A carbureted engine's fuel system is a complex network designed to deliver the right amount of fuel to the engine for optimal performance. One crucial component of this system is the fuel return line, which plays a vital role in ensuring efficient operation. This paragraph will explore the necessity of a fuel return line in a carbureted engine, examining its function, benefits, and potential issues.

| Characteristics | Values |

|---|---|

| Fuel Return Line Purpose | To prevent fuel accumulation in the carburetor when the engine is not running, ensuring proper fuel-air mixture. |

| Engine Type | Carbureted engines, commonly found in older vehicles. |

| Fuel System | The return line is part of the fuel system, which also includes the fuel tank, fuel pump, and carburetor. |

| Function | It allows excess fuel to return to the fuel tank, preventing the carburetor from becoming flooded with fuel when the engine is off. |

| Performance Impact | Proper fuel return lines ensure optimal engine performance, efficient fuel usage, and reduced risk of engine damage. |

| Common Issues | Clogged or damaged fuel return lines can lead to fuel starvation, engine misfires, and reduced power. |

| Maintenance | Regular inspection and cleaning of the fuel return line are essential to maintain engine health. |

What You'll Learn

- Fuel Delivery: Carburetors use a return line to recycle fuel for efficient operation

- Engine Performance: Proper return line ensures optimal power and fuel efficiency

- Emission Control: Return lines reduce emissions by preventing fuel accumulation in the carburetor

- Engine Reliability: A well-functioning return line enhances engine longevity and reliability

- Maintenance: Regular inspection of the return line is crucial for carburetor maintenance

Fuel Delivery: Carburetors use a return line to recycle fuel for efficient operation

The concept of a fuel return line is an essential component in the intricate system of a carbureted engine, ensuring efficient fuel delivery and optimal performance. When an engine operates, the carburetor plays a crucial role in mixing air and fuel, creating a combustible mixture for combustion. However, the process of fuel delivery and its management is a complex one.

