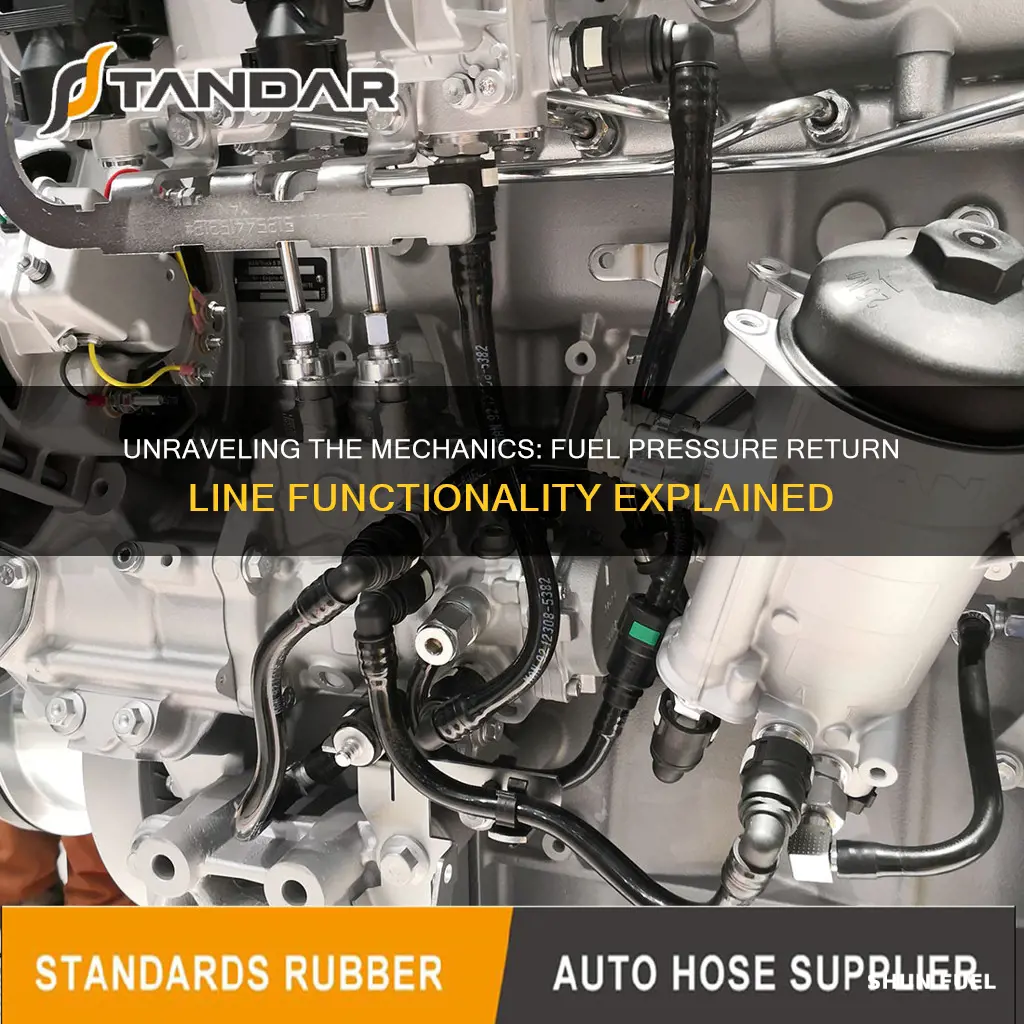

The fuel pressure return line is a crucial component in the fuel system of an engine, responsible for managing the flow of fuel from the fuel pump to the engine and back to the fuel tank. This line is designed to maintain optimal fuel pressure and ensure efficient operation. When the engine is running, the fuel pump creates pressure in the fuel system, and the return line allows excess fuel to flow back to the tank, preventing overpressure and potential engine damage. It also helps to regulate the fuel level, ensuring that the engine receives the correct amount of fuel for optimal performance. Understanding the function of this return line is essential for maintaining a well-functioning fuel system and ensuring the longevity of the engine.

What You'll Learn

- Fuel Pressure Regulation: The return line regulates pressure by controlling fuel flow back to the tank

- Pressure Relief: It releases excess pressure to prevent engine damage

- Fuel Efficiency: Efficient pressure return optimizes fuel usage and engine performance

- Safety Mechanism: The line prevents fuel buildup, reducing fire hazards

- Engine Performance: Proper return line function ensures stable engine operation

Fuel Pressure Regulation: The return line regulates pressure by controlling fuel flow back to the tank

The fuel pressure return line is a critical component in the fuel system of an engine, playing a vital role in maintaining optimal fuel pressure and ensuring efficient combustion. This return line is designed to manage the flow of fuel as it travels from the fuel pump to the engine and back to the tank, effectively regulating pressure throughout the process.

When the engine is running, the fuel pump is activated, drawing fuel from the tank and sending it through the fuel lines to the injectors or carburetor. As the fuel passes through the system, it encounters resistance, which generates pressure. The return line is strategically positioned to capture this excess pressure and direct it back to the fuel tank. This process is essential as it prevents the fuel pressure from becoming too high, which could lead to inefficient combustion and potential engine damage.

The return line's function is twofold. Firstly, it acts as a safety mechanism by limiting the maximum fuel pressure. When the pressure exceeds a certain threshold, the return line opens, allowing excess fuel to flow back into the tank. This prevents the pressure from building up to dangerous levels, ensuring the engine operates within safe parameters. Secondly, the return line helps maintain a consistent fuel pressure throughout the engine's operation. By controlling the flow of fuel, it ensures that the injectors or carburetor receive the precise amount of fuel required for optimal combustion at all engine speeds and loads.

In engines with electronic fuel injection, the return line's role becomes even more critical. These systems rely on precise fuel pressure control to deliver the correct fuel-air mixture to the engine cylinders. The return line's ability to regulate pressure ensures that the fuel injectors receive the desired fuel pressure, allowing for accurate fuel metering and injection timing. This results in improved engine performance, better fuel efficiency, and reduced emissions.

Additionally, the return line's design often includes a check valve or a pressure-relief mechanism to further enhance its functionality. These features prevent fuel from flowing back into the pump when the engine is not running, ensuring that the pump remains protected and operational when needed. By incorporating these safety measures, the return line contributes to the overall reliability and longevity of the fuel system.

Fuel Line Placement: Carb Dirtbike Guide

You may want to see also

Pressure Relief: It releases excess pressure to prevent engine damage

The fuel pressure return line is a critical component in an engine's fuel system, serving a vital role in maintaining optimal performance and preventing potential damage. Its primary function is to manage and control the pressure of the fuel as it circulates through the engine, ensuring a steady and efficient flow. This is particularly important in engines where fuel pressure must be precisely regulated to achieve the desired power output while maintaining fuel efficiency.

One of the key aspects of the fuel pressure return line is its ability to release excess pressure. Engines operate under high-pressure conditions, and without proper pressure management, this can lead to several issues. Excessive fuel pressure can cause the engine to run too rich, resulting in inefficient combustion and increased emissions. It may also lead to the formation of carbon deposits in the engine's intake system, affecting performance and potentially causing engine knock.

The pressure relief mechanism in the return line is designed to counteract these potential problems. When the fuel pressure exceeds a predetermined threshold, the return line activates its relief valve. This valve is strategically positioned to open when pressure becomes too high, allowing excess fuel to be released back into the fuel tank or reservoir. By doing so, the engine's fuel pressure is regulated, preventing any adverse effects on performance and longevity.

This pressure relief feature is especially crucial during engine start-up and when the engine is under varying loads. During start-up, the engine may require a higher fuel pressure to establish a stable combustion environment. However, as the engine warms up, the pressure should gradually decrease to maintain optimal performance. The return line's pressure relief function ensures that the fuel pressure remains within the desired range, adapting to the changing conditions without causing any harm.

In summary, the fuel pressure return line's pressure relief mechanism is a critical safety feature. It ensures that the engine operates within safe pressure limits, preventing potential damage and maintaining efficient performance. This design element is a testament to the intricate engineering required to balance power, efficiency, and longevity in modern engines.

Aluminum Fuel Lines: Pros and Cons for Fuel Injection Systems

You may want to see also

Fuel Efficiency: Efficient pressure return optimizes fuel usage and engine performance

The fuel pressure return line is a critical component in modern engine systems, playing a vital role in optimizing fuel efficiency and overall engine performance. This system is designed to manage the pressure of the fuel as it circulates through the engine, ensuring that it is delivered at the precise moment and in the correct amount required for efficient combustion.

In an internal combustion engine, fuel is injected into the engine's cylinders to facilitate the combustion process. The pressure return line is responsible for managing the fuel pressure as it moves from the fuel pump to the engine's injectors and then back to the fuel tank. This process is crucial for several reasons. Firstly, it ensures that the fuel is delivered at the optimal pressure, which is essential for efficient atomization and mixing with air. Proper atomization allows for better combustion, resulting in increased power output and reduced emissions.

The design of the pressure return line is such that it minimizes fuel pressure drop as it travels from the pump to the injectors. This is achieved through careful consideration of the line's diameter, length, and material properties. A larger diameter line reduces the restriction, allowing for a smoother flow of fuel. Additionally, the use of materials with low friction coefficients helps maintain pressure throughout the system. This efficient pressure management ensures that the fuel reaches the injectors with the required pressure, optimizing the fuel-air mixture and combustion process.

Moreover, the pressure return line also plays a role in fuel economy. By maintaining a consistent and controlled fuel pressure, the engine can operate at its most efficient level. This is particularly important in modern vehicles, where engines are designed to meet strict emission standards while also providing excellent fuel economy. Efficient pressure return ensures that the engine receives the right amount of fuel at the right time, reducing waste and improving overall fuel efficiency.

In summary, the fuel pressure return line is a key element in achieving optimal engine performance and fuel efficiency. Its design and functionality directly impact the engine's ability to deliver power efficiently while minimizing fuel consumption and emissions. Understanding and optimizing this system can lead to significant improvements in vehicle performance and environmental sustainability.

When Fuel Lines Detach: Understanding the Consequences and Solutions

You may want to see also

Safety Mechanism: The line prevents fuel buildup, reducing fire hazards

The fuel pressure return line is a critical component in the fuel system of an engine, and its primary function is to ensure safe and efficient fuel management. This line plays a vital role in preventing fuel buildup, which can lead to hazardous situations, especially in high-performance or high-pressure fuel systems.

In the context of safety, the fuel pressure return line acts as a safeguard against potential fuel-related risks. When an engine operates, it requires a precise and controlled amount of fuel to function optimally. If fuel were to accumulate in the system, it could lead to several dangerous consequences. One of the primary concerns is the risk of fire. Fuel, especially when in a concentrated state, can ignite under certain conditions, leading to potential engine damage or even a fire hazard. The return line is designed to mitigate this risk by ensuring that excess fuel is directed back into the fuel tank or reservoir, preventing it from accumulating in the system.

The mechanism works by allowing fuel to flow back to the tank when the engine's fuel pressure exceeds a certain threshold. This threshold is carefully calibrated to ensure that the system operates within safe limits. When the pressure builds up, the return line opens, allowing fuel to flow back, thus maintaining a balanced pressure and preventing any excess from causing potential issues. This process is particularly important in high-performance engines where fuel pressure can reach very high levels.

Additionally, the design of the return line often includes various safety features. For instance, it may incorporate a check valve that only allows fuel to return when the pressure is in the correct range. This prevents any backflow of air or contaminants into the fuel system, ensuring that the fuel remains clean and free from potential hazards. The line's material and construction are also chosen to withstand the corrosive nature of fuel, preventing degradation over time.

In summary, the fuel pressure return line is a critical safety mechanism that prevents fuel buildup, a situation that could lead to fire hazards and other engine-related issues. Its design and functionality are carefully considered to maintain optimal fuel management, ensuring the engine operates efficiently and safely. Understanding this component's role is essential for anyone working with fuel-powered systems, as it highlights the importance of proper fuel handling and system design.

Fuel Line Splice: A Comprehensive Guide to Installation

You may want to see also

Engine Performance: Proper return line function ensures stable engine operation

The fuel pressure return line is a critical component in an engine's fuel system, playing a vital role in maintaining stable engine operation. This return line is responsible for managing the fuel pressure and ensuring that it remains within optimal levels, which is essential for efficient combustion and overall engine performance. When the engine is running, the fuel pressure needs to be regulated to prevent excessive pressure that could lead to engine knock or premature fuel atomization.

The function of the return line is to allow excess fuel pressure to escape from the fuel system back to the fuel tank or a reservoir. This is achieved through a carefully designed valve or check valve, which is strategically positioned along the return line. When the engine is idling or operating at lower speeds, the fuel pressure is relatively stable, and the return line ensures that any excess pressure is released, maintaining a balanced fuel-air mixture. This is crucial as it prevents the fuel from becoming too concentrated, which could lead to inefficient combustion and potential engine damage.

During acceleration or high-load conditions, the engine's demand for fuel increases, causing a temporary rise in fuel pressure. In such scenarios, the return line's function becomes even more critical. It allows for a controlled release of pressure, ensuring that the fuel pressure doesn't spike to dangerous levels. This controlled release is essential to maintain the engine's performance and prevent any potential issues caused by over-pressurization.

Proper functioning of the fuel pressure return line is directly linked to engine stability and longevity. A well-designed return line system ensures that the engine receives the correct amount of fuel at the right pressure, promoting efficient combustion and reducing the risk of engine damage. It also contributes to better fuel economy and reduced emissions, as a properly functioning return line helps maintain optimal fuel-air ratios.

In summary, the fuel pressure return line is a key element in the engine's fuel system, ensuring that the fuel pressure remains stable and within safe limits. Its proper function is essential for engine performance, reliability, and longevity, making it a critical component that engine manufacturers design with precision and care. Understanding the role of this return line can help in diagnosing and addressing issues related to fuel pressure, ultimately contributing to a smoother and more efficient driving experience.

Cooper Fuel Lines: Enhanced Performance for Air-Cooled Engines

You may want to see also

Frequently asked questions

The fuel pressure return line is an essential component in a vehicle's fuel system, designed to manage the pressure and flow of fuel from the fuel pump to the engine. It ensures that the fuel is delivered at the correct pressure to the engine's fuel injectors or carburetor, allowing for efficient combustion and optimal engine performance.

This line plays a critical role in maintaining the desired fuel pressure by allowing excess fuel to return to the fuel tank or reservoir. When the fuel pump is activated, it creates a vacuum, drawing fuel from the tank. The return line then guides the fuel back to the tank, preventing excessive pressure buildup and ensuring a steady fuel supply.

Absolutely! The return line is crucial for several reasons. Firstly, it helps regulate fuel pressure, ensuring it remains within the optimal range for engine operation. Secondly, it prevents fuel wastage by recycling excess fuel, which can be beneficial in fuel-efficient vehicles. Additionally, a well-functioning return line contributes to better engine performance, improved fuel economy, and reduced emissions.