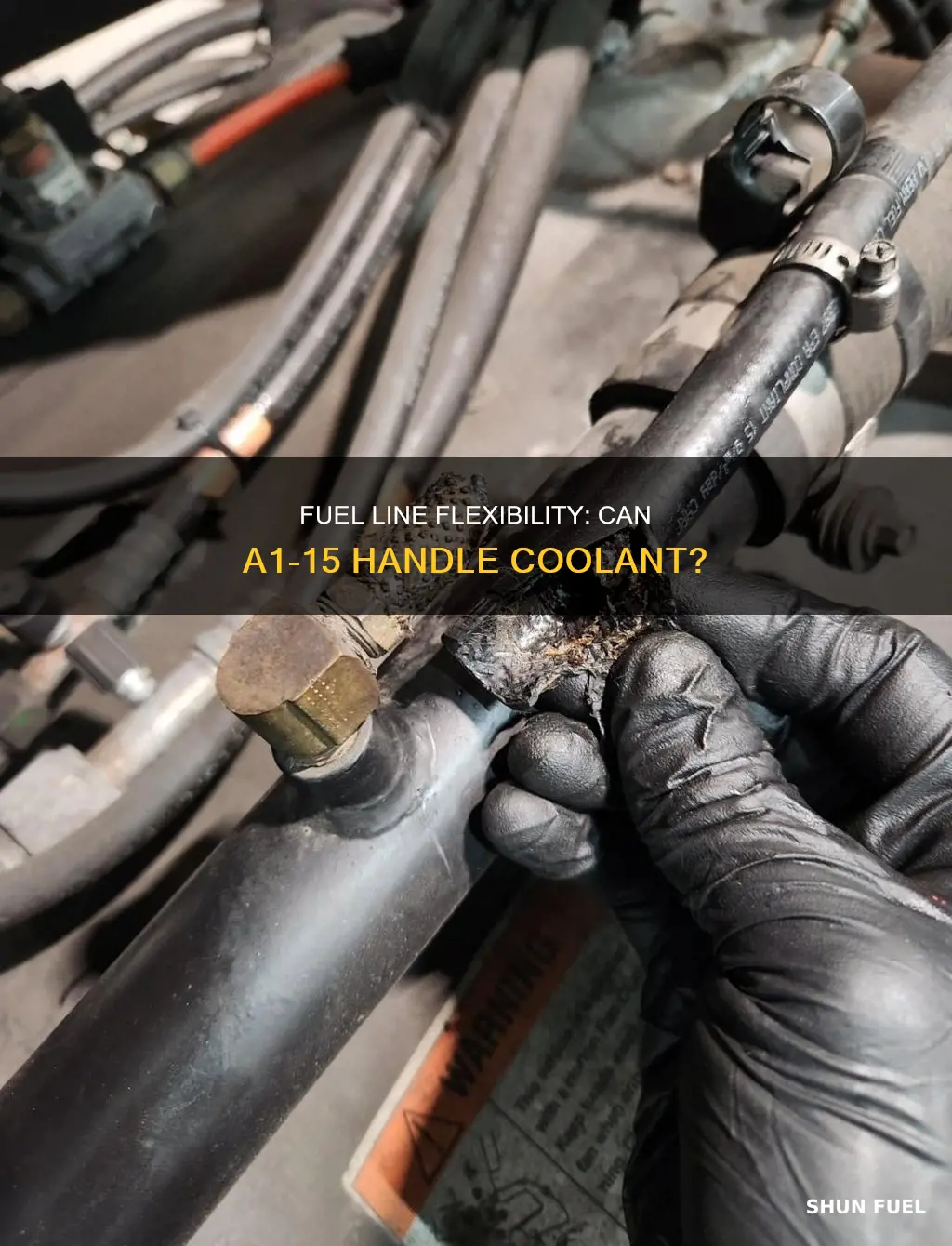

Installation Guidelines: Proper installation ensures coolant and fuel lines work harmoniously

When it comes to automotive systems, ensuring the proper functioning of coolant and fuel lines is crucial for optimal engine performance and longevity. The A1-15 fuel line, designed for specific vehicle models, plays a vital role in this context. While it is primarily intended for fuel transport, there might be instances where you consider using it for coolant as well. However, it's essential to understand the compatibility and potential challenges before making any modifications.

The installation process begins with a thorough inspection of the vehicle's existing coolant and fuel lines. Ensure that the A1-15 line is compatible with the vehicle's system and that there are no pre-existing issues with the current lines. If any damage or leaks are detected, address them promptly before proceeding with the installation. Cleaning the lines is crucial to remove any contaminants that could interfere with the new line's performance.

Proper installation requires careful attention to detail. Start by identifying the correct placement of the A1-15 line, ensuring it follows the manufacturer's guidelines. Secure the line using appropriate clamps or fittings to prevent any movement or leakage. It is essential to maintain a secure connection throughout the length of the line to avoid potential hazards. Additionally, consider the routing of the line, ensuring it is not subjected to excessive heat, pressure, or physical damage during its operation.

When connecting the A1-15 line to the engine and other components, use the right tools and techniques. Tighten connections securely but avoid over-tightening, as it may lead to damage. Properly seal all connections to prevent coolant or fuel leaks, which could cause engine issues. After the installation, test the system to ensure there are no leaks and that the coolant and fuel lines are functioning as intended.

Regular maintenance and monitoring are key to the long-term success of this installation. Check for any signs of deterioration, leaks, or blockages regularly. Keep the lines clean and free from debris to maintain optimal performance. By following these installation guidelines and providing regular care, you can ensure that the A1-15 fuel line, when used for coolant, functions harmoniously with the rest of the vehicle's cooling and fuel systems.

Mastering Fuel Line Pressure: A Comprehensive Testing Guide

You may want to see also

Frequently asked questions

Yes, the A1-15 fuel line is commonly used for carrying coolant in many automotive applications. It is designed to withstand the corrosive nature of coolant and can handle the temperature fluctuations that coolant experiences. However, it's important to ensure that the specific fuel line is compatible with the coolant type and the vehicle's system to avoid any potential issues.

The A1-15 fuel line offers several benefits for coolant transport. It is typically made of high-quality materials, such as rubber or synthetic compounds, which provide excellent resistance to coolant chemicals. This fuel line is also flexible and durable, allowing for easy installation and routing within the engine compartment. Additionally, its design often includes a reinforced structure to handle high pressure, ensuring a reliable coolant circulation system.

When using A1-15 fuel line for coolant, it's crucial to follow the manufacturer's guidelines and specifications. Ensure that the fuel line is properly sized and compatible with the vehicle's cooling system. Check for any potential leaks or damage during installation and regularly inspect the fuel line for signs of wear and tear. It's also recommended to use a coolant that is compatible with the fuel line material to prevent degradation over time.