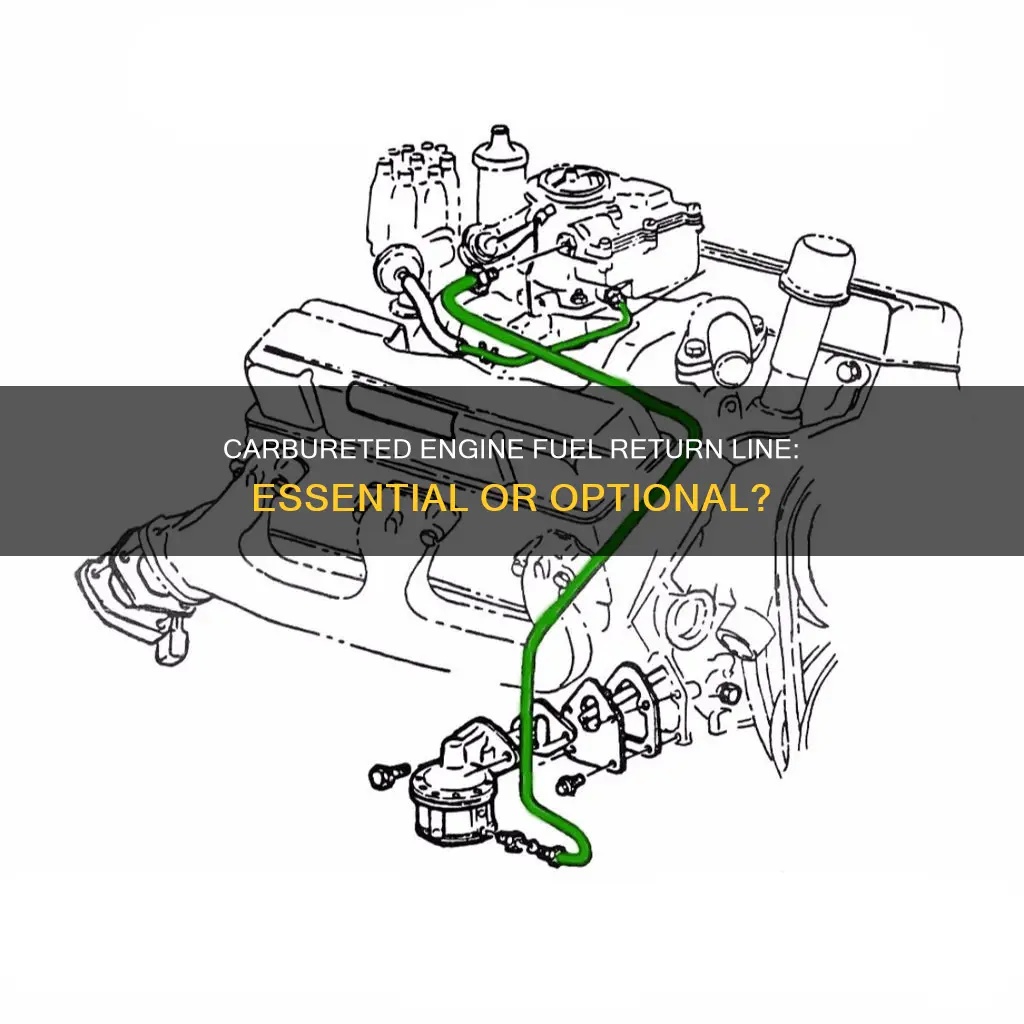

In a carbureted engine, the fuel return line is a vital feature that facilitates the recycling of fuel. This line connects the carburetor to the fuel tank, allowing for a continuous flow of fuel. As the engine runs, the carburetor draws fuel from the tank, mixes it with air, and then injects it into the engine's cylinders. The return line's primary function is to capture and redirect the excess fuel that is not immediately used in the combustion process.

When the engine is idling or during low-speed operation, the carburetor may not require the full amount of fuel it can handle. The return line ensures that this excess fuel is sent back to the fuel tank, preventing wastage and maintaining a steady fuel supply. This recycling process is crucial for efficient fuel usage and overall engine performance. By recycling fuel, the return line helps to optimize the air-fuel mixture, ensuring that the engine receives the correct ratio of fuel and air for efficient combustion.

Furthermore, the fuel return line also contributes to the engine's ability to start quickly. When the engine is cold, the fuel system may require a richer mixture to ignite. The return line allows for the recycling of this richer fuel mixture, ensuring that the engine can start promptly even in cold conditions. This feature is particularly useful in environments with varying temperatures, where engines may need to start frequently.

In summary, the fuel return line is a critical component in the fuel delivery system of a carbureted engine. It enables efficient fuel usage, optimizes the air-fuel mixture, and aids in quick engine starts. By recycling fuel, the return line ensures that the engine operates smoothly and effectively, making it a vital aspect of carburetor design and functionality. Understanding this process is essential for anyone working with or maintaining a carbureted engine.

Choosing the Right Size: Steel Fuel Line for Your 1000cc Engine

You may want to see also

Engine Performance: Proper return line ensures optimal power and fuel efficiency

The fuel return line is a crucial component in a carbureted engine's fuel system, often overlooked but essential for optimal performance. This line plays a vital role in ensuring that the engine receives the correct amount of fuel for efficient combustion. When an engine operates, it creates a vacuum that pulls fuel from the carburetor into the engine. However, this process can lead to a phenomenon known as "vacuum surge," where the fuel flow is inconsistent, causing the engine to run rich (with excess fuel) or lean (with insufficient fuel).

A fuel return line is designed to address this issue by providing a path for excess fuel to return to the fuel tank. As the engine's throttle opens and closes, the fuel flow varies, and the return line allows any excess fuel that is not immediately used by the engine to be recycled. This ensures that the carburetor maintains a consistent fuel level, promoting stable engine operation. Without a return line, the fuel system would be prone to fuel accumulation in the carburetor, leading to potential issues like engine flooding and reduced performance.

The proper functioning of the fuel return line is critical for achieving optimal power output. When the engine requires more power, it demands a higher fuel-to-air ratio. The return line facilitates this by allowing a precise control of fuel delivery, ensuring that the engine receives the required amount of fuel for efficient combustion. This results in improved power delivery and a more responsive engine. Additionally, a well-functioning return line contributes to better fuel efficiency. By preventing fuel accumulation and ensuring a consistent fuel-air mixture, the engine can operate at its most efficient state, burning fuel more effectively.

In summary, the fuel return line is an essential component in a carbureted engine's setup, directly impacting engine performance and efficiency. It ensures that the engine receives the right amount of fuel, promoting stable operation, optimal power output, and improved fuel economy. Regular maintenance and inspection of this line are recommended to guarantee its effectiveness and longevity, ultimately contributing to a well-performing and reliable engine.

Fixing Fuel Lines: A Guide to Replacing Homelite Chainsaw Lines

You may want to see also

Emission Control: Return lines reduce emissions by preventing fuel accumulation in the carburetor

In the context of emission control, return lines play a crucial role in modernizing carbureted engines. The primary function of a return line is to ensure that excess fuel is directed back to the fuel tank, preventing it from accumulating in the carburetor. This is an essential feature, especially in older carbureted engines, as it directly contributes to reducing harmful emissions.

When a carbureted engine operates, it requires a precise balance of air and fuel for efficient combustion. If fuel accumulates in the carburetor, it can lead to a rich fuel-air mixture, resulting in incomplete combustion and increased emissions of pollutants such as carbon monoxide and hydrocarbons. These emissions are detrimental to the environment and can also lead to engine performance issues.

The return line acts as a bypass, allowing excess fuel to be returned to the fuel tank instead of remaining in the carburetor. This ensures that the carburetor maintains a consistent fuel level, promoting optimal air-fuel mixture ratios. By preventing fuel accumulation, the return line helps to minimize the formation of harmful emissions, making it an essential component in the fight against air pollution.

In addition to its role in emission control, the return line also contributes to improved engine performance. By maintaining a steady fuel supply, it ensures that the engine receives the correct amount of fuel for each combustion cycle, resulting in better power output and overall engine efficiency. This is particularly beneficial for high-performance applications where precise fuel management is critical.

In summary, return lines are a vital component in the design of carbureted engines, especially in the context of emission control. By preventing fuel accumulation in the carburetor, they help to reduce harmful emissions and improve engine performance. Understanding the function and importance of return lines is essential for maintaining and optimizing the efficiency of older carbureted engines while adhering to modern environmental standards.

Mastering the Art of Rubber Fuel Line Removal: A Comprehensive Guide

You may want to see also

Engine Reliability: A well-functioning return line enhances engine longevity and reliability

A well-functioning return line is a critical component in the fuel system of a carbureted engine, and its importance often goes unnoticed until it fails. The primary role of the return line is to ensure that the fuel mixture is properly balanced and delivered to the engine in the correct ratio. This is especially crucial for carbureted engines, which rely on a precise fuel-to-air mixture for optimal performance and efficient combustion.

In a carbureted engine, the fuel return line connects the fuel bowl to the engine's intake manifold. When the engine is running, the return line allows excess fuel to flow back to the fuel bowl, preventing the accumulation of fuel in the carburetor. This is essential because an excess of fuel can lead to poor performance, increased emissions, and even engine damage. By maintaining a steady and balanced fuel supply, the return line ensures that the engine operates efficiently, delivering power and performance consistently.

The reliability of the return line is vital for several reasons. Firstly, it helps prevent fuel starvation. If the return line were to malfunction or become clogged, the engine might not receive enough fuel, leading to stalling, reduced power, or even engine failure. This is particularly problematic during high-load conditions or when the engine is under stress, such as during acceleration or climbing steep inclines. A well-functioning return line ensures that the engine always has the necessary fuel supply to meet its demands.

Secondly, a properly functioning return line contributes to better fuel economy. When the fuel mixture is correctly balanced, the engine can burn fuel more efficiently, resulting in improved mileage. This is especially important for vehicles with high fuel consumption rates, as proper return line functionality can lead to significant savings over time. Additionally, efficient fuel management can reduce the risk of fuel-related issues, such as engine knocking or premature wear, further enhancing the engine's longevity.

In summary, the return line plays a pivotal role in maintaining engine reliability and performance. Its proper function ensures a consistent fuel supply, prevents fuel-related issues, and contributes to overall engine health. Regular maintenance and inspection of the return line are essential to guarantee its effectiveness, especially in older vehicles with carbureted engines. By understanding the significance of this often-overlooked component, vehicle owners can take proactive measures to keep their engines running smoothly and reliably.

Unveiling Ford's Fuel Supply Line Color: A Quick Guide

You may want to see also

Maintenance: Regular inspection of the return line is crucial for carburetor maintenance

The return line is an essential component of a carbureted engine's fuel system, and its proper maintenance is often overlooked. This line plays a critical role in ensuring that the engine receives the correct fuel-air mixture for optimal performance. Over time, this return line can become susceptible to various issues, such as clogs, leaks, or damage, which can lead to poor engine performance or even failure. Therefore, regular inspection and maintenance of the return line are vital to keep the carburetor in good working condition.

During routine maintenance, it is essential to inspect the return line for any signs of wear and tear. Start by checking for any visible damage, such as cracks, kinks, or bends. These issues can cause fuel to leak or restrict flow, leading to engine misfires or reduced power. Look for any signs of corrosion or rust, especially if the engine is exposed to harsh weather conditions or has been in use for an extended period. Corrosion can impede the line's functionality and may require replacement.

Another critical aspect of return line maintenance is ensuring that it is free from clogs. Over time, debris, dirt, or even small fuel contaminants can accumulate in the line, restricting fuel flow. This can result in a lean fuel mixture, causing the engine to run poorly or even stall. To prevent this, it is recommended to use a fuel filter and regularly inspect and replace it as per the manufacturer's guidelines. Additionally, keeping the engine's fuel system clean can help maintain the return line's integrity.

Regularly checking the return line's connections is also an important part of maintenance. These connections can loosen or become corroded over time, leading to fuel leaks or reduced performance. Ensure that all fittings and hoses are secure and tight. If any connections are found to be damaged or loose, they should be tightened or replaced immediately to prevent potential engine issues.

In summary, the return line is a critical component that requires regular attention to ensure the carburetor's longevity and optimal performance. By inspecting the line for damage, clogs, and secure connections, you can identify and address potential issues before they cause significant problems. Proper maintenance of the return line will contribute to a well-functioning engine and a more efficient fuel system.

E85 Fuel Line: Choosing the Right Option for Your Engine

You may want to see also

Frequently asked questions

A fuel return line is an essential component in a carbureted engine's fuel system. Its primary function is to allow excess fuel to return from the carburetor to the fuel tank, ensuring that the engine operates with the correct fuel-air mixture. This line prevents fuel accumulation in the carburetor, which could lead to poor performance, idling issues, and potential engine damage.

In a carbureted engine, the fuel-air mixture is carefully balanced to provide optimal combustion. The fuel return line is crucial because it ensures that any excess fuel not used in the combustion process is returned to the tank. Without this line, fuel would accumulate in the carburetor, leading to a rich fuel-air mixture, which can cause engine misfires, reduced power, and increased emissions.

It is not recommended to operate a vehicle without a fuel return line, as it can lead to significant performance issues. The absence of this line can result in a rich fuel mixture, causing the engine to run poorly, potentially stalling, and even causing long-term damage to the engine's internal components.

A properly functioning fuel return line ensures that the carburetor maintains the correct fuel level, allowing for precise fuel-air mixture control. This results in improved engine performance, including better acceleration, smoother operation, and enhanced fuel efficiency. It also contributes to reduced emissions, making the engine more environmentally friendly.

Yes, several symptoms can indicate a problem with the fuel return line. These include engine misfires, rough idling, reduced power, and increased fuel consumption. If you notice any of these issues, it is advisable to inspect the fuel system, including the return line, to ensure it is functioning correctly and making the necessary adjustments to the fuel-air mixture